Free Transport Load Planning

1. Introduction

Transport load planning is a strategic process crucial to managing and optimizing the transportation of goods. As we advance towards 2050, this process becomes increasingly sophisticated, integrating emerging technologies and adapting to evolving global trade dynamics. This document outlines [Your Company Name]'s comprehensive approach to transport load planning, detailing strategies, technologies, and processes to ensure efficiency, cost-effectiveness, and superior service delivery.

2. Objectives of Transport Load Planning

Effective transport load planning aims to achieve several key objectives, including optimization of resource utilization, cost reduction, and improvement in service levels. These objectives are vital for maintaining operational efficiency and meeting customer expectations.

2.1 Optimization of Resource Utilization

Optimizing resource utilization is a primary goal of transport load planning. This involves:

Maximizing Cargo Space: Efficiently using available space within transport vehicles to accommodate the maximum amount of cargo.

Loading Techniques: Implementing advanced loading techniques such as vertical stacking and strategic placement to utilize every inch of available space.

Load Optimization Software: Using specialized software to calculate the best way to arrange cargo to maximize space utilization.

Minimizing Empty Miles: Reducing the distance traveled without cargo to improve overall fuel efficiency and lower costs.

Backhauling: Arranging for return loads or secondary cargo to avoid empty trips.

Dynamic Routing: Utilizing real-time data to adjust routes and fill empty miles with additional cargo whenever possible.

Enhancing Route Efficiency: Planning the most efficient routes to minimize travel time and fuel consumption.

Route Optimization Algorithms: Using algorithms to calculate the most efficient paths considering factors like traffic, road conditions, and delivery windows.

Geographic Information Systems (GIS): Leveraging GIS for detailed route planning and analysis.

2.2 Cost Reduction

Reducing transportation costs is critical for maintaining profitability and competitiveness. Key strategies include:

Lower Fuel Consumption: Optimizing routes and load distribution to minimize fuel usage.

Fuel Efficiency Technologies: Implementing technologies such as fuel-efficient engines and aerodynamic enhancements.

Alternative Fuels: Exploring the use of alternative fuels like electric or hydrogen to reduce reliance on traditional fuels.

Reduced Labor Costs: Efficient planning reduces the need for last-minute adjustments and additional labor.

Automated Systems: Implementing automated systems for scheduling and load planning to minimize manual labor.

Streamlined Processes: Developing streamlined procedures to reduce the time and effort required for planning and execution.

Decreased Maintenance Costs: Proper load planning ensures vehicles are used within their optimal capacity, reducing wear and tear.

Preventive Maintenance: Scheduling regular maintenance to prevent costly repairs and downtime.

Load Management: Ensuring that vehicles are not overloaded to avoid excessive wear and tear.

2.3 Improvement in Service Levels

Improving service levels is essential for customer satisfaction and loyalty. This involves:

Timely Deliveries: Accurate planning ensures that deliveries are made within the promised time frames.

On-Time Performance Metrics: Tracking and analyzing on-time performance to identify and address delays.

Customer Communication: Keeping customers informed about delivery status and any potential delays.

Customer Satisfaction: Efficient load planning helps in meeting customer expectations and improving satisfaction rates.

Feedback Mechanisms: Collecting and analyzing customer feedback to continuously improve service quality.

Personalized Services: Offering customized solutions based on customer needs and preferences.

3. Key Components of Transport Load Planning

Effective transport load planning involves several key components, including data collection, load optimization algorithms, and scheduling and routing.

3.1 Data Collection

Accurate data collection is fundamental for successful load planning. Key data points include:

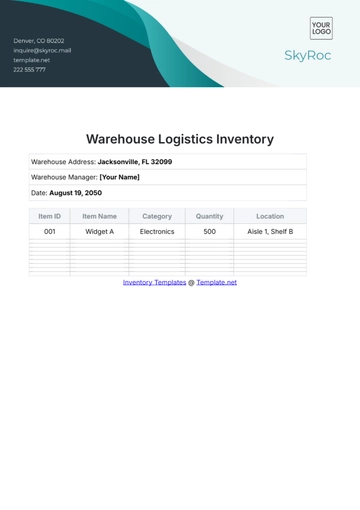

Data Type | Description | Sources |

|---|---|---|

Cargo Specifications | Details about the dimensions, weight, and handling requirements of the cargo. | Shipping documents, cargo manifest |

Vehicle Capacities | Information on the capacity, volume, and weight limits of available transport vehicles. | Vehicle specifications, fleet management systems |

Route Information | Data on routes, including distances, road conditions, and potential obstacles. | GPS data, traffic reports, road maps |

3.2 Load Optimization Algorithms

Load optimization algorithms play a crucial role in determining the most efficient way to distribute cargo. These include:

Bin Packing Algorithms: Used to determine how to pack cargo into available space most efficiently.

