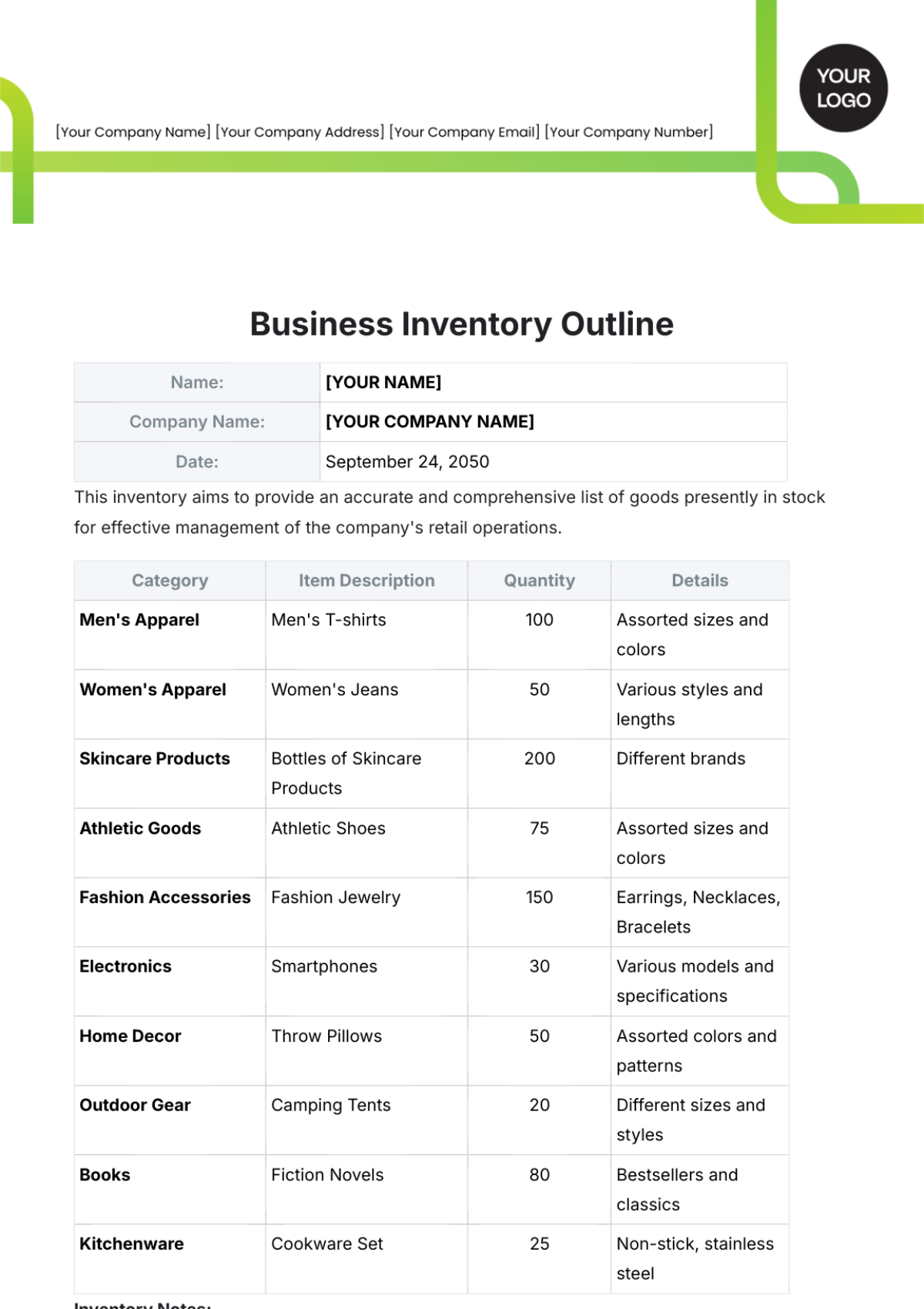

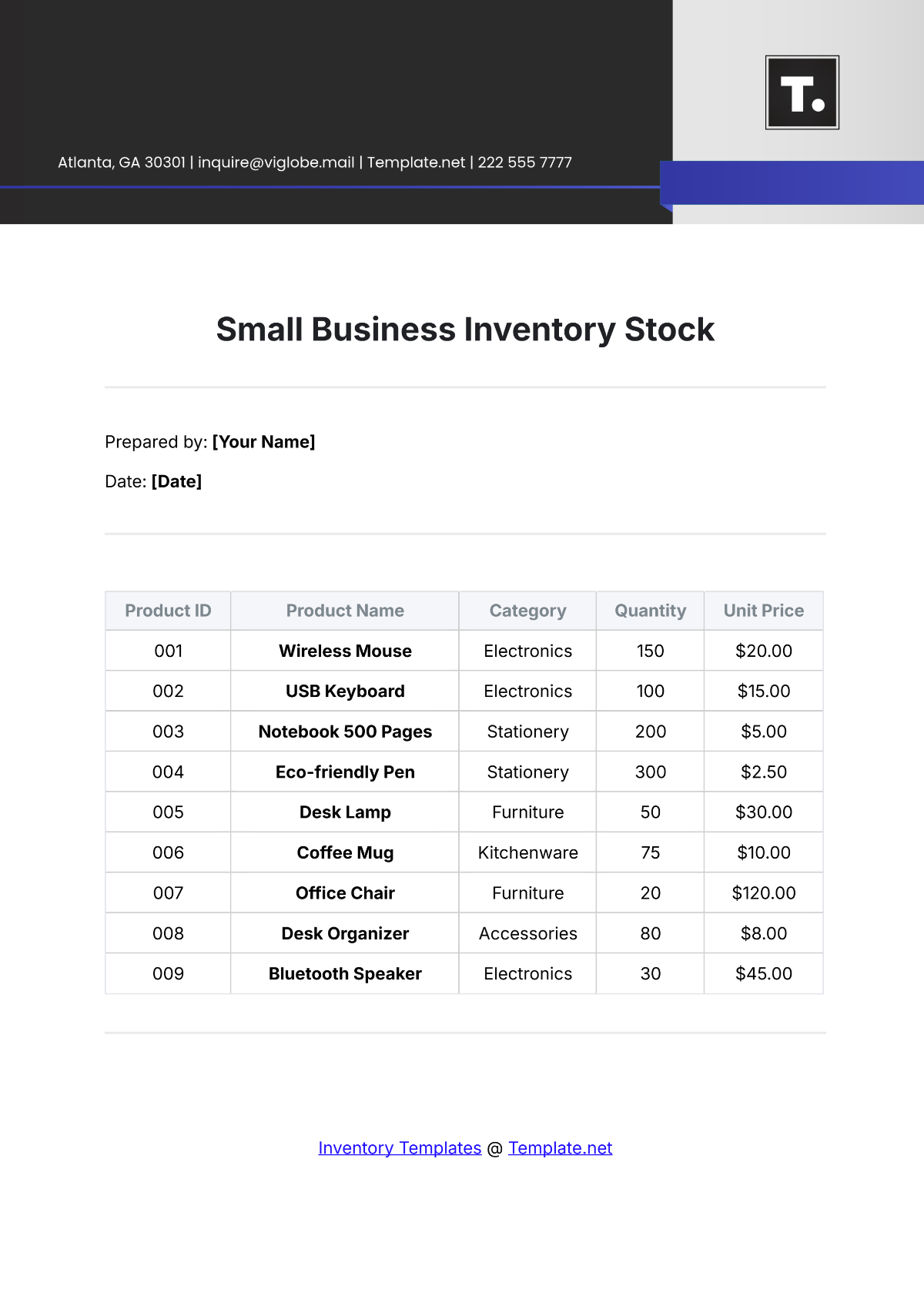

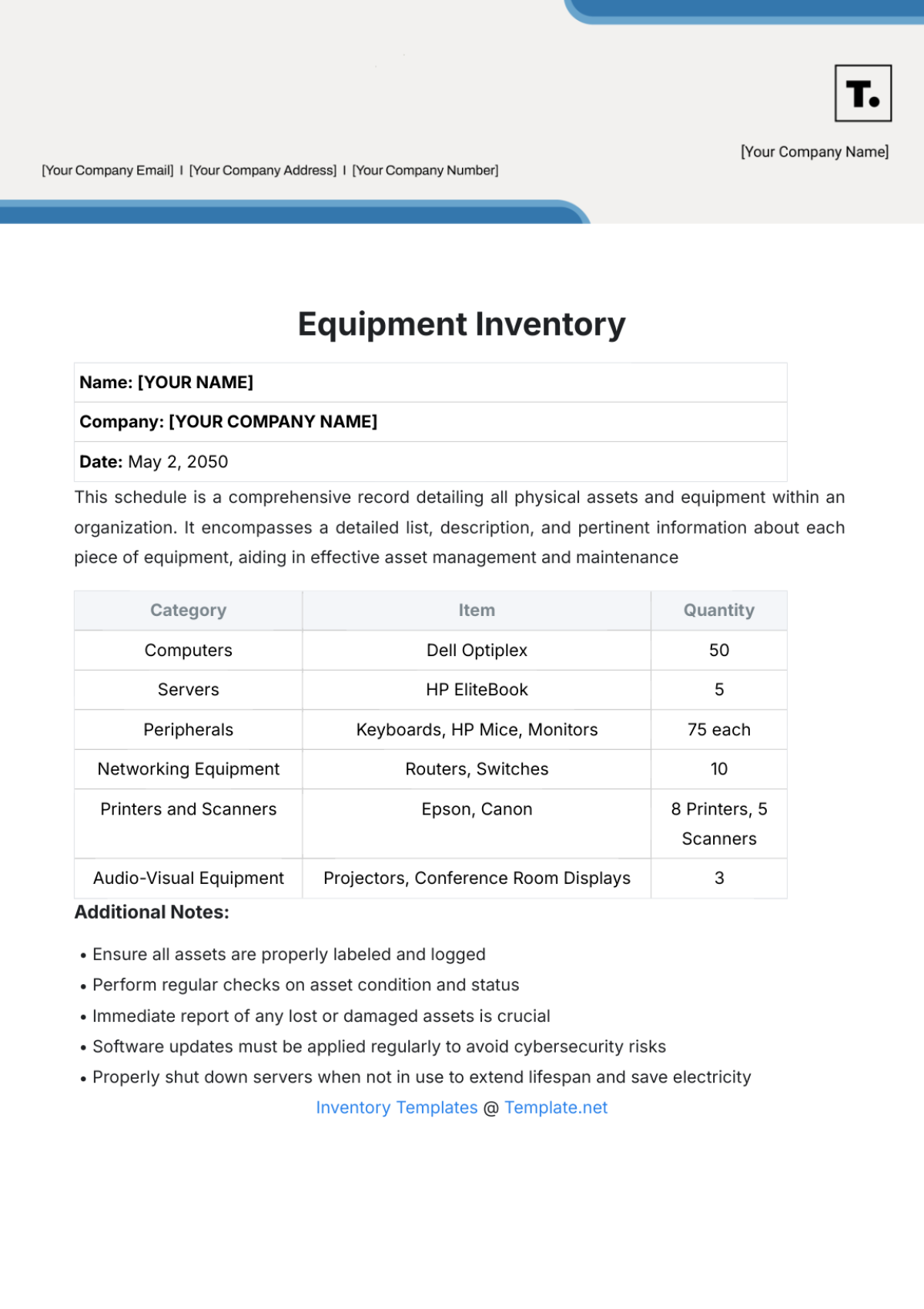

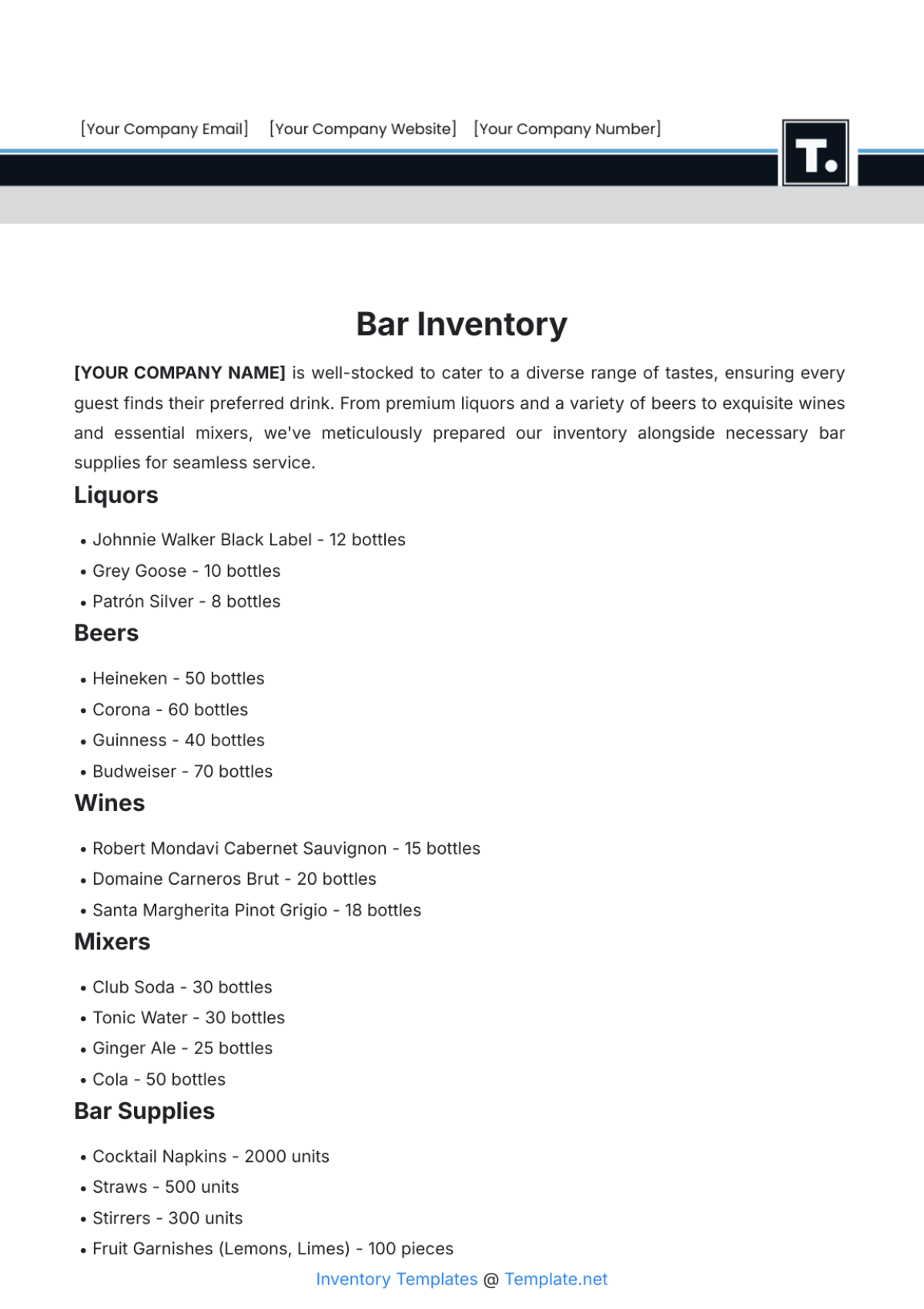

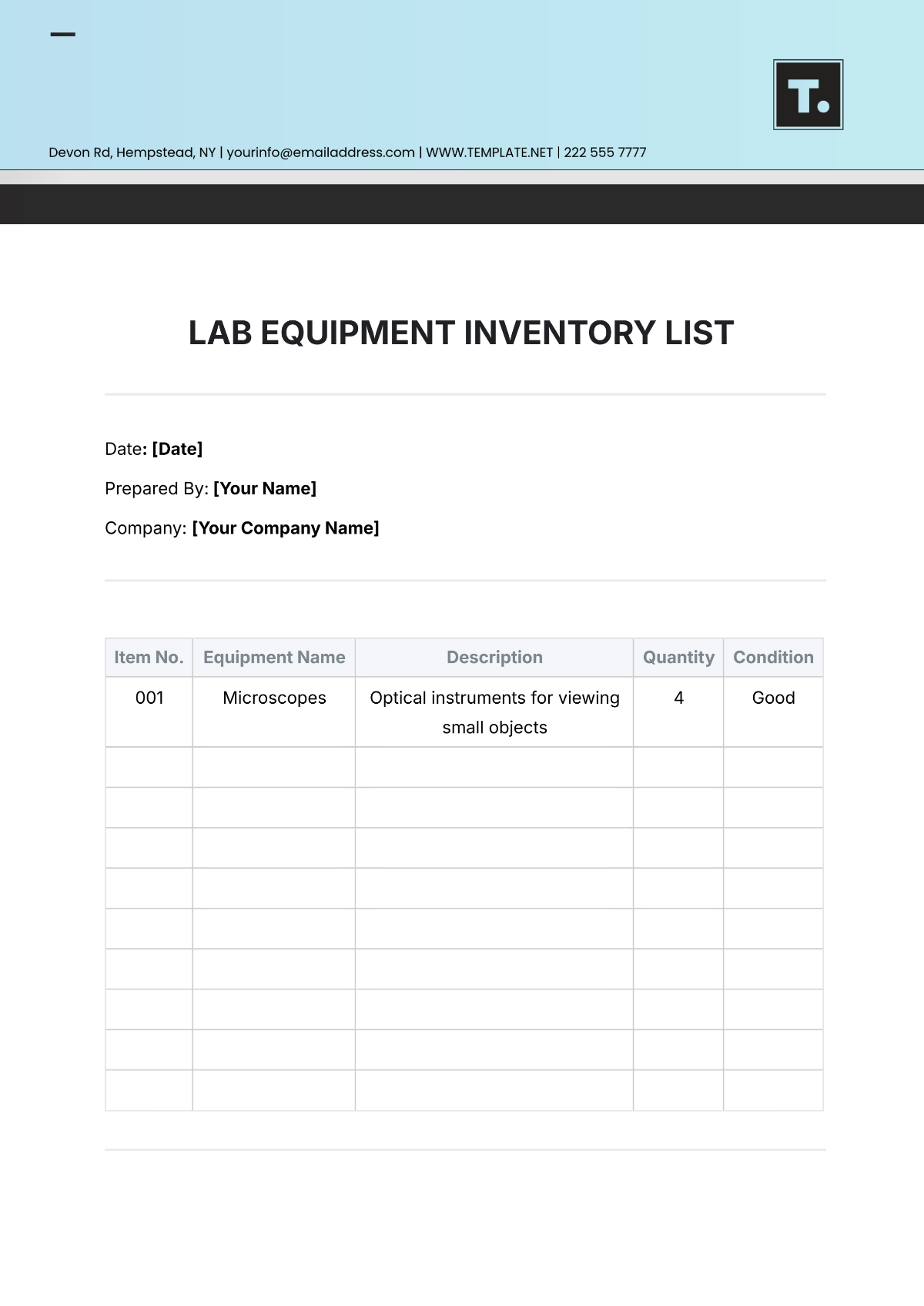

Free Professional Product Inventory Report

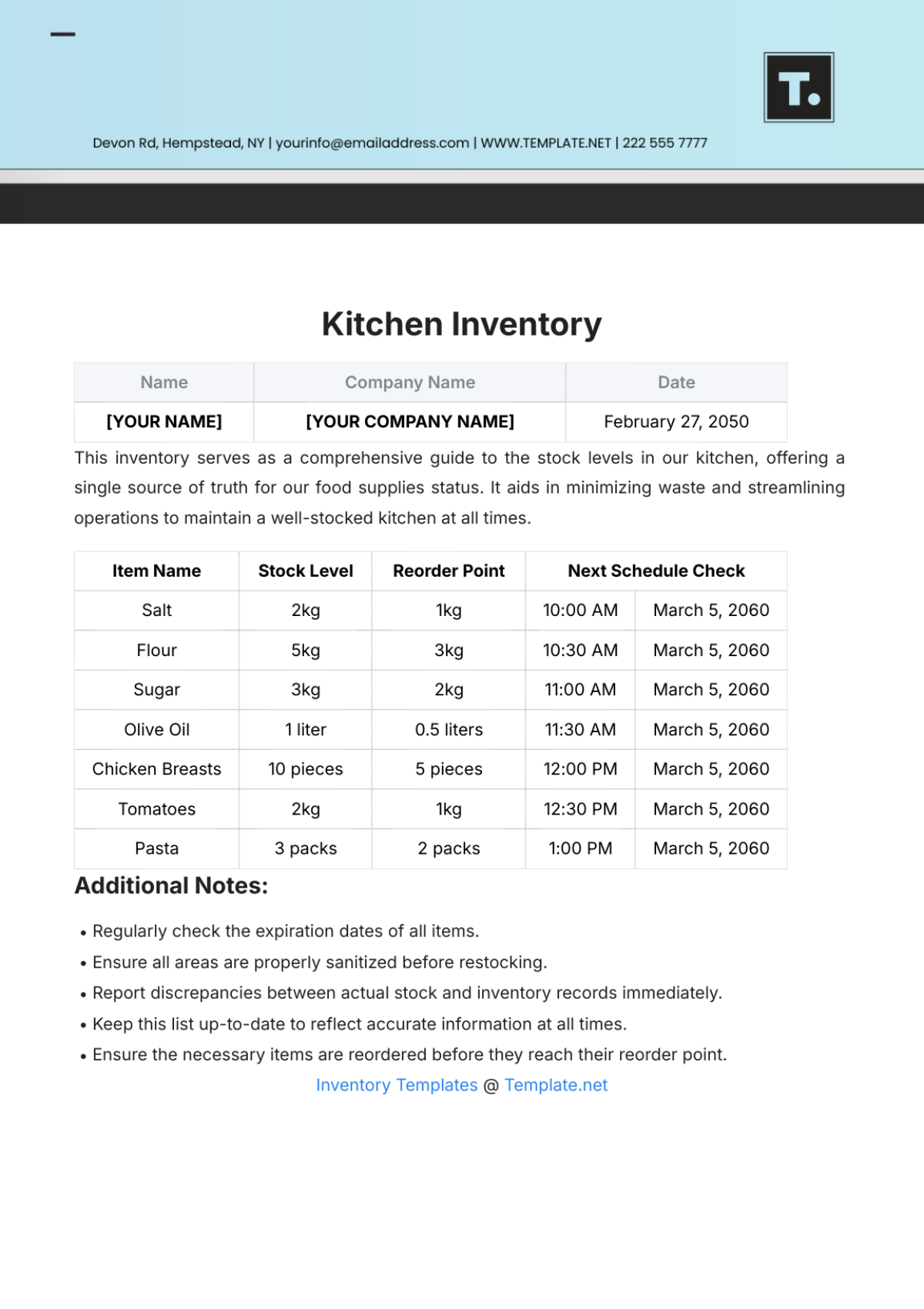

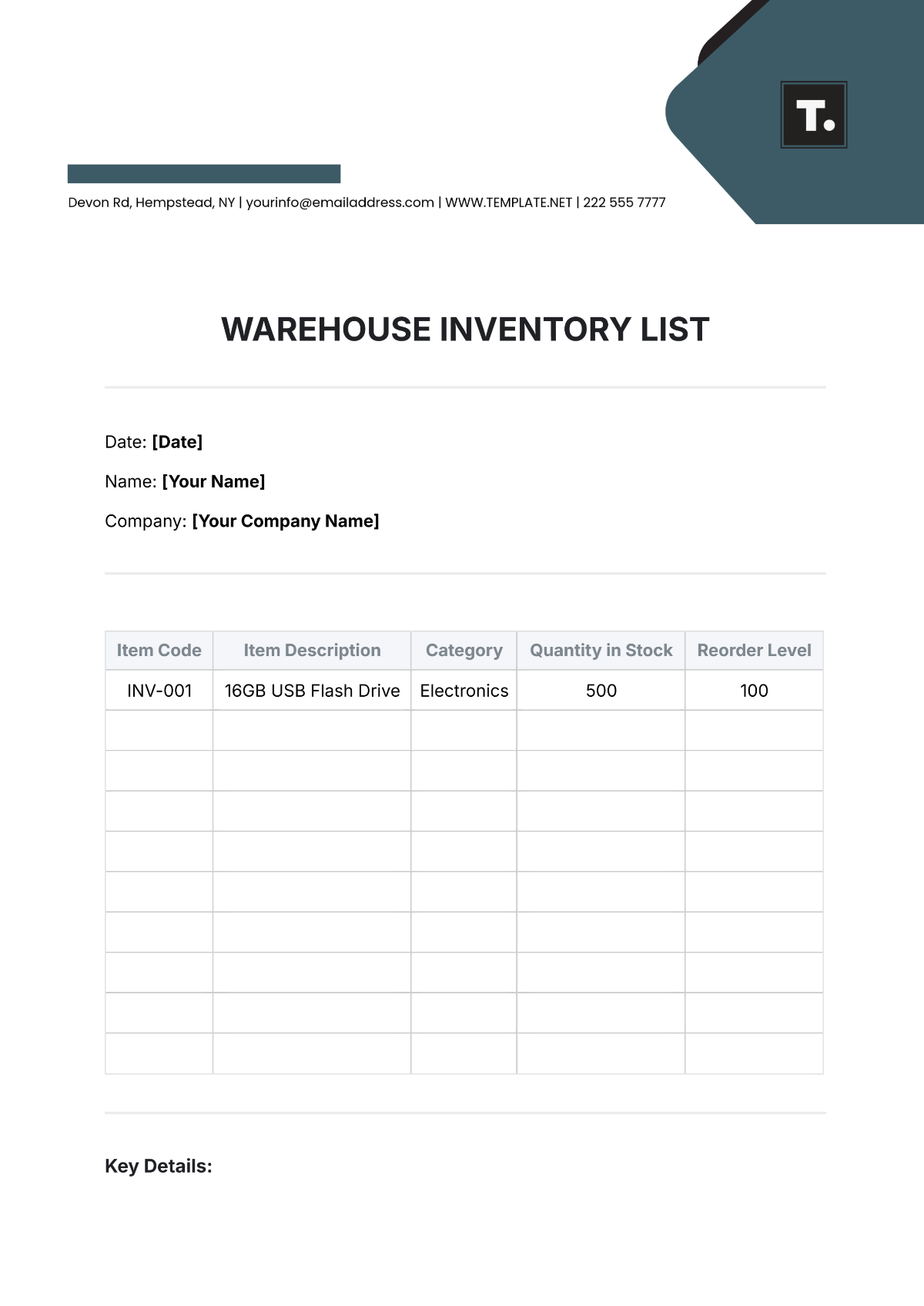

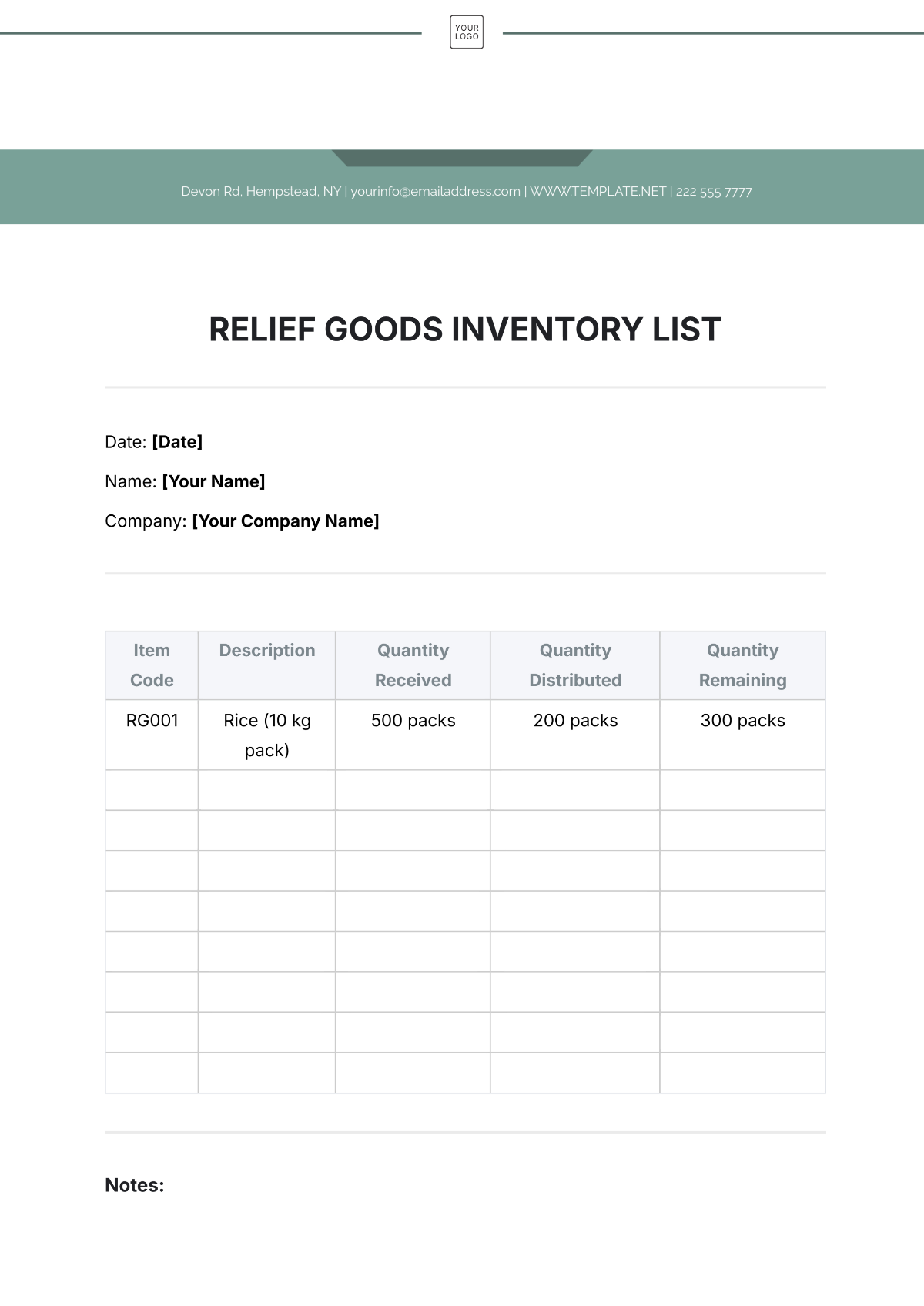

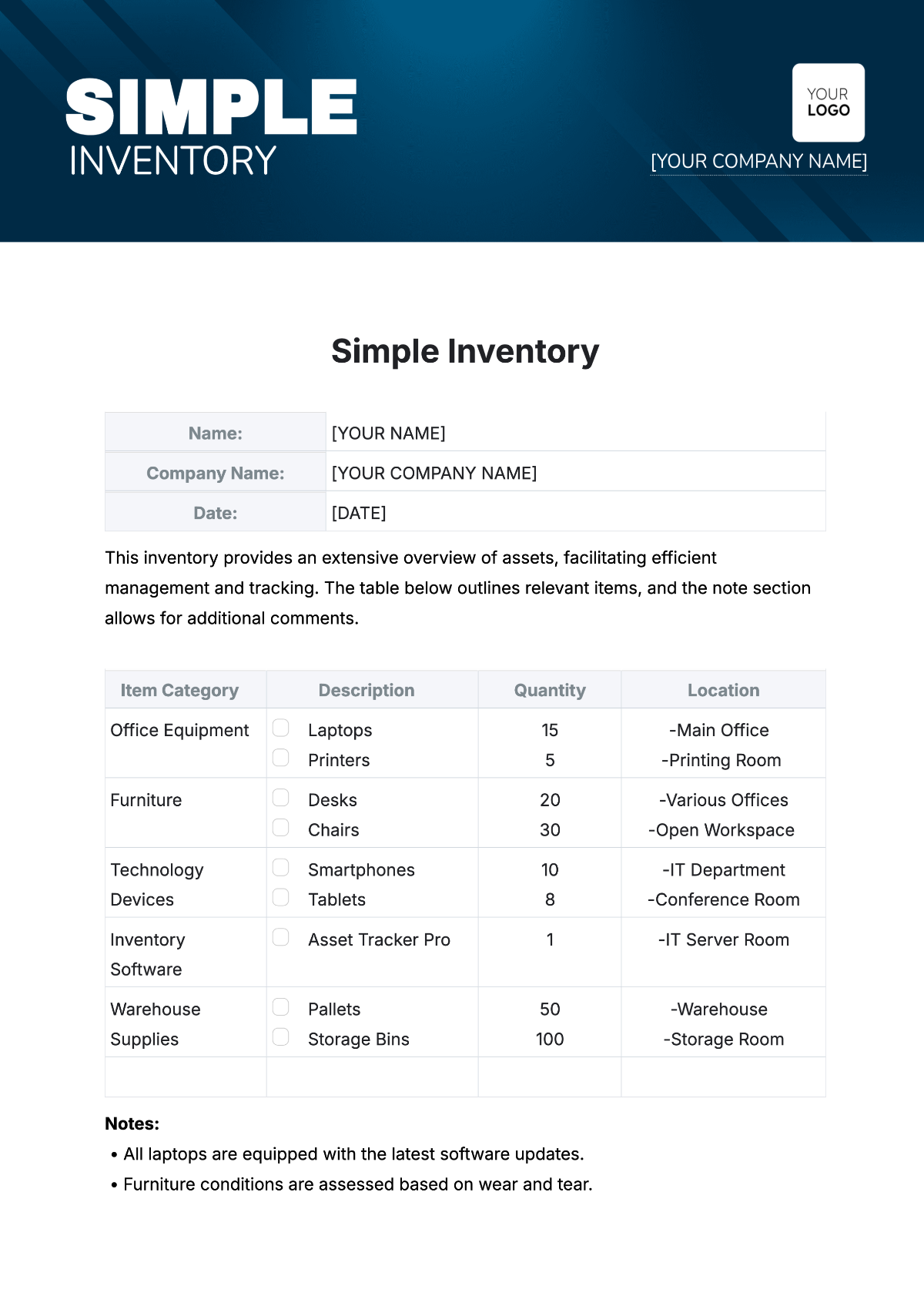

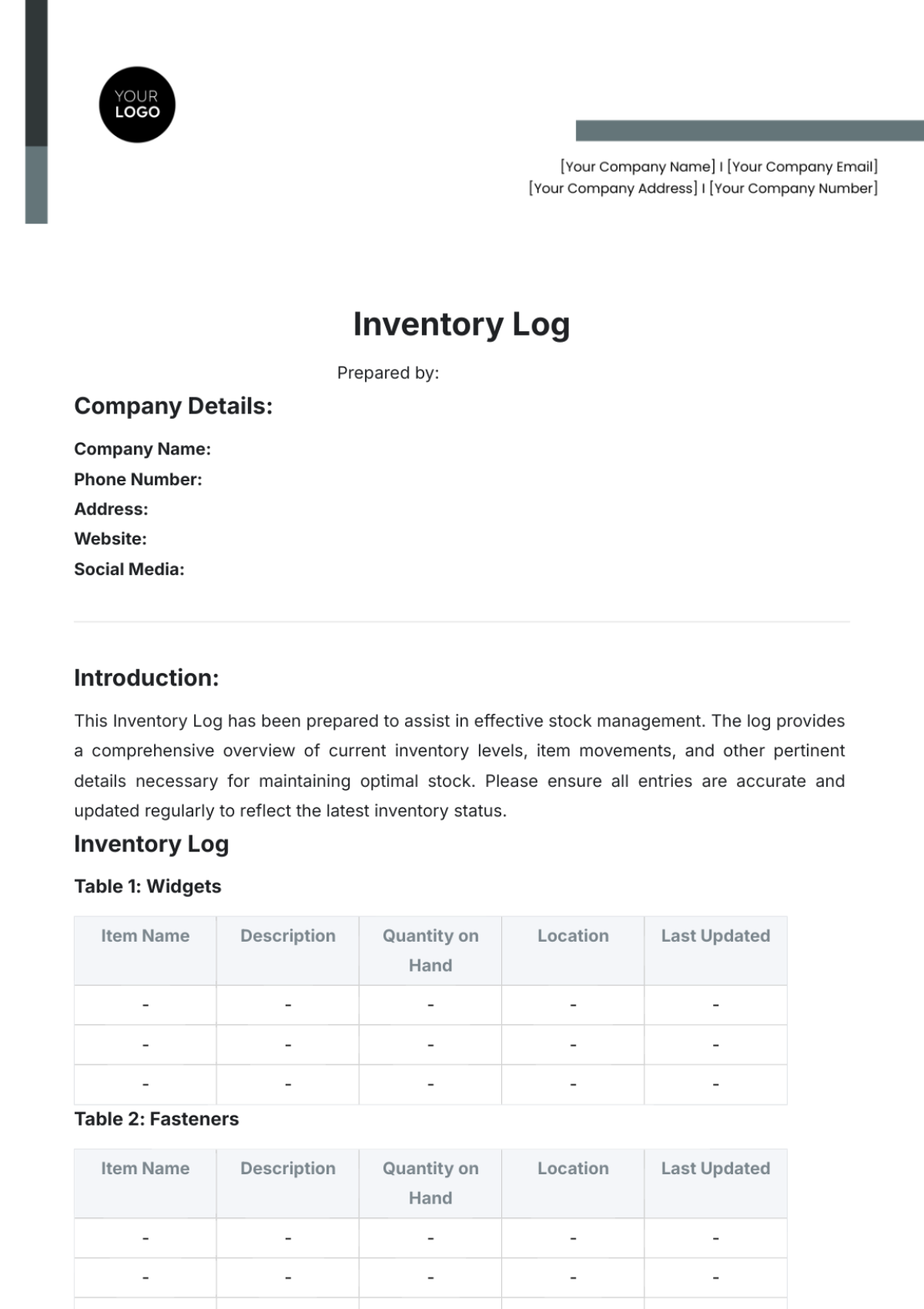

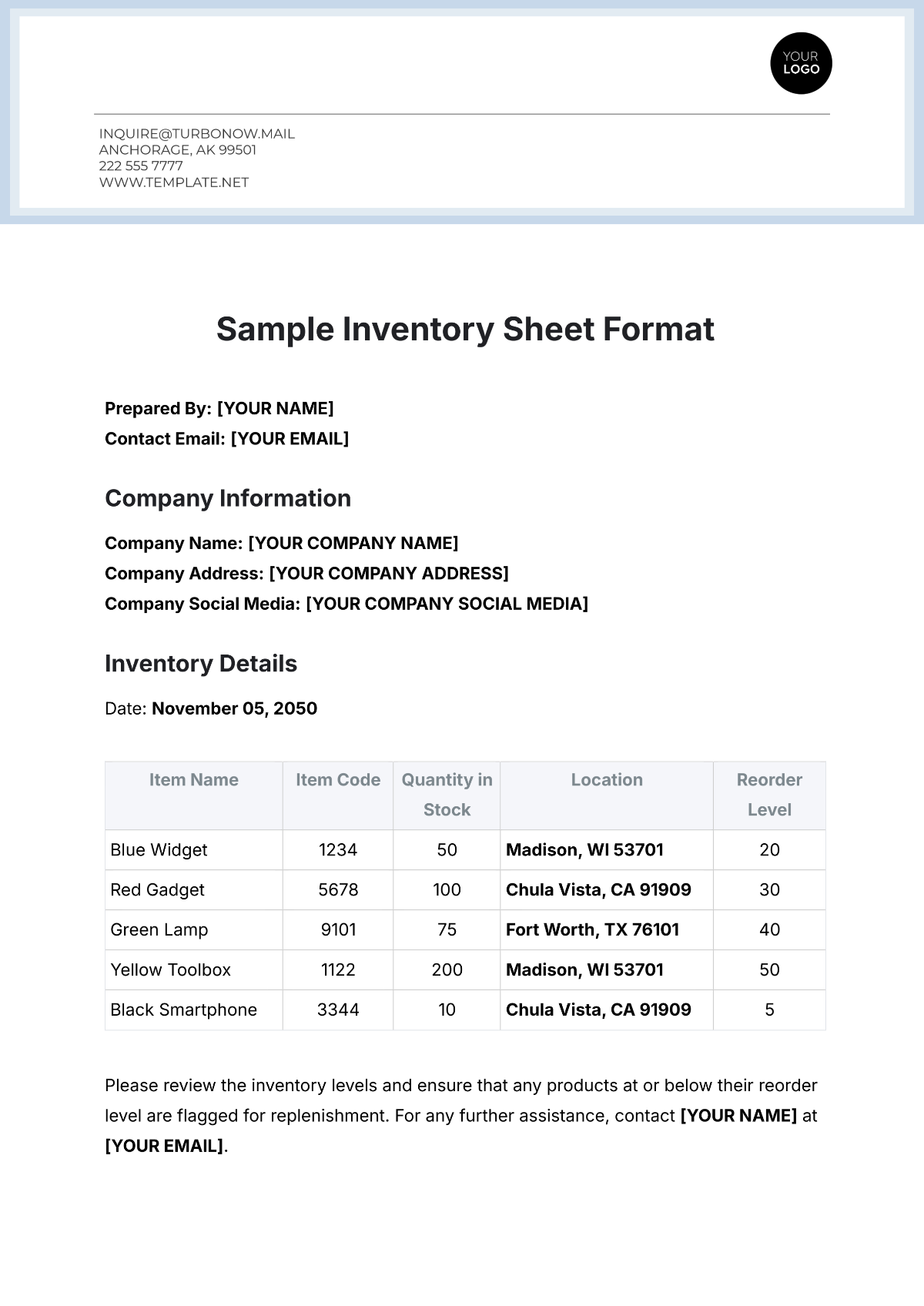

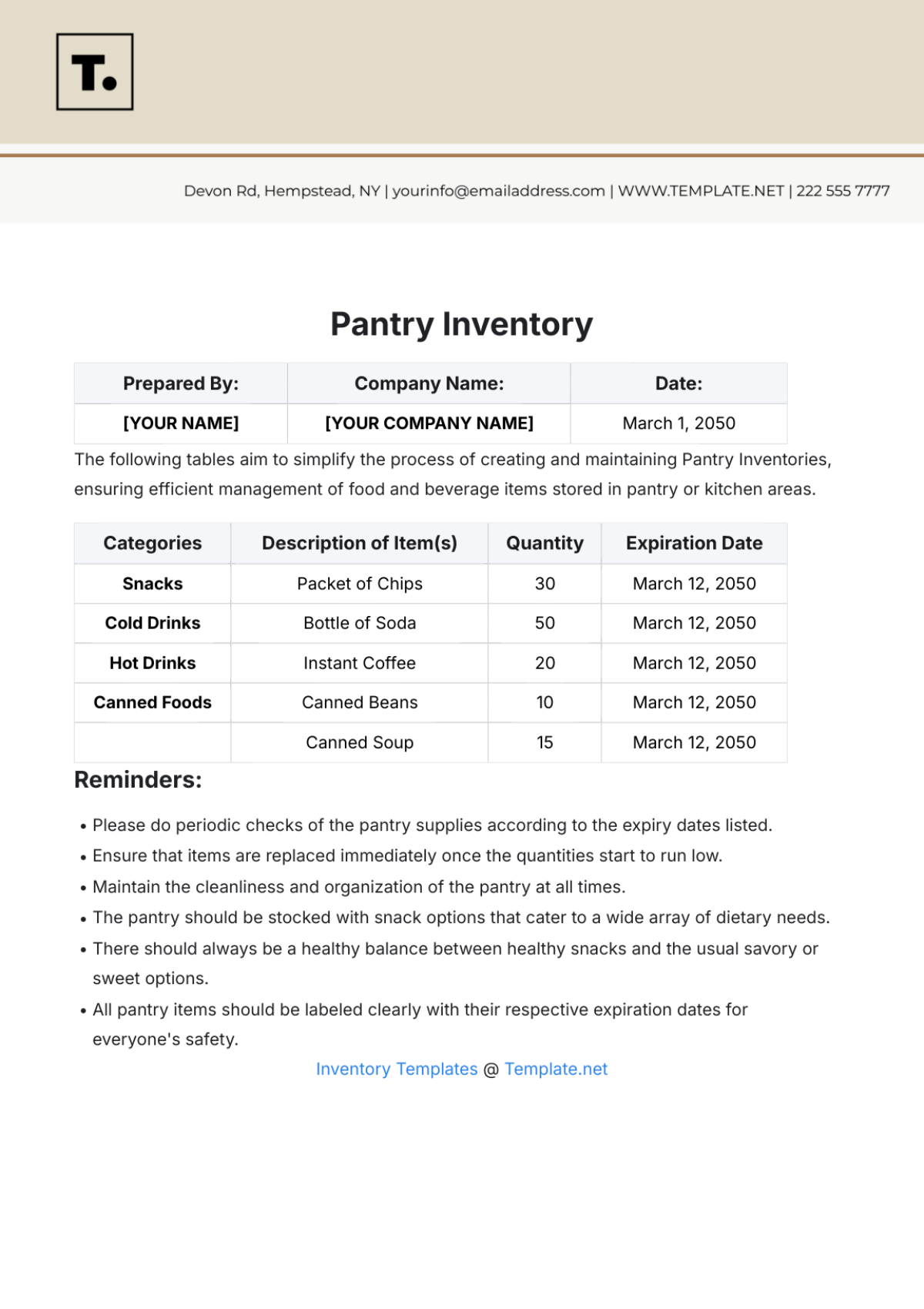

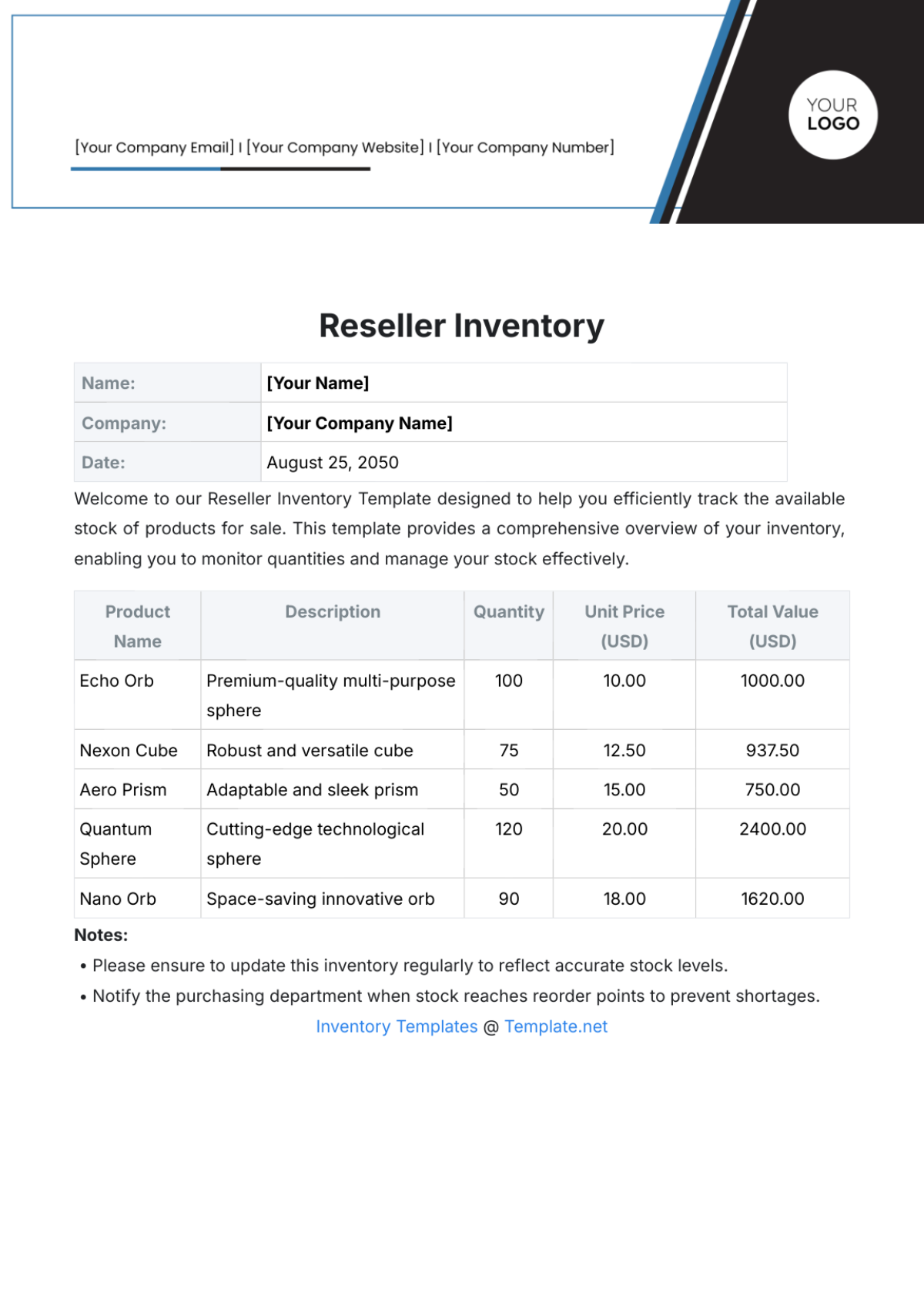

The Professional Product Inventory Report Template from Template.net is your go-to solution for streamlined inventory management. This fully editable and customizable template allows you to tailor every detail to your needs. Effortlessly create comprehensive reports using our Ai Editor Tool, making inventory tracking efficient and effective for your business. Transform your inventory process today!