Free Heavy Equipment Weekly Inspection

I. Introduction

The objective of the weekly inspection report is to ensure the operational safety, maintenance, and performance of heavy equipment used on-site. This involves a thorough check of various components, systems, and functionality to identify potential issues early and mitigate risks.

II. Equipment Details

A. General Information

Equipment Type | Excavator |

|---|---|

Model | Caterpillar 320D |

Serial Number | CAT0320DJFBX12345 |

Location | Construction Site A |

Date of Inspection | October 6, 2023 |

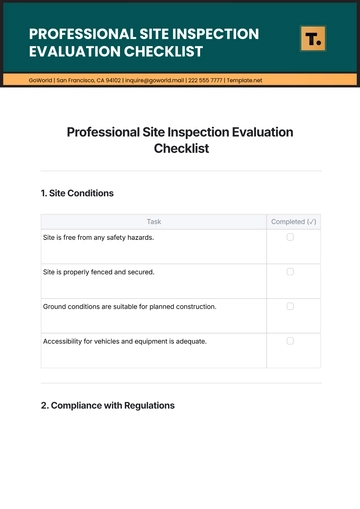

III. Inspection Checklist

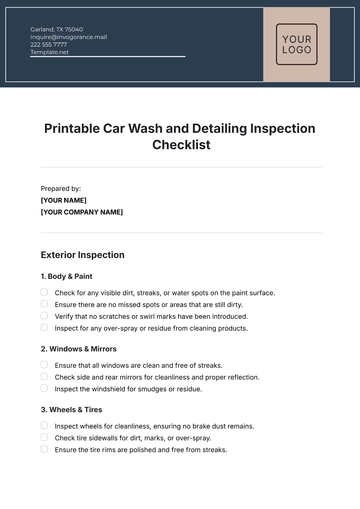

A. Visual Inspection

The visual inspection focuses on identifying any apparent signs of wear, damage, or leaks. This includes checking for cracks, dents, and missing components. The table below summarizes the findings.

Component | Condition | Notes |

|---|---|---|

Exterior | Good | No visible damage |

Hydraulic Lines | Fair | Minor wear observed |

Tracks | Poor | Tracks require replacement |

B. Functional Tests

Functional tests are essential for evaluating the performance of each system. These tests assess the operational readiness of the critical components. The inspection covers the hydraulic system, electrical components, and engine performance.

Tested Component | Status | Remarks |

|---|---|---|

Hydraulic System | Passed | Normal operation |

Electrical Components | Passed | All lights functioning |

Engine | Failed | Noise detected, further diagnostics needed |

IV. Maintenance Recommendations

Based on the inspection results, the following maintenance tasks are recommended to ensure continued safe and efficient operation of the equipment:

Replace the tracks: Immediate attention required due to significant wear and tear.

Inspect hydraulic lines: Replace during next maintenance.

Engine diagnostics: Perform a detailed engine diagnostic to identify and resolve the cause of the unusual noise.

V. Conclusion

The weekly inspection of the heavy equipment highlighted both the strengths and areas needing attention. Proactive maintenance and timely repairs are essential to prevent downtime and ensure the safety of operations. Adhering to these recommendations will help in maintaining optimal performance and extending the lifespan of the equipment.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Ensure safety and compliance with Template.net’s Heavy Equipment Weekly Inspection Template. Customizable and editable in our AI Editor Tool, this template helps document the condition, usage, and required maintenance of heavy machinery. Ideal for construction and industrial sites, it ensures that equipment inspections are conducted regularly and reported thoroughly, promoting operational efficiency and safety.