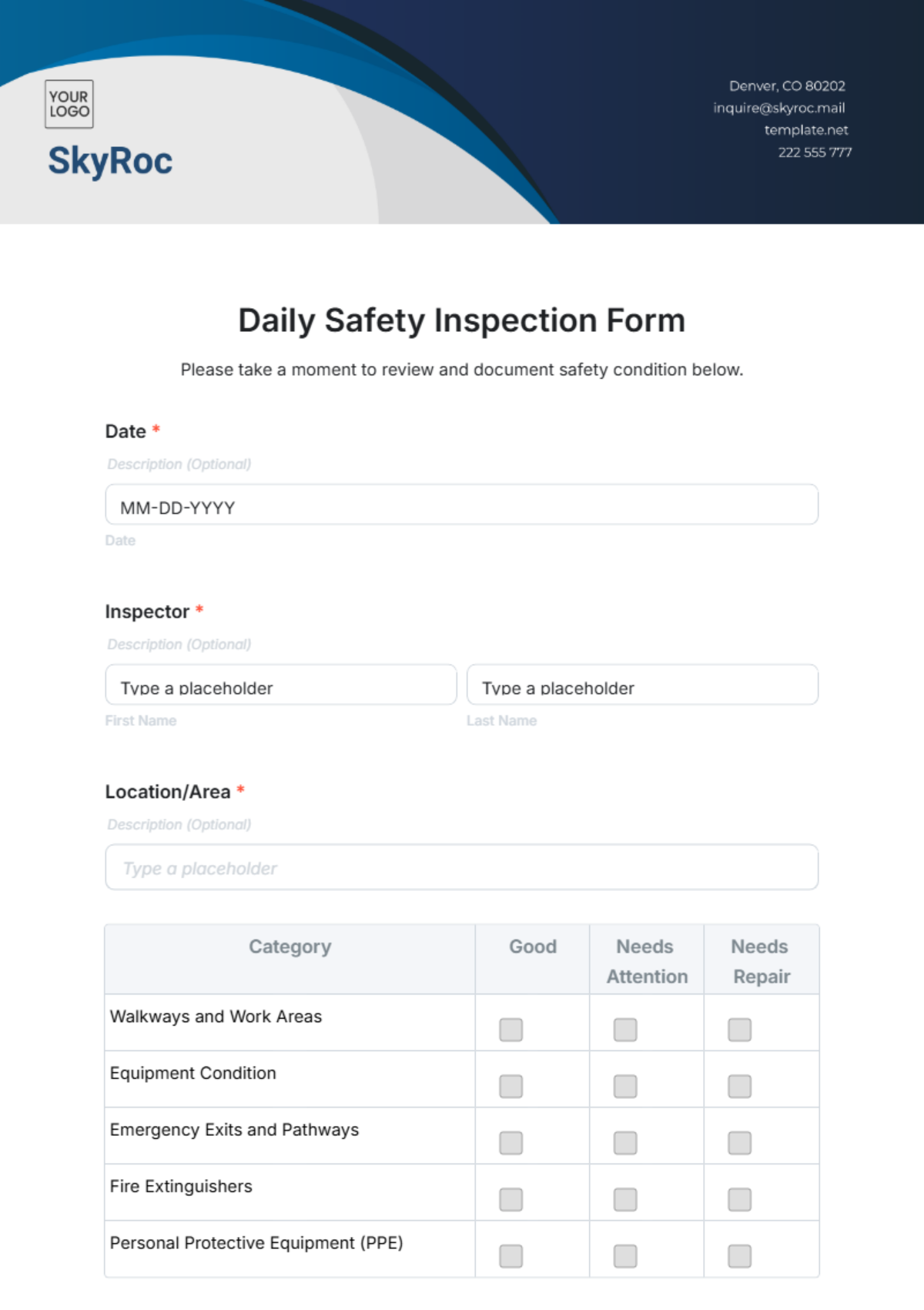

Health & Safety Inspection Checklist

Ensure a safe working environment by using this checklist to identify potential hazards and verify compliance with safety standards.

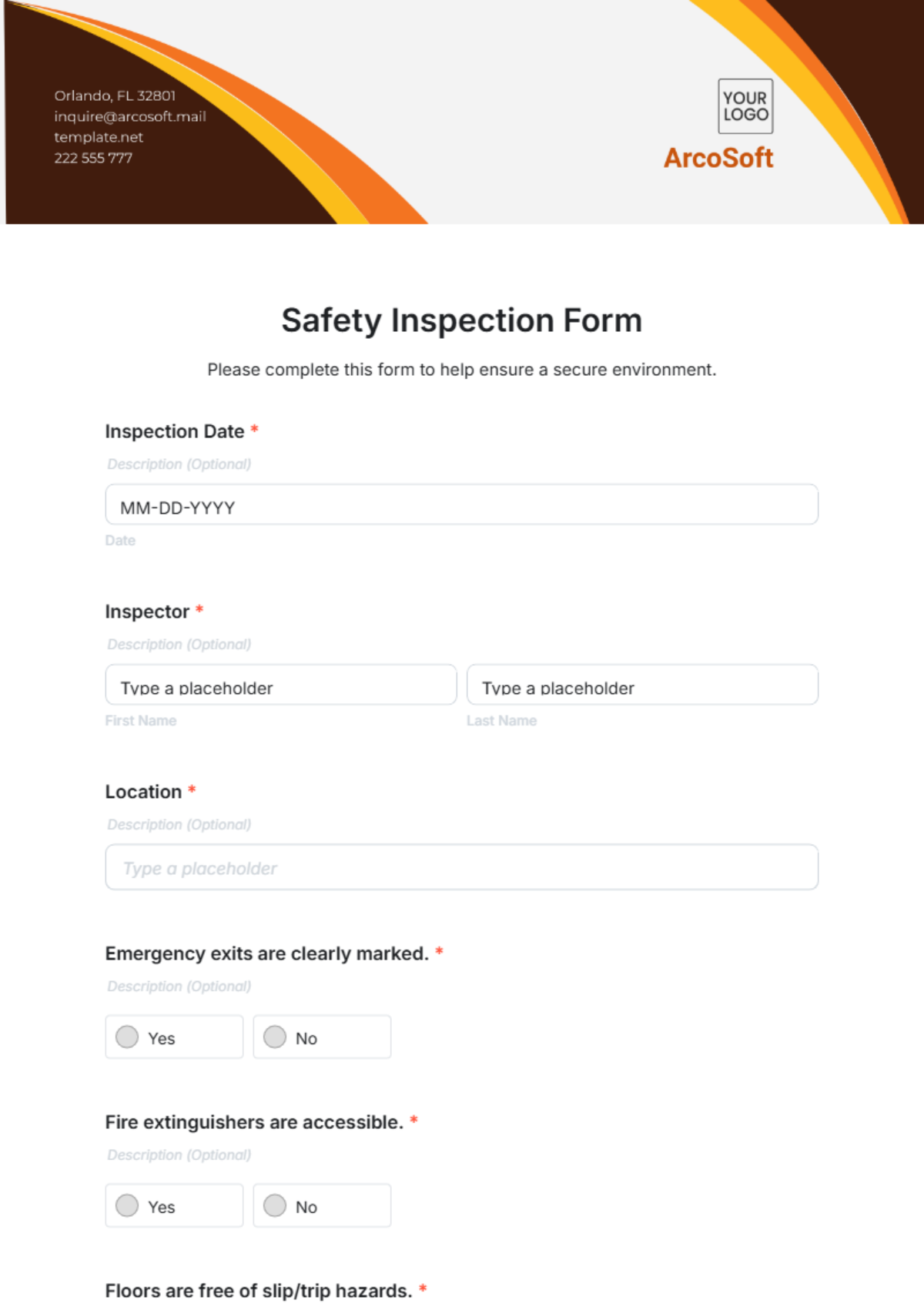

Inspection Date

Inspector's Name

Location

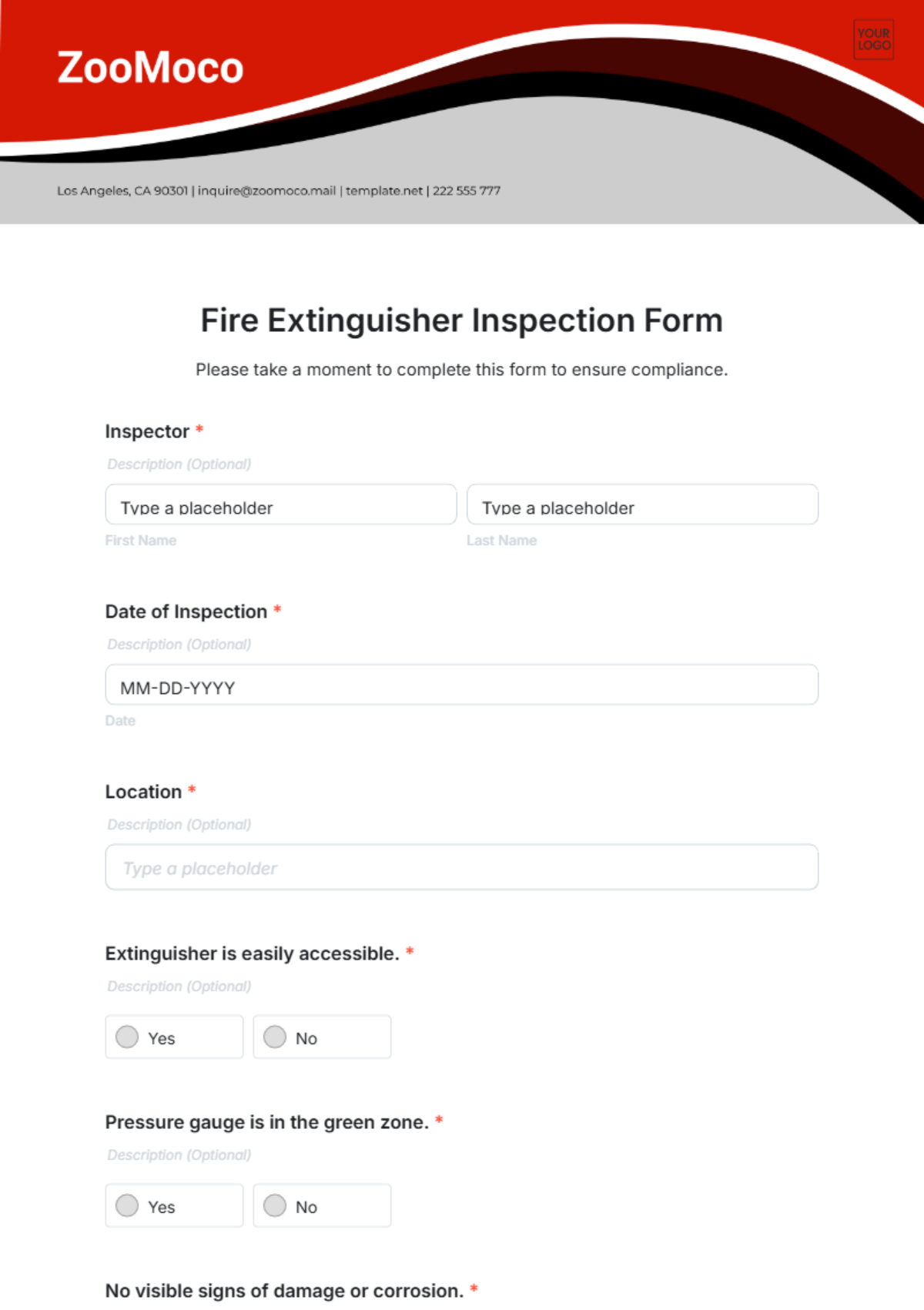

I. Safety Equipment

A. Fire Extinguishers

Accessible and easily identifiable

Properly charged and operational

Inspection tags are up-to-date

Clear signage indicating locations

Monthly check logs maintained

B. First Aid Kits

Fully stocked with bandages, antiseptics, and other supplies

Items have not expired

Clearly marked and easily accessible

Regular inspection and restocking schedule in place

First aid instructions are visible

C. Emergency Exits

Clearly marked with illuminated signs

Routes to exits are unobstructed

Doors open easily and are not locked

Exit routes are regularly reviewed and tested

Emergency lighting functional and tested

D. Emergency Alarms and Systems

Alarms tested regularly for functionality

Clear and audible in all areas

Alarm locations are clearly marked

Emergency procedures are posted and up-to-date

Staff trained on alarm response

E. Safety Drills

Regularly scheduled and documented

Participation from all employees

Follow-up on drill effectiveness

Issues identified during drills are addressed

Records of drills maintained

II. Hazard Identification

A. Slips, Trips, and Falls

Floors are clean, dry, and free of obstructions

Anti-slip mats or coverings in high-risk areas

Proper signage for wet or hazardous areas

Adequate lighting in walkways and staircases

Regular inspection of flooring and pathways

B. Machinery and Equipment

Machinery is properly maintained and serviced

Safety guards and emergency shut-offs are in place

Equipment is used according to manufacturer instructions

Training provided on safe operation

Regular inspections and maintenance logs updated

C. Electrical Hazards

Electrical panels and wiring are in good condition

No exposed or frayed wires

Outlets are not overloaded

Extension cords are in good condition and used properly

Electrical systems inspected by a licensed electrician

D. Chemical Hazards

Proper labeling and storage of chemicals

Material Safety Data Sheets (MSDS) available

Personal protective equipment (PPE) used as required

Spill containment and clean-up procedures in place

Regular training on chemical handling and emergency procedures

E. Fire Hazards

Flammable materials stored properly

Fire lanes and access points are clear

Regular inspection of fire alarm systems

Compliance with fire safety regulations

Staff trained on fire emergency procedures

III. Personal Protective Equipment (PPE)

A. Availability

PPE is readily available for all tasks requiring it

PPE is provided in sufficient quantities

PPE meets regulatory standards

Specialized PPE available for specific hazards

PPE storage areas are clean and organized

B. Condition

PPE is in good repair and free from damage

Regular inspections and maintenance of PPE

Replacement of worn or damaged PPE

Proper cleaning procedures for reusable PPE

Records of PPE condition and replacement kept

C. Usage

Employees are trained in correct PPE usage

PPE is worn as required during specific tasks

Compliance with PPE policies monitored

PPE usage is enforced by supervisors

Feedback from employees on PPE comfort and fit collected

D. Training

Regular training on proper use and maintenance of PPE

Training records maintained and up-to-date

Refresher courses provided as needed

Training includes emergency procedures involving PPE

New employees receive PPE training during orientation

E. PPE Signage

Clear signage indicating required PPE for specific areas

Signs are in visible locations

Signage updated as hazards or requirements change

Regular review of signage effectiveness

Feedback on signage clarity collected from employees

IV. Workplace Conditions

A. Ventilation

Ventilation systems are functioning properly

Regular maintenance and filter replacement

Adequate airflow in all work areas

Monitoring of air quality and exposure limits

Proper ventilation for hazardous materials or processes

B. Lighting

Adequate illumination in work and walking areas

Lighting fixtures are clean and functional

Replacement of burned-out bulbs and damaged fixtures

Emergency lighting systems operational

Regular inspection of lighting conditions

C. Temperature Control

Heating and cooling systems are functional

Temperature levels are within comfortable and safe ranges

Monitoring and adjustment of temperature as needed

Access to temperature control mechanisms for employees

Regular maintenance of HVAC systems

D. Noise Levels

Monitoring of noise levels to ensure they are within acceptable limits

Noise control measures implemented in high-noise areas

Provision of hearing protection where necessary

Regular noise assessments conducted

Employee feedback on noise levels collected

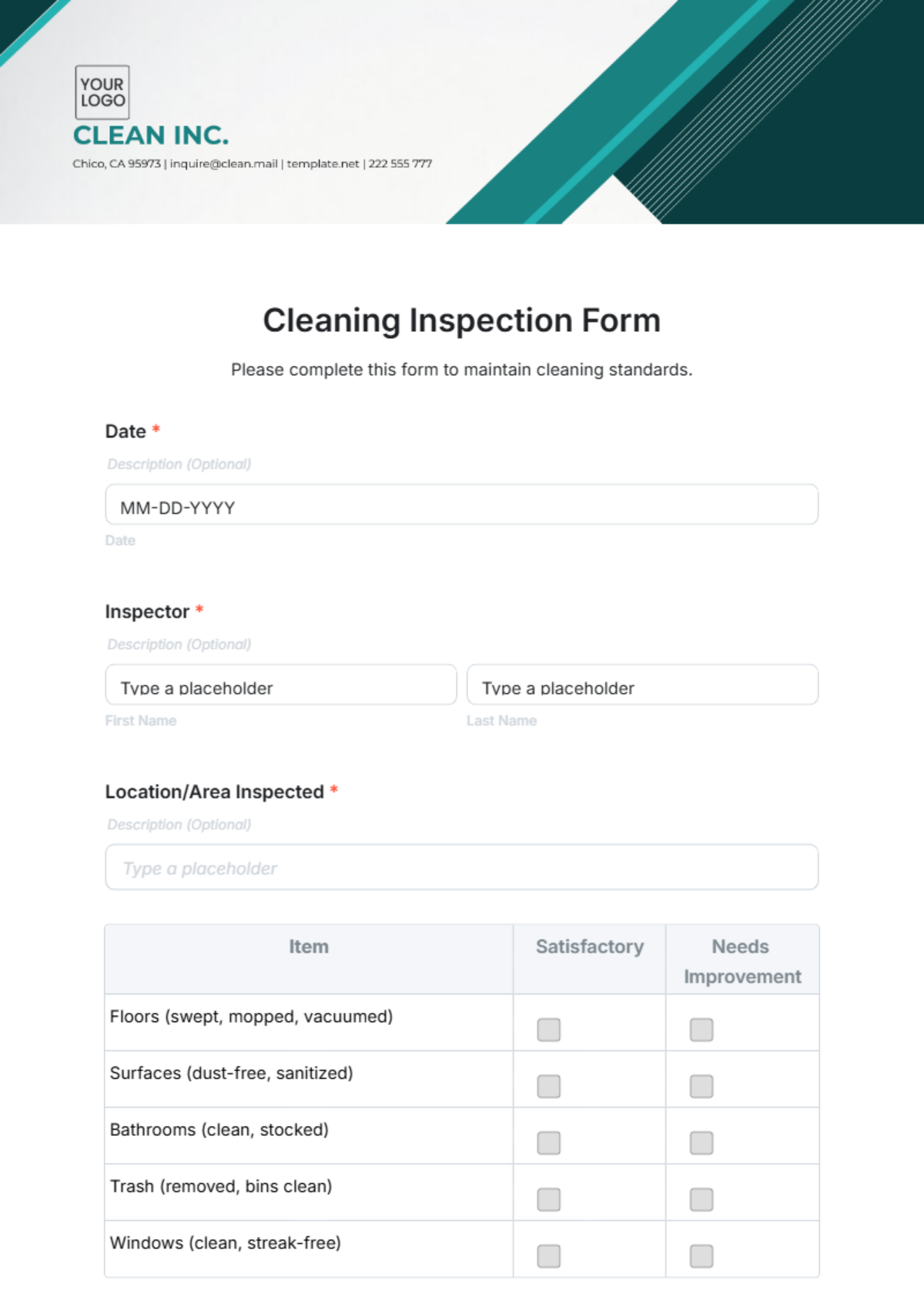

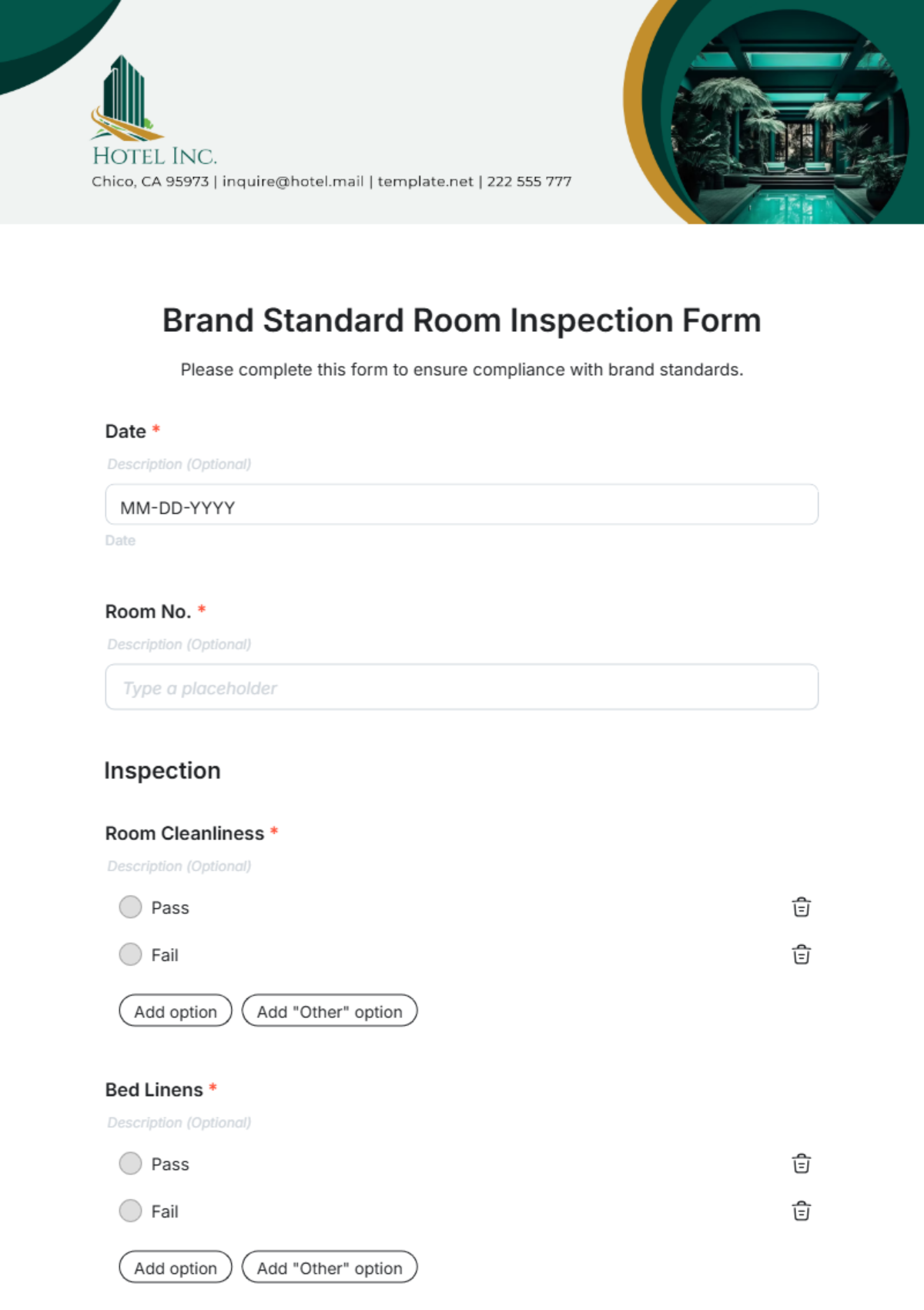

E. Cleanliness and Hygiene

Regular cleaning and maintenance of work areas

Availability of handwashing facilities and sanitizers

Proper waste disposal and management

Clean and well-maintained restrooms

Regular inspections to ensure cleanliness standards are met

V. Compliance and Documentation

A. Regulatory Compliance

Adherence to local, state, and national safety regulations

Up-to-date with changes in safety laws and regulations

Regular review of compliance requirements

Documentation of compliance measures and actions

Audit and inspection reports reviewed for compliance

B. Training Records

Documentation of employee safety training and certifications

Records updated with recent training activities

Training programs evaluated for effectiveness

Tracking of renewal dates for certifications

New employees’ training records maintained

C. Incident Reports

Documentation of all accidents and near-misses

Follow-up actions and corrective measures recorded

Analysis of incidents to identify trends and preventive measures

Regular review of incident reports by management

Records of incidents and actions taken maintained

D. Safety Policies and Procedures

Up-to-date safety policies and procedures documented

Policies reviewed and revised regularly

Accessibility of policies to all employees

Training on new or updated policies provided

Documentation of policy distribution and acknowledgment

E. Audit and Inspection Records

Regular internal and external audits conducted

Documentation of audit findings and corrective actions

Tracking of inspection dates and results

Review of audit and inspection reports by relevant personnel

Action plans for addressing audit findings documented