First-Fit Algorithm: Assigns items to the first available bin that fits, ensuring that space is utilized efficiently.

Best-Fit Algorithm: Places items into the bin that will leave the least empty space, optimizing space usage.

Knapsack Problems: These solutions help maximize the value of cargo loaded within weight and volume constraints.

0/1 Knapsack Problem: Determines the optimal selection of items to maximize value without exceeding weight limits.

Genetic Algorithms: Simulate evolutionary processes to find optimal solutions for complex load planning scenarios.

Chromosome Representation: Represents possible solutions as chromosomes and uses crossover and mutation to evolve better solutions.

3.3 Scheduling and Routing

Scheduling and routing are essential for ensuring timely deliveries and efficient use of resources. Key aspects include:

Time Windows: Defining specific time frames for pickups and deliveries to ensure timely service.

Time Window Constraints: Scheduling deliveries within customer-defined time windows to meet service level agreements.

Route Optimization: Utilizing software tools to find the shortest or fastest routes while considering traffic conditions and road restrictions.

Route Optimization Software: Tools like Google Maps API, HERE, and Route4Me that provide real-time routing and traffic updates.

Dynamic Routing: Adjusting routes in real-time based on traffic updates and unexpected delays.

Real-Time Traffic Data: Integrating traffic data to adjust routes dynamically and avoid congestion.

4. Tools and Technologies

Various tools and technologies support effective transport load planning, including Transportation Management Systems (TMS), load planning software, and Internet of Things (IoT) devices.

4.1 Transportation Management Systems (TMS)

Transportation Management Systems (TMS) are comprehensive software platforms that facilitate load planning. Key features include:

Feature | Description |

|---|---|

Real-Time Data | Provides up-to-date information on vehicle locations, traffic conditions, and cargo status. |

Automating Processes | Streamlines tasks such as load planning, route optimization, and scheduling through automation. |

Integration with Other Systems | Works seamlessly with Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) systems. |

4.2 Load Planning Software

Load planning software tools are specialized applications designed to optimize cargo distribution. Key functionalities include:

Functionality | Description |

|---|---|

Visualizing Load Configurations | Allows planners to visualize how cargo can be arranged within vehicles for optimal space utilization. |

Simulating Different Scenarios | Tests various loading scenarios to find the most efficient configuration. |

Providing Analytics | Offers insights and analytics on load planning performance, helping identify areas for improvement. |

4.3 Internet of Things (IoT)

IoT enhances transport load planning through various applications:

Application | Description |

|---|---|

Real-Time Tracking | Monitors cargo and vehicle conditions in real time, providing visibility throughout the transport process. |

Predictive Maintenance | Uses data from IoT sensors to predict maintenance needs and prevent breakdowns. |

Improved Decision-Making | Leverages data analytics to make informed decisions about load planning and route adjustments. |

5. Load Planning Process

The load planning process involves several stages, from initial assessment to post-delivery evaluation.

5.1 Initial Assessment

The initial assessment is the first step in the load planning process and includes:

Cargo Analysis: Evaluating the type, volume, and weight of the cargo to determine suitable transport options.

Cargo Characteristics: Assessing characteristics such as size, weight, and any special handling requirements.

Vehicle Assessment: Checking the availability and capacity of vehicles to match the cargo requirements.

Vehicle Types: Identifying the types of vehicles that can handle the cargo efficiently, such as flatbeds, refrigerated trucks, or containerized trucks.

Route Evaluation: Assessing possible routes based on distance, road conditions, and traffic patterns.

Route Alternatives: Considering multiple route options to determine the best choice based on factors like distance, time, and cost.

5.2 Load Configuration

Configuring the load involves:

Arranging Cargo: Determining the best arrangement of cargo within the vehicle to maximize space and minimize shifting.

Loading Patterns: Using patterns such as vertical stacking, palletizing, or modular configurations to optimize space utilization.

Securing Cargo: Ensuring that cargo is properly secured to prevent damage during transit.

Securing Techniques: Implementing techniques such as strapping, bracing, or using load bars to secure cargo.

Optimizing Load Distribution: Balancing the load within the vehicle to avoid overloading and ensure safe handling.

Load Balancing: Distributing weight evenly across the vehicle to maintain stability and prevent issues such as tire wear or axle damage.

5.3 Scheduling and Dispatching

Scheduling and dispatching are critical for ensuring timely deliveries and efficient resource utilization. Key aspects include:

Setting Pickup and Delivery Times: Establishing precise times for cargo pickup and delivery to align with customer expectations.

Time Constraints: Factoring in time constraints such as delivery windows, customer availability, and operational hours.

Coordinating with Drivers: Communicating plans and instructions to drivers to ensure smooth execution.

Driver Instructions: Providing clear instructions regarding routes, cargo handling, and any special requirements.

Monitoring Progress: Tracking the progress of each shipment to address any issues that may arise during transit.

Tracking Systems: Using GPS and other tracking systems to monitor real-time progress and address delays promptly.

5.4 Post-Delivery Evaluation

Post-delivery evaluation involves:

Reviewing Performance: Assessing the effectiveness of the load planning process based on delivery outcomes and customer feedback.

Performance Metrics: Analyzing metrics such as on-time delivery rates, cost per delivery, and customer satisfaction scores.

Identifying Issues: Analyzing any problems encountered during transit and identifying areas for improvement.

Issue Analysis: Investigating issues such as delays, damage, or discrepancies to identify root causes and implement corrective actions.

Updating Procedures: Making necessary adjustments to planning procedures based on lessons learned.

Continuous Improvement: Implementing changes to processes and procedures to enhance efficiency and effectiveness.

6. Challenges and Solutions

Transport load planning faces several challenges, which can be addressed with targeted solutions.

6.1 Handling Variability

Dealing with variability in cargo, routes, and vehicle availability can be challenging. Solutions include:

Flexible Planning: Implementing flexible planning strategies that can adapt to changes in cargo or route conditions.

Adaptive Algorithms: Using algorithms that can adjust to varying load and route conditions dynamically.

Advanced Forecasting: Using predictive analytics to anticipate potential issues and plan accordingly.

Demand Forecasting: Leveraging historical data and predictive models to forecast demand and plan resources accordingly.

6.2 Technological Integration

Integrating new technologies with existing systems can be complex. Solutions include:

Phased Implementation: Rolling out new technologies in phases to manage integration smoothly.

Pilot Programs: Starting with pilot programs to test new technologies and refine integration strategies.

Training and Support: Providing adequate training and support to ensure staff can effectively use new systems.

Training Programs: Developing comprehensive training programs and providing ongoing support to staff.

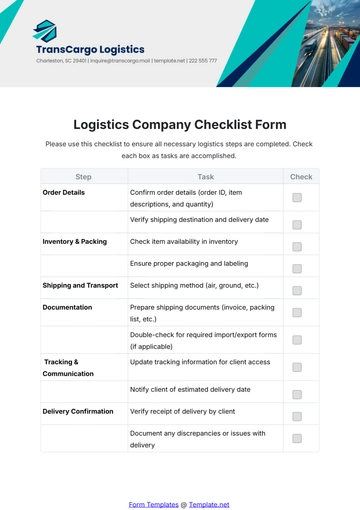

6.3 Regulatory Compliance

Meeting regulatory requirements for transport can be demanding. Solutions include:

Staying Informed: Keeping up-to-date with regulations and ensuring compliance through regular reviews.

Regulatory Updates: Monitoring changes in regulations and updating procedures to remain compliant.

Implementing Best Practices: Adopting best practices for documentation and adherence to regulatory standards.

Compliance Checklists: Using checklists and audits to ensure adherence to regulatory requirements.

7. Future Trends in Transport Load Planning

Several future trends are expected to shape transport load planning, including automation, sustainability, and enhanced connectivity.

7.1 Automation and Artificial Intelligence (AI)

Automation and AI will increasingly influence transport load planning, offering:

Automated Load Planning: Using AI algorithms to automate load planning tasks and optimize cargo distribution.

Algorithmic Planning: AI-driven algorithms that can automate complex load planning tasks, reducing manual effort and increasing efficiency.

Predictive Analytics: Leveraging AI to predict and manage potential disruptions in the supply chain.

Predictive Models: Using AI to forecast potential disruptions and optimize planning strategies accordingly.

7.2 Sustainability and Green Logistics

Sustainability will become a significant focus, with an emphasis on:

Reducing Carbon Footprint: Implementing strategies to lower emissions and promote eco-friendly practices.

Green Technologies: Adopting green technologies such as electric vehicles and renewable energy sources.

Optimizing Fuel Usage: Adopting technologies that improve fuel efficiency and reduce environmental impact.

Fuel Management Systems: Using systems to monitor and optimize fuel usage and emissions.

7.3 Enhanced Connectivity

Enhanced connectivity through advanced communication technologies will facilitate:

Real-Time Data Sharing: Improving the flow of information between stakeholders for better coordination and decision-making.

Data Integration: Integrating data from various sources to provide a comprehensive view of operations.

Smart Infrastructure: Utilizing smart infrastructure to support efficient transport operations and load planning.

Smart Sensors: Implementing sensors and IoT devices to monitor and manage infrastructure effectively.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Maximize load efficiency with the Transport Load Planning Template from Template.net. This editable and customizable template helps in planning and managing loads. Tailor it using our Ai Editor Tool to ensure optimal load distribution and transport efficiency.