Inventory Distribution Report

Company: [Your Company Name]

Prepared by: [Your Name]

Report Period: [Date]

I. Introduction

This report presents a detailed analysis of the current inventory distribution for our organization. The purpose of this inventory distribution report is to offer insights into the allocation and utilization of resources, identify the current status of supplies across various departments and locations, and recommend improvements for effective inventory management.

II. Current Inventory Status

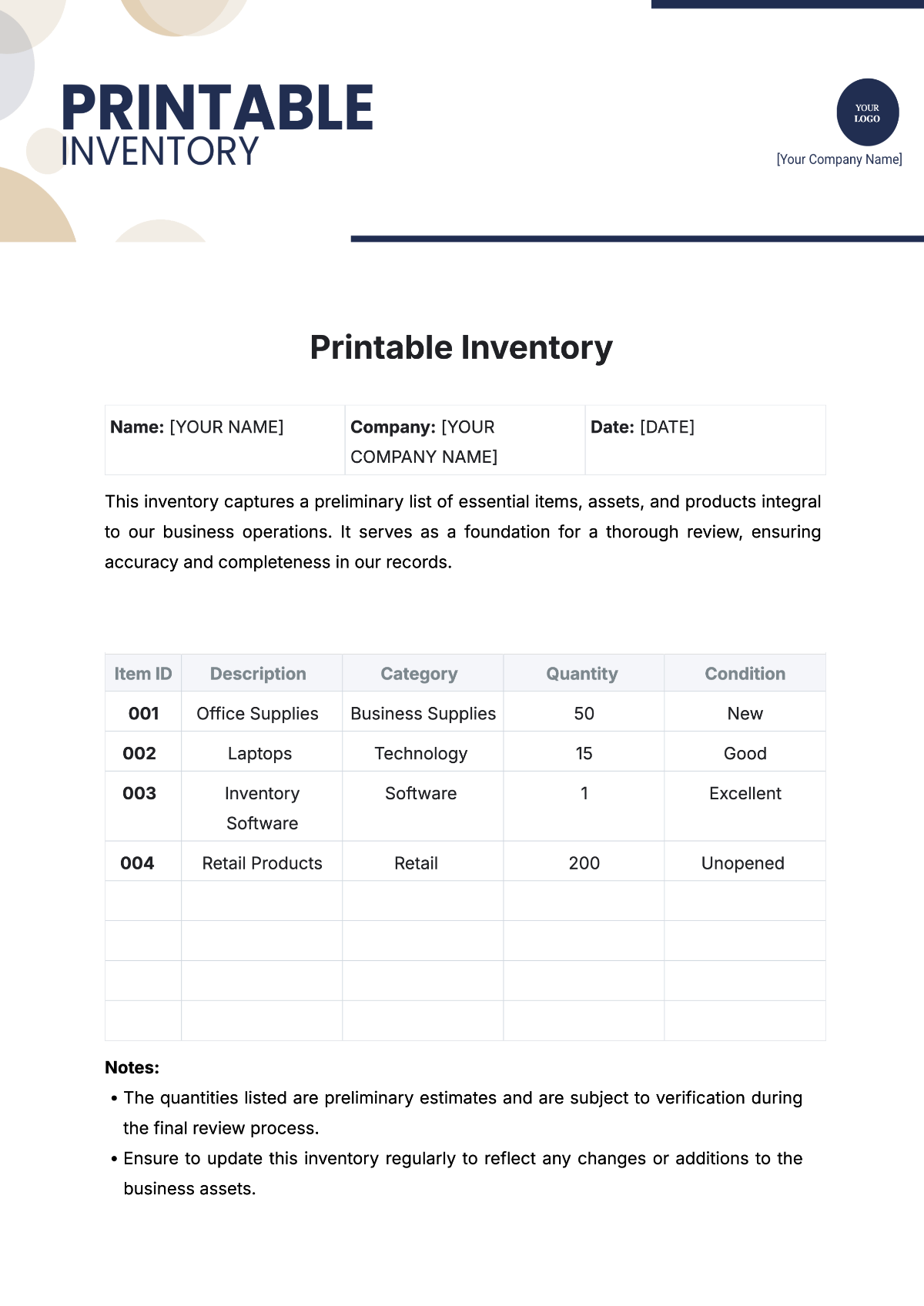

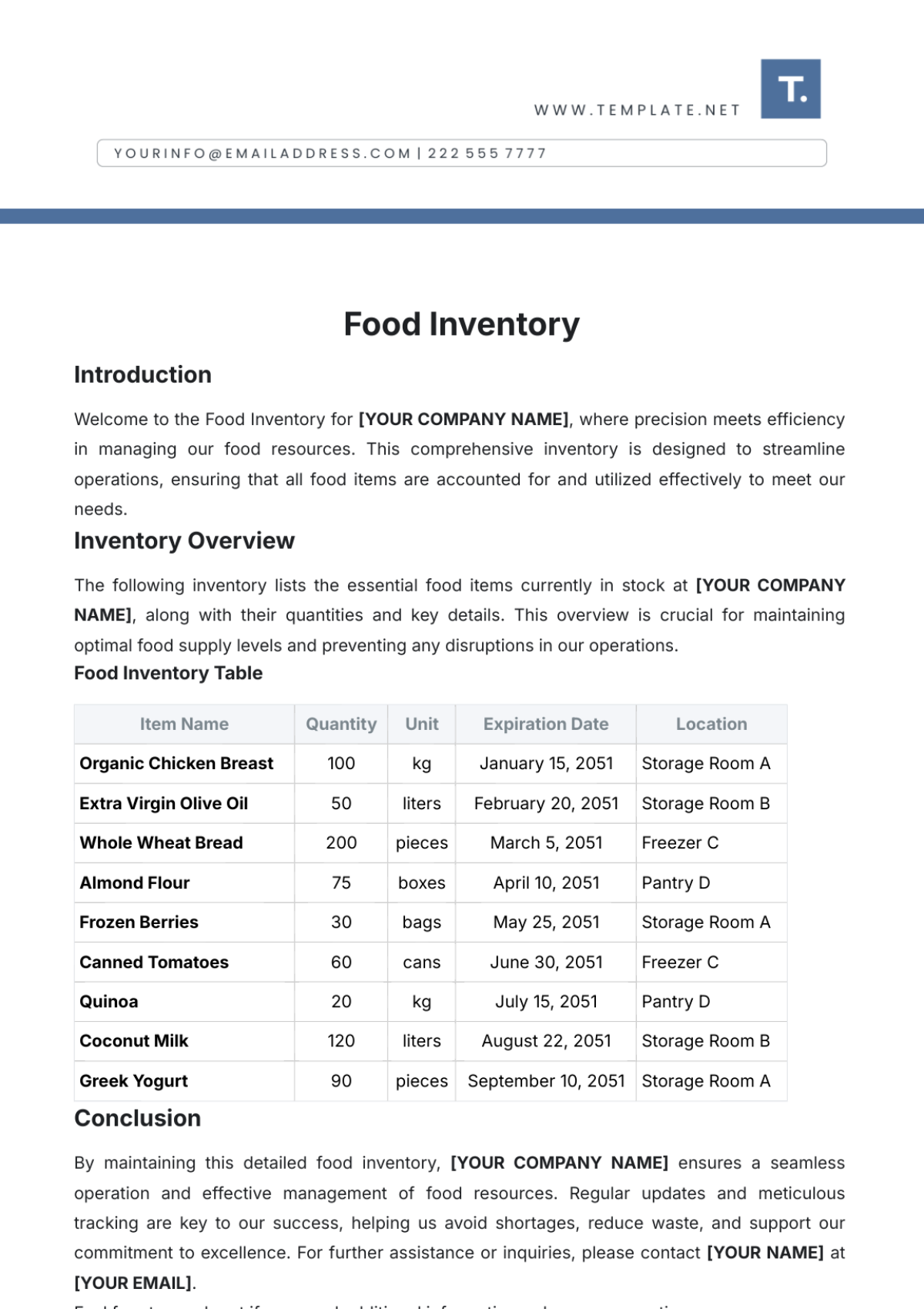

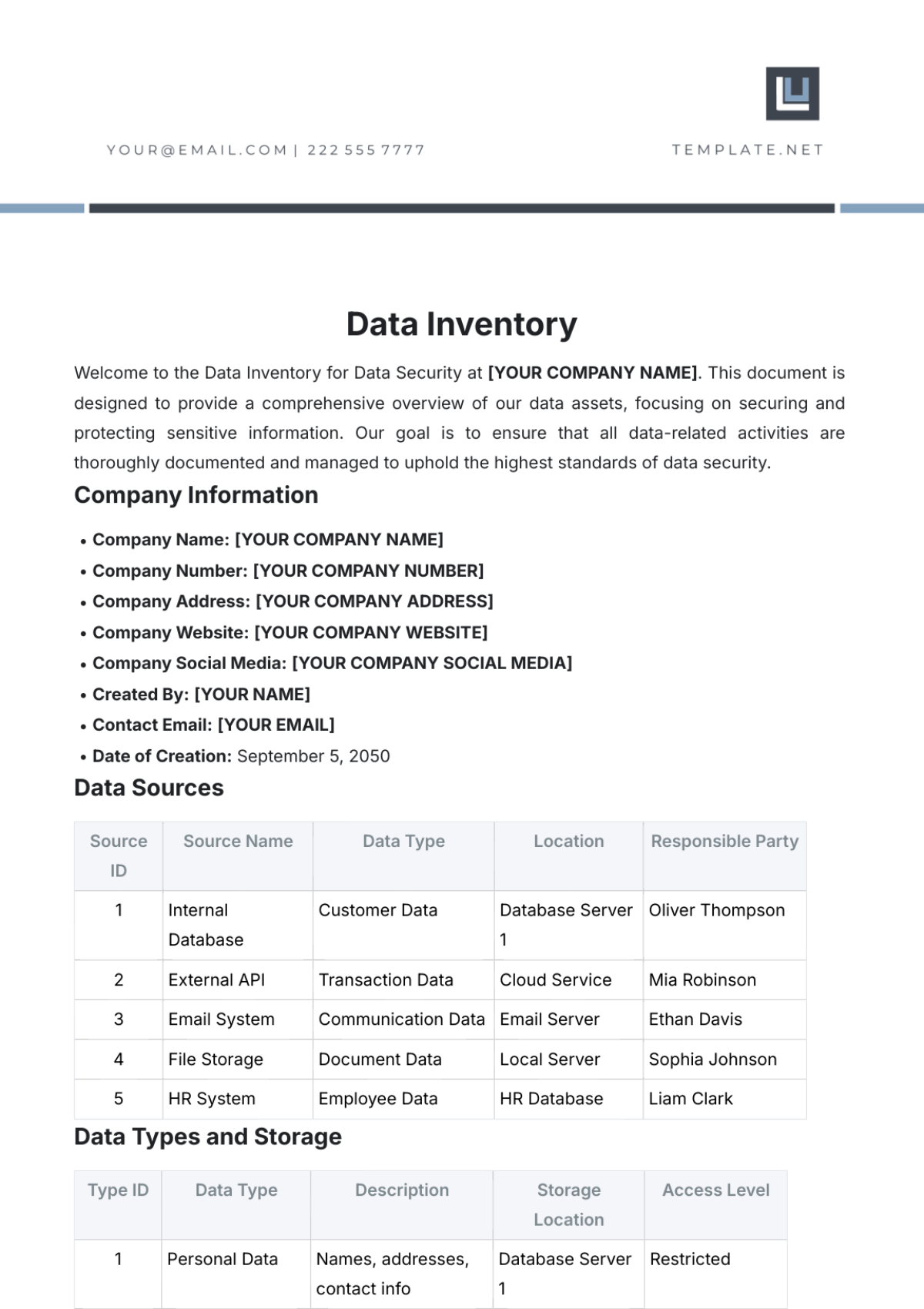

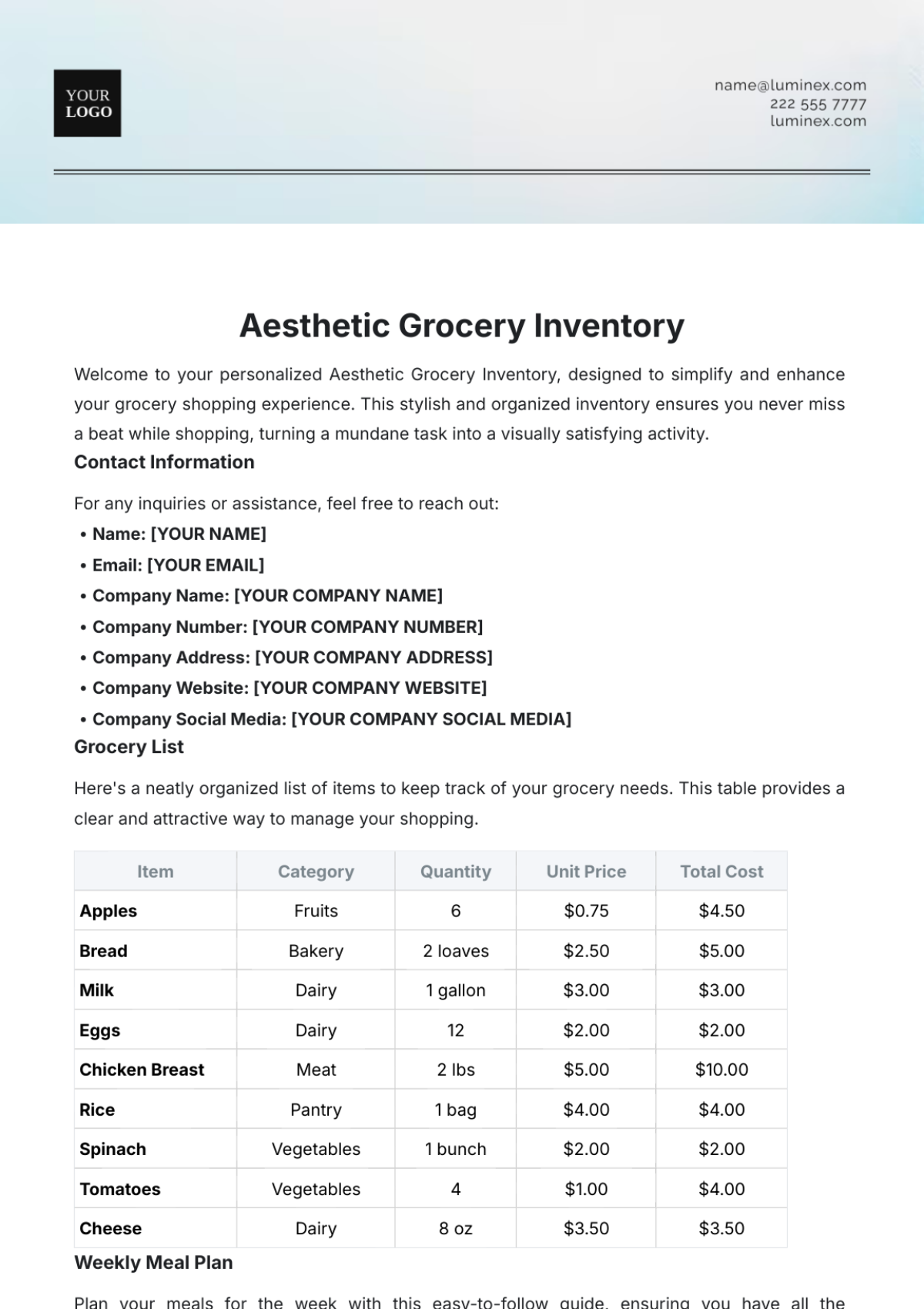

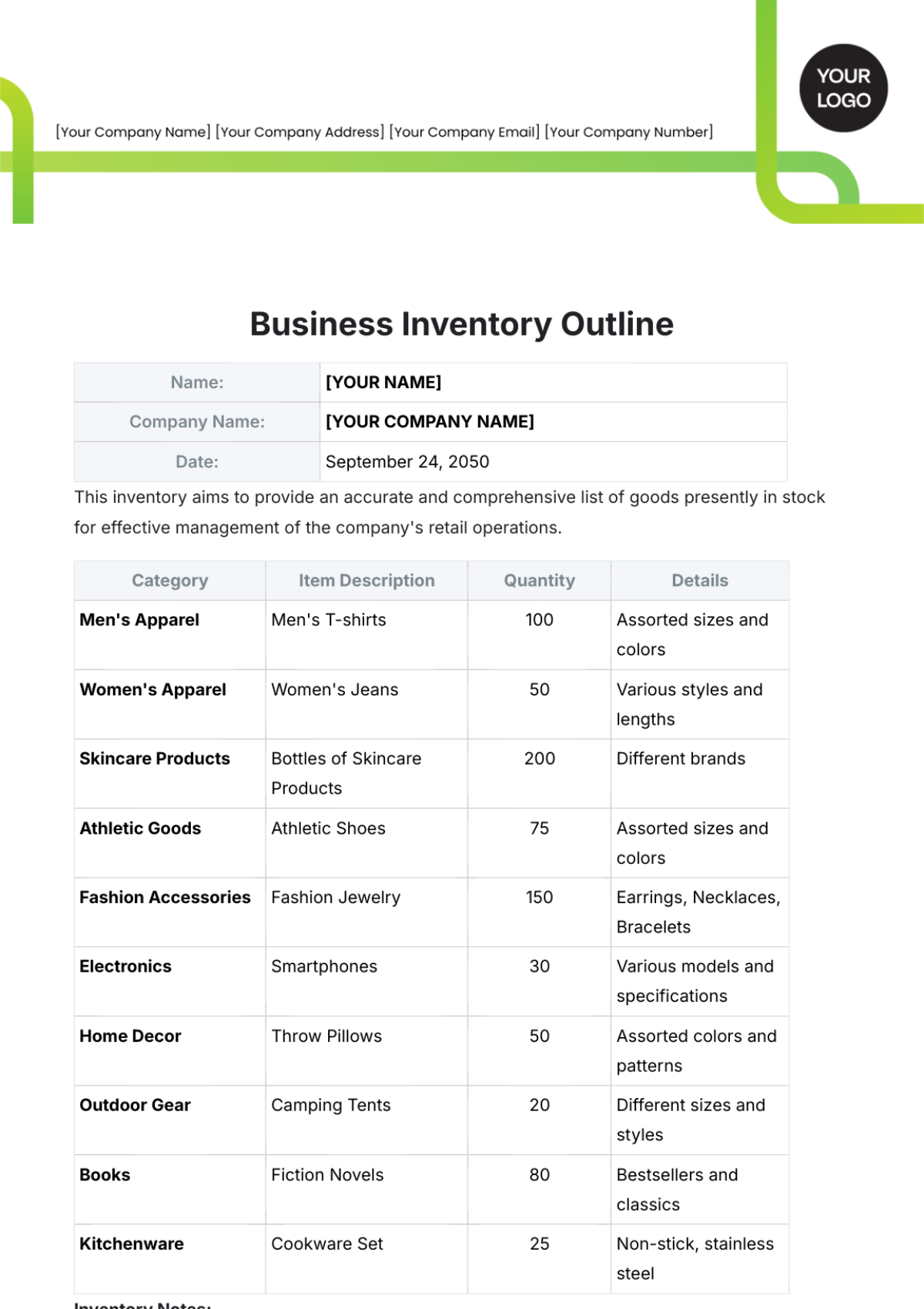

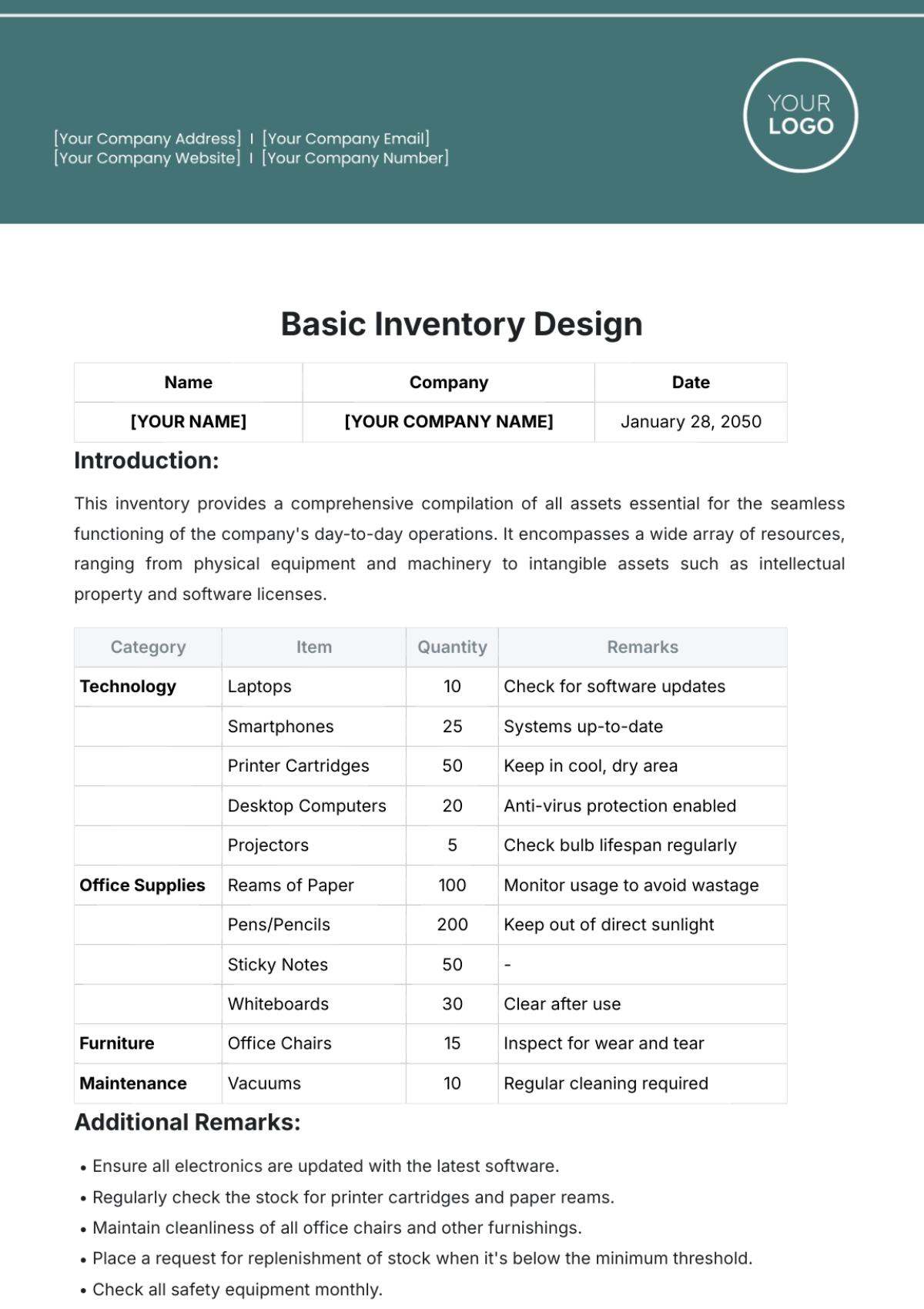

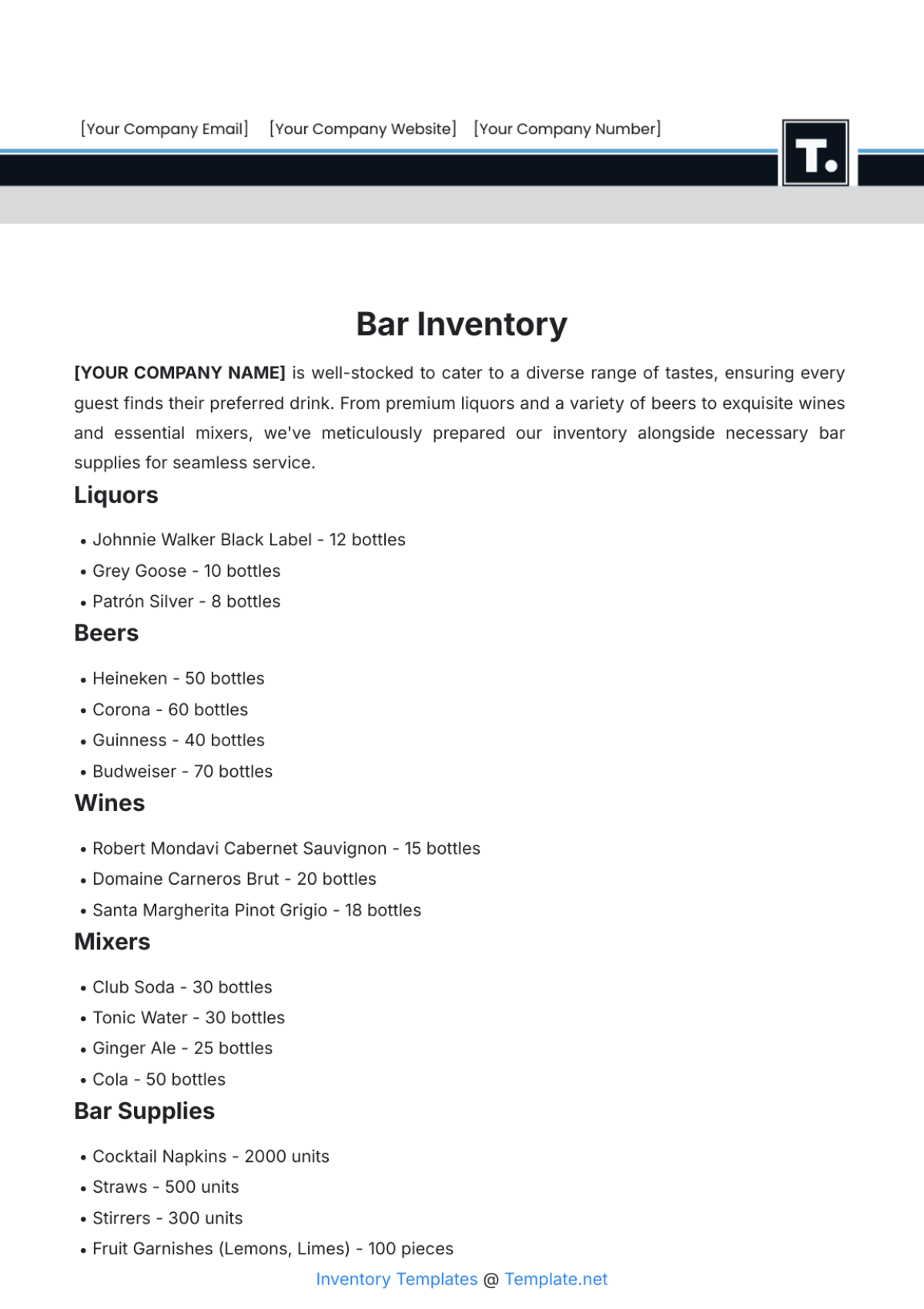

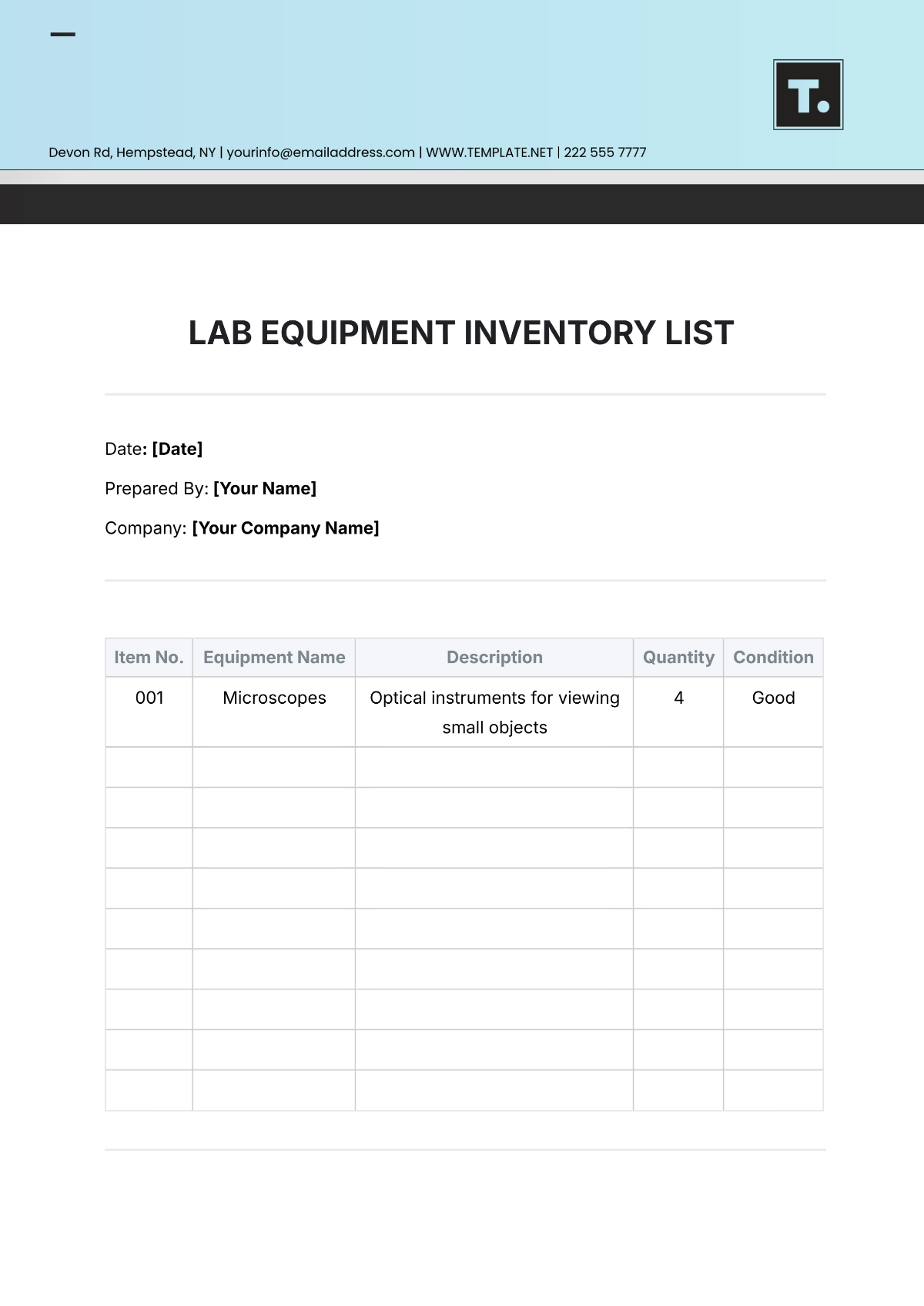

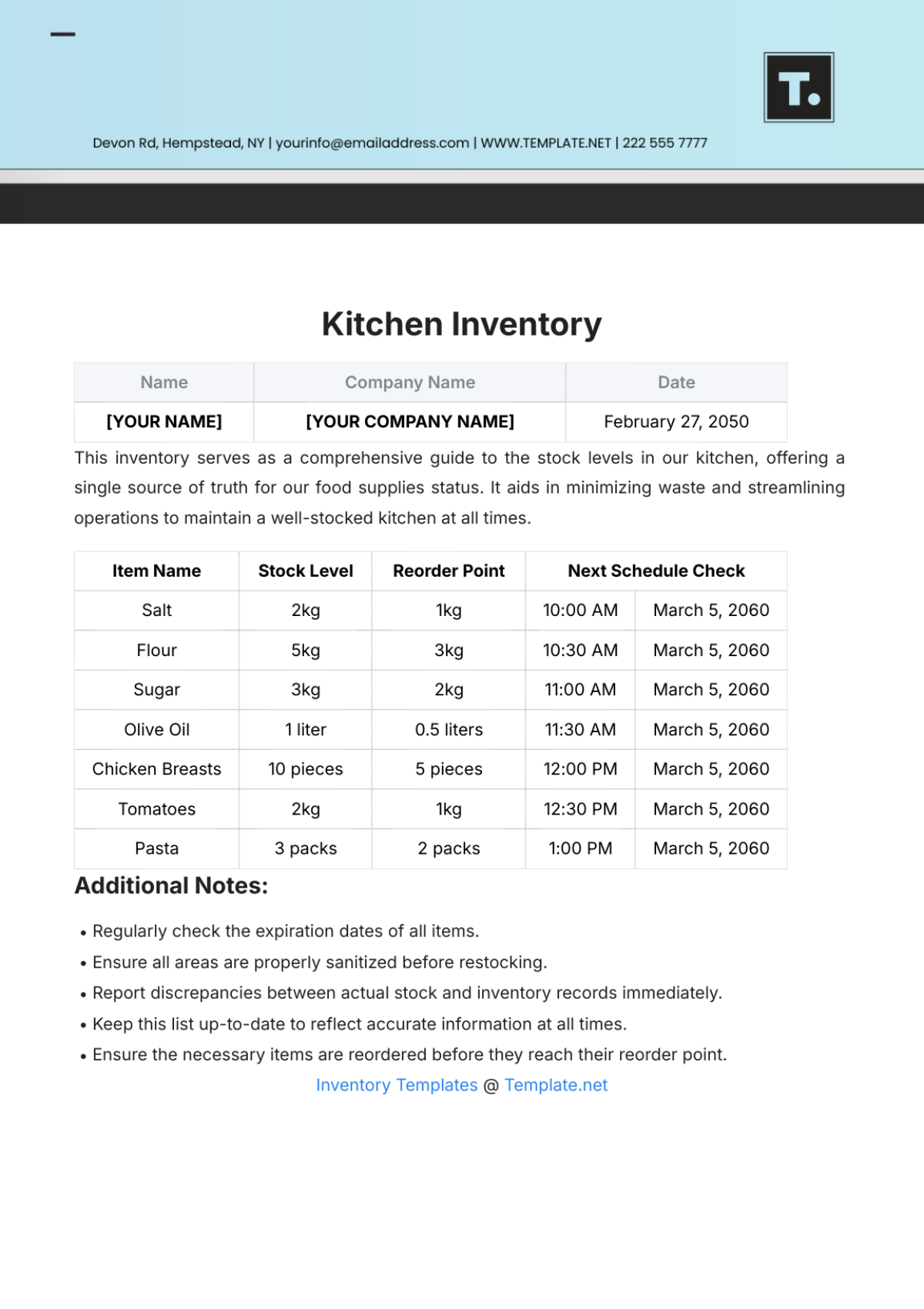

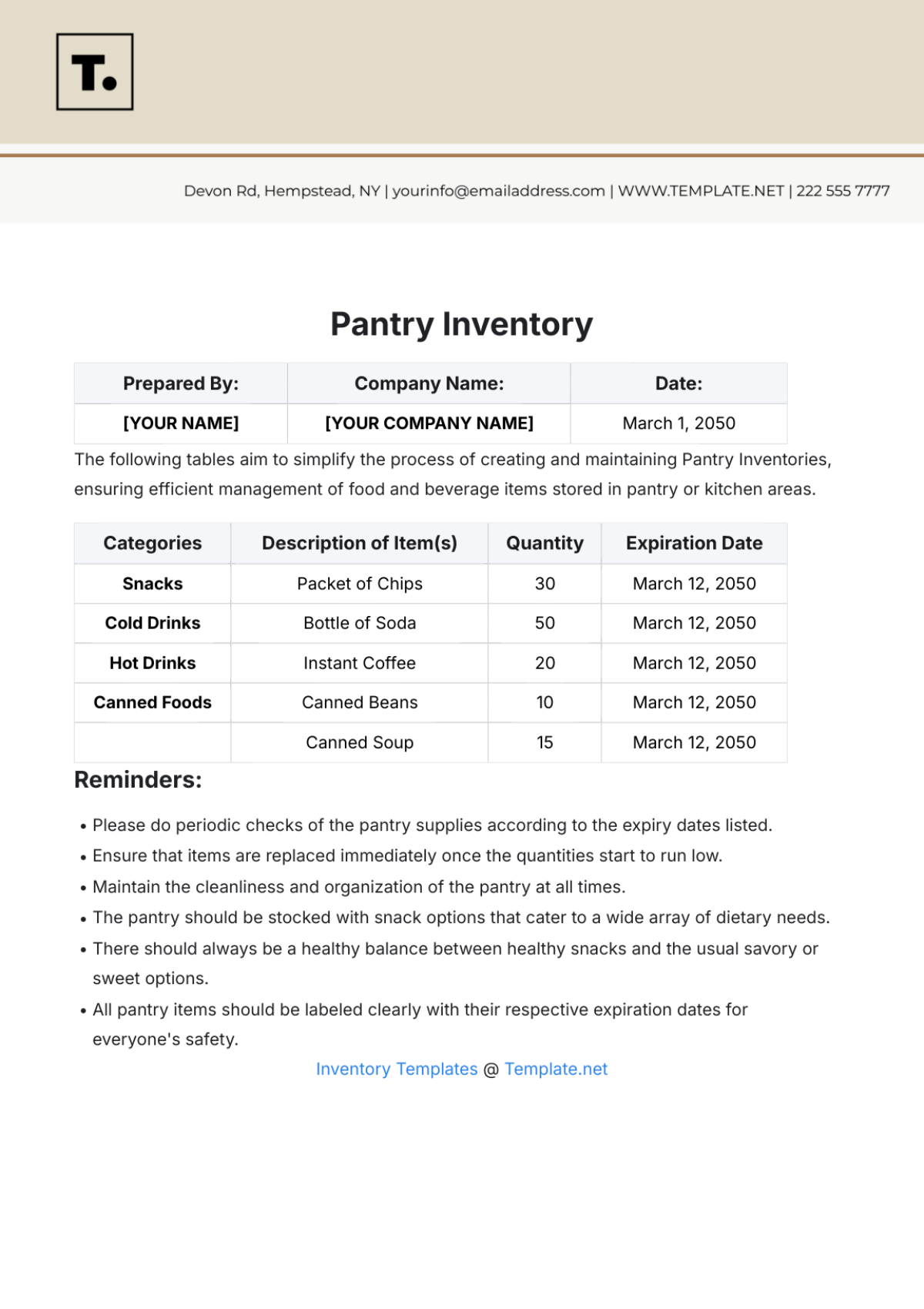

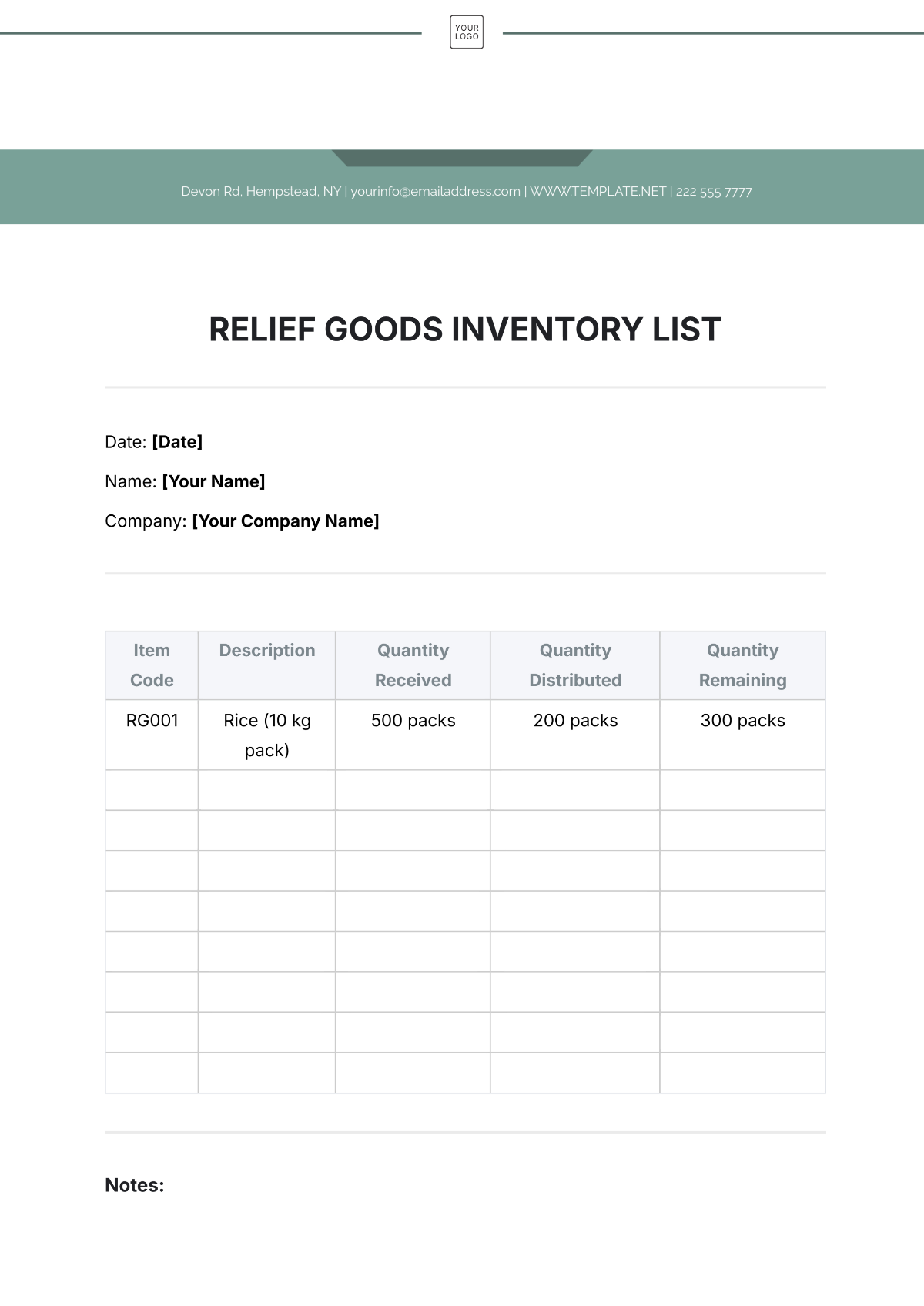

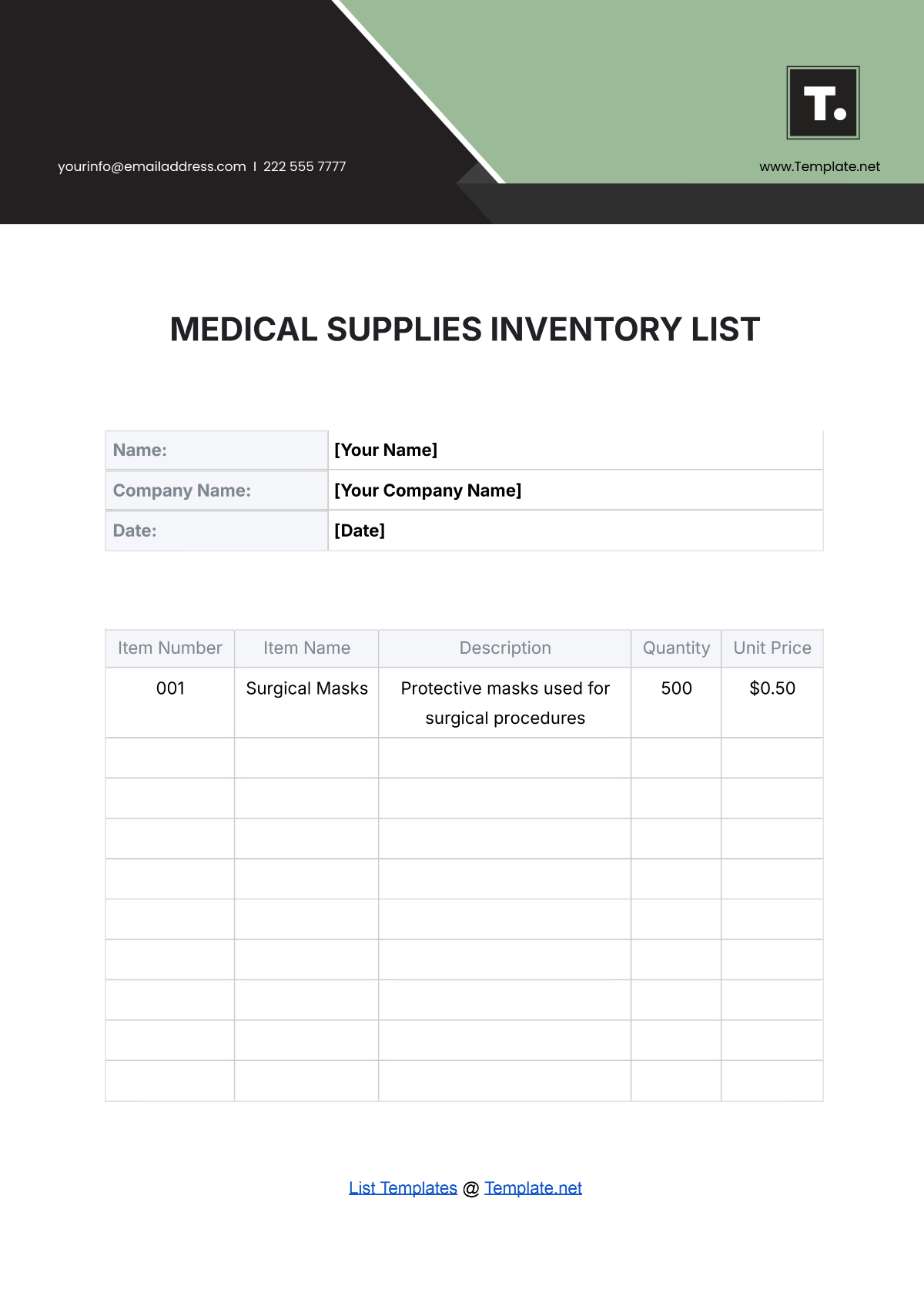

The current inventory is categorized into four main sections: Office Supplies, Manufacturing Materials, Finished Goods, and Miscellaneous Items. Each category is tracked and managed separately to ensure that adequate stock levels are maintained.

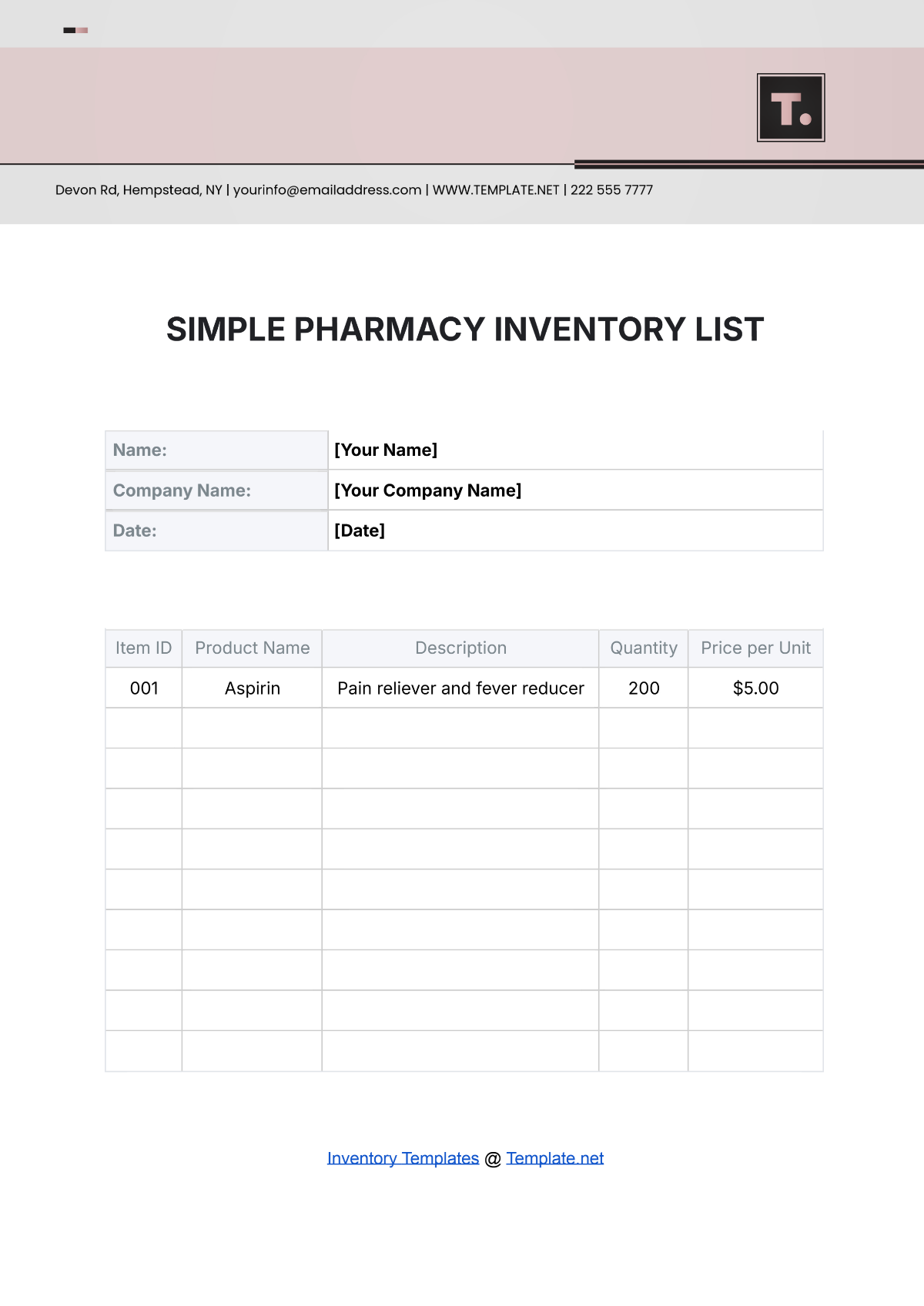

A. Office Supplies

Office supplies include items such as stationery, paper products, and electronics. Below is the current distribution of office supplies:

Item | Location | Quantity |

|---|---|---|

Stationery Sets | Headquarters | 250 |

Printer Paper | Regional Offices | 5000 sheets |

Laptops | All Locations | 120 |

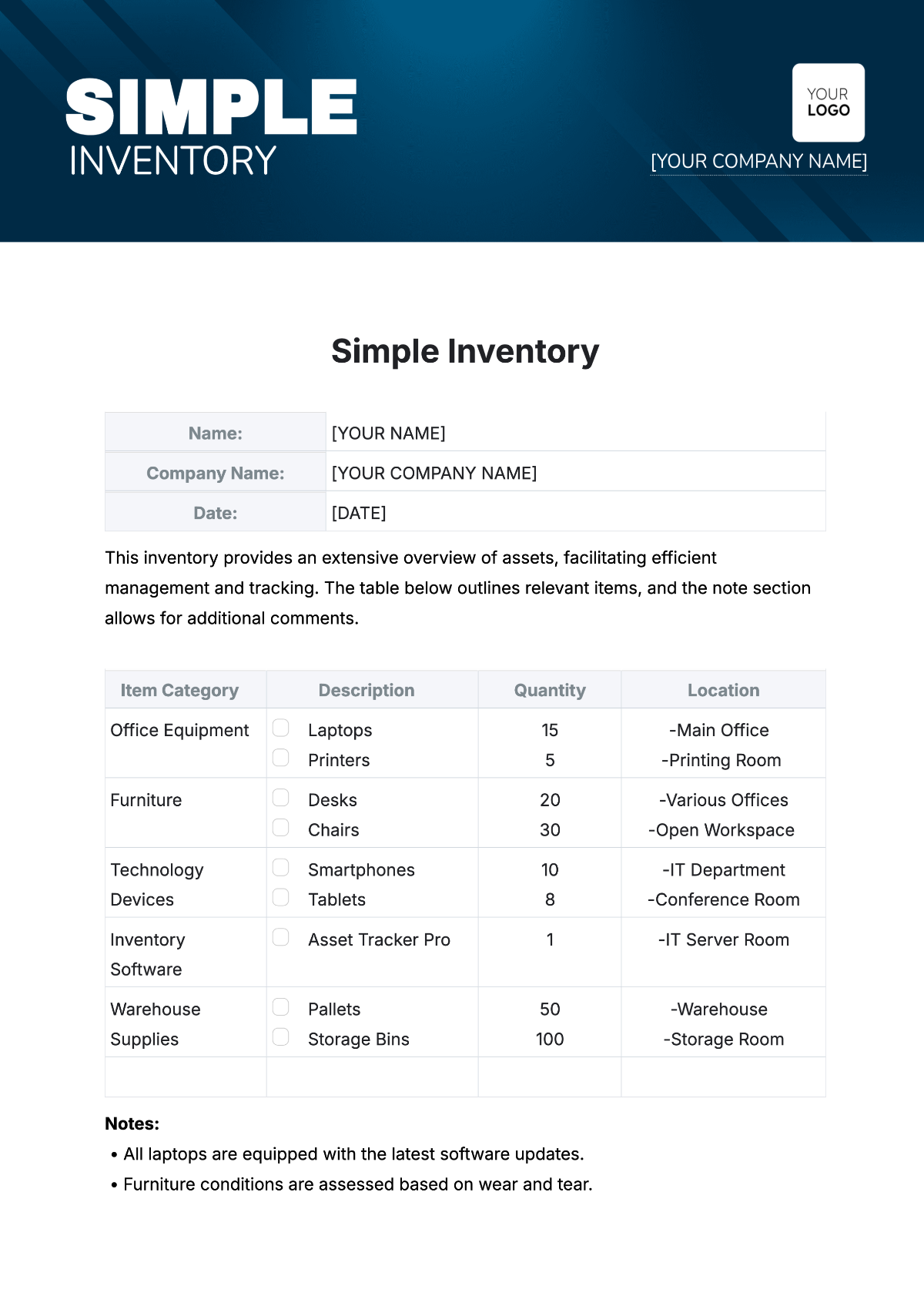

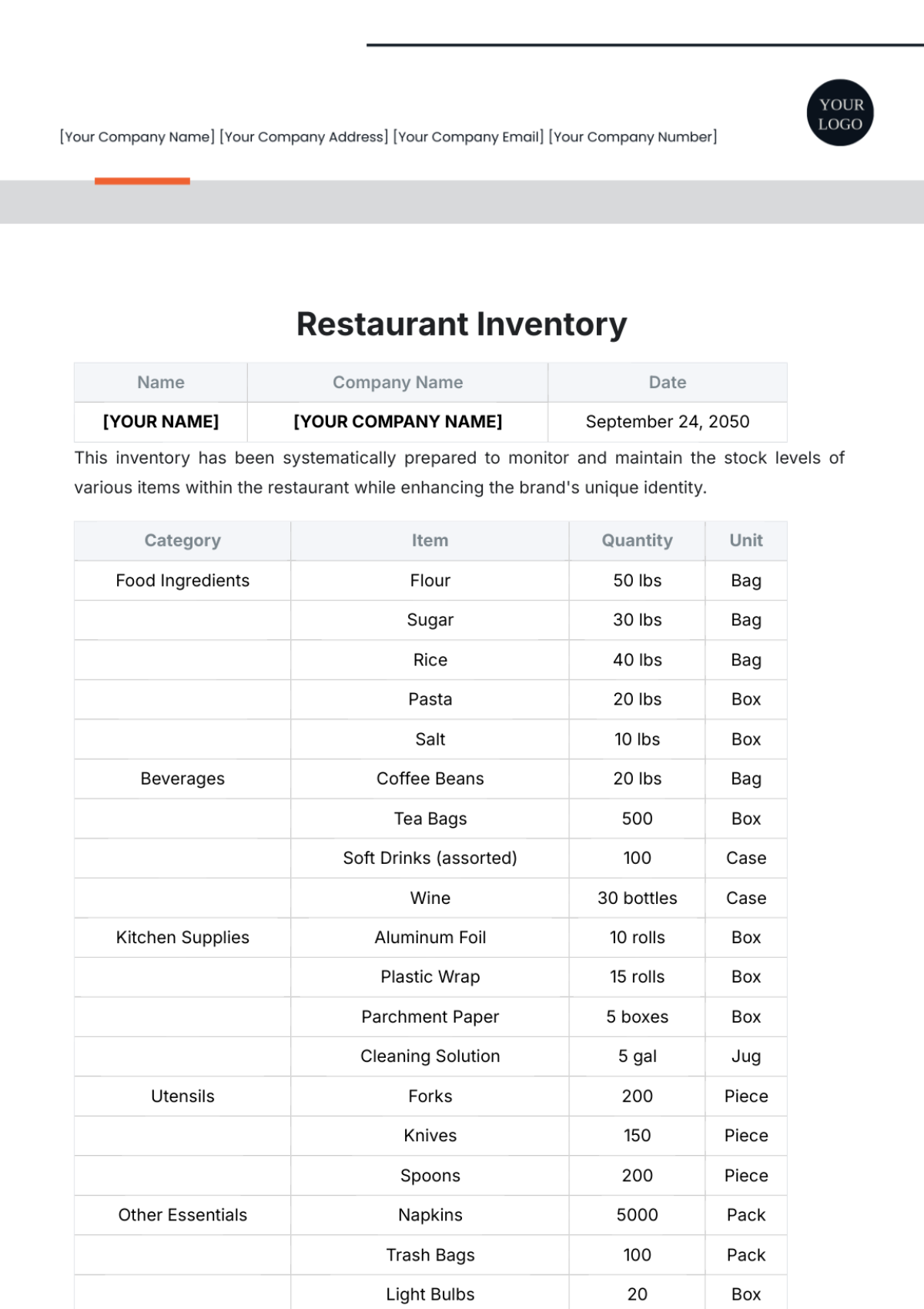

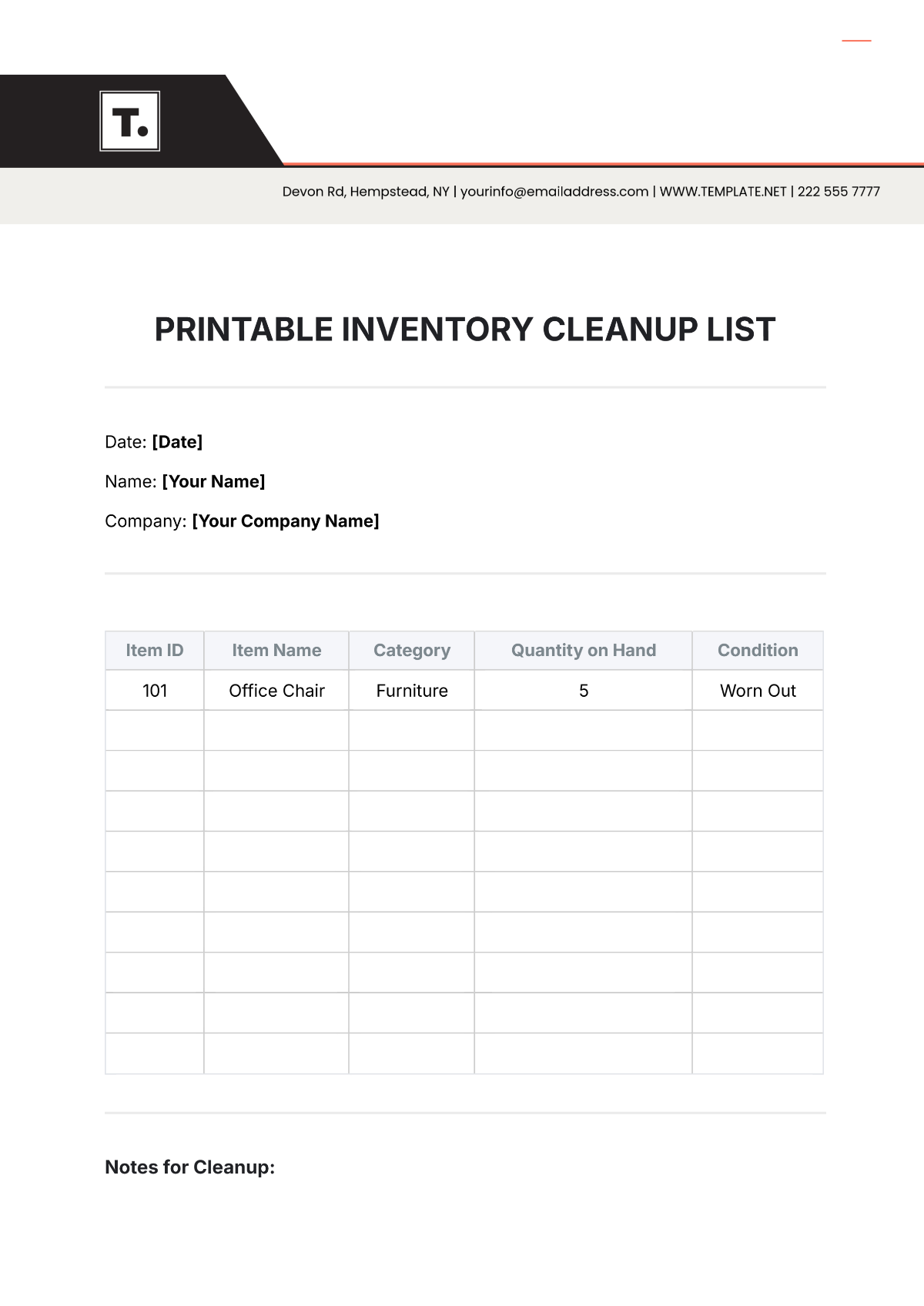

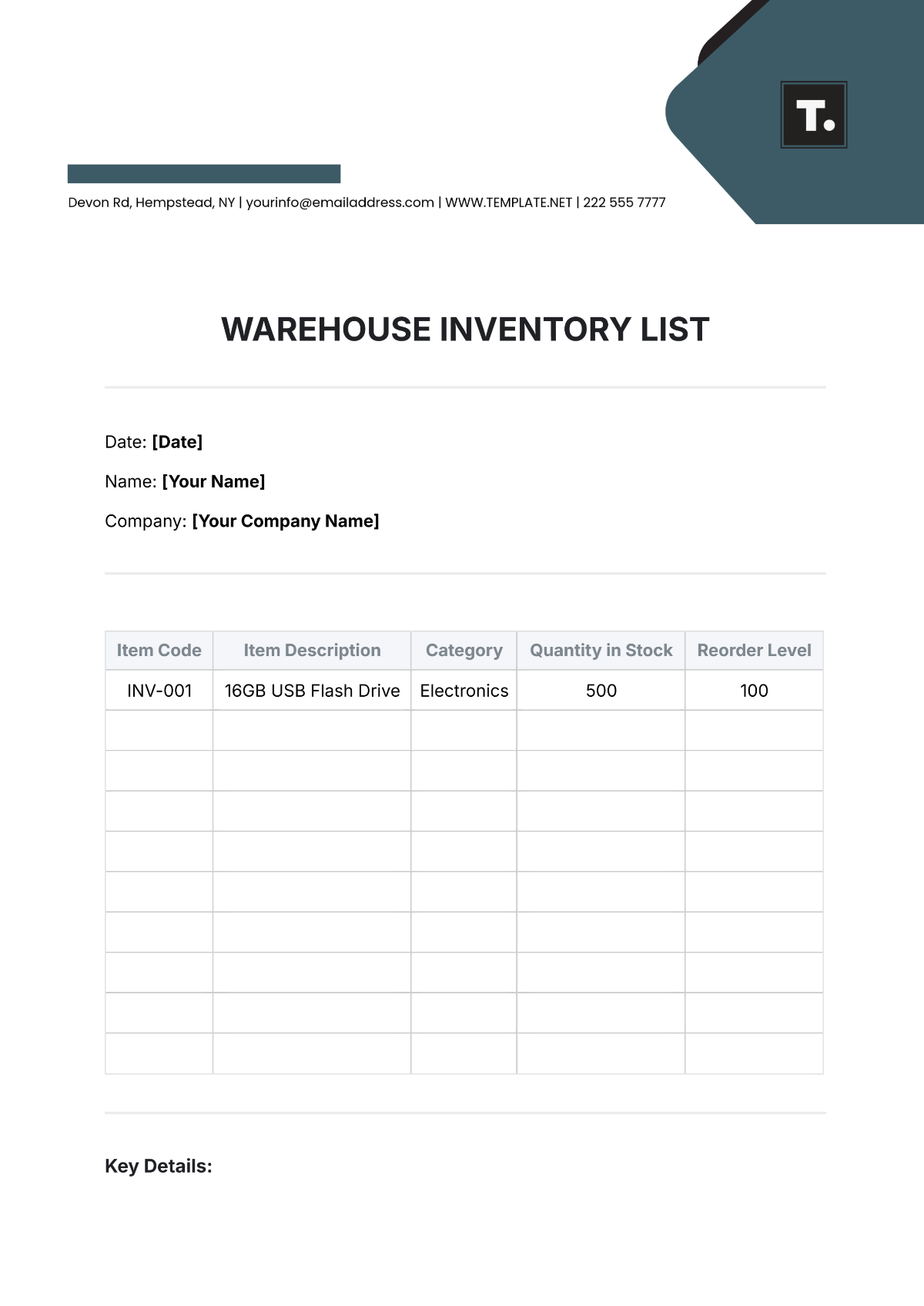

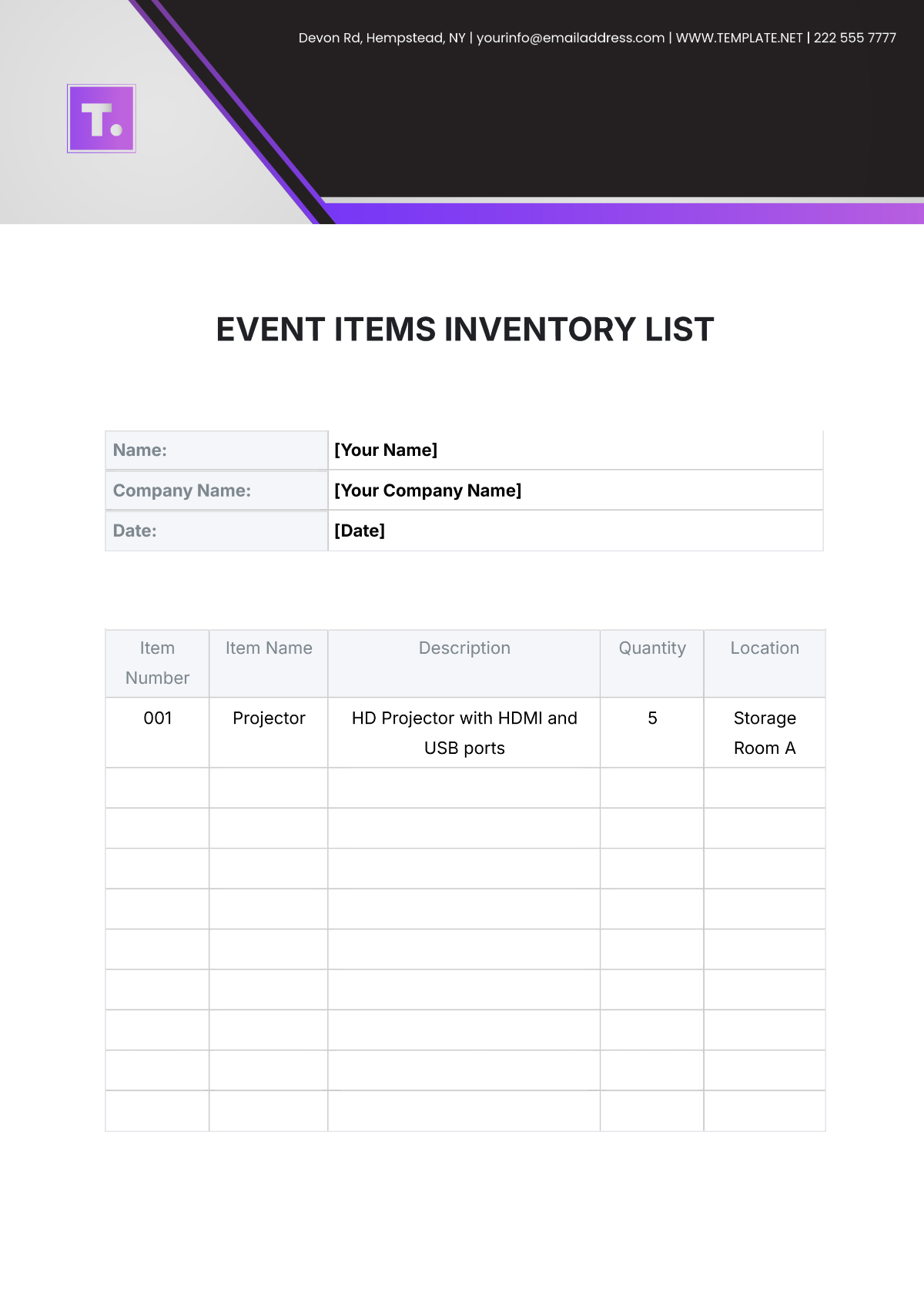

B. Manufacturing Materials

Manufacturing materials are essential raw materials used in the production process. The table below provides details of their distribution:

Material | Warehouse | Volume |

|---|---|---|

Aluminum Sheets | Warehouse A | 30 tons |

Plastic Pellets | Warehouse B | 50 tons |

Steel Rods | Warehouse C | 10 tons |

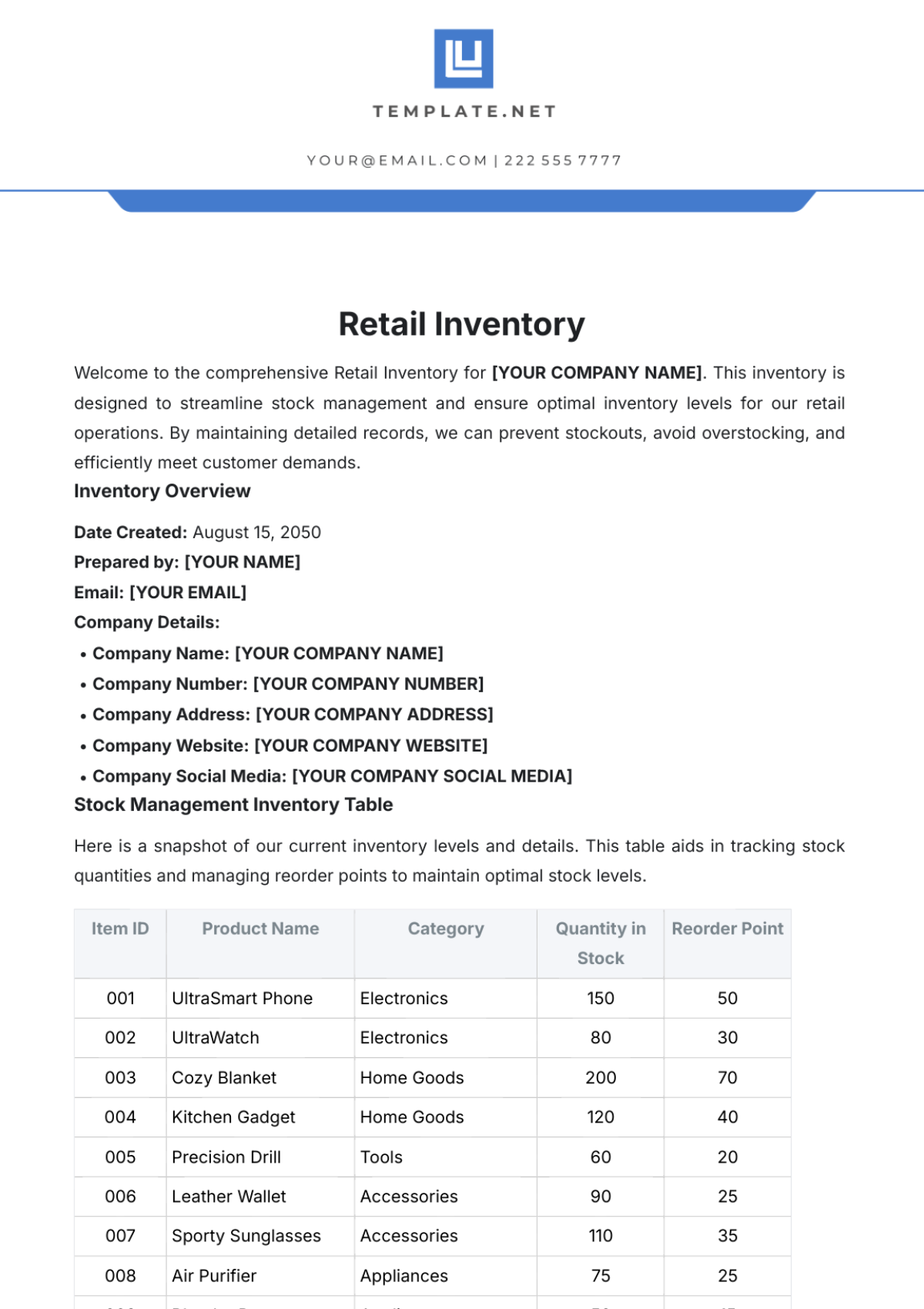

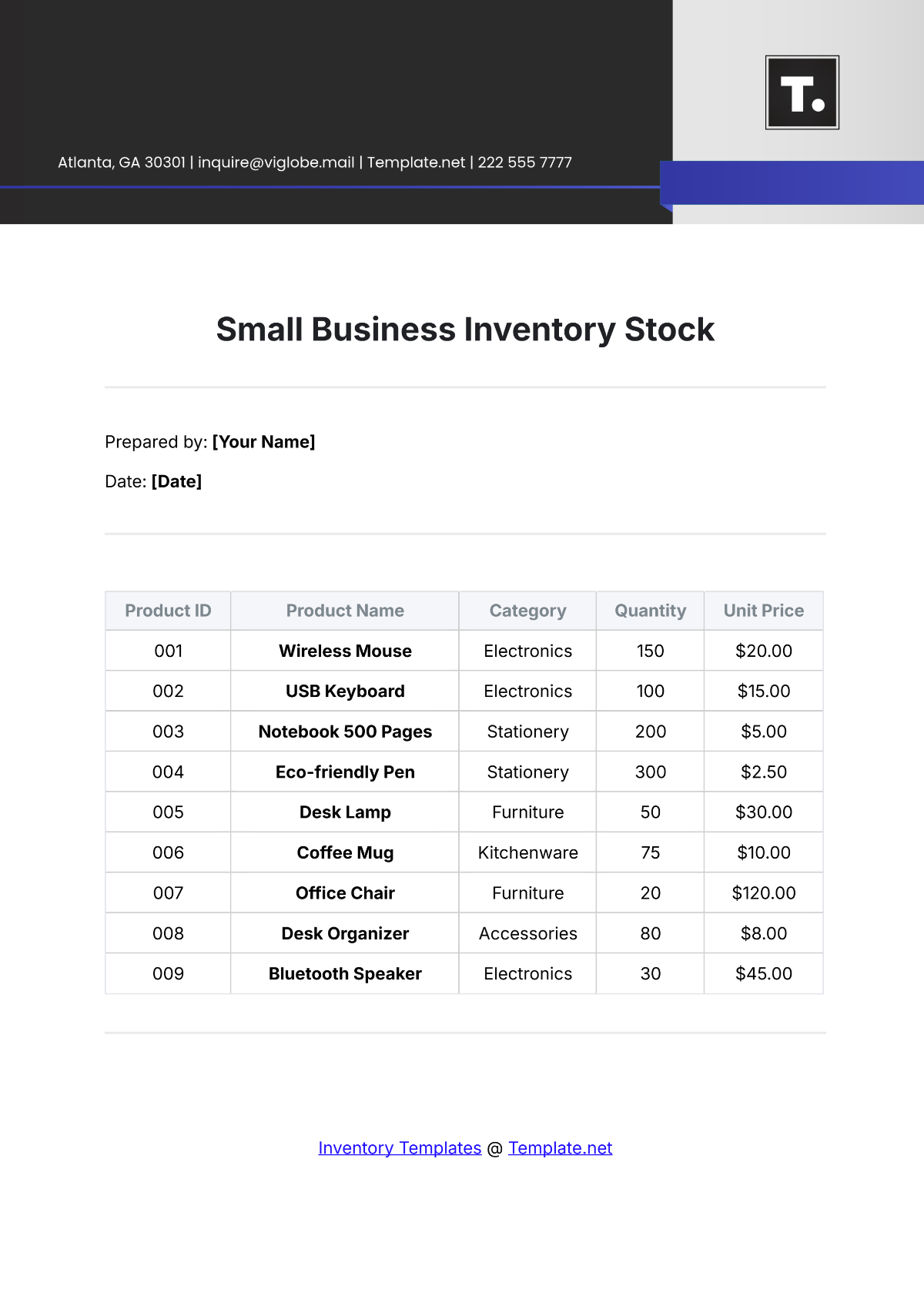

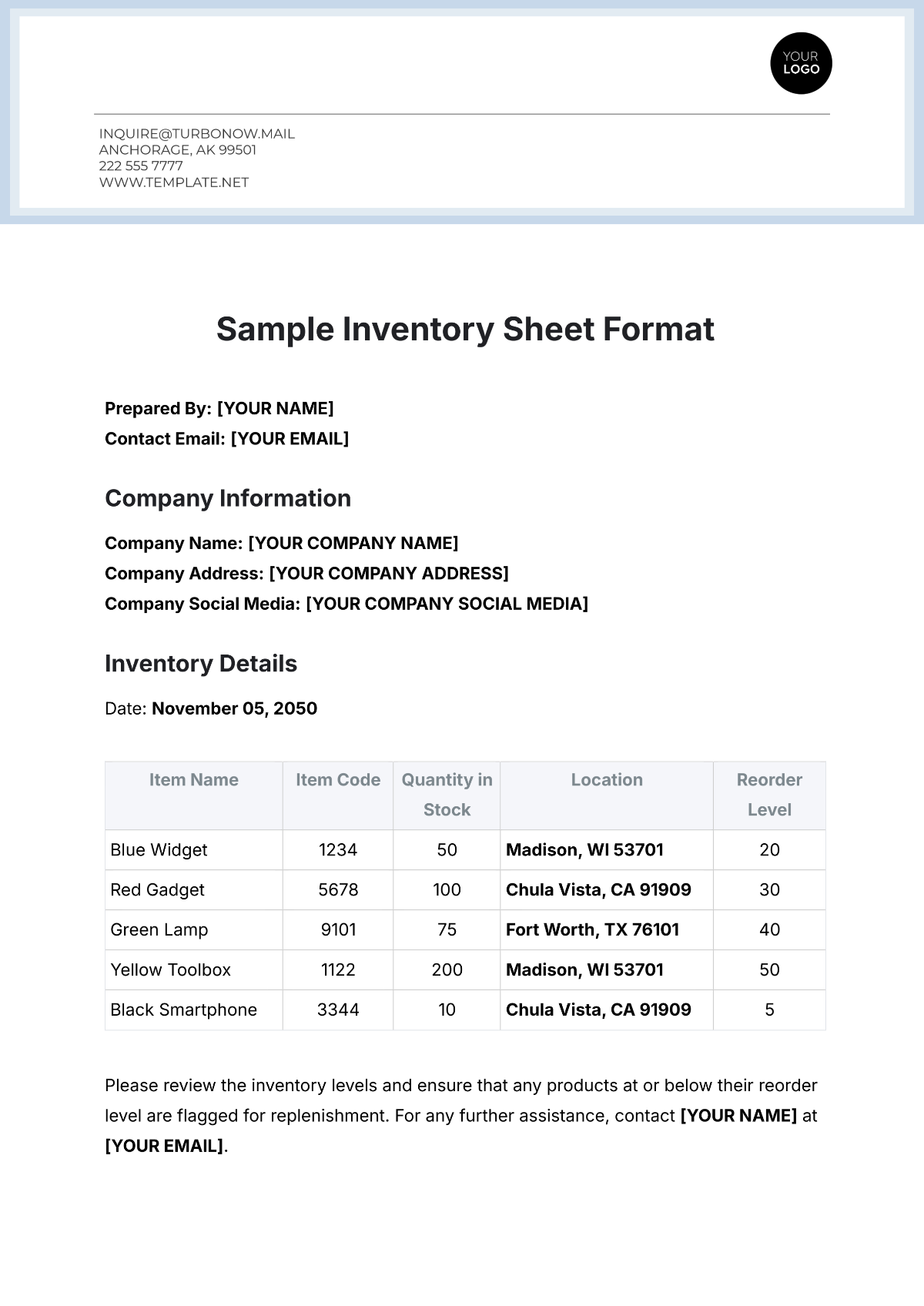

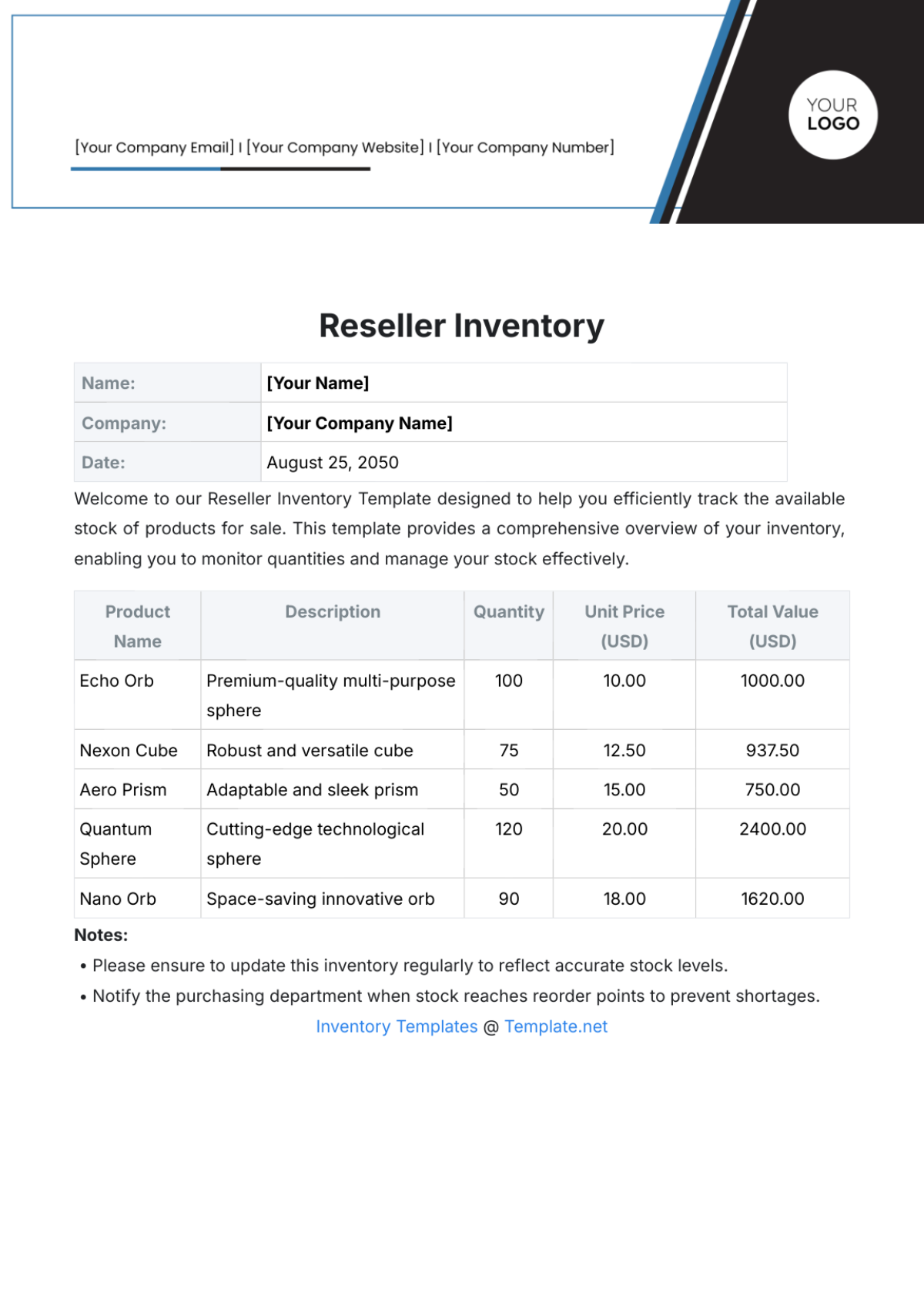

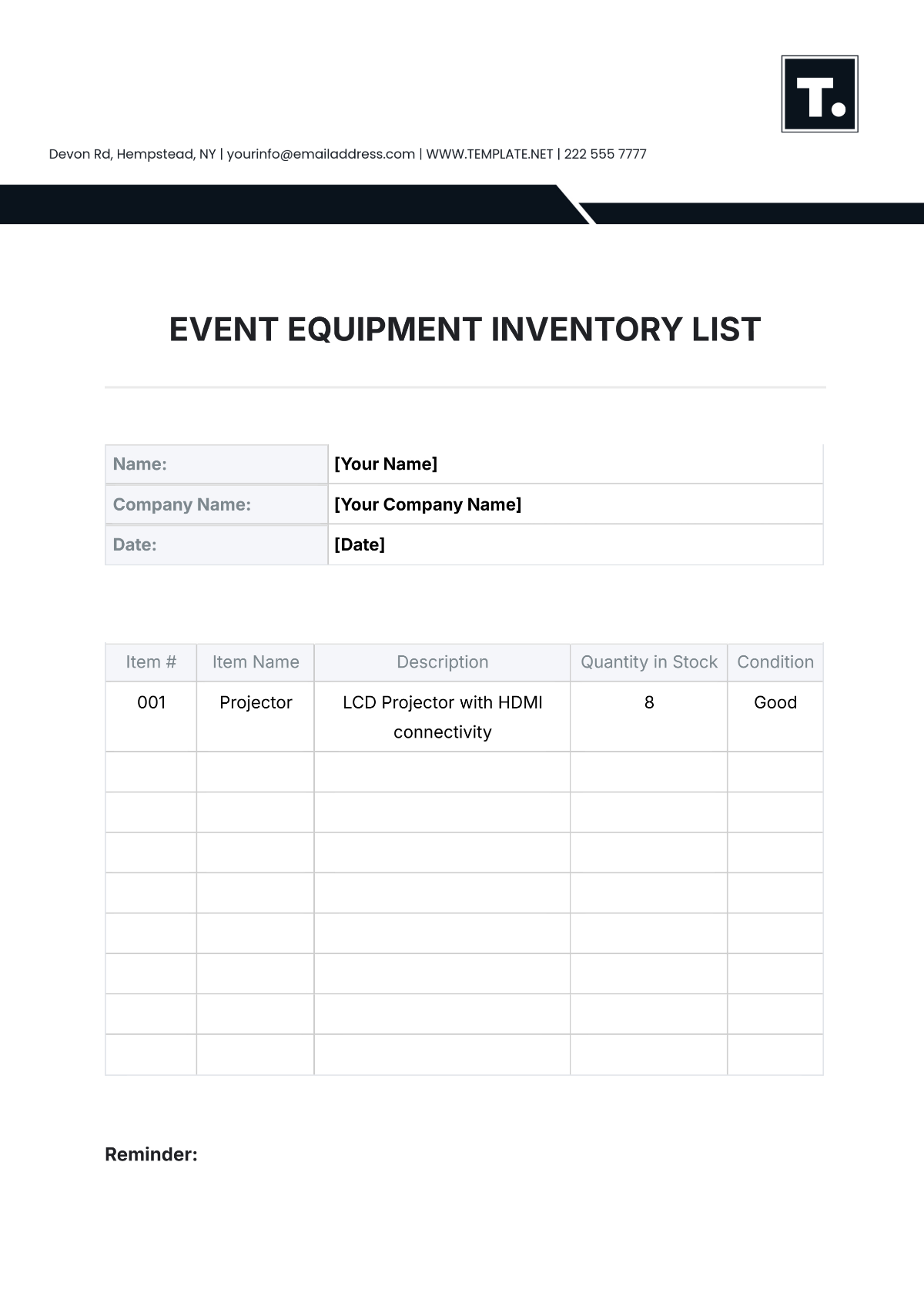

C. Finished Goods

The following table displays the availability of finished goods across different distribution points:

Product | Distribution Center | Stock Level |

|---|---|---|

Model X Gadgets | Central Hub | 2000 units |

Model Y Devices | East Coast Hub | 1500 units |

Model Z Appliances | West Coast Hub | 2500 units |

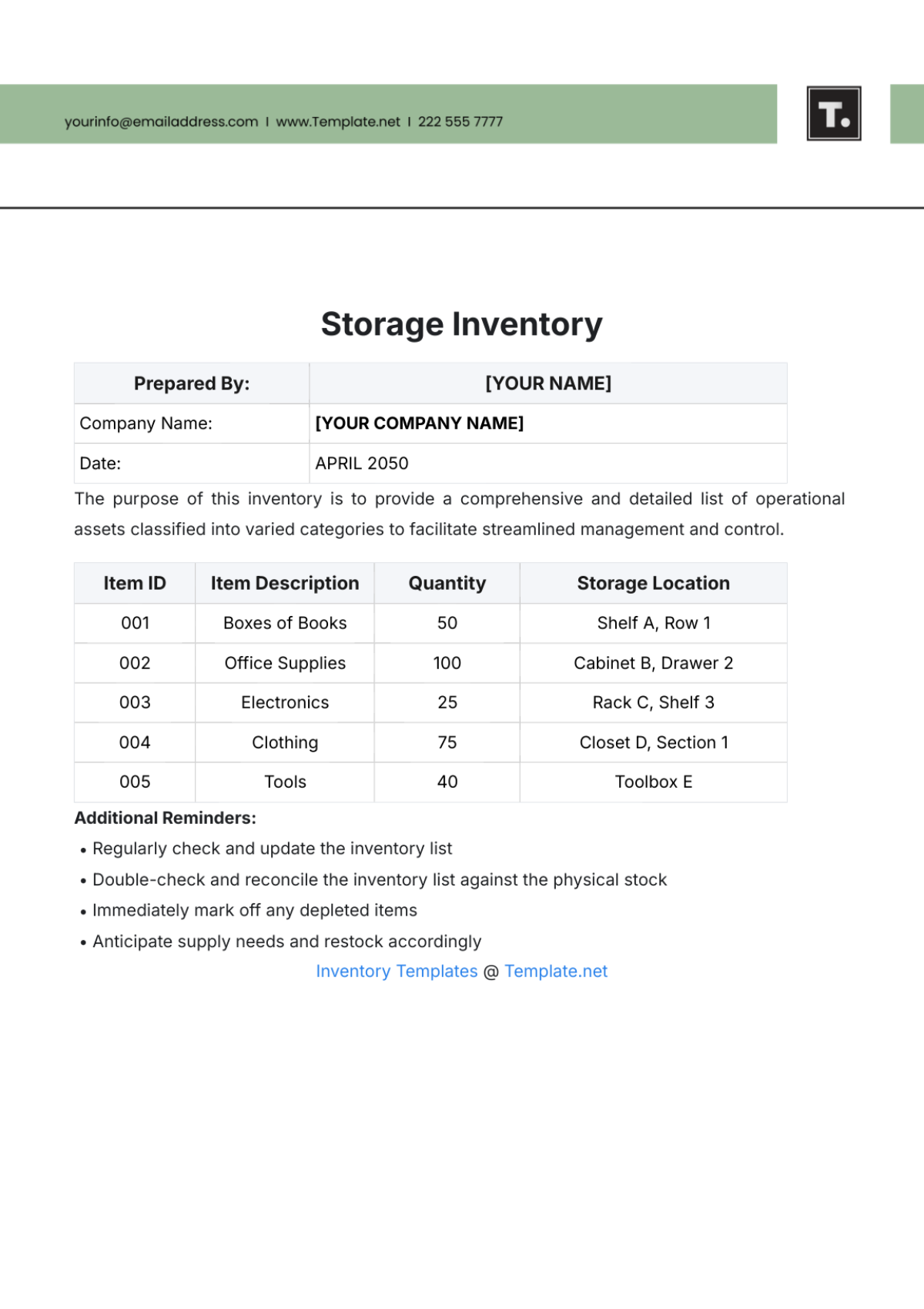

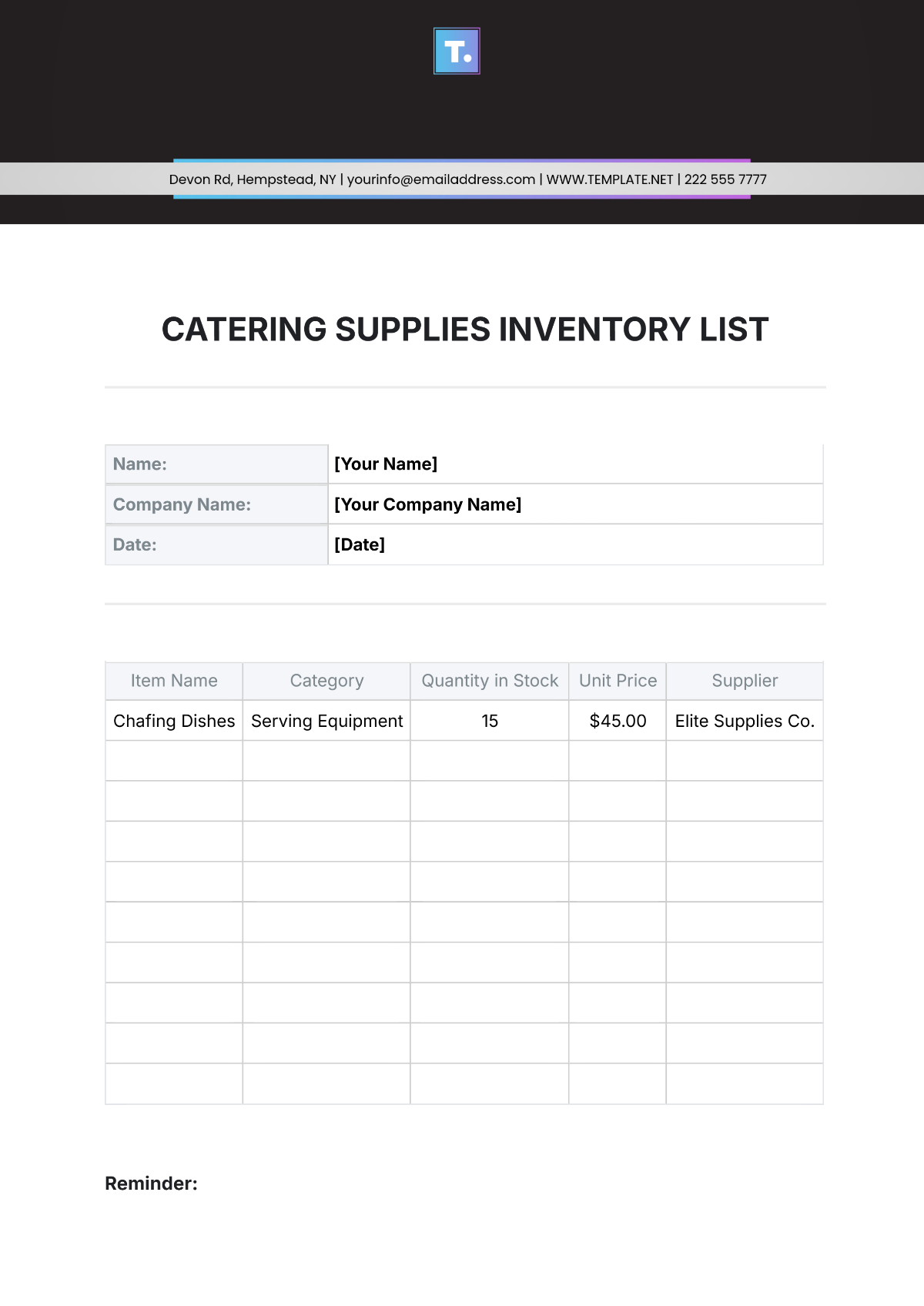

D. Miscellaneous Items

Miscellaneous items cover a variety of inventory that does not fall under the previous headings:

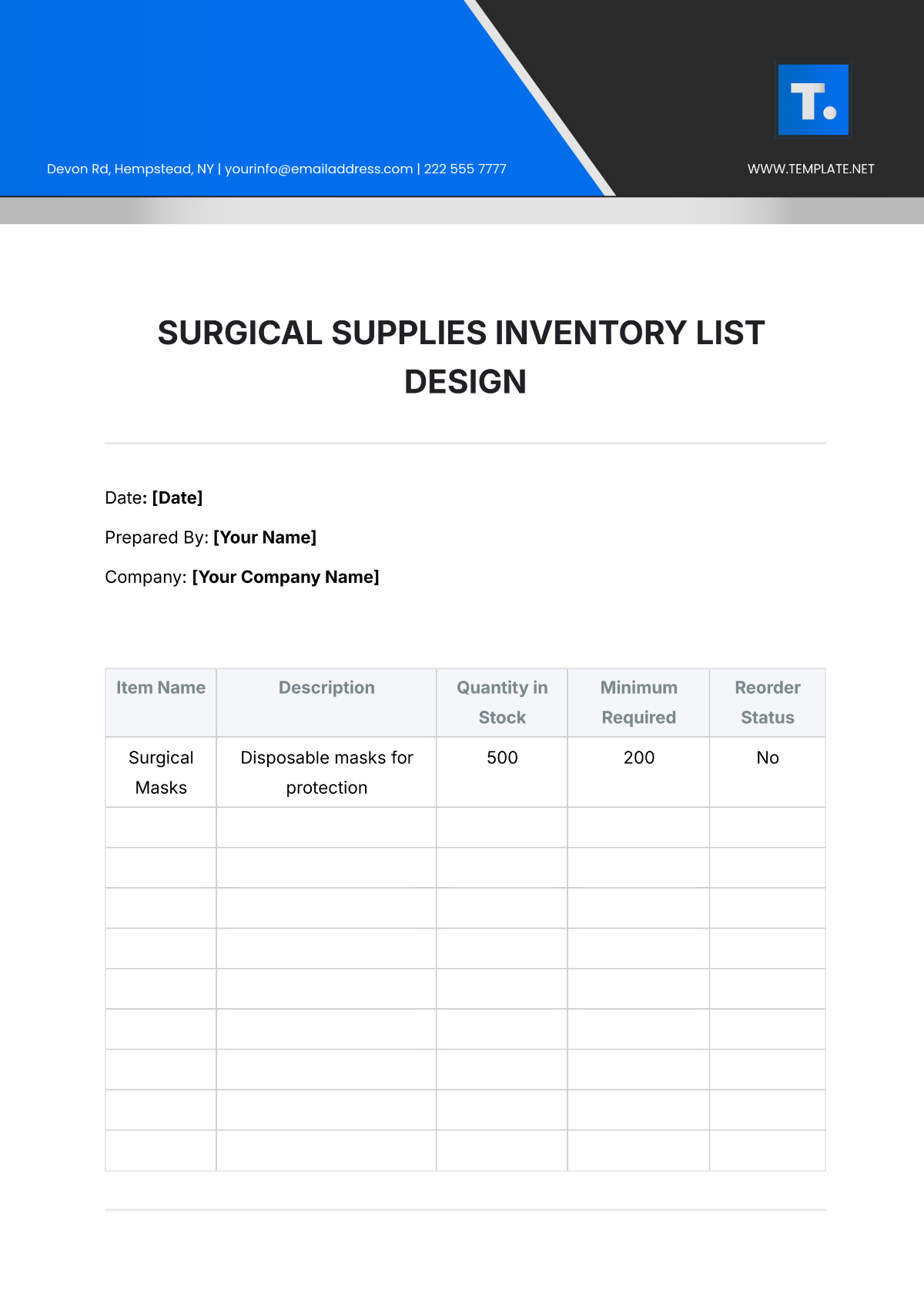

Maintenance Tools: Available across all maintenance departments.

Cleaning Supplies: Adequately stocked at each facility to ensure hygiene compliance.

Safety Gear: Distributed to locations depending on the workforce size and risk profile.

III. Inventory Management Practices

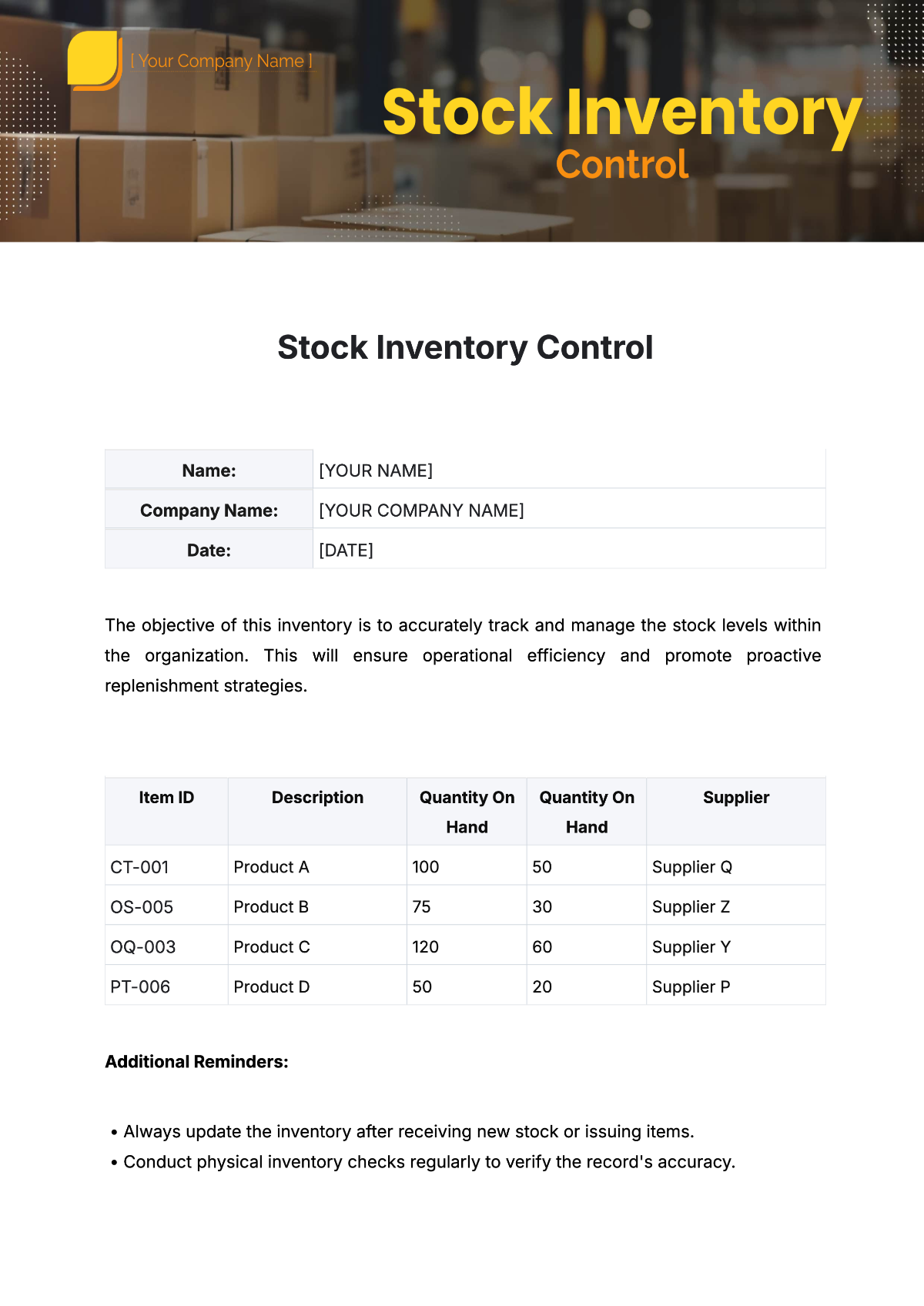

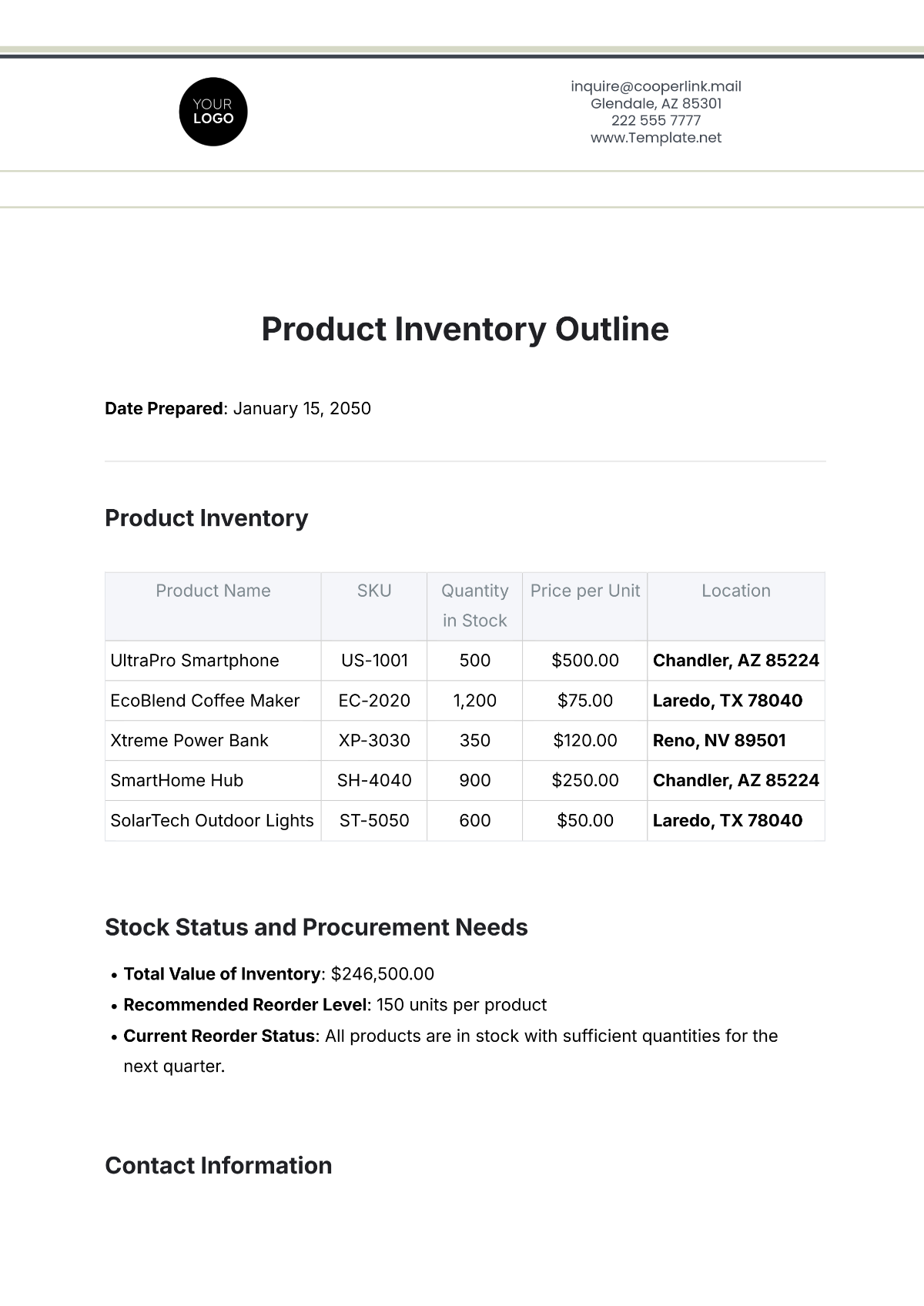

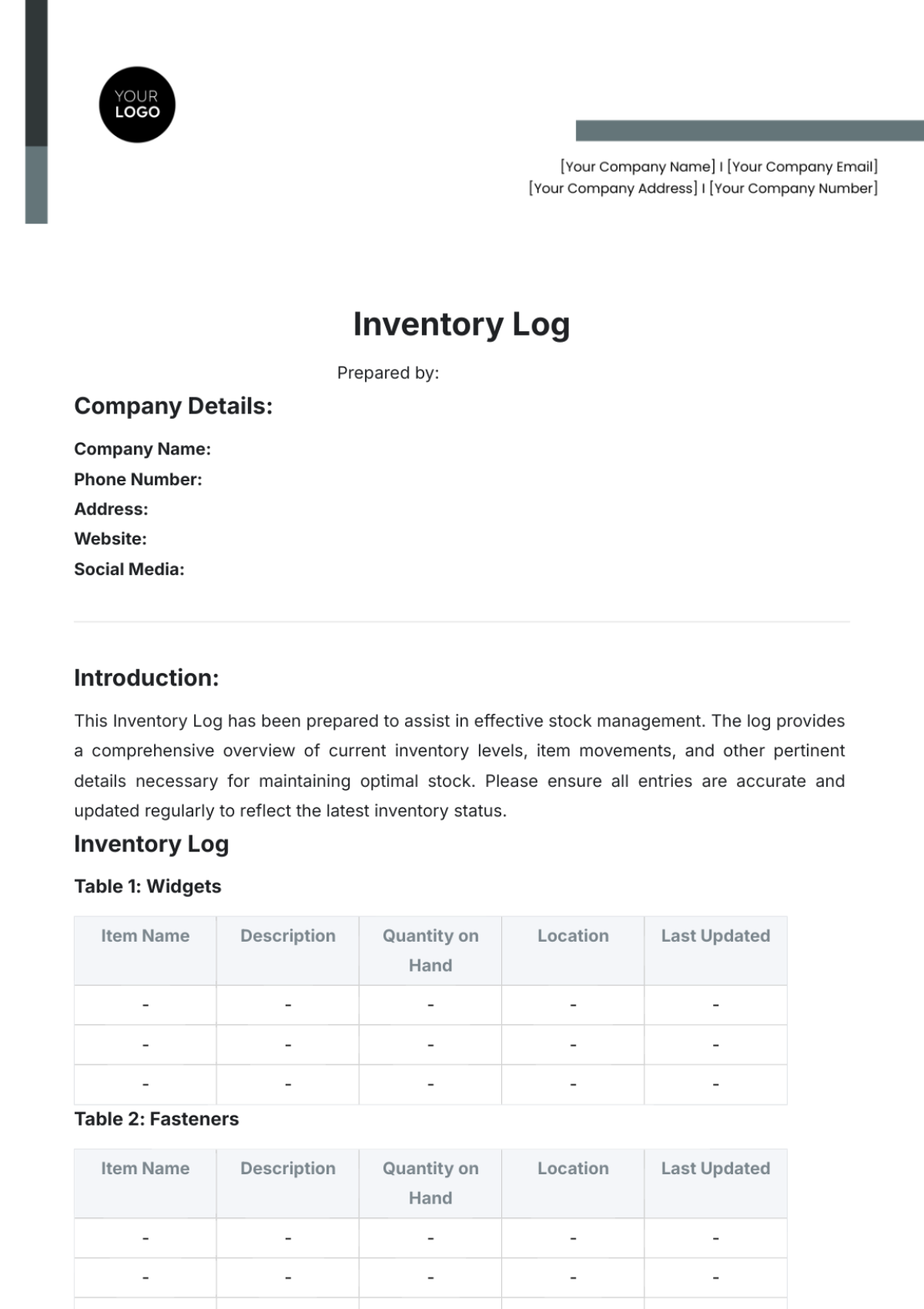

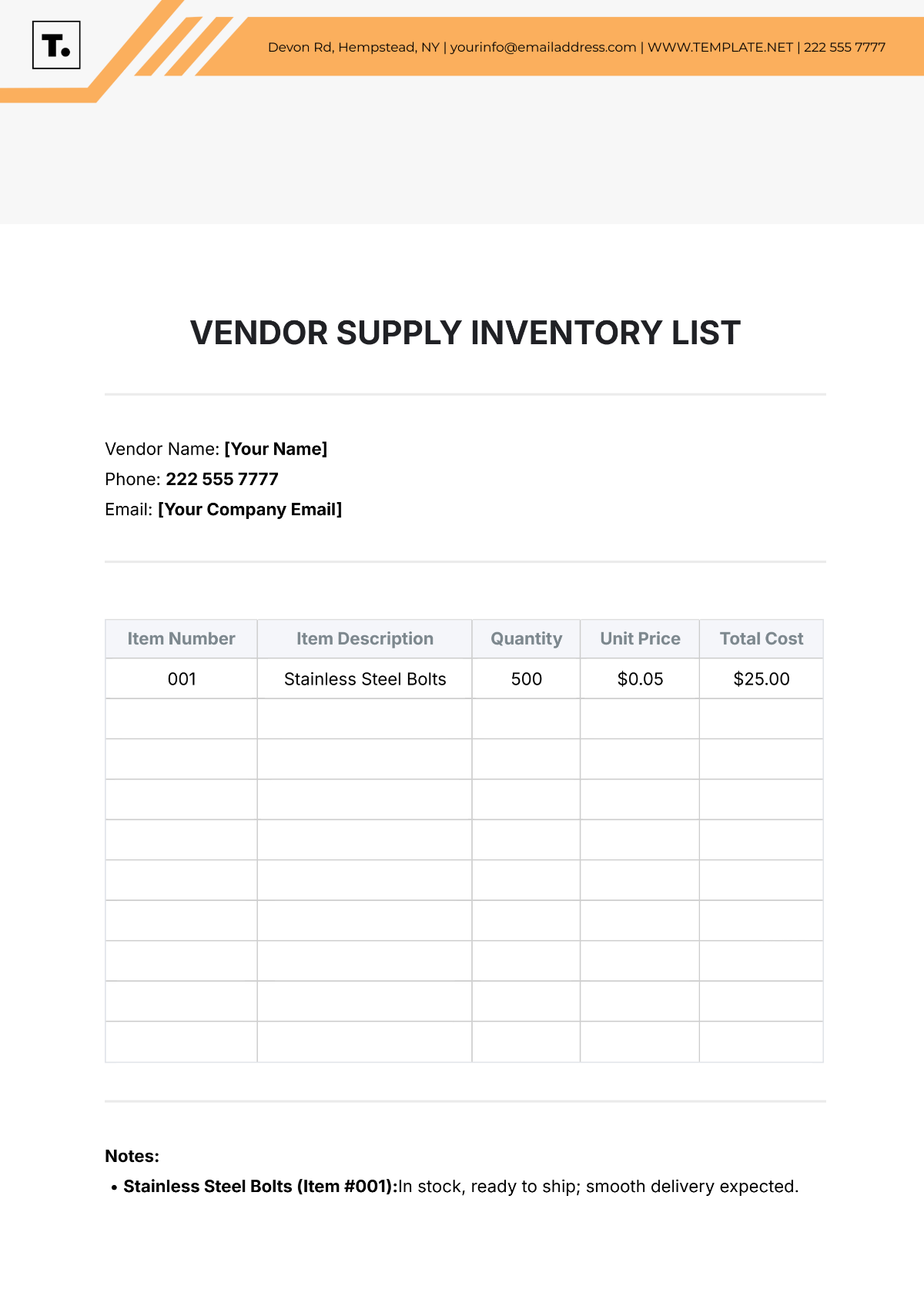

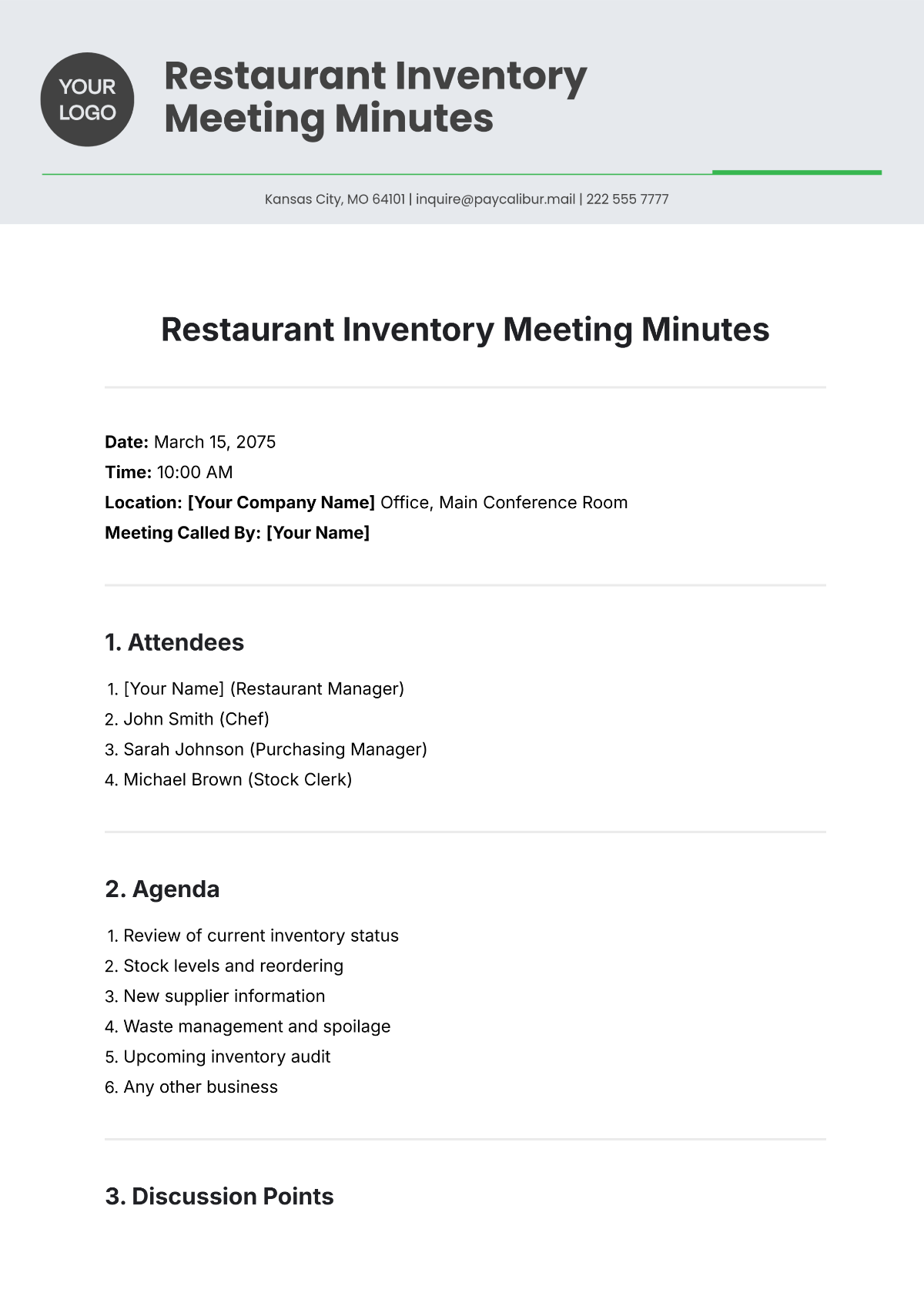

Efficient inventory management is crucial for optimizing resource allocation and minimizing costs. Below are the current practices implemented in our inventory management system:

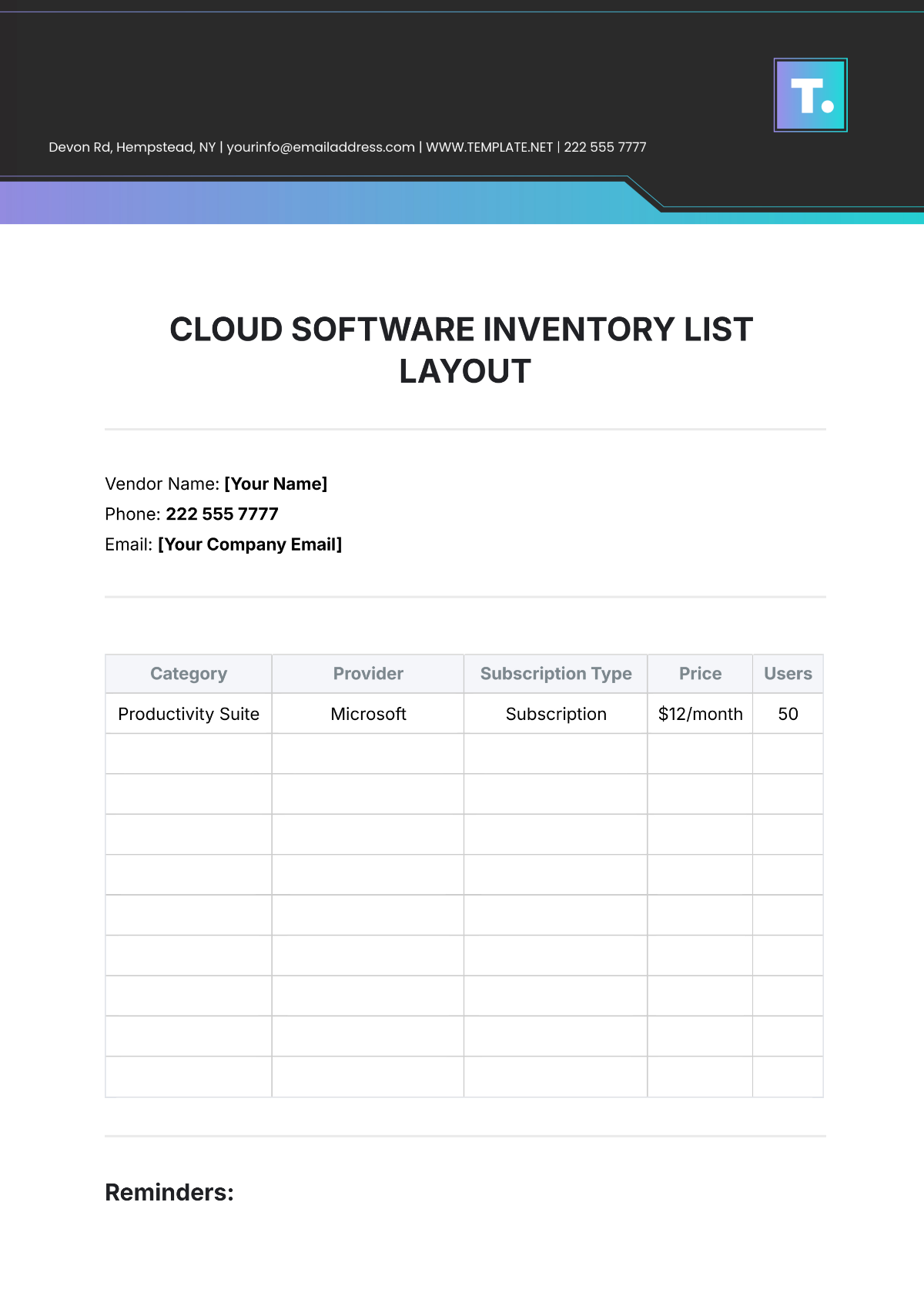

Real-Time Tracking: Our inventory is tracked in real-time using advanced software that updates stock levels instantly across all locations.

Demand Forecasting: Historical data and market trends are used to forecast demand, allowing us to adjust stock levels proactively.

Reorder Point Calculation: The reorder points are calculated systematically to trigger restocking before the stock reaches critical levels.

Periodic Audits: Regular inventory audits ensure accuracy in reporting and help in identifying discrepancies.

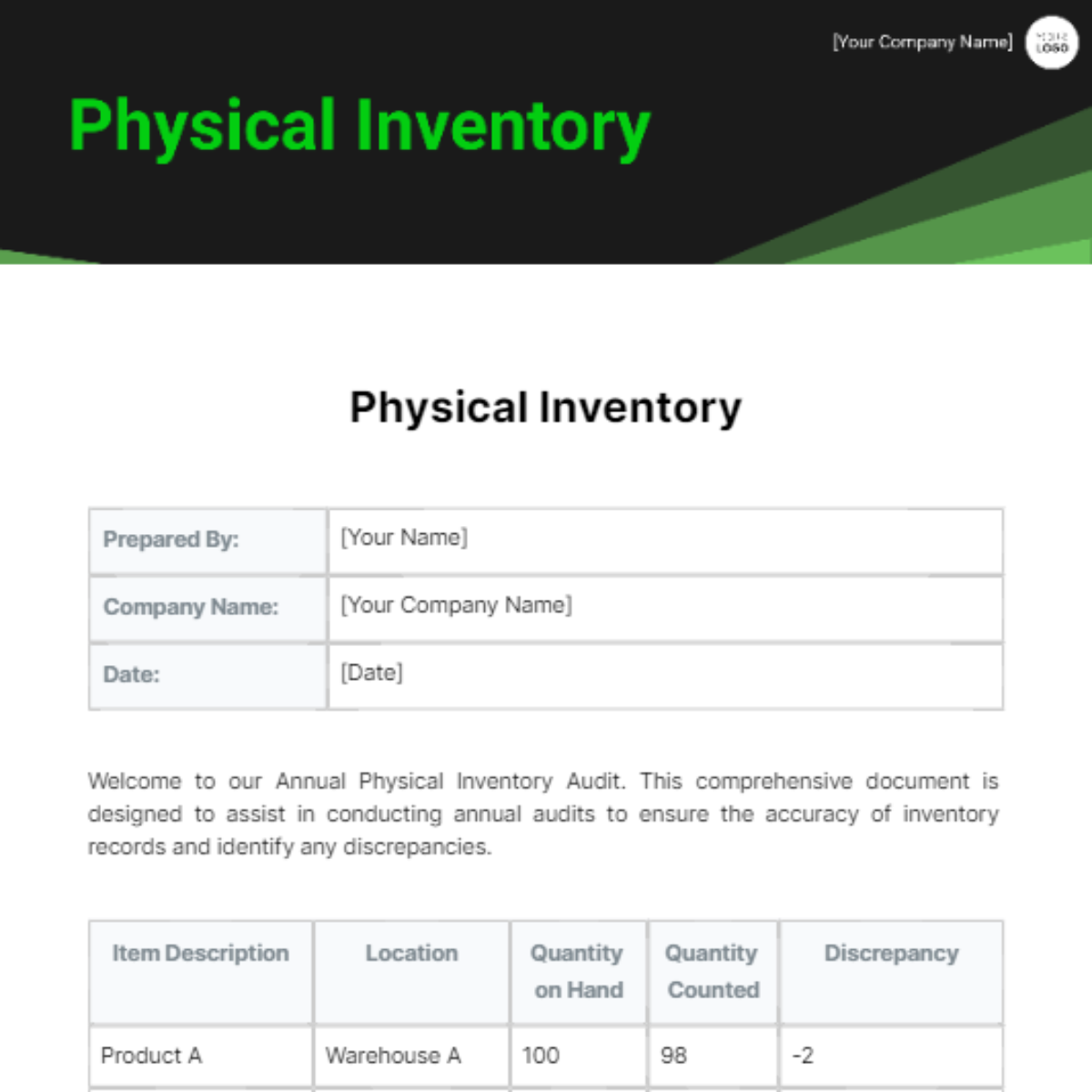

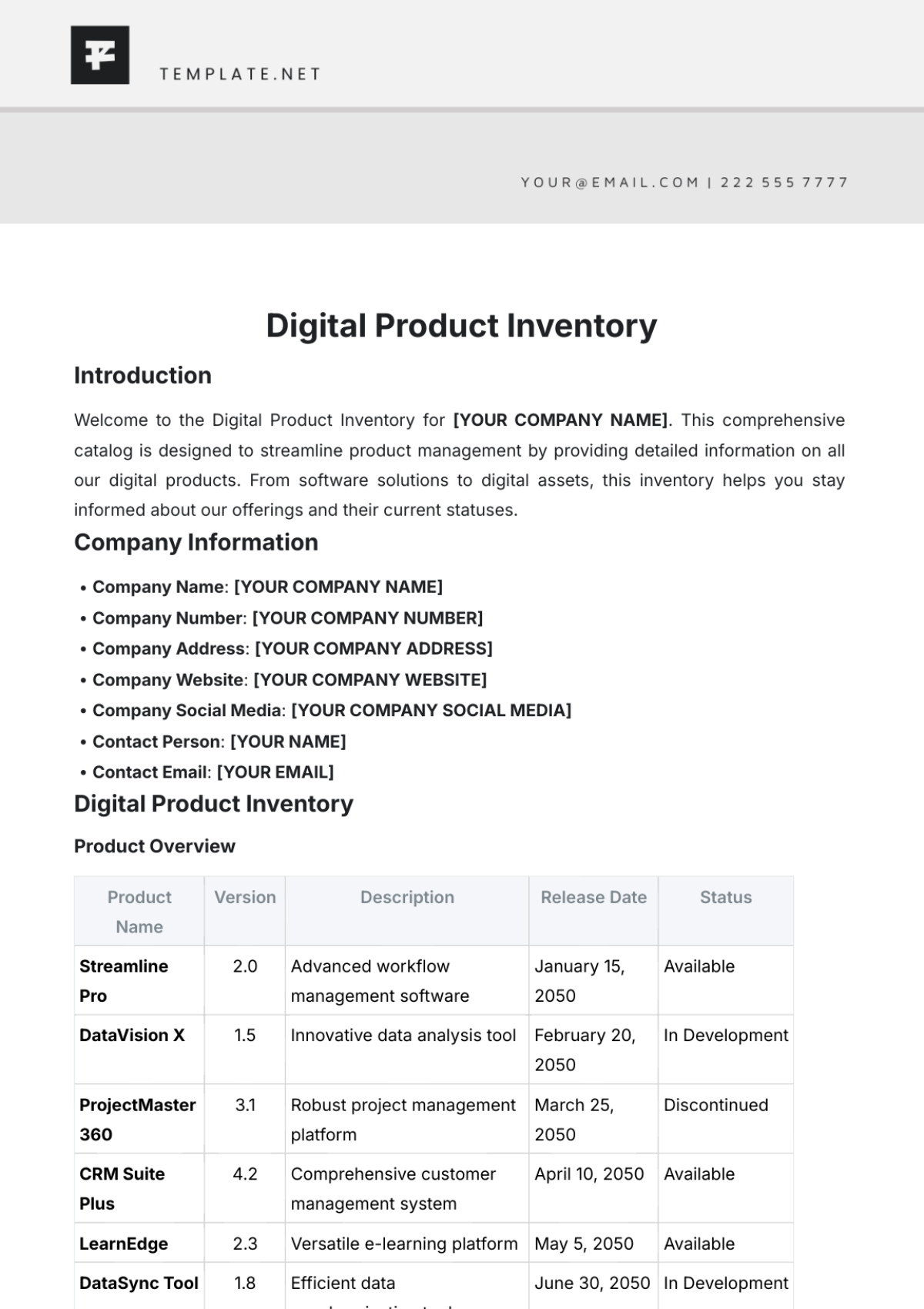

IV. Challenges in Inventory Distribution

Despite robust practices in place, several challenges persist in inventory distribution:

Supply Chain Disruptions: External factors such as supplier delays and logistic bottlenecks affect timely inventory replenishment.

Demand Variability: Fluctuating customer demand poses difficulties in maintaining optimal stock levels.

Storage Limitations: Limited storage space restricts the ability to store large volumes of inventory.

V. Recommendations for Improvement

To further refine our inventory distribution process, the following recommendations are proposed:

Strengthen Supplier Relationships: Build strong relationships with suppliers to ensure priority in stock replenishments during high-demand periods.

Invest in Additional Storage Facilities: Expand storage capacity to accommodate a larger inventory, enabling better preparation for demand spikes.

Leverage Technology: Implement AI and machine learning algorithms to enhance demand forecasting and optimize stock levels dynamically.

VI. Conclusion

In conclusion, effective inventory distribution is critical for meeting organizational goals. By addressing current challenges and implementing the recommended strategies, we can enhance our inventory management, leading to greater efficiency, cost savings, and customer satisfaction.