Cycle Count Inventory Report

Company: [Your Company Name]

Prepared by: [Your Name]

Report Period: [Date]

I. Introduction

This cycle count inventory report provides a comprehensive overview of the inventory status and related activities conducted over a specified period. The primary objective of this report is to ensure that the records accurately reflect the physical stock counts. It highlights discrepancies, evaluates processes, and suggests improvements to ensure the integrity and accuracy of the inventory management system.

II. Cycle Count Methodology

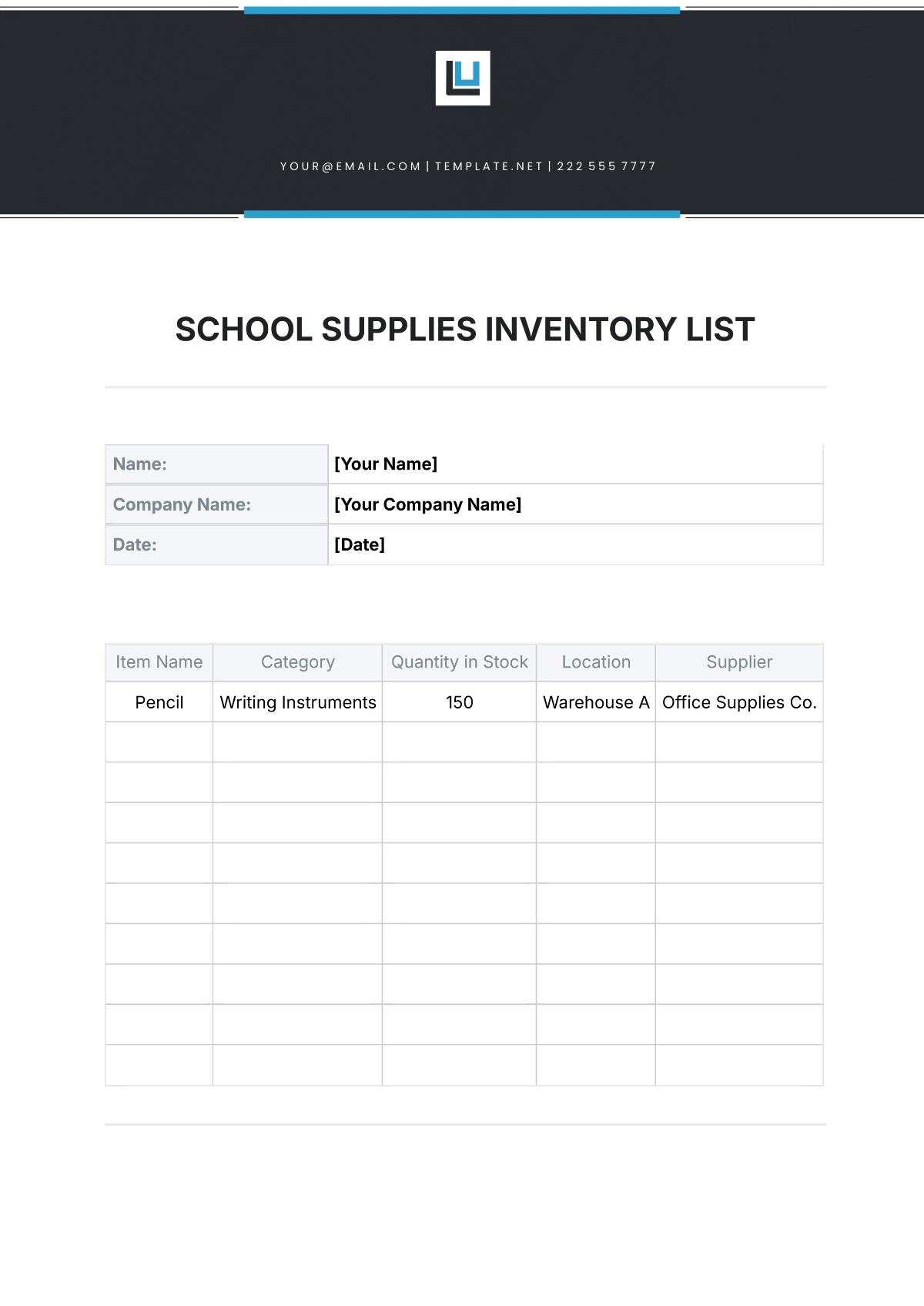

A. Selection of Items

The items selected for the cycle count are based on specific criteria, including their movement frequency, value, and strategic importance to operations. High-value and high-velocity items are prioritized to reduce potential losses and ensure seamless operations.

B. Count Frequency

Items are categorized into different classes (A, B, C) following the ABC analysis. Class A items are counted most frequently (monthly), Class B items are counted quarterly, and Class C items are counted bi-annually.

C. Process Overview

Preparation and scheduling of counts, including allocation of resources.

Execution of physical counts by trained personnel.

Recording of physical counts and comparison with system records.

Investigation of discrepancies and necessary adjustments.

Implementation of process improvements based on findings.

III. Results and Analysis

A. Overall Inventory Accuracy

The overall inventory accuracy for the period was 95.6%. This indicates a 2.3% improvement compared to the previous cycle count report. The improvement is attributed to enhanced training and refined processes.

B. Discrepancy Analysis

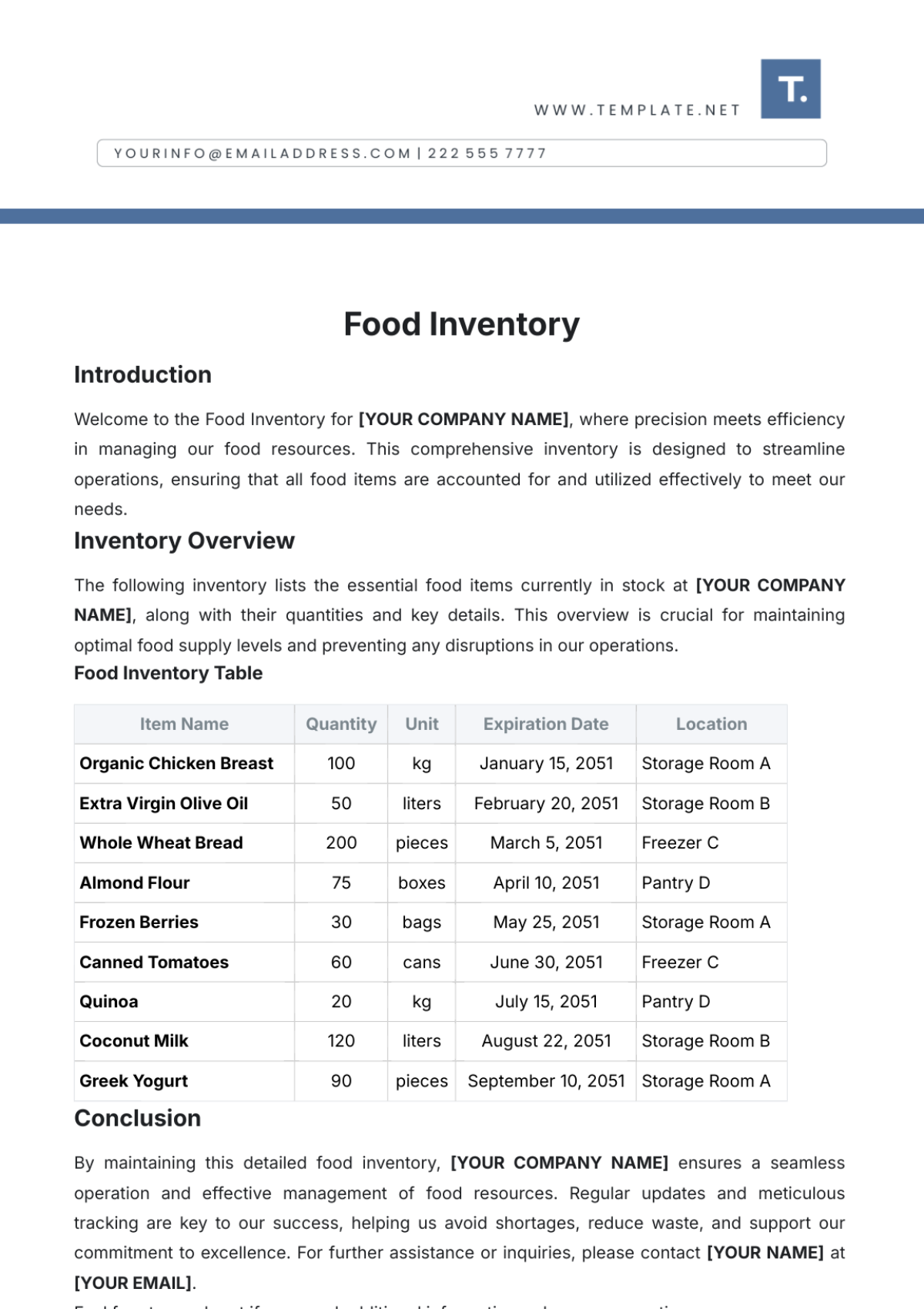

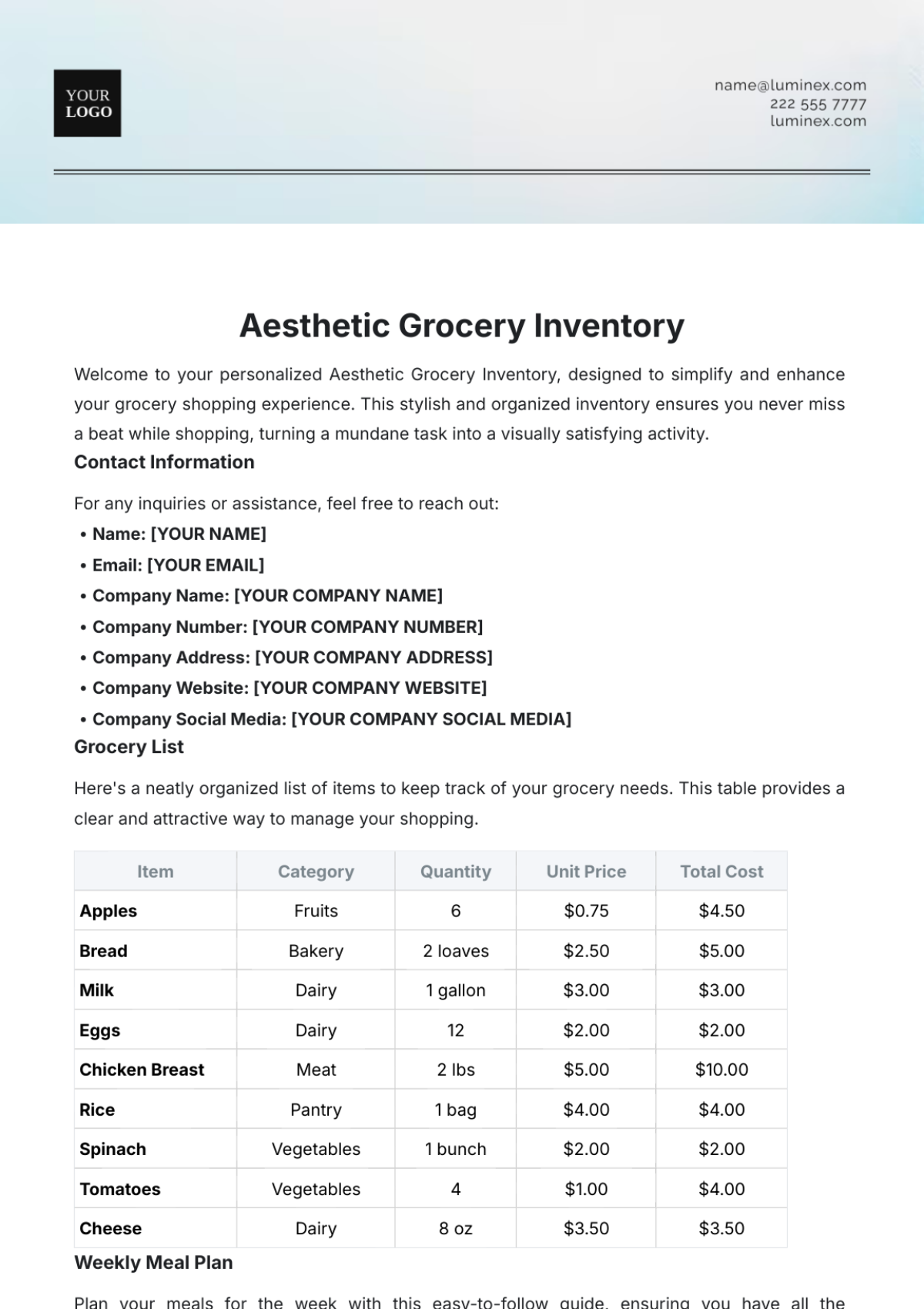

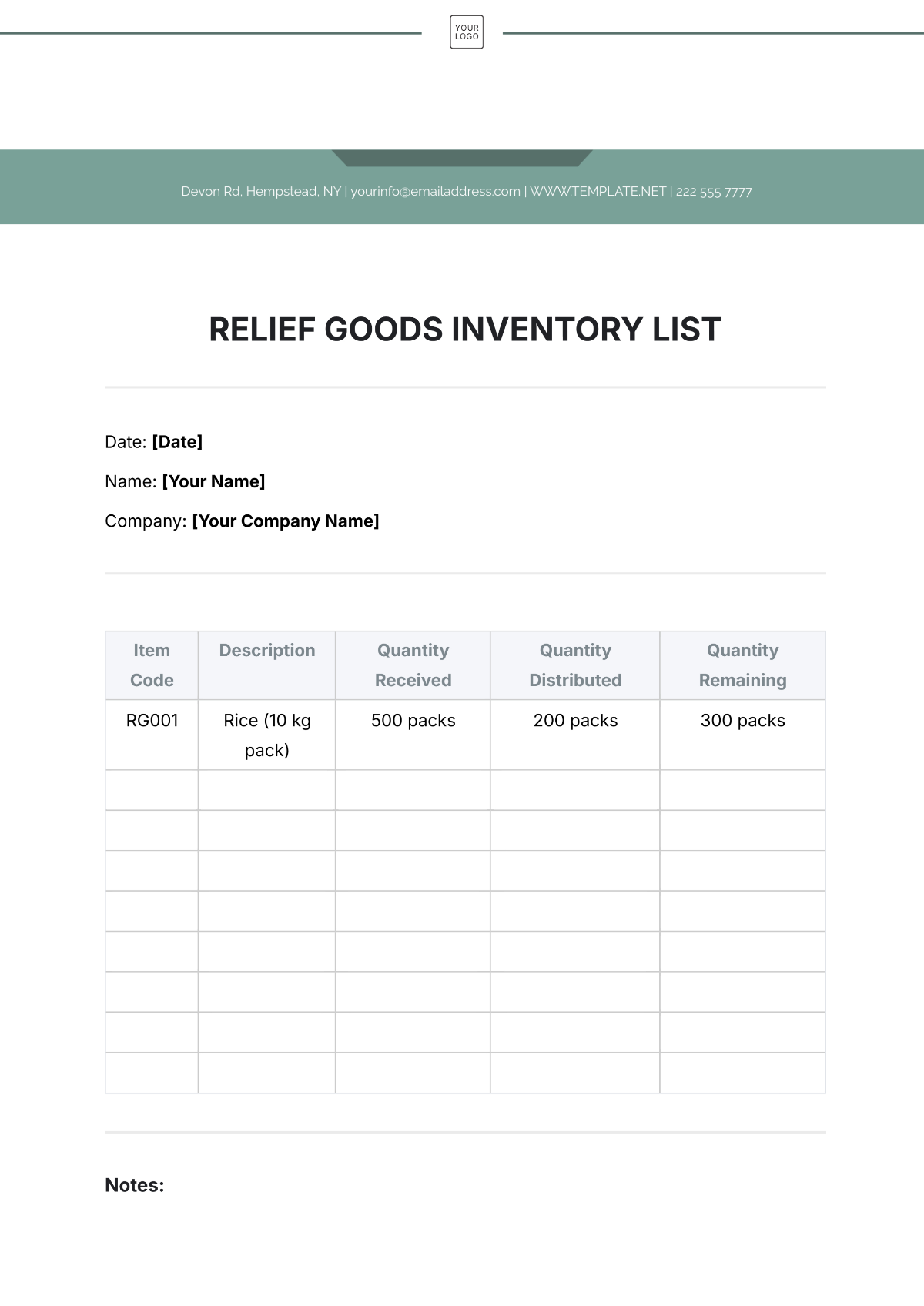

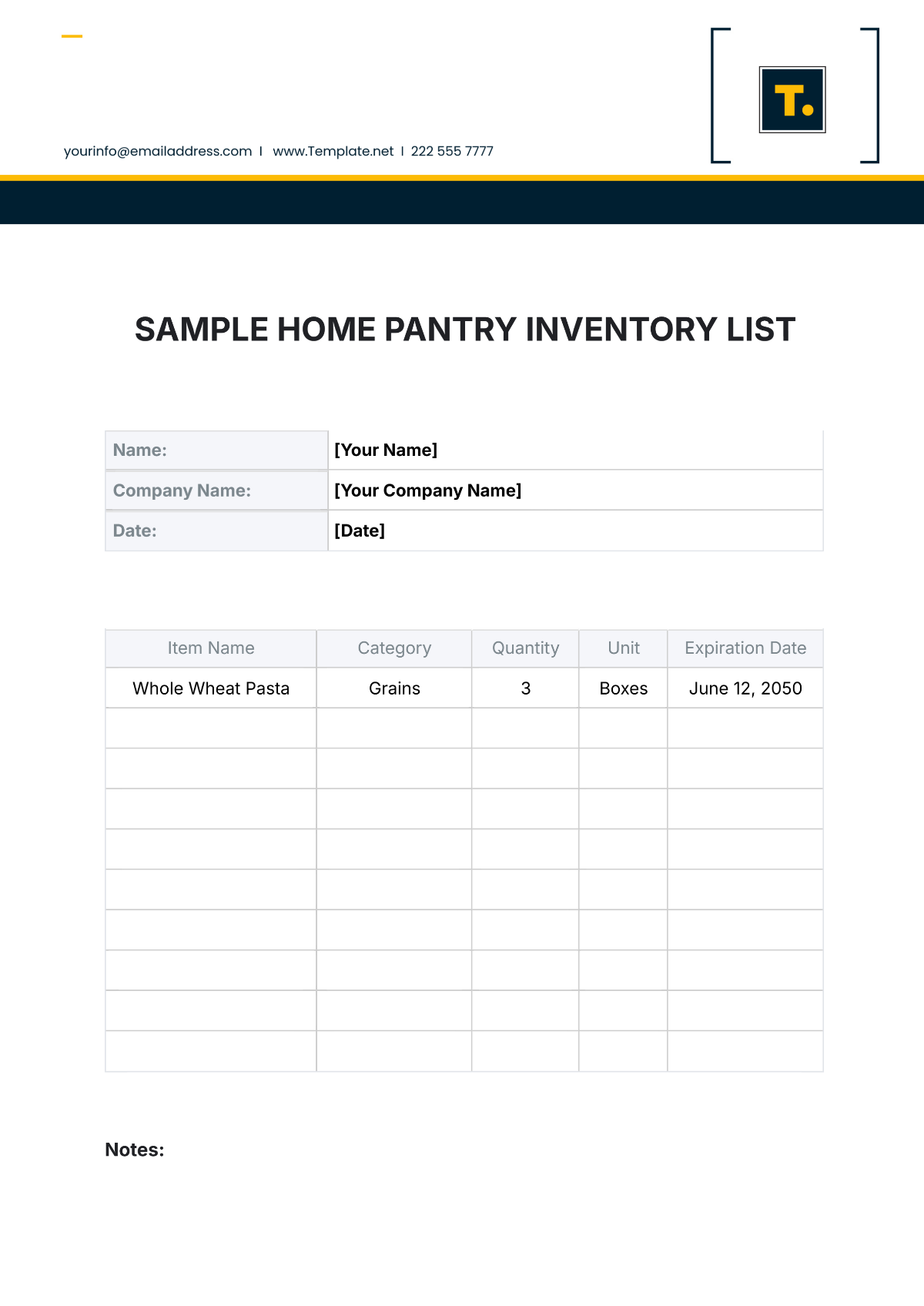

A detailed analysis of discrepancies revealed common causes, including operational errors, miscounts, and system entry errors. The breakdown of discrepancies is provided in the table below:

Discrepancy Type | Number of Incidents | Percentage |

|---|---|---|

Operational Errors | 45 | 55% |

Miscounts | 25 | 30% |

System Entry Errors | 10 | 15% |

C. Key Findings

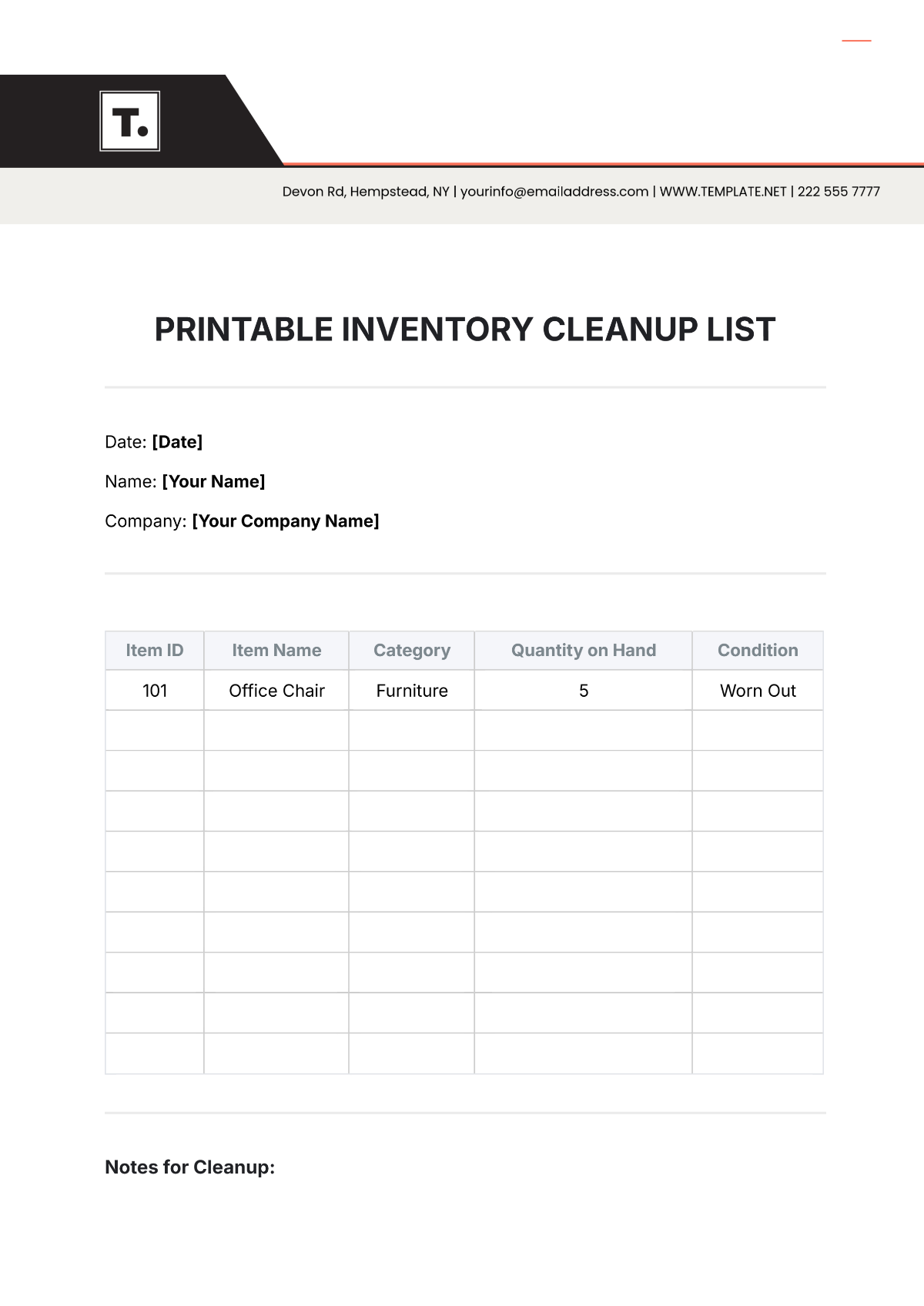

Most discrepancies occur in high turnover departments.

Operational errors significantly influence stock inaccuracies.

Proper training and accountability have a positive impact on accuracy.

IV. Recommendations

A. Enhanced Training Programs

Develop and implement comprehensive training programs aimed at reducing operational errors. Sessions should focus on proper handling, counting techniques, and real-time data entry skills.

B. Technology Integration

Invest in advanced inventory management systems with real-time tracking capabilities to minimize entry errors and provide instant feedback on stock levels.

C. Regular Audits

Conduct regular audits to ensure adherence to improved processes and procedures. These audits will help maintain high standards of inventory accuracy and integrity.

V. Conclusion

This cycle count inventory report emphasizes the critical importance of accurate inventory records. By implementing the recommendations outlined herein, the organization can further improve its inventory management processes, ultimately enhancing overall operational efficiency and reducing costs.