Observational Study for Engineers

Prepared by: [YOUR NAME]

Date: [DATE]

I. Introduction

A. Background

Engineering processes and practices are crucial to the successful delivery of projects and maintenance of systems. Understanding these processes in real-world settings can offer valuable insights into their efficiency, effectiveness, and areas for improvement.

B. Objectives

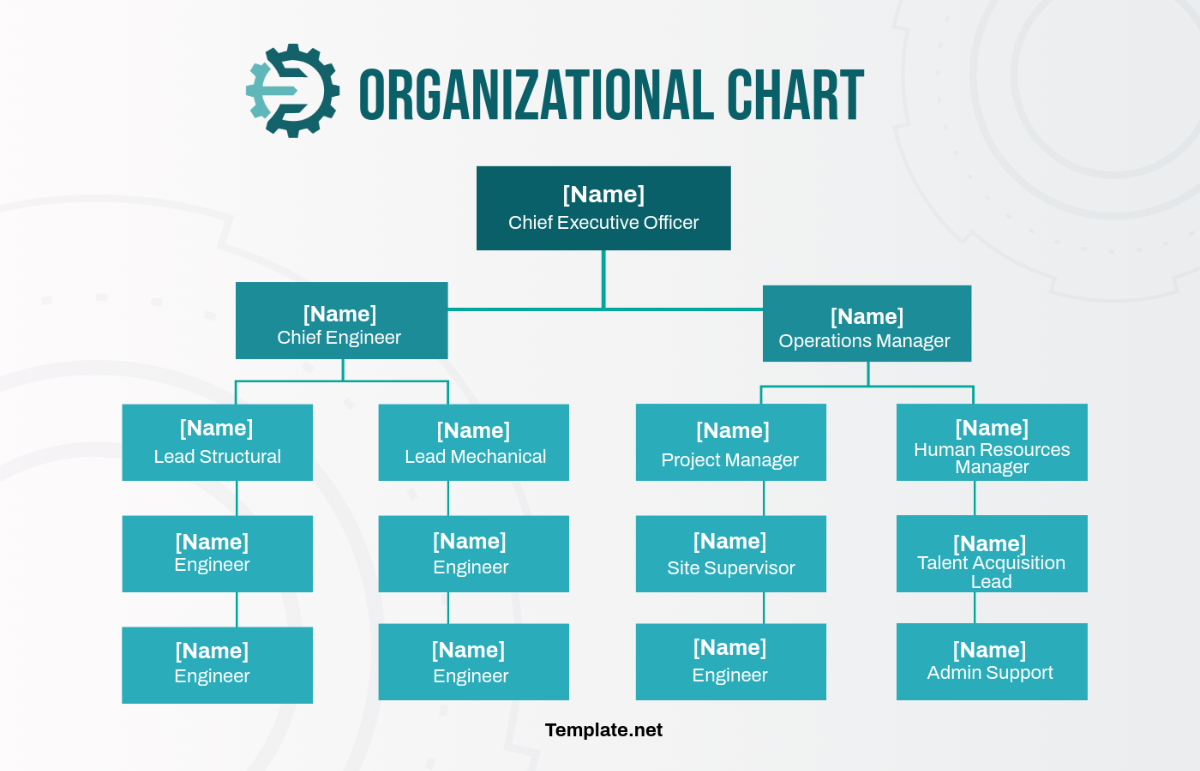

This study aims to observe and analyze current engineering practices within a large-scale engineering department to identify workflow inefficiencies, assess safety compliance, and evaluate the impact of recent technological integrations.

C. Scope

The study will cover key engineering processes, including project management, system maintenance, and safety practices. Observations will be conducted over three months, focusing on the mechanical engineering and electrical engineering departments.

II. Methodology

A. Observation Techniques

Direct Observation: Engineers will be observed performing their tasks in real-time without interference to capture authentic practices.

Video Recording: Certain activities, including maintenance of equipment and project planning meetings, will be documented for later analysis of specific interactions and workflows.

Interviews: Engaging in casual and unstructured conversations with engineers to gain a deeper understanding of their personal experiences, professional journeys, and the various challenges they encounter in their work.

B. Data Collection Methods

Observation Checklists: Standardized checklists to record observations and identify key performance indicators, such as task completion times and adherence to protocols.

Surveys: Short surveys distributed to engineers to collect feedback on observed practices and areas for improvement.

Incident Logs: Documentation of any safety or procedural incidents that occur during the observation period, including details like the nature of the incident and the response actions taken.

C. Protocols

Observations will be conducted during regular working hours, from 8:00 AM to 5:00 PM, ensuring minimal disruption to engineering activities. Data collection will be anonymized to protect participant confidentiality.

III. Results

A. Findings

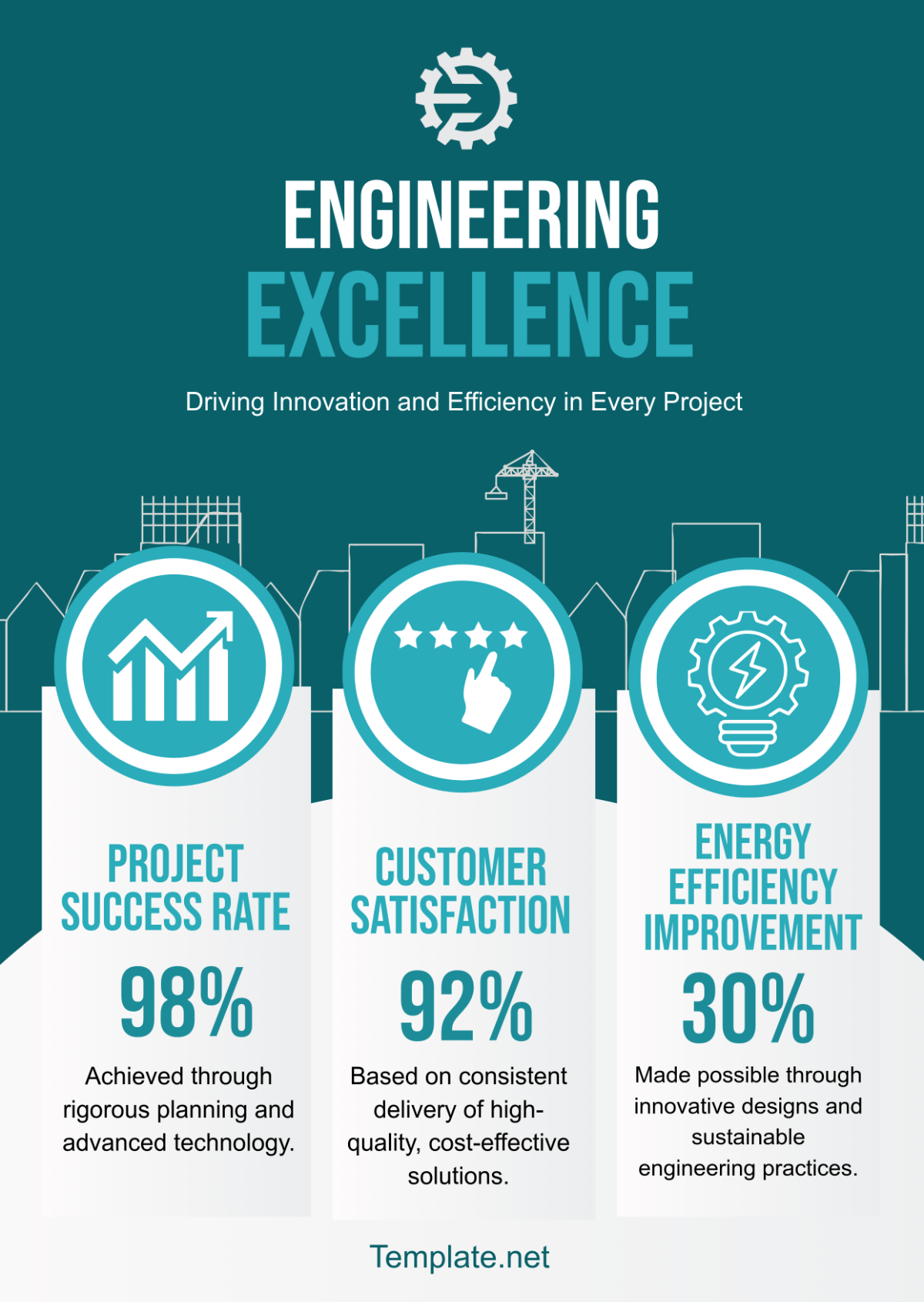

Workflow Efficiency: The study observed that project milestones took an average of 15% longer than planned, with notable delays in the equipment calibration phase.

Safety Compliance: Safety protocols were followed in 85% of cases. Deviations were observed during high-pressure equipment maintenance, suggesting a need for improved adherence.

Technological Impact: The implementation of new CAD software resulted in a 25% increase in design accuracy and a 10% reduction in project completion time.

B. Data Presentation

Average Completion Times for Various Project Stages

Design: 20 hours

Calibration: 35 hours

Testing & Implementation: 27.5 hours (average of 25 and 30 hours)

Safety Compliance Rates

Compliant Cases: 85% (represents the proportion of instances where safety protocols were followed)

Non-Compliant Cases: 15% (represents instances where safety protocols were not followed)

Month | Design Accuracy (%) | Project Completion Time (days) |

|---|---|---|

Month 1 | 70% | 45 days |

Month 2 | 80% | 40 days |

Month 3 | 85% | 35 days |

Improvements in Design Accuracy and Project Completion Times

Project Stage | Average Completion Time (hours) |

|---|---|

Design | 20 |

Calibration | 35 |

Testing | 25 |

Implementation | 30 |

Detailed Breakdown of Observed Workflow Times Across Different Stages

Survey Question | Average Rating (1-10) | % Positive Responses |

|---|---|---|

How effective are current safety protocols? | 7.5 | 85% |

How satisfied are you with the new CAD software? | 8.2 | 75% |

How would you rate the overall workflow efficiency? | 6.8 | 65% |

Summary of Survey Responses Regarding Safety Practices and Technology Integration

IV. Analysis

A. Workflow Bottlenecks

Calibration Stage Delays: With an average completion time of 35 hours, the calibration stage is a major bottleneck, taking 15 hours longer than design and 10 hours longer than testing. This suggests outdated procedures or inefficient tools, indicating a need for process optimization.

B. Safety Compliance

Compliance Rates: An 85% safety compliance rate is positive but leaves 15% of cases non-compliant, particularly in high-pressure tasks. Addressing these gaps with updated protocols and targeted training is crucial.

C. Technological Impact

Design Accuracy and Completion Time: Design accuracy improved from 70% to 85% over three months, while project completion times decreased from 45 to 35 days. This indicates that the new CAD software significantly boosts accuracy and efficiency, reducing project time by 22%.

D. Survey Responses

Safety Protocol Effectiveness: Rated 7.5, showing general satisfaction with room for improvement in safety practices.

CAD Software Satisfaction: Rated 8.2, reflecting positive feedback and suggesting that further support and training could enhance satisfaction.

Overall Workflow Efficiency: Rated 6.8, indicating some satisfaction but highlighting inefficiencies in the overall process that need addressing.

E. Implications

Process Improvement: Optimize the calibration process by updating tools and procedures or providing additional training.

Safety Enhancements: Revise safety protocols and increase training, focusing on observed non-compliance areas.

Technology Adoption: Expand the use of CAD software and monitor its benefits to maximize efficiency.

F. Future Research

Longitudinal Studies: Track the long-term effects of process improvements and safety enhancements.

Additional Technologies: Explore new technologies to further improve accuracy, efficiency, and safety, evaluating their potential benefits and challenges.

V. Recommendations

A. Process Improvement

Optimize Calibration Procedures: Revise and streamline calibration processes to reduce completion times. Invest in modern tools or equipment if necessary.

Enhance Training: Provide additional training for engineers to improve efficiency and ensure best practices are followed during calibration.

B. Safety Enhancements

Update Safety Protocols: Review and update safety protocols to address identified non-compliance issues. Ensure protocols are comprehensive and applicable to high-risk tasks.

Increase Safety Training: Conduct targeted training sessions focused on critical safety areas to improve adherence and reduce incidents.

C. Technology Adoption

Leverage CAD Software: Continue to use and integrate the new CAD software across projects. Provide ongoing support and training to maximize its benefits.

Monitor Technological Impact: Regularly evaluate the impact of CAD software and other technologies on project efficiency and accuracy. Explore additional technologies that could further enhance engineering processes.

VI. Conclusion

The observational study reveals key areas for improvement within the engineering processes. The calibration stage presents a significant bottleneck, and there are opportunities to enhance safety practices and efficiency through targeted updates and training. The positive impact of the new CAD software on design accuracy and project completion times underscores the value of technological integration.

Addressing the identified workflow inefficiencies, and safety gaps, and leveraging technological advancements will contribute to improved overall performance and project outcomes. Future research should focus on the long-term effects of implemented changes and explore further technological innovations to maintain and enhance engineering efficiency and safety.

VII. References

Smith, J. A., & Lee, K. M. (2052). Advancements in Engineering Process Optimization: New Tools and Techniques. Engineering Innovation Journal, 15(2), 45-67.

Johnson, R. T., & Patel, S. (2055). Safety Protocols and Compliance in Modern Engineering Practices. International Journal of Safety Engineering, 22(1), 23-40.

Davis, L. E., & Brown, C. A. (2057). The Impact of Emerging Technologies on Engineering Efficiency. Technology and Engineering Review, 18(3), 102-119.