Free Construction Equipment Maintenance Schedule

Prepared by: [Your Name]

Overview

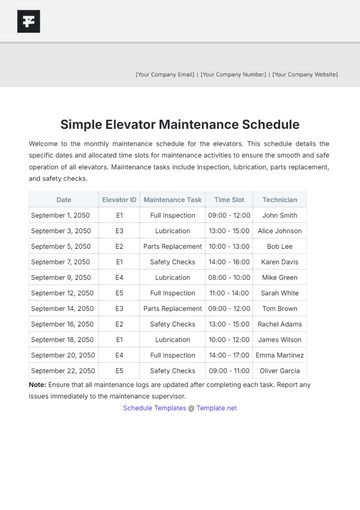

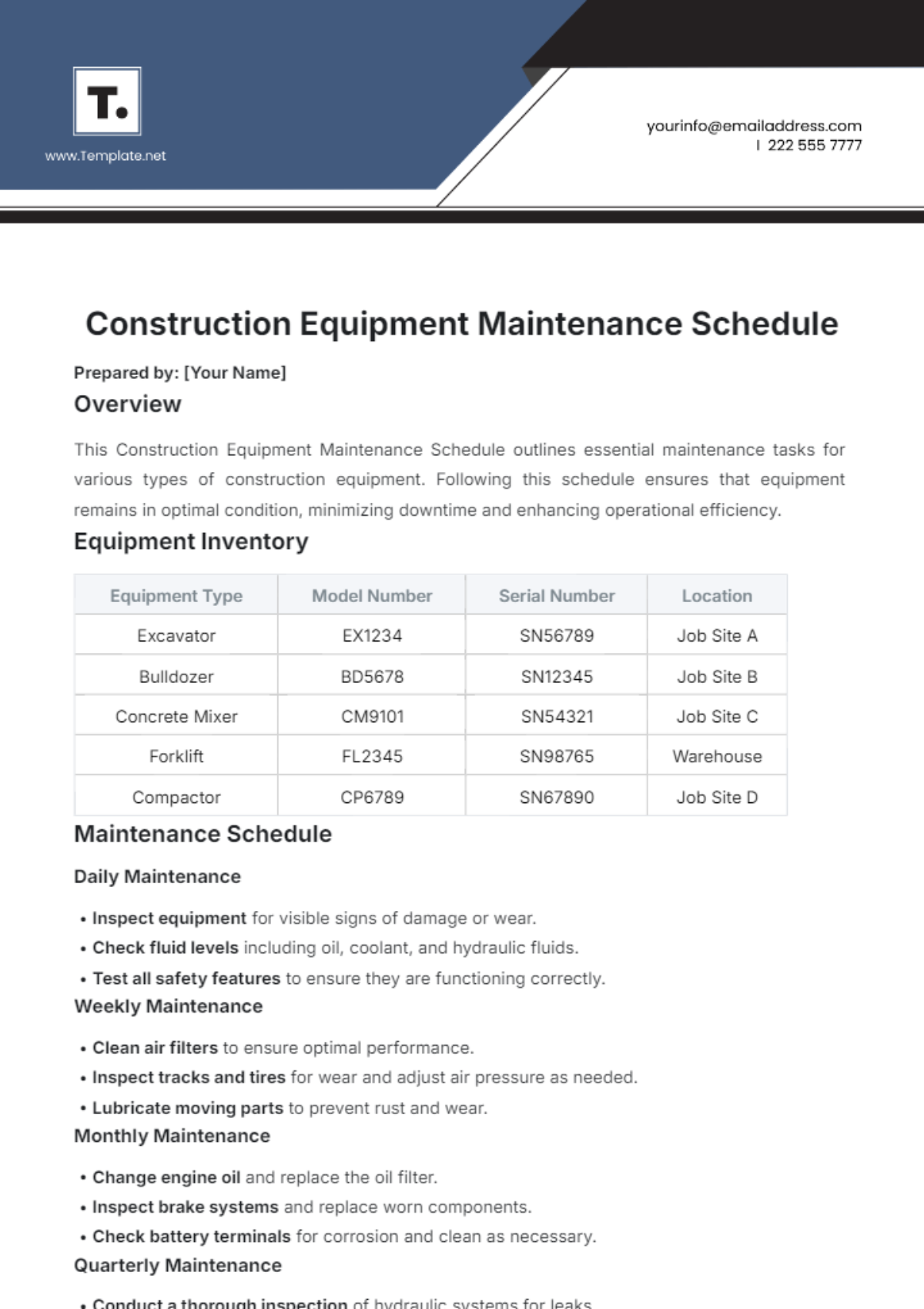

This Construction Equipment Maintenance Schedule outlines essential maintenance tasks for various types of construction equipment. Following this schedule ensures that equipment remains in optimal condition, minimizing downtime and enhancing operational efficiency.

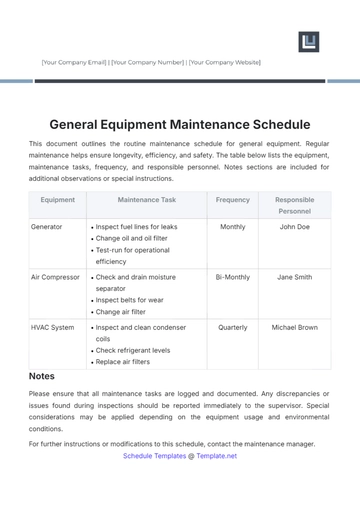

Equipment Inventory

Equipment Type | Model Number | Serial Number | Location |

|---|---|---|---|

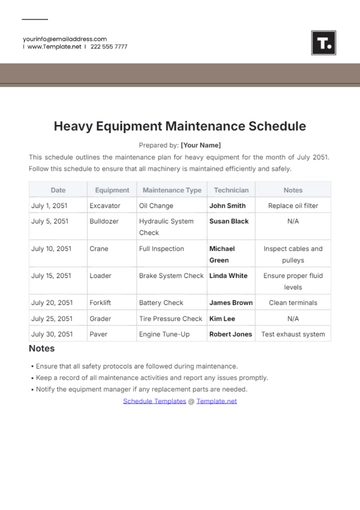

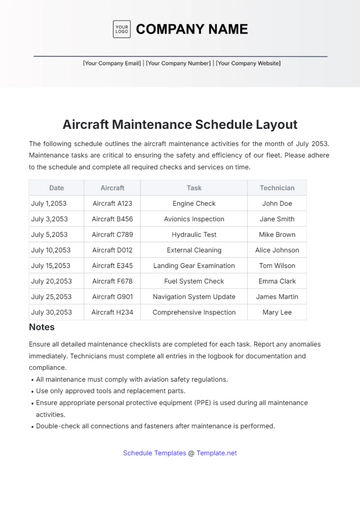

Excavator | EX1234 | SN56789 | Job Site A |

Bulldozer | BD5678 | SN12345 | Job Site B |

Concrete Mixer | CM9101 | SN54321 | Job Site C |

Forklift | FL2345 | SN98765 | Warehouse |

Compactor | CP6789 | SN67890 | Job Site D |

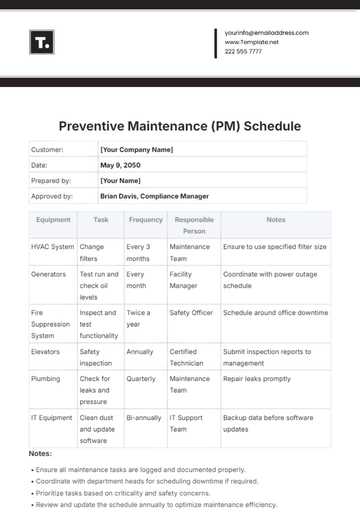

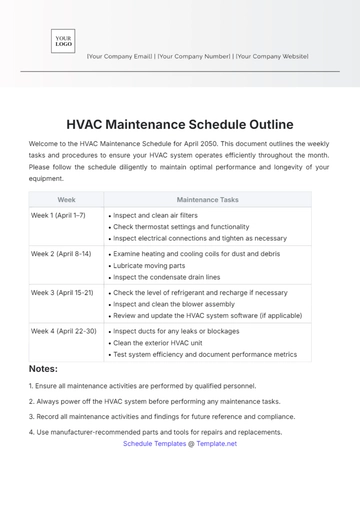

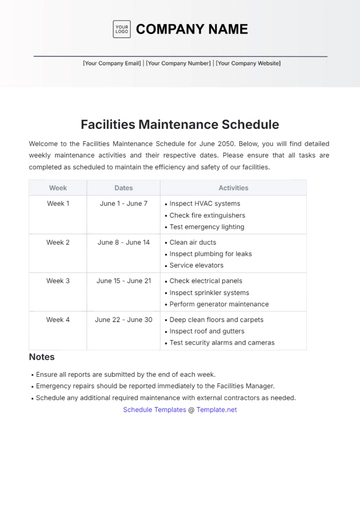

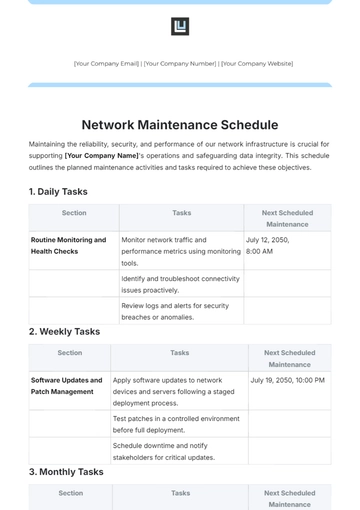

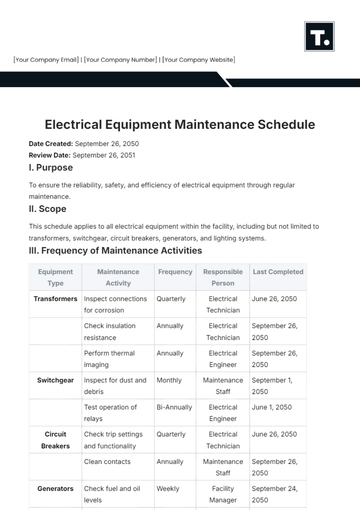

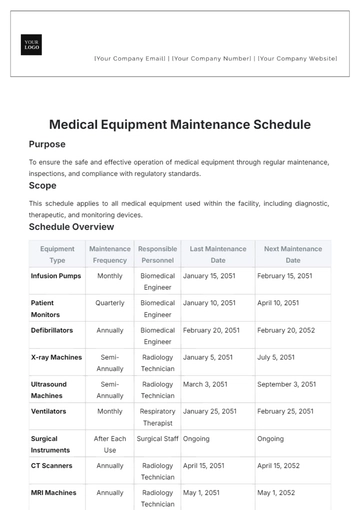

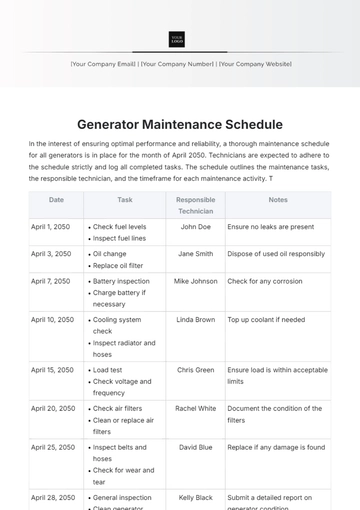

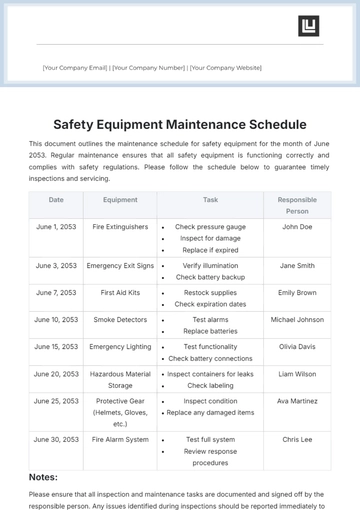

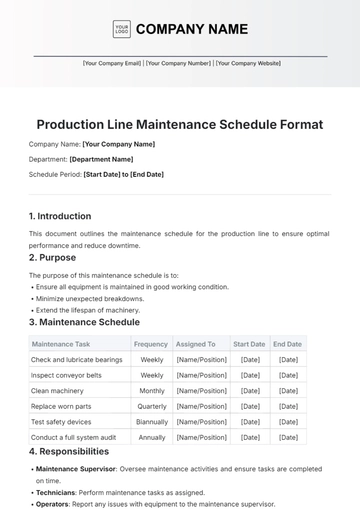

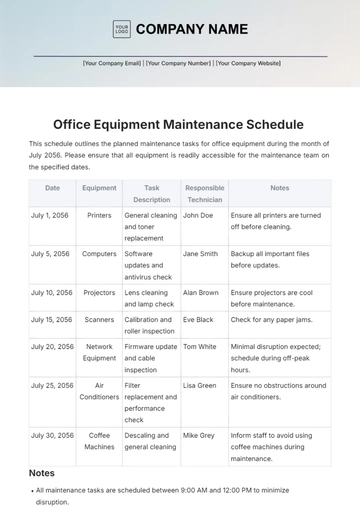

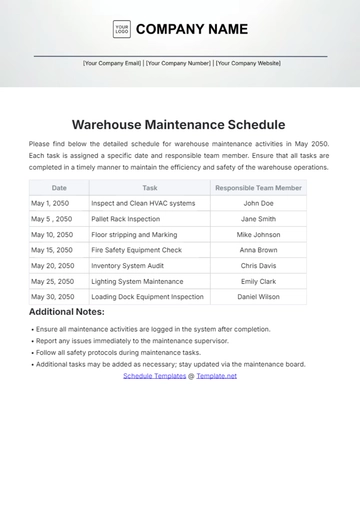

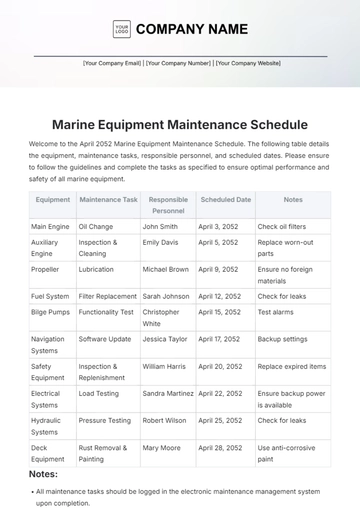

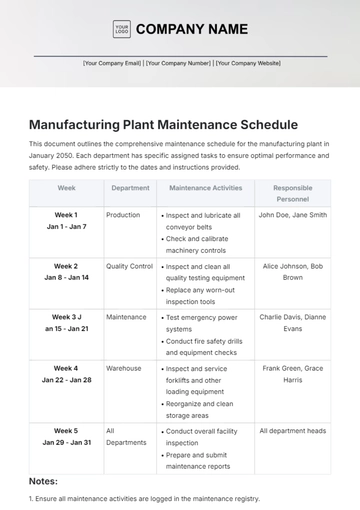

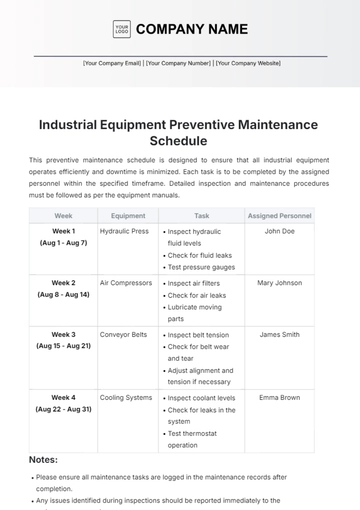

Maintenance Schedule

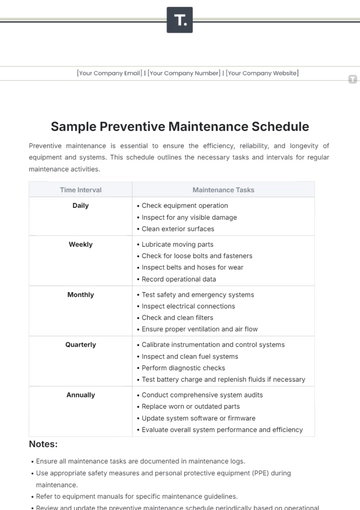

Daily Maintenance

Inspect equipment for visible signs of damage or wear.

Check fluid levels including oil, coolant, and hydraulic fluids.

Test all safety features to ensure they are functioning correctly.

Weekly Maintenance

Clean air filters to ensure optimal performance.

Inspect tracks and tires for wear and adjust air pressure as needed.

Lubricate moving parts to prevent rust and wear.

Monthly Maintenance

Change engine oil and replace the oil filter.

Inspect brake systems and replace worn components.

Check battery terminals for corrosion and clean as necessary.

Quarterly Maintenance

Conduct a thorough inspection of hydraulic systems for leaks.

Test electrical systems for proper functioning.

Inspect and replace worn belts and hoses.

Annual Maintenance

Complete a full equipment service performed by a certified technician.

Calibrate all measurement systems to ensure accuracy.

Evaluate equipment performance and determine any necessary upgrades.

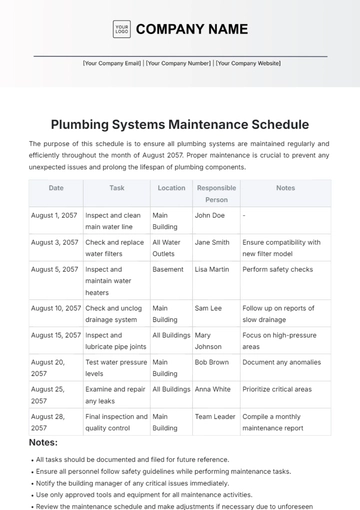

Record Keeping

It is essential to maintain accurate records of all maintenance activities performed on equipment. Records should include the date of service, details of tasks performed, and any parts replaced.

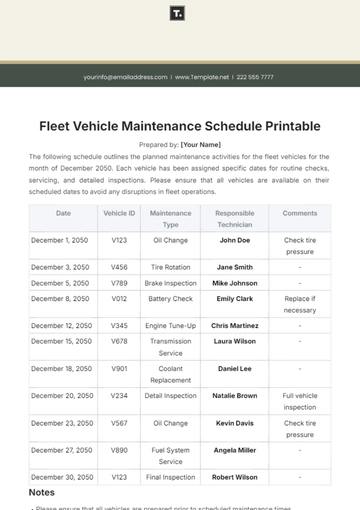

Date | Equipment Type | Service Performed | Technician Name |

|---|---|---|---|

01/15/2050 | Excavator | Engine oil change | Jonatan Farrell |

01/22/2050 | Bulldozer | Brake inspection | Lyda Fadel |

02/05/2050 | Forklift | Battery maintenance | Maria Turner |

Responsible Personnel

Equipment Manager: Oversee maintenance schedules and compliance.

Maintenance Technician: Perform scheduled maintenance and repairs.

Safety Officer: Ensure all maintenance activities meet safety standards.

For inquiries or further information, please contact [Your Name] at [Your Email]. For any urgent matters, reach out to [Your Company Name] at [Your Company Email] or call [Your Company Number].

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Maintain your construction equipment effectively with the Construction Equipment Maintenance Schedule Template, offered by Template.net. This customizable, downloadable, and printable template is editable in our AI Editor Tool. Ideal for organizing and tracking routine maintenance tasks such as inspections, repairs, and servicing, it helps ensure timely upkeep, enhancing performance and minimizing downtime on job sites.

You may also like

- Schedule Appointment

- Work Schedule

- Weekly Schedule

- Cleaning Schedule

- Payment Schedule

- School Schedule

- Maintenance Schedule

- Daily Schedule

- Class Schedule

- Workout Schedule

- Event Schedule

- Marketing Schedule

- Weekly Cleaning Schedule

- Work From Home Schedule

- Payroll Schedule

- Restaurant Schedule

- Kitchen Cleaning Schedule

- Schedule of Values

- Hourly Schedule

- Study Schedule

- University Schedule

- Construction Schedule

- Preventive Maintenance Schedule

- Fitness Schedule

- Education Schedule

- Training Schedule

- Agency Schedule

- Panel Schedule

- Monthly Schedule

- Nursing Home Schedule

- Project Schedule

- Real Estate Schedule

- Freelancer Schedule

- Medication Schedule

- IT and Software Schedule

- Interior Design Schedule

- Travel Schedule

- Travel Agency Schedule

- Hotel Schedule

- Wedding Schedule

- Camp Schedule