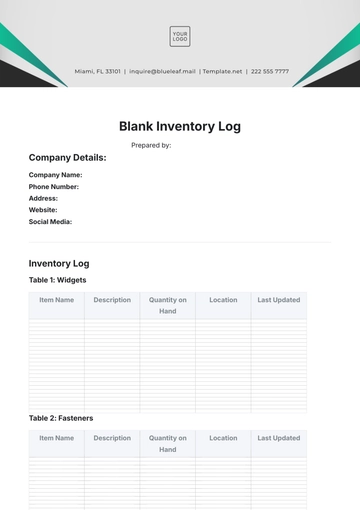

Free Blank Inventory Tracking Report

Company: [Your Company Name]

Prepared by: [Your Name]

Report Period: [Date]

This report aims to provide a comprehensive framework for tracking inventory effectively, ensuring efficient management, and minimizing loss or waste. With a proper inventory tracking system in place, businesses can maintain optimal stock levels, streamline operations, and improve overall productivity.

I. Introduction to Inventory Tracking

Inventory tracking is a critical component of supply chain management, offering insights into stock levels, product availability, and ordering needs. It enables businesses to minimize overstocking and understocking while ensuring inventory accuracy. As businesses scale and diversify, a robust inventory tracking system becomes imperative for maintaining order and efficiency.

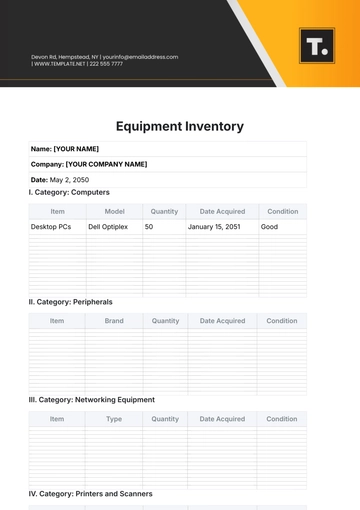

II. Components of Inventory Tracking Systems

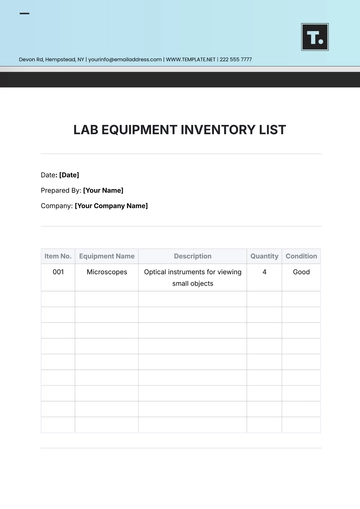

An effective inventory tracking system comprises several key components that help in achieving accurate and timely stock management.

A. Hardware Components

Barcode Scanners: Used for quick and accurate data entry of stock.

RFID Tags: Enable automatic tracking and updating of inventory statuses.

Computers and Mobile Devices: Used to manage inventory software applications.

B. Software Components

Inventory Management Software: Provides real-time tracking and reporting functionalities.

Database Management Systems: Store all inventory information securely and efficiently.

C. Human Resources

Training and dedication of personnel are crucial for the successful implementation of an inventory tracking system. Employees should be adept at using both hardware and software components efficiently.

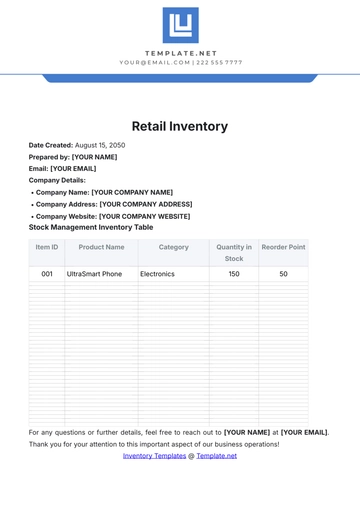

III. Inventory Tracking Methods

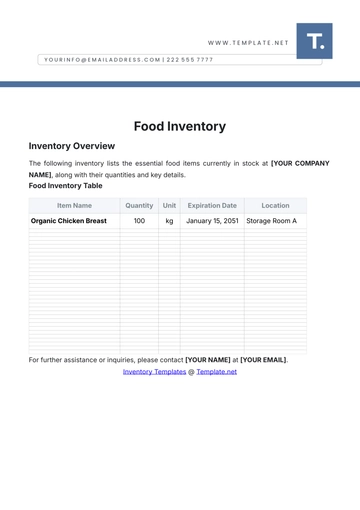

There are several methods used in tracking inventory. The choice of method depends on the nature and size of the business.

A. Perpetual Inventory System

This system constantly updates inventory records with each transaction. It uses advanced software to provide real-time data and is suitable for businesses that require accurate stock levels at all times.

B. Periodic Inventory System

Unlike the perpetual system, this method involves frequent physical counts of stock at regular intervals (e.g., monthly, or quarterly). It is often used by smaller businesses with minimal inventory variety.

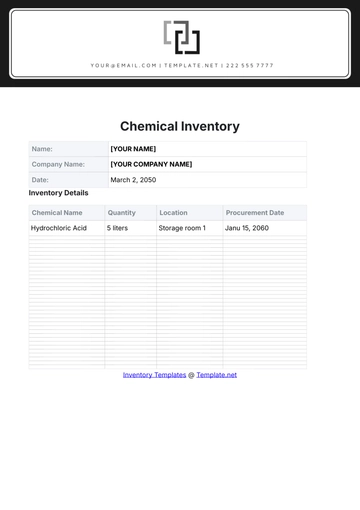

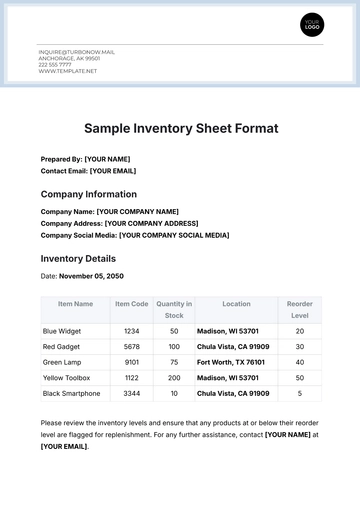

IV. Challenges in Inventory Tracking

Despite the many benefits of an inventory tracking system, businesses face several challenges in its implementation and maintenance.

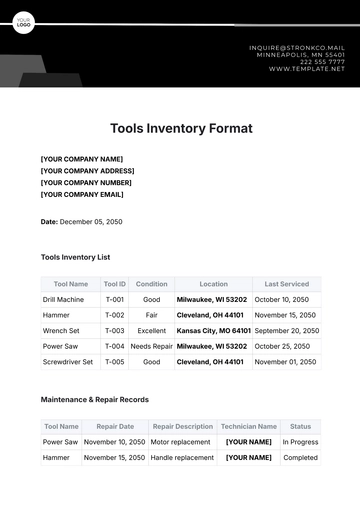

Challenge | Impact |

|---|---|

Data Inaccuracy | Leads to poor decision-making and customer dissatisfaction. |

Overstocking/Understocking | Results in financial loss and potential obsolescence of products. |

Technological Investment | High initial cost and ongoing maintenance expenses. |

Employee Training | Requires time and resources to ensure proficiency in system usage. |

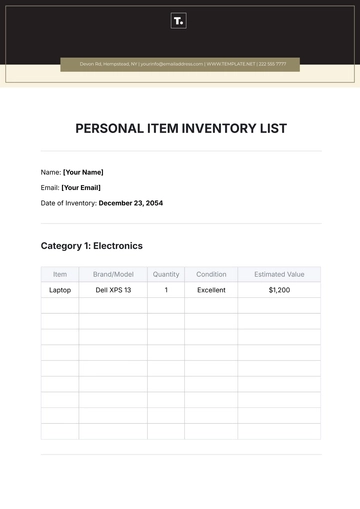

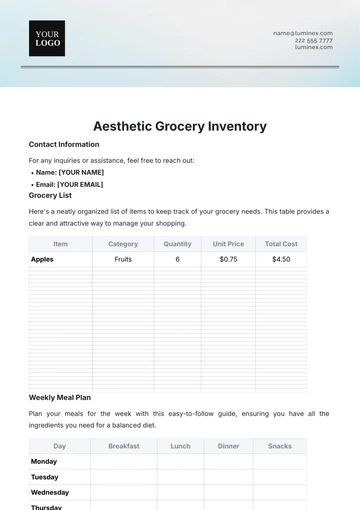

V. Strategies for Effective Inventory Management

To mitigate challenges and maximize the effectiveness of inventory tracking systems, businesses can adopt the following strategies:

Automate Processes: Integrate technological solutions to automate repetitive tasks and reduce errors.

Enhance Employee Training: Conduct regular training sessions to keep personnel updated on the latest system features and best practices.

Implement Forecasting Models: Use predictive analytics to anticipate demand and adjust inventory levels accordingly.

Regular Audits: Perform frequent checks and audits to ensure the accuracy of recorded inventory data.

VI. Conclusion

A comprehensive inventory tracking system is vital for efficient business operations. By understanding and implementing necessary components, methods, and strategies, businesses can maintain optimal stock levels and support sustainable growth. Continuous evaluation and adaptation of the inventory tracking process will yield long-term advantages and contribute to overall success.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor