Product Defects Analysis

I. Introduction

The Product Defects Analysis Report provides an in-depth examination of defects found in our product lines over the last quarter. This analysis aims to identify key areas of concern, determine underlying causes, and propose actionable strategies for defect reduction and quality improvement. The report is structured into several sections to systematically cover various aspects of the analysis.

II. Defect Identification

1. Defect Types

Defect identification is crucial in understanding the quality issues faced during production. The major defect types identified in the last quarter include mechanical failures, electrical malfunctions, and cosmetic imperfections.

2. Frequency of Defects

Data analysis reveals the frequency of different defect types. The table below shows the proportion of each defect type.

Defect Type | Frequency | Percentage |

|---|---|---|

Mechanical Failures | 150 | 45% |

Electrical Malfunctions | 100 | 30% |

Cosmetic Imperfections | 80 | 25% |

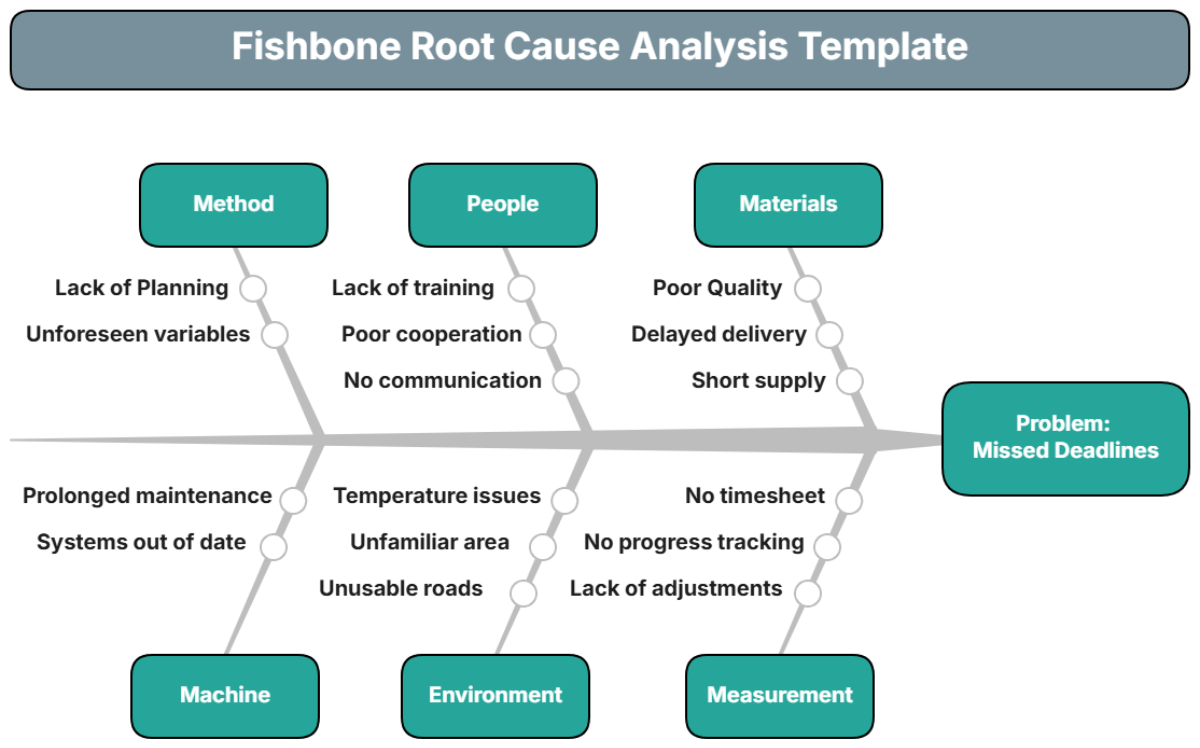

III. Root Cause Analysis

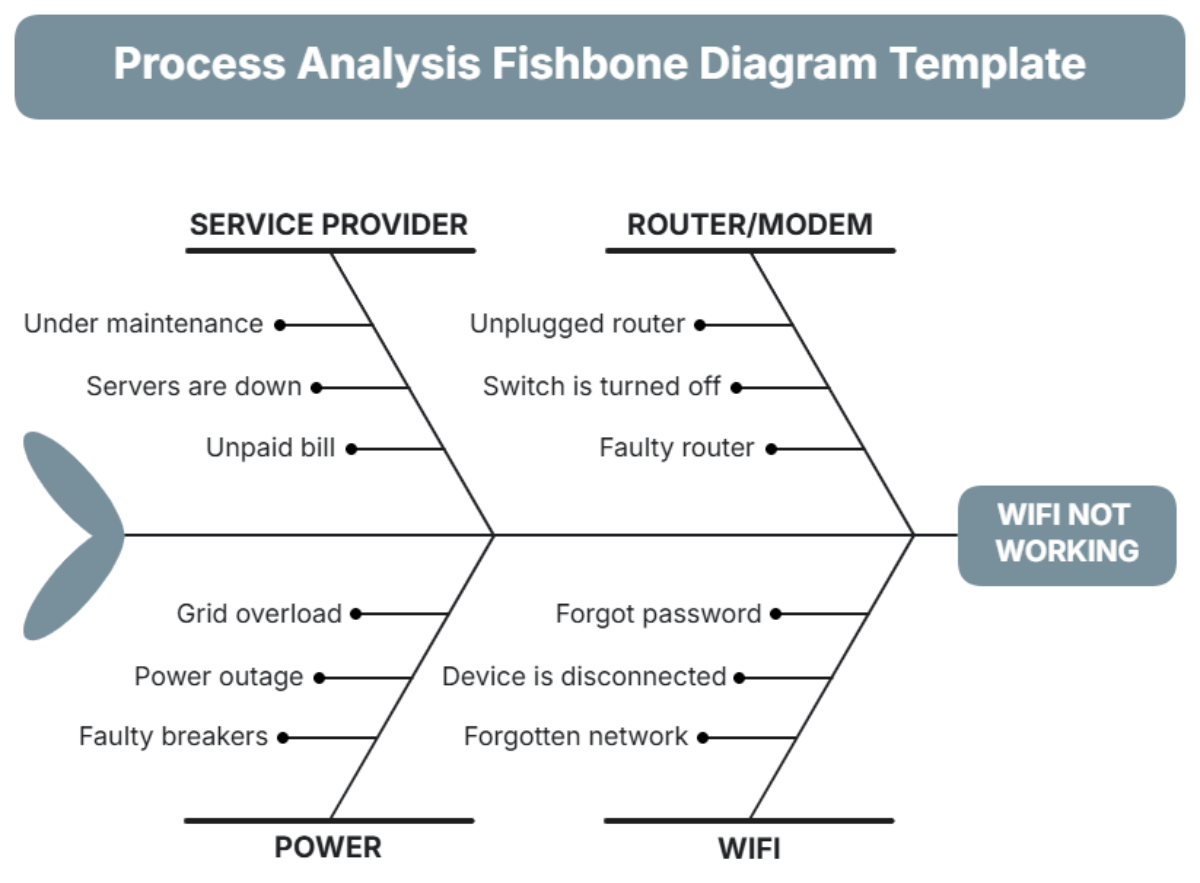

1. Methods of Analysis

Root cause analysis involves a systematic investigation to identify the fundamental reasons behind defect occurrence. Several methods were employed, including cause-and-effect diagrams, failure mode and effect analysis (FMEA), and the 5-whys technique.

2. Key Findings

The following list summarizes the key findings from the root cause analysis:

Insufficient quality checks in the assembly line.

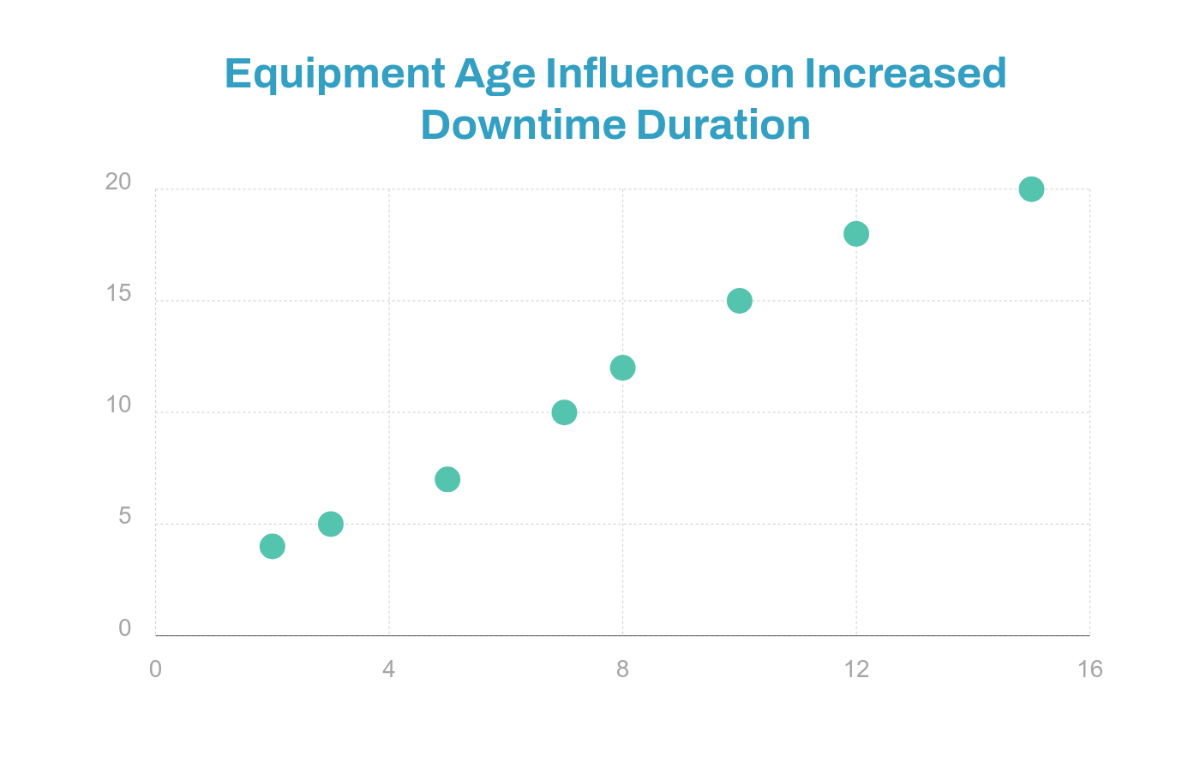

Outdated machinery leads to increased mechanical failures.

Inadequate training for new employees affects production consistency.

IV. Corrective Measures

1. Immediate Actions

To address the identified defects, the following immediate actions are recommended:

Enhance quality control protocols in the manufacturing process.

Invest in upgraded machinery and technology.

Implement comprehensive training programs for all production staff.

2. Long-term Strategies

Long-term strategies focus on sustainable improvements to product quality, as outlined in the table below:

Strategy | Description |

|---|---|

Continuous Improvement Programs | Ongoing initiatives aimed at reducing defects over time through gradual enhancements. |

Supplier Quality Assurance | Engagement with suppliers to ensure they meet the highest standards of quality. |

Feedback Loops | Establishing systems to capture customer feedback for continuous quality monitoring. |

V. Conclusion

The Product Defects Analysis Report highlights the significant defects encountered and provides an actionable roadmap for improvements. By focusing on both immediate corrective measures and long-term strategies, the company can enhance product quality, customer satisfaction, and operational efficiency. Regular monitoring and analysis of defects will ensure continuous improvement and sustained success.