E-Commerce Inventory Management Guide

I. Introduction

This guide outlines best practices, processes, and policies designed to manage inventory effectively, reduce wastage, and maintain a reliable supply chain. The goal is to provide clarity and structure for managing inventory across all departments while aligning with business objectives and industry standards.

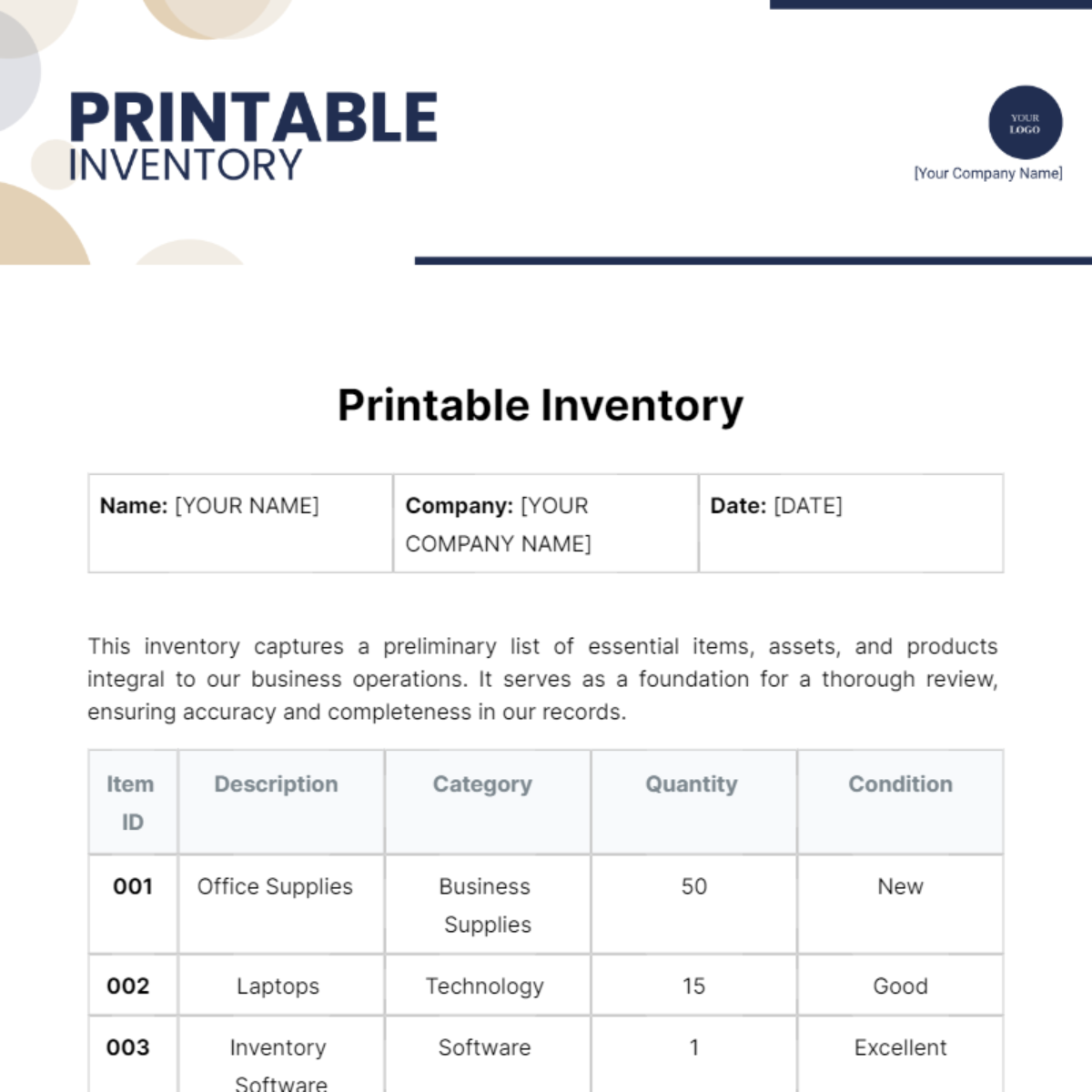

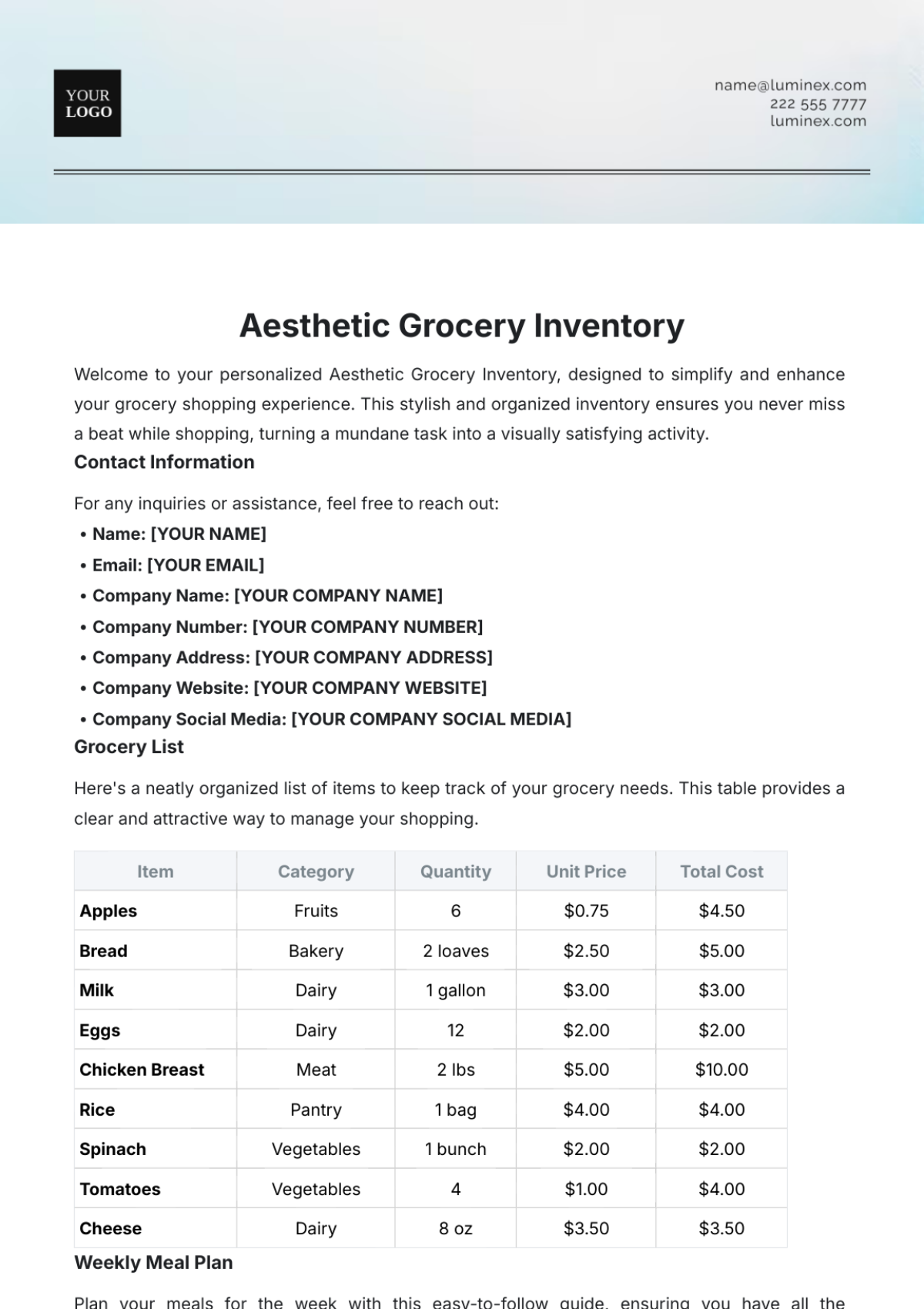

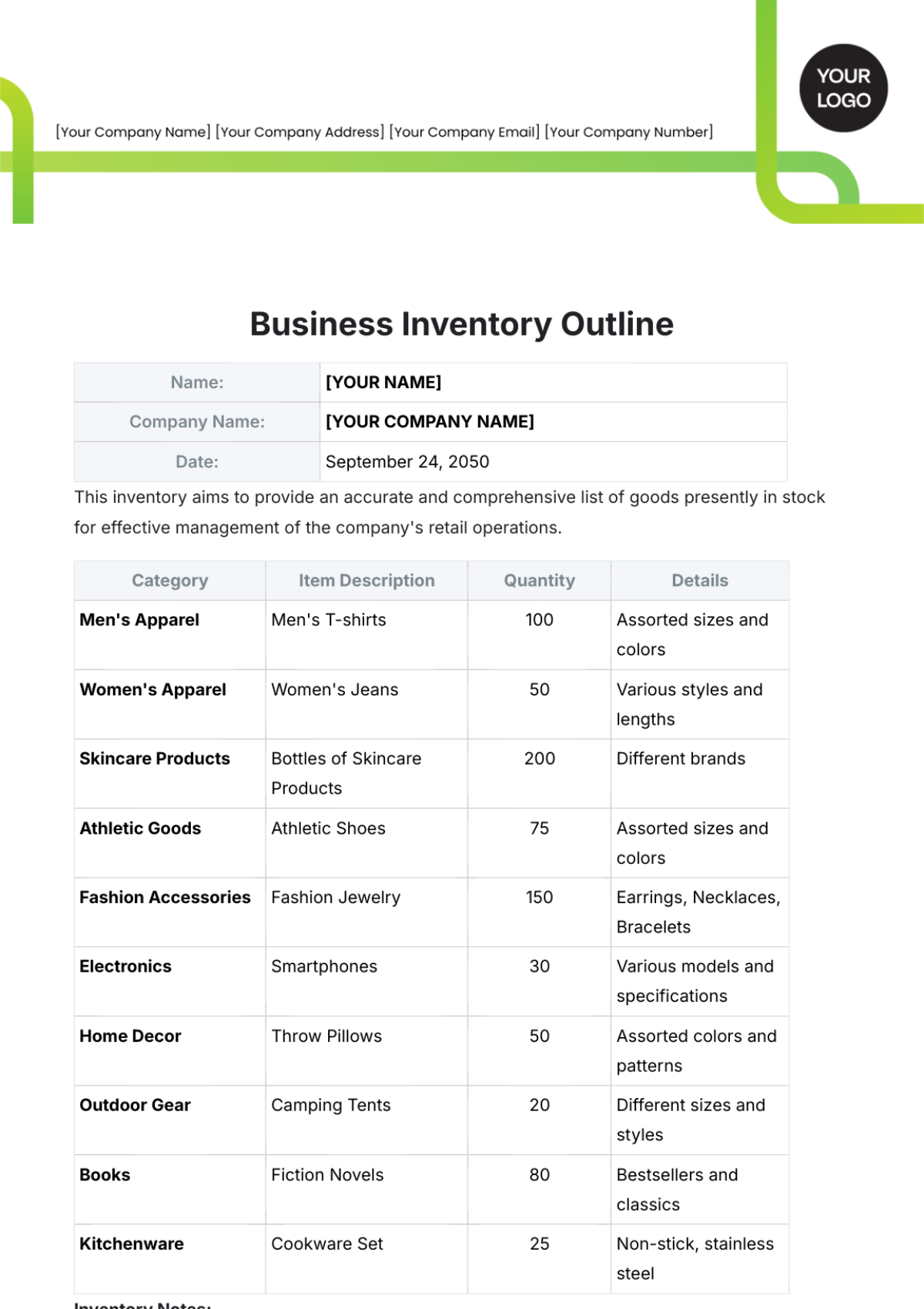

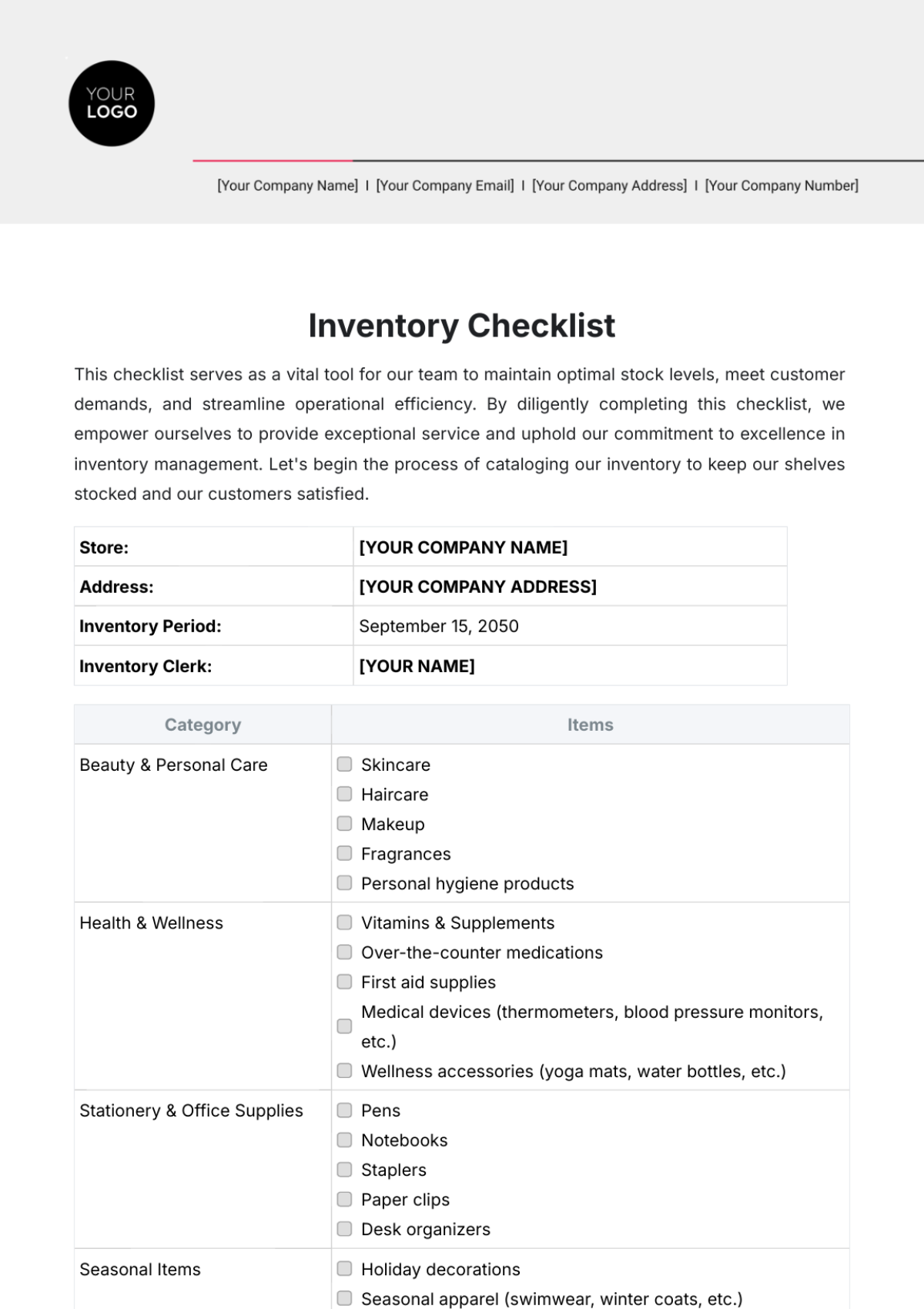

II. Inventory Categorization

Proper categorization is the foundation of effective inventory management, allowing the company to track and manage stock accurately. By organizing inventory into categories, [Your Company Name] ensures better control and reporting.

Raw Materials: Materials used to create products or fulfill services, such as packaging supplies or specialty tools. Accurate tracking ensures the availability of key materials for production.

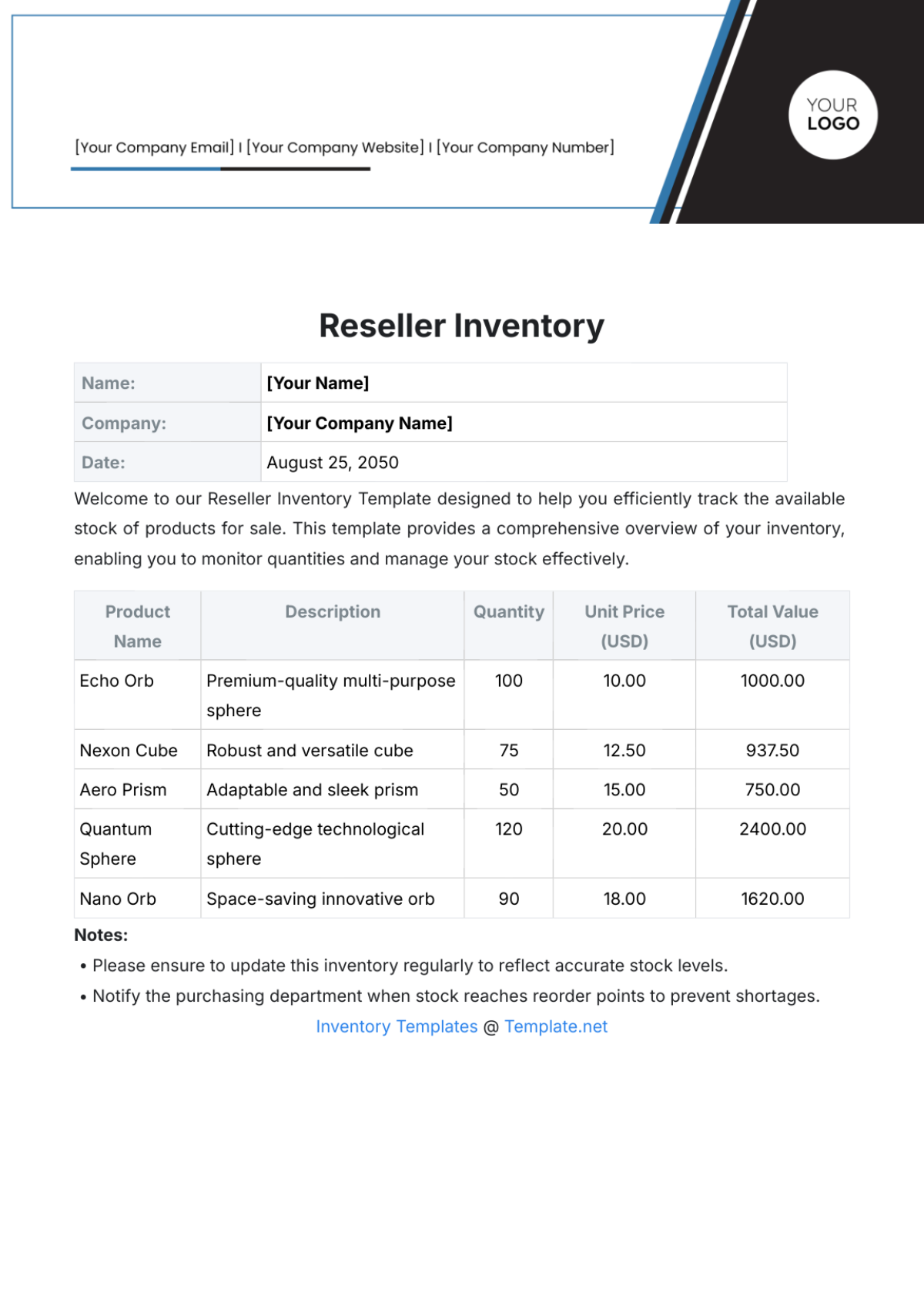

Finished Goods: Items ready for sale to customers, categorized by type, size, or model. This organization streamlines sales and fulfillment processes.

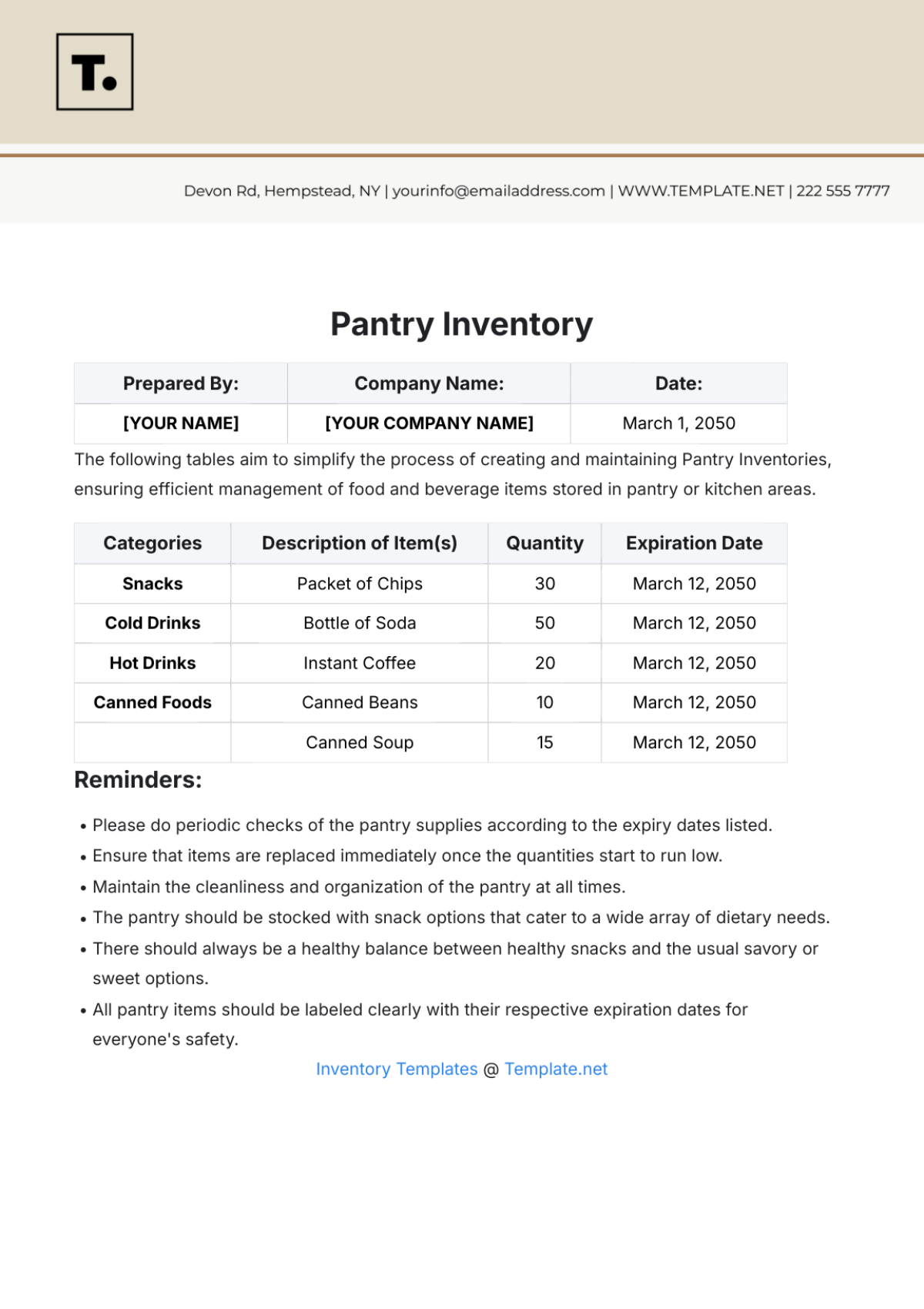

Consumables: Items such as cleaning supplies, office materials, or other non-sellable assets that support operations. Monitoring these helps manage expenses effectively.

Slow-Moving Inventory: Stock that sees infrequent turnover is identified for strategic discounts or reallocation to reduce carrying costs.

High-Turnover Stock: Frequently sold items are monitored to ensure steady availability and prevent stock outs. Efficient tracking of these boosts customer satisfaction and sales.

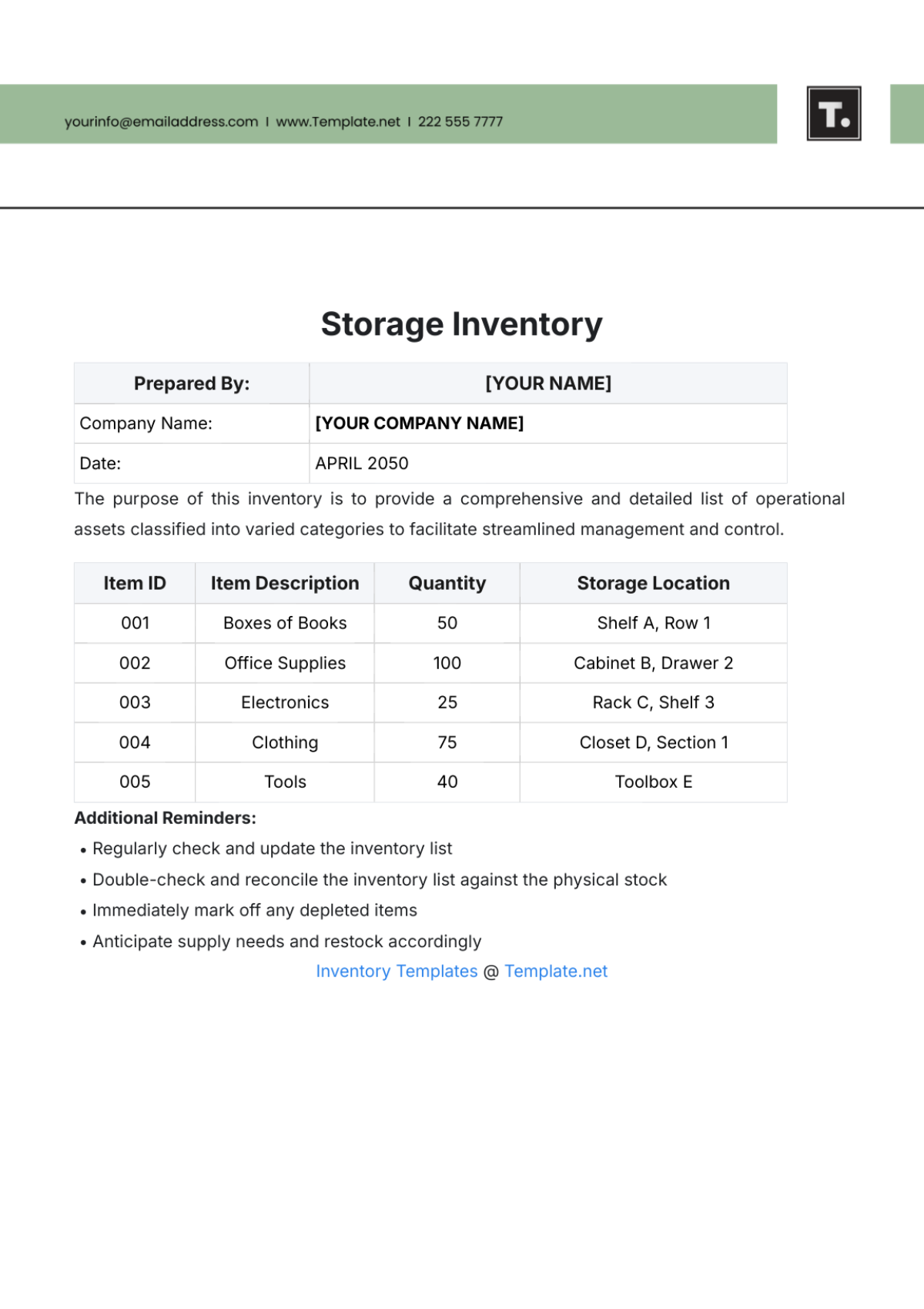

