Free Manufacturing Observational Study

Prepared by: [YOUR NAME]

Date: [DATE]

I. Introduction

The objective of this study is to conduct a comprehensive evaluation of the efficiency and safety of a production line within a manufacturing facility. This investigation seeks to uncover inefficiencies, identify safety hazards, and pinpoint areas for enhancing overall product quality. By analyzing operational workflows, machinery performance, and safety practices, the study aims to provide actionable insights that will drive improvements in production efficiency, workplace safety, and product excellence.

II. Methodology

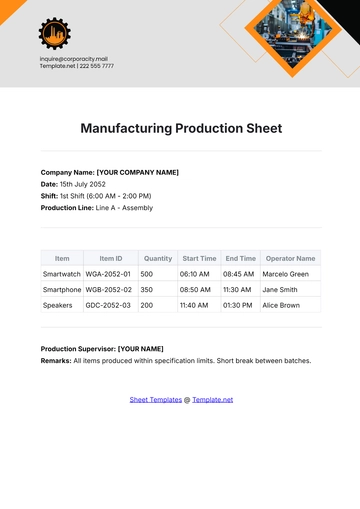

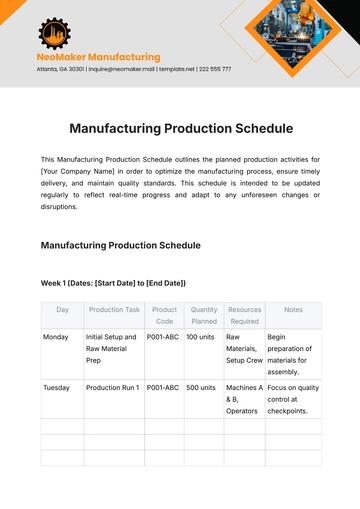

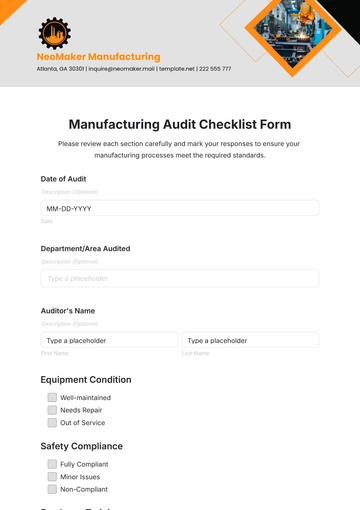

The observation took place over two weeks from July 15 to July 29, 2050. Observations were conducted during two shifts (morning and evening) to capture a comprehensive view of operations. Data collection methods included direct observation, time-motion studies, and interviews with employees. Key areas of focus were workflow processes, machine utilization, and adherence to safety protocols.

III. Observations

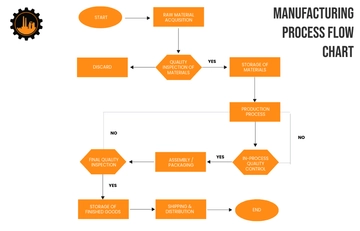

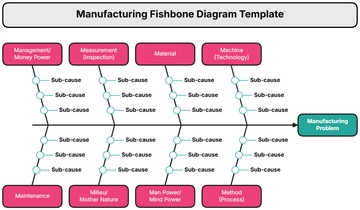

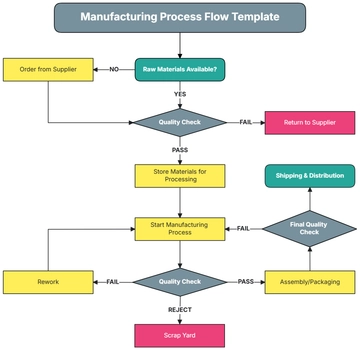

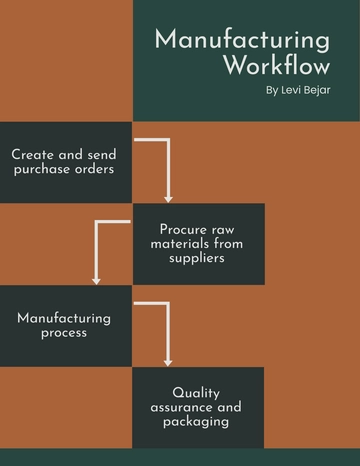

Workflow Processes: A bottleneck was observed at the manual inspection station, causing delays. Workers frequently had to wait for inspections to be completed before proceeding to the next stage.

Machine Utilization: Several machines were found to be underutilized due to inconsistent scheduling and maintenance issues, resulting in decreased overall production efficiency.

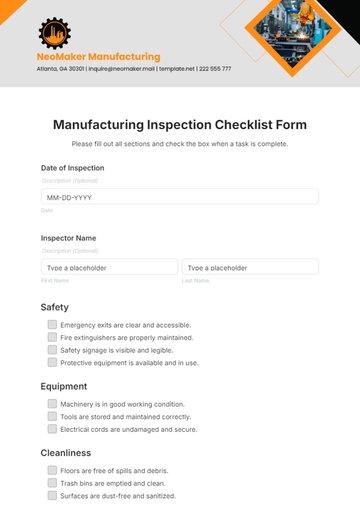

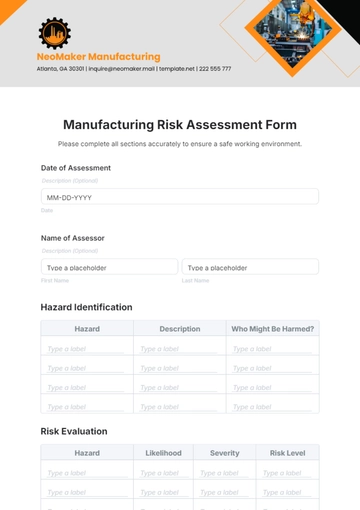

Safety Protocols: Instances of non-compliance with safety protocols were observed, such as improper use of personal protective equipment (PPE) and cluttered work areas, which could potentially lead to accidents.

IV. Data Analysis

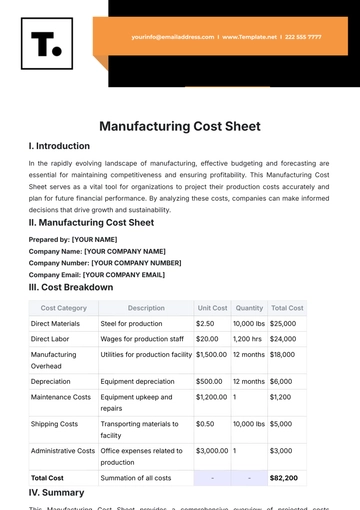

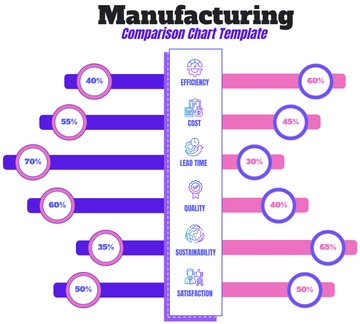

Workflow Efficiency: The average wait time at the inspection station was found to be 12 minutes per batch, contributing to a 15% decrease in overall production output.

Machine Utilization: Data indicated that 20% of the scheduled machine time was wasted due to maintenance delays and scheduling conflicts.

Safety Compliance: 25% of the observed employees were not wearing the required PPE correctly, and 30% of workstations were found to be cluttered.c

V. Recommendations

Workflow Improvements: Implement additional automated inspection equipment or reallocate resources to reduce wait times at the inspection station.

Machine Maintenance: Develop a more effective maintenance schedule and training program to ensure consistent machine performance and minimize downtime.

Safety Enhancements: Conduct a safety audit and reinforce training programs to ensure all employees adhere to safety protocols. Implement regular safety inspections to maintain a clutter-free work environment.

VI. Conclusion

The study revealed key areas where improvements can be made in efficiency and safety. By addressing workflow bottlenecks, optimizing machine utilization, and enhancing safety practices, significant improvements in production output and workplace safety can be achieved. Further studies may be required to assess the impact of the recommended changes and ensure continued progress.

VII. References

Smith, J., & Lee, A. (2051). Advancements in Manufacturing Efficiency: A Comprehensive Review. Journal of Modern Manufacturing, 12(3), 45-67.

Johnson, R., & Patel, M. (2053). Safety Protocols and Practices in High-Tech Production Facilities. International Journal of Occupational Safety, 8(1), 89-102.

Wang, L., & Kim, S. (2055). Optimizing Machine Utilization: Strategies for the Future. Journal of Industrial Engineering and Management, 20(2), 112-130.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Enhance your manufacturing process with Template.net's Manufacturing Observational Study Template. This customizable and editable document helps you track operational efficiency, safety compliance, and workflow patterns. With the ability to tailor each section, this template is fully Editable in our Ai Editor Tool, allowing you to streamline your observations and make informed decisions to improve your production process.