PUMP DATASHEET

Manufacturer: [YOUR COMPANY NAME]

Model: FF-CEN-2050

Product Code: 2050FF-CEN-01

Issue Date: January 10, 2050

Revision: 1.0

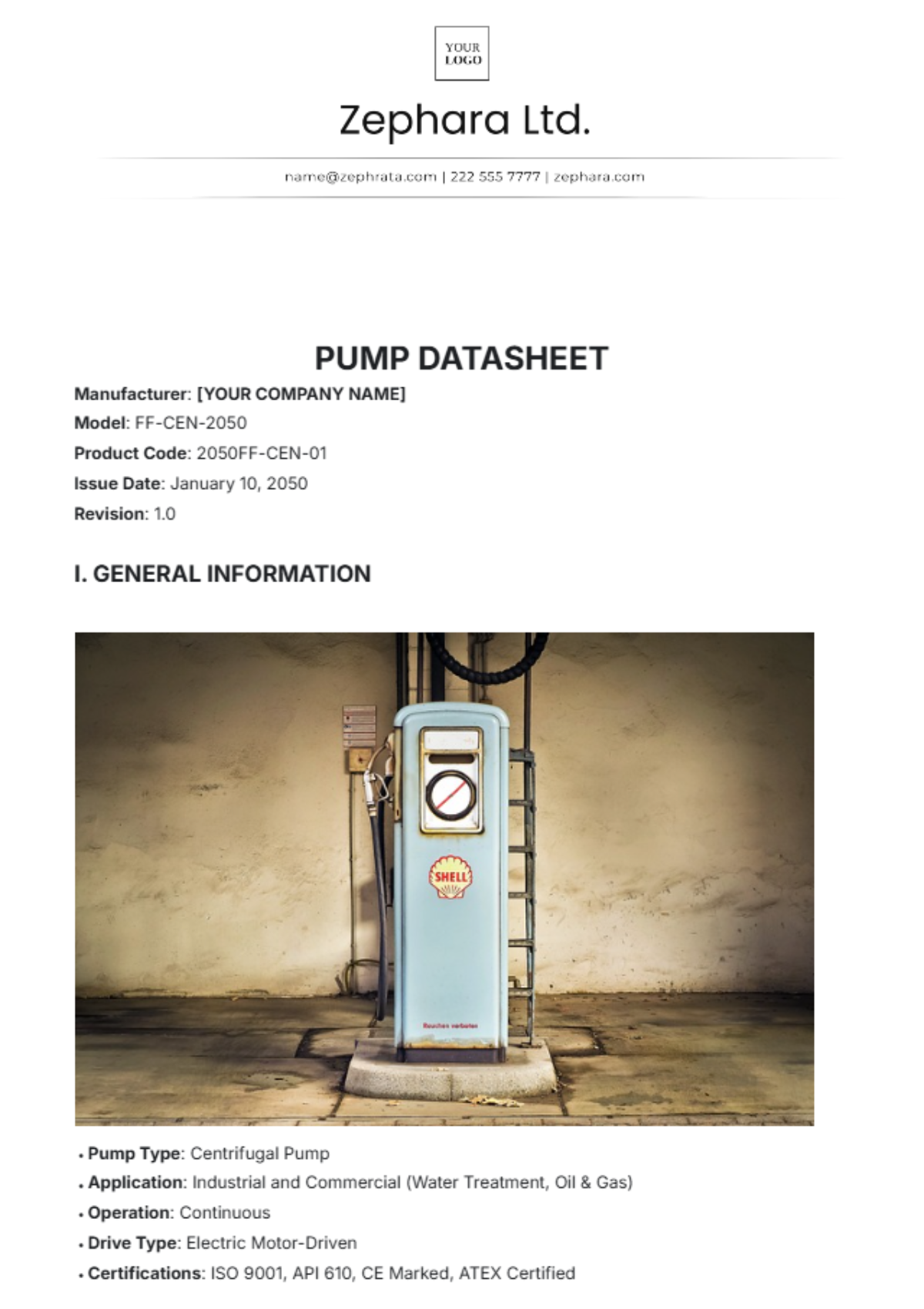

I. GENERAL INFORMATION

Pump Type: Centrifugal Pump

Application: Industrial and Commercial (Water Treatment, Oil & Gas)

Operation: Continuous

Drive Type: Electric Motor-Driven

Certifications: ISO 9001, API 610, CE Marked, ATEX Certified

II. DESIGN SPECIFICATIONS

III. PERFORMANCE DATA

Flow Rate Range: 50 - 350 m³/h

Head Range: 20 - 150 meters

Pump Efficiency: 85%

NPSHr: 4 meters

Pump Speed: 2900 RPM

Power Requirement: 55 kW

Fluid Handled:

Water (Potable, Raw, and Seawater)

Oil (Crude, Refined)

Chemical Liquids (pH 4-12)

Viscosity Range: 1 to 100 cP

Solid Handling Capacity: Maximum particle size: 5 mm

IV. OPERATIONAL REQUIREMENTS

Motor Type: Induction Motor

Motor Power: 55 kW (75 HP)

Motor Voltage: 400V / 690V

Frequency: 50 Hz / 60 Hz

Protection Class: IP66

Explosion Protection: ATEX Zone 2 compliant

Ambient Temperature Range: -20°C to 50°C

V. DIMENSIONAL DATA

Overall Length: 1800 mm

Overall Width: 900 mm

Overall Height: 1200 mm

Inlet Diameter: 4 inches

Outlet Diameter: 3 inches

Foundation Bolt Size: M16

Suction/Discharge Flange Type: ANSI 150#

VI. CERTIFICATIONS & STANDARDS

Compliance:

Additional Features

VII. MAINTENANCE INFORMATION

Manufacturer Contact Information:

Company: [YOUR COMPANY NAME]

Address: [YOUR COMPANY ADDRESS]

Phone: [YOUR COMPANY NUMBER]

Datasheet Templates @ Template.net