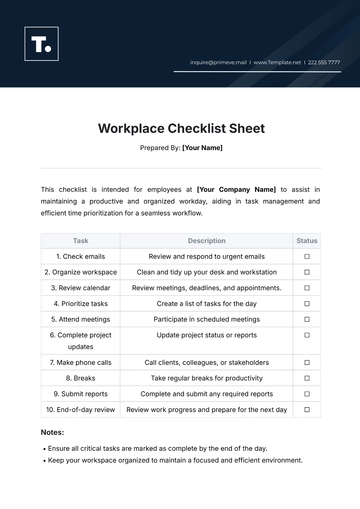

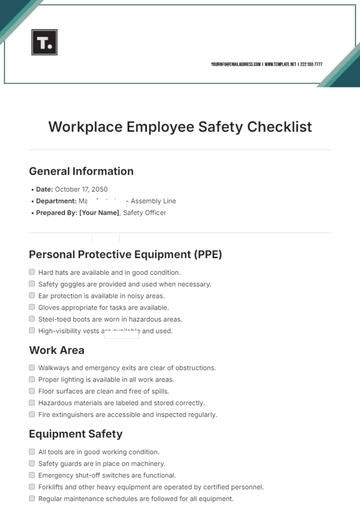

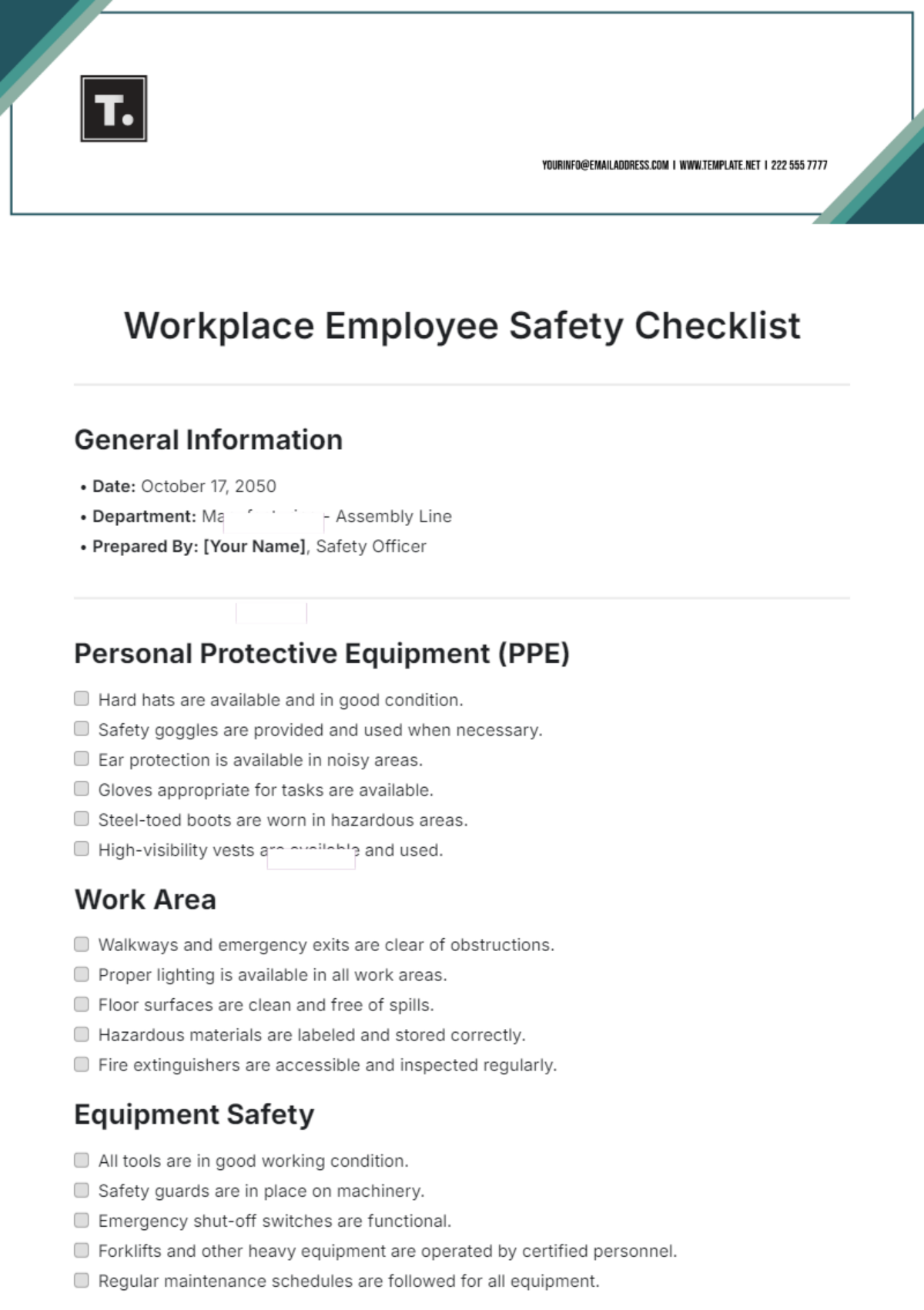

Free Workplace Employee Safety Checklist

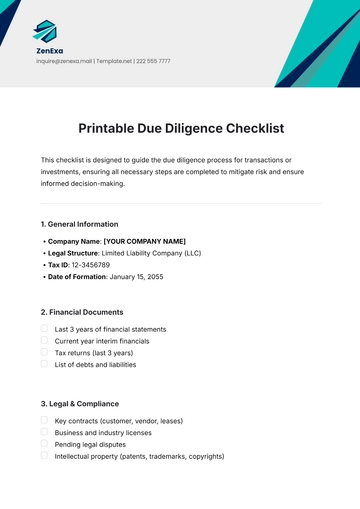

General Information

Date: October 17, 2050

Department: Manufacturing - Assembly Line

Prepared By: [Your Name], Safety Officer

Personal Protective Equipment (PPE)

Hard hats are available and in good condition.

Safety goggles are provided and used when necessary.

Ear protection is available in noisy areas.

Gloves appropriate for tasks are available.

Steel-toed boots are worn in hazardous areas.

High-visibility vests are available and used.

Work Area

Walkways and emergency exits are clear of obstructions.

Proper lighting is available in all work areas.

Floor surfaces are clean and free of spills.

Hazardous materials are labeled and stored correctly.

Fire extinguishers are accessible and inspected regularly.

Equipment Safety

All tools are in good working condition.

Safety guards are in place on machinery.

Emergency shut-off switches are functional.

Forklifts and other heavy equipment are operated by certified personnel.

Regular maintenance schedules are followed for all equipment.

Emergency Preparedness

Emergency contact numbers are posted and accessible.

First aid kits are stocked and easily accessible.

Fire evacuation plans are posted and practiced.

Employees are trained in emergency procedures.

Training and Awareness

Safety training sessions are conducted regularly.

Employees are aware of their roles in safety procedures.

Safety meetings are held to discuss issues and improvements.

Safety data sheets (SDS) for hazardous materials are accessible.

Reporting and Feedback

A system is in place for reporting safety hazards.

Employees are encouraged to report unsafe conditions without fear of reprisal.

Regular safety audits are conducted to ensure compliance.

Safety Officer Signature: [Your Name]

Date: October 17, 2050

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Ensure workplace safety with the Workplace Employee Safety Checklist Template from Template.net. This customizable, fully editable checklist helps you stay compliant and organized. Editable in our AI Editor Tool, it's designed for quick adjustments to fit your needs, making safety management easier and more efficient for your team. Download now for seamless workplace safety tracking!

You may also like

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

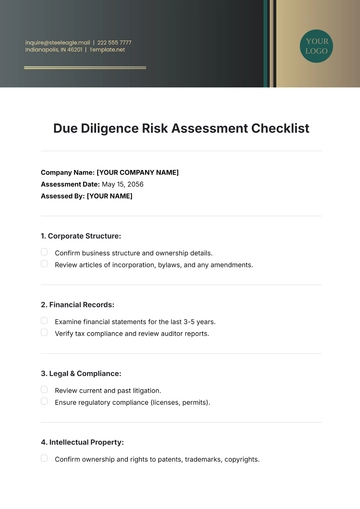

- Risk Assessment Checklist

- Onboarding Checklist

- Quality Checklist

- Compliance Checklist

- Audit Checklist

- Registry Checklist

- HR Checklist

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

- Construction Checklist

- Task Checklist

- Professional Checklist

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

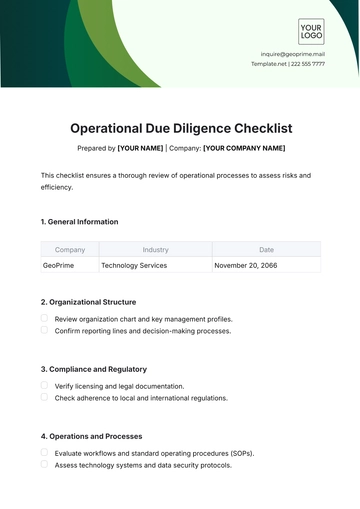

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

- Medical Checklist

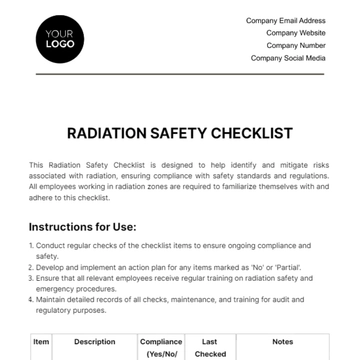

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

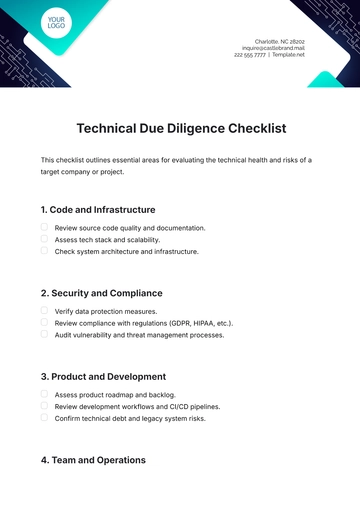

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

- School Checklist

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

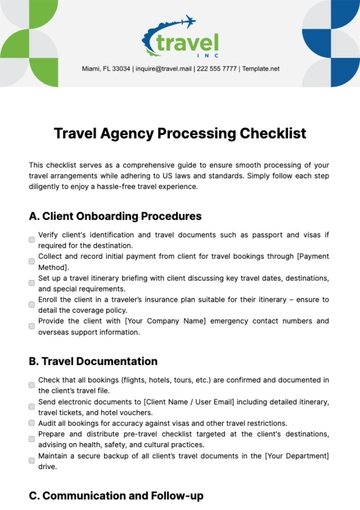

- Travel Agency Checklist

- Vehicle Inspection Checklist

- Interior Design Checklist

- Backpacking Checklist

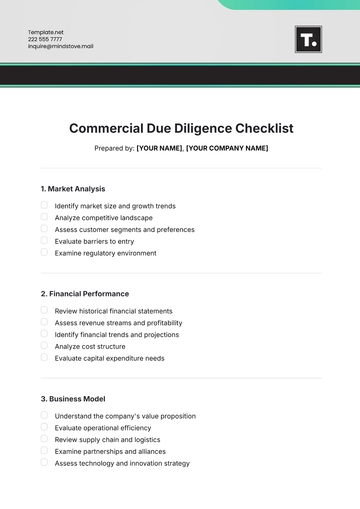

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist