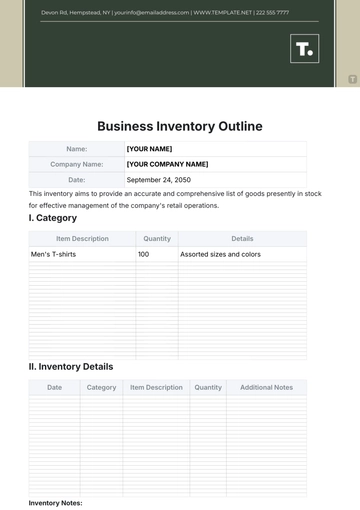

Free Manufacturing Inventory Report

Company: [Your Company Name]

Prepared by: [Your Name]

Report Period: [Date]

This report provides a detailed analysis of the manufacturing inventory as of the current month. The aim is to assess inventory levels, identify potential shortfalls, and offer suggestions for optimization. The report covers raw materials, work-in-progress, and finished goods.

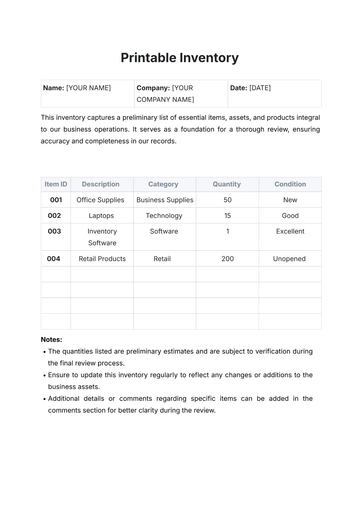

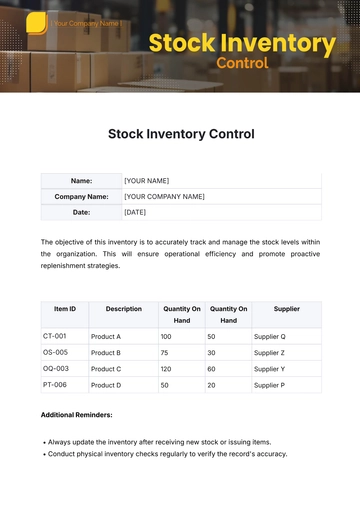

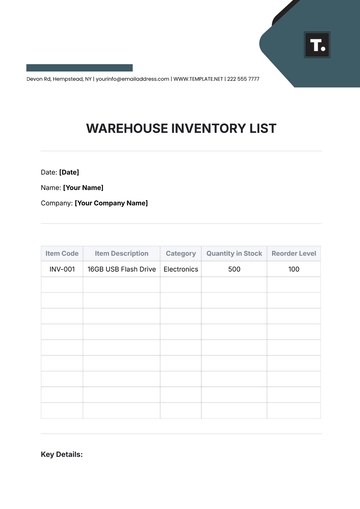

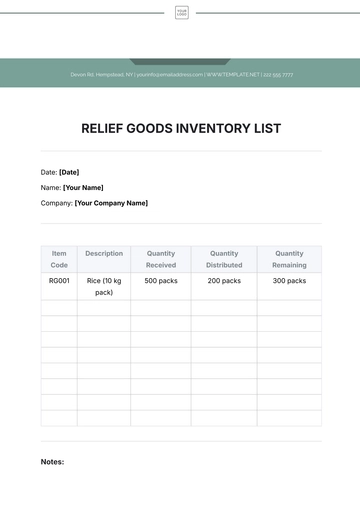

I. Raw Materials

The raw materials inventory is crucial for maintaining seamless production processes. It includes all the basic components required to produce finished products.

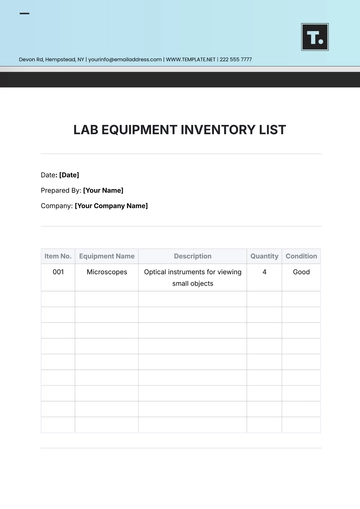

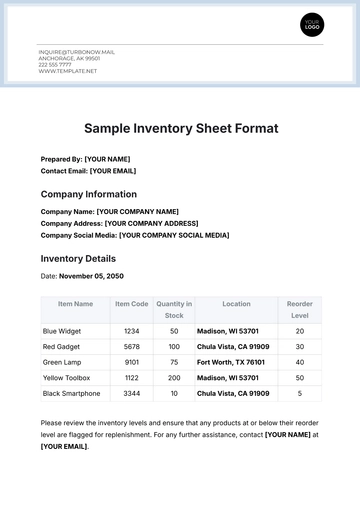

A. Current Inventory Levels

Material | Quantity | Units | Reorder Level |

|---|---|---|---|

Steel | 500 | tons | 200 tons |

Plastic | 1200 | kg | 500 kg |

Rubber | 800 | kg | 300 kg |

The current levels of steel, plastic, and rubber are sufficient to meet production demands for the next two months. However, close monitoring is recommended to avoid sudden shortages.

B. Potential Issues

Increasing raw material costs could impact inventory levels and production costs.

Supply chain disruptions may result in delayed restocking.

C. Recommendations

It is advisable to negotiate long-term contracts with suppliers to lock in prices and ensure timely delivery. Establishing safety stock levels will help mitigate supply chain risks.

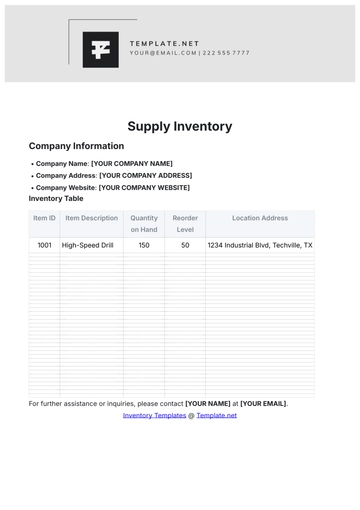

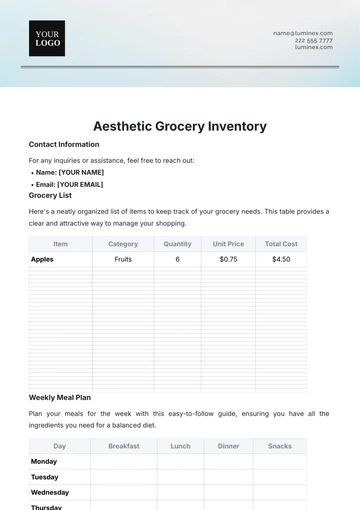

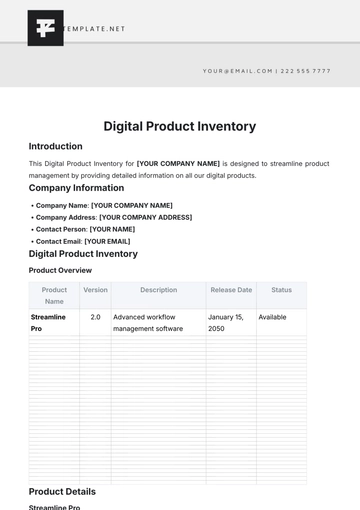

II. Work-in-Progress (WIP)

The WIP inventory includes products that are in various stages of the production process but are not yet finished.

A. Current Levels

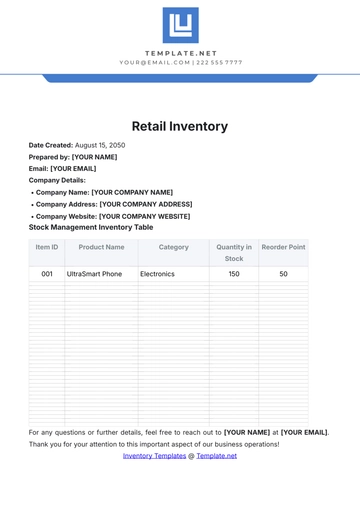

Product | Quantity | Completion Status |

|---|---|---|

Type A Gizmos | 300 | 60% |

Type B Widgets | 450 | 70% |

Type C Devices | 150 | 90% |

The current WIP levels indicate a healthy flow of production. However, attention must be paid to reducing lead times and improving throughput rates.

B. Challenges

Delays in WIP can affect overall production schedules and delivery timelines.

Balancing labor allocation to optimize the production cycle.

C. Strategies

Implementing lean manufacturing principles could enhance efficiency. Investing in training for the workforce on advanced manufacturing techniques will help reduce bottlenecks.

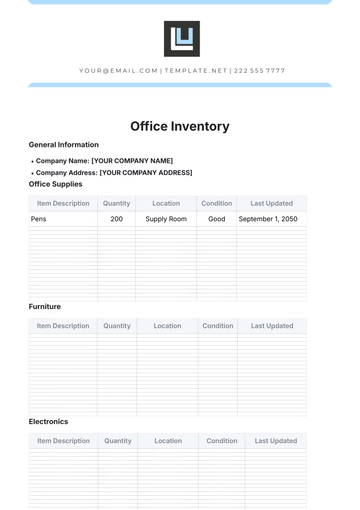

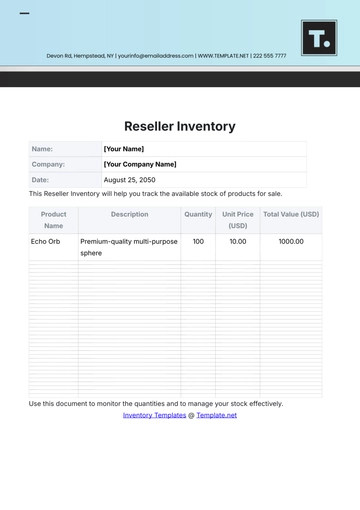

III. Finished Goods

The finished goods inventory represents completed products ready for shipment to customers or distribution centers.

A. Current Levels

Product | Quantity | Days of Supply |

|---|---|---|

Type A Gizmos | 600 | 15 days |

Type B Widgets | 300 | 10 days |

Type C Devices | 200 | 20 days |

The finished goods inventory is in a stable condition with sufficient stock to meet short-term demand. However, market fluctuations may necessitate adjustments in production schedules.

B. Concerns

Excessive inventory of finished goods could lead to increased holding costs.

Insufficient stock risks losing market share to competitors.

C. Proposals

Introducing just-in-time production could minimize holding costs while meeting demand efficiently. Additionally, employing advanced forecasting techniques will enhance inventory planning.

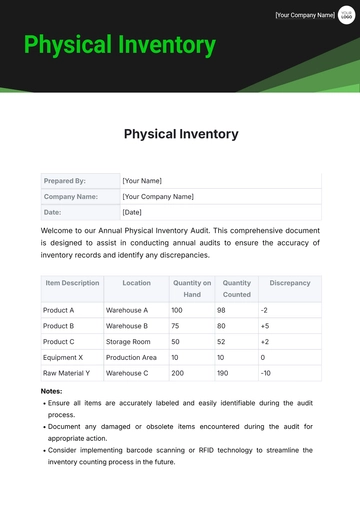

IV. Conclusion

The current manufacturing inventory is well-maintained with areas identified for improvement. By addressing supply chain vulnerabilities, optimizing production processes, and refining inventory management strategies, the manufacturing operation can enhance its competitive edge and operational efficiency.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor