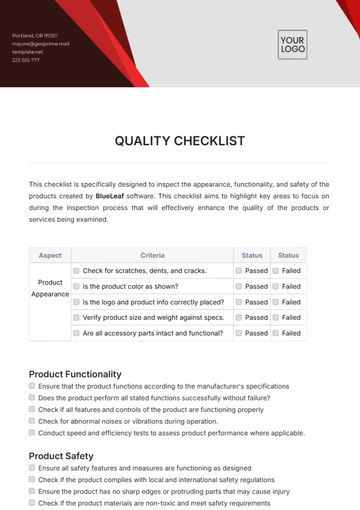

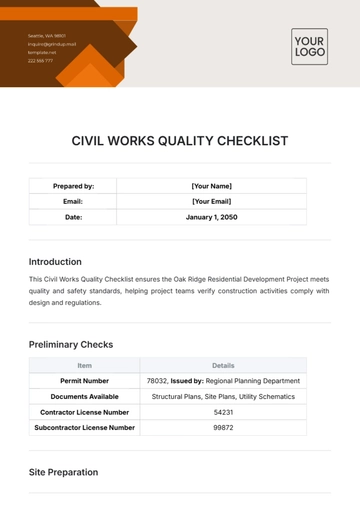

POWDER COATING QUALITY CHECKLIST

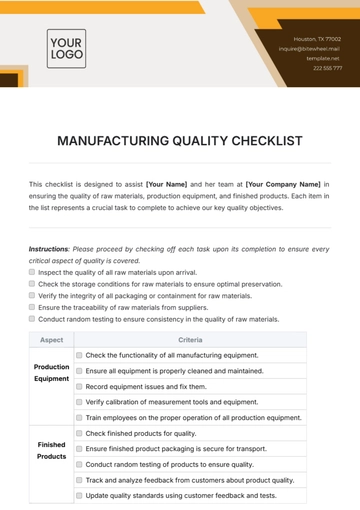

Ensuring high-quality powder coating is essential for durability, aesthetics, and performance. This checklist serves as a guide to monitor and document each step of the powder coating process, from preparation to packaging. By following these steps, we can maintain consistency, meet customer expectations, and ensure that all parts meet the highest quality standards.

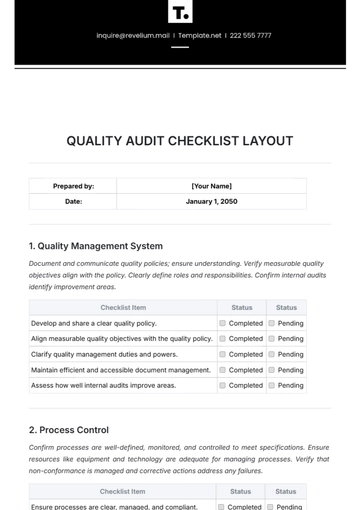

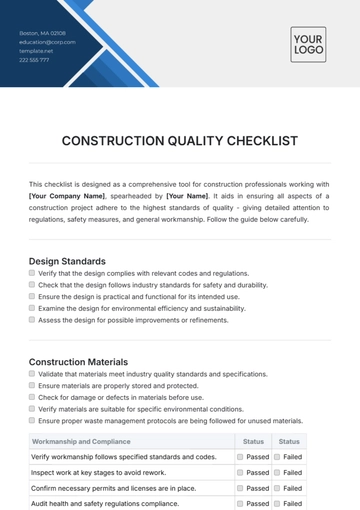

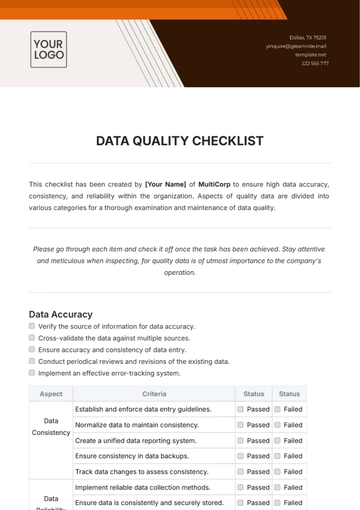

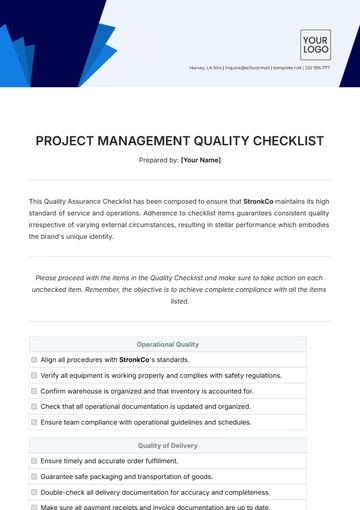

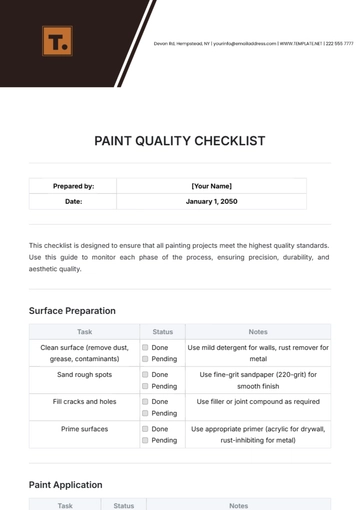

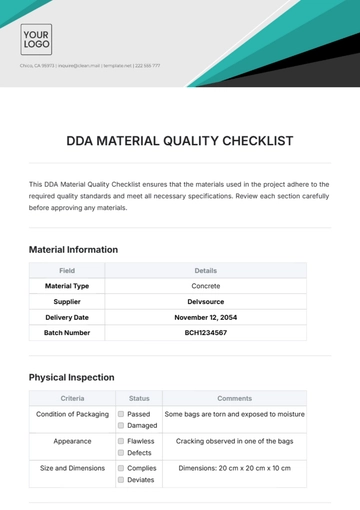

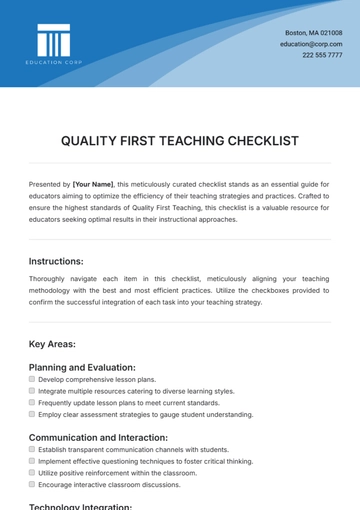

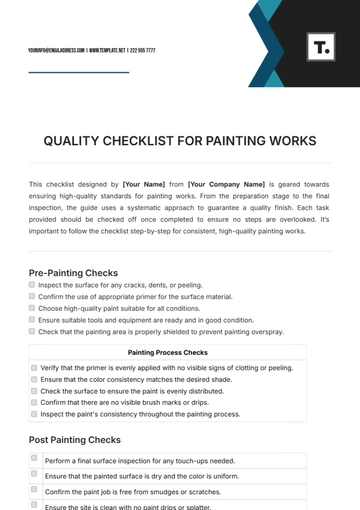

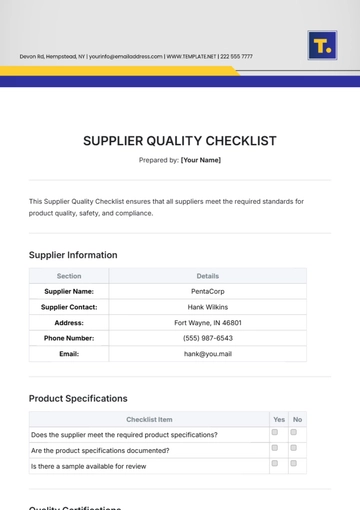

Preparation Phase

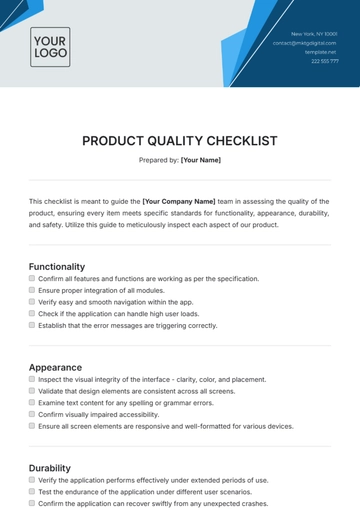

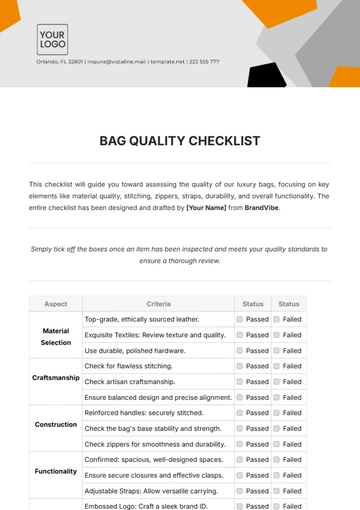

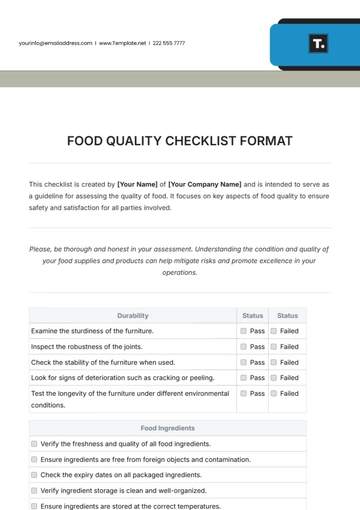

Coating Application

Curing Process

Post-Coating Inspection

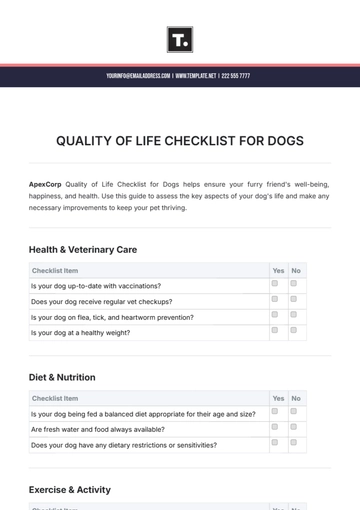

Packaging and Shipping

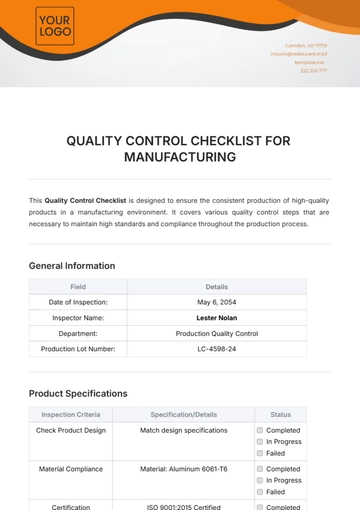

Final Sign-Off

Quality inspector's name: Floyd Cremin

Approval signature: [Your Name]

Contact information: [Your Email]

Date of inspection: October 15, 2054

By following this checklist, we can ensure that each powder-coated part meets the required standards for quality and durability. This thorough approach helps reduce errors, improve product consistency, and increase customer satisfaction. Regular inspection and attention to detail throughout the process are essential to maintain the high standards of BrandKat.

Checklist Templates @ Template.net