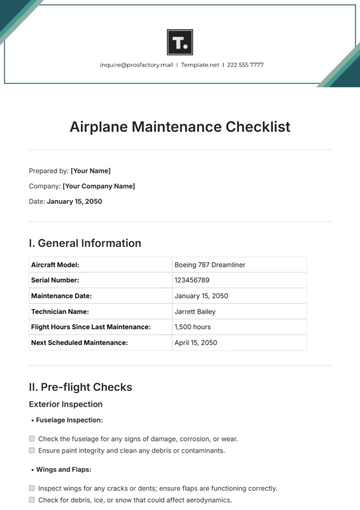

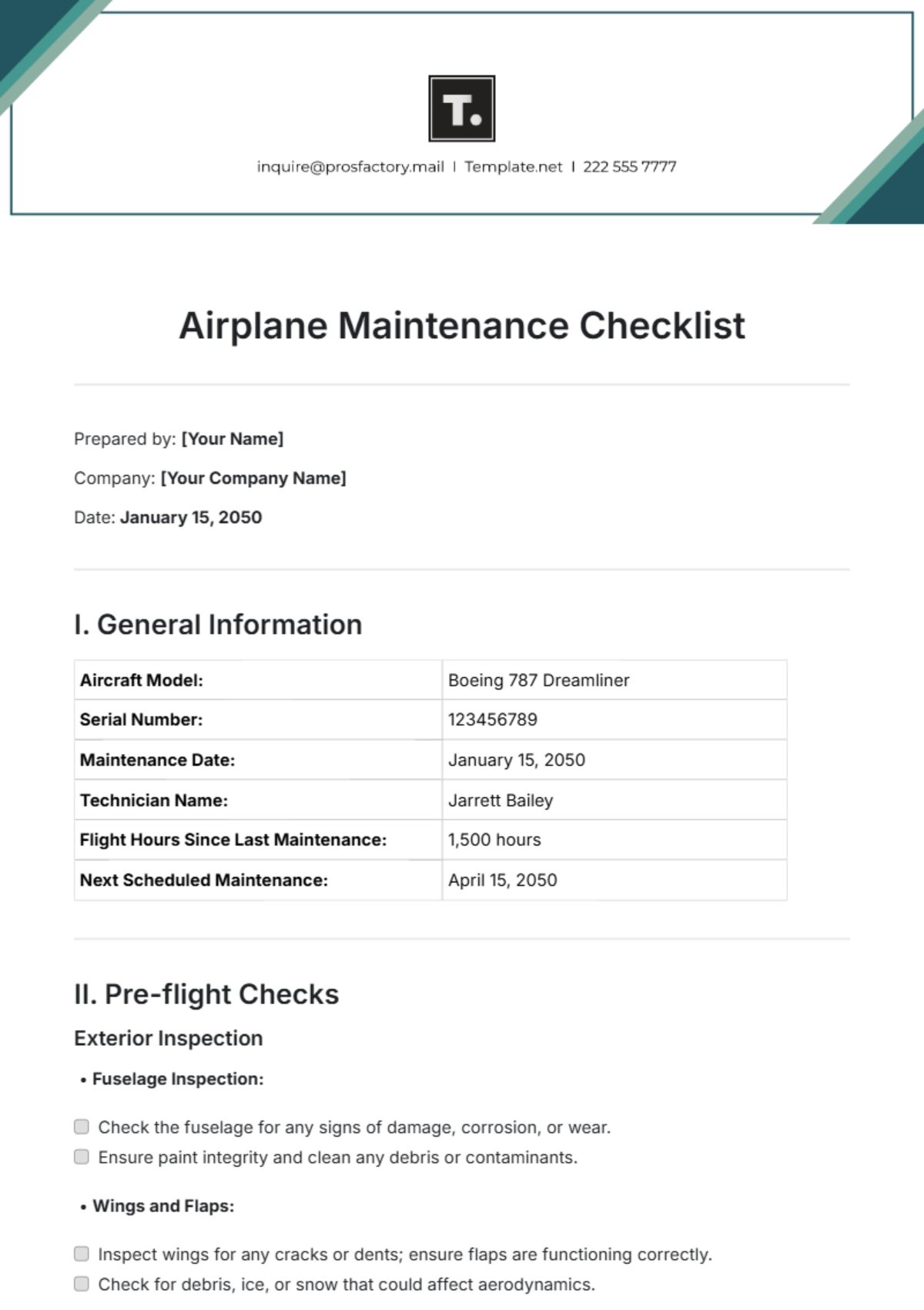

Free Airplane Maintenance Checklist

Prepared by: [Your Name]

Company: [Your Company Name]

Date: January 15, 2050

I. General Information

Aircraft Model: | Boeing 787 Dreamliner |

Serial Number: | 123456789 |

Maintenance Date: | January 15, 2050 |

Technician Name: | Jarrett Bailey |

Flight Hours Since Last Maintenance: | 1,500 hours |

Next Scheduled Maintenance: | April 15, 2050 |

II. Pre-flight Checks

Exterior Inspection

Fuselage Inspection:

Check the fuselage for any signs of damage, corrosion, or wear.

Ensure paint integrity and clean any debris or contaminants.

Wings and Flaps:

Inspect wings for any cracks or dents; ensure flaps are functioning correctly.

Check for debris, ice, or snow that could affect aerodynamics.

Landing Gear:

Ensure landing gear is secure and properly locked in place.

Confirm that tires are inflated to the recommended pressure (main: 210 psi, nose: 150 psi).

Interior Inspection

Cockpit Instruments:

Verify that all cockpit instruments (altimeter, airspeed indicator, etc.) are operational and calibrated.

Check the functionality of communication and navigation systems.

Seating and Emergency Exits:

Inspect all seating for wear and secure attachment.

Ensure emergency exits are easily accessible and functioning.

Cargo Security:

Verify that all cargo is secured and balanced to prevent shifting during flight.

III. Routine Maintenance Tasks

Engine Maintenance

Oil Change:

Change the engine oil (using high-performance synthetic oil).

Check for leaks around the oil pan and seals.

Air Filter:

Inspect air filters for dirt and debris; replace if needed.

Clean air intake to ensure optimal airflow.

Fuel System:

Inspect fuel lines for integrity; replace any frayed or damaged hoses.

Conduct fuel quality tests to ensure no contamination.

Electrical System

Battery Performance:

Test battery performance and charge levels; replace if below 75%.

Check battery terminals for corrosion.

Wiring Inspection:

Inspect wiring harnesses for signs of wear, fraying, or damage.

Ensure connections are secure and weatherproof.

Navigation Lights:

Check all navigation lights for proper operation.

Replace any burnt-out bulbs.

IV. Inspection Procedures

Scheduled Inspections

360-Degree Walk-around:

Conduct a thorough 360-degree visual inspection of the aircraft.

Look for any inconsistencies or potential safety issues.

Logbook Review:

Complete a detailed logbook review for maintenance history and compliance.

Verify that all previous maintenance actions were recorded accurately.

Fatigue Examination:

Examine wear-prone areas such as the wing roots, landing gear, and control surfaces for signs of fatigue or corrosion.

Unscheduled Inspections

Crew Reports:

Assess any reported issues from the flight crew, addressing concerns raised.

Conduct focused inspections on any newly repaired areas.

Critical Safety Components:

Random checks on critical safety components, such as emergency equipment and control surfaces.

V. Sign-off Section

Jarrett Bailey

Technician Signature

Date: January 15, 2050

[Your Name]

Supervisor Approval

Date: January 15, 2050

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Ensure the safety and reliability of your aircraft with our Airplane Maintenance Checklist Template available at Template.net. This editable and customizable template offers a thorough framework for tracking all necessary maintenance tasks. Easily adjust and personalize it in our Ai Editor Tool to meet your specific operational requirements. Maintain peak performance and compliance with this essential resource for aviation professionals.

You may also like

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

- Quality Checklist

- Compliance Checklist

- Audit Checklist

- Registry Checklist

- HR Checklist

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

- Construction Checklist

- Task Checklist

- Professional Checklist

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

- Medical Checklist

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

- IT and Software Checklist

- Performance Checklist

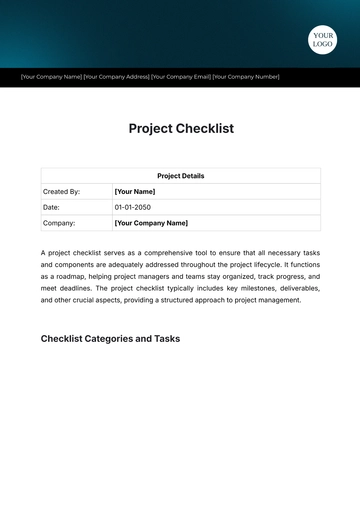

- Project Checklist

- Startup Checklist

- Education Checklist

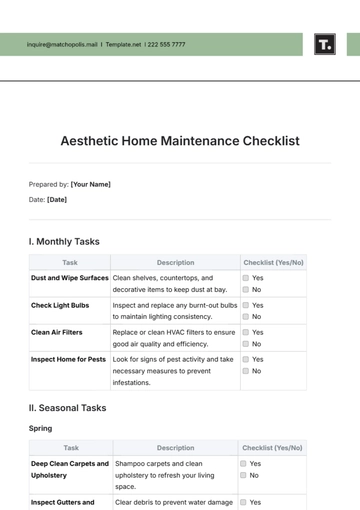

- Home Checklist

- School Checklist

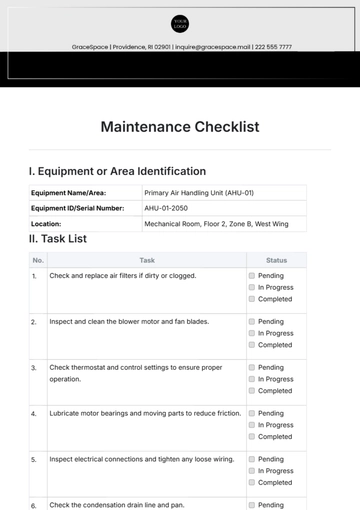

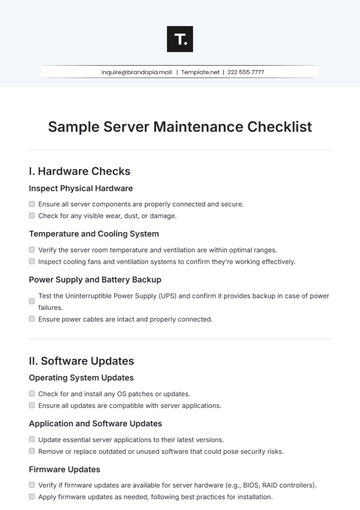

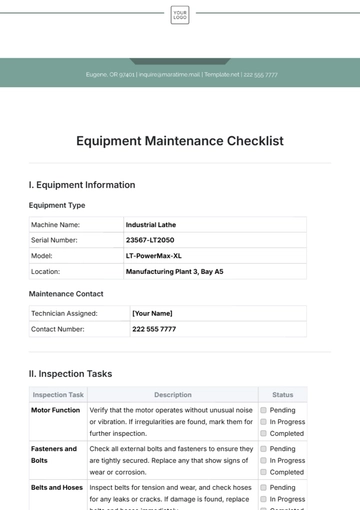

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

- Travel Agency Checklist

- Vehicle Inspection Checklist

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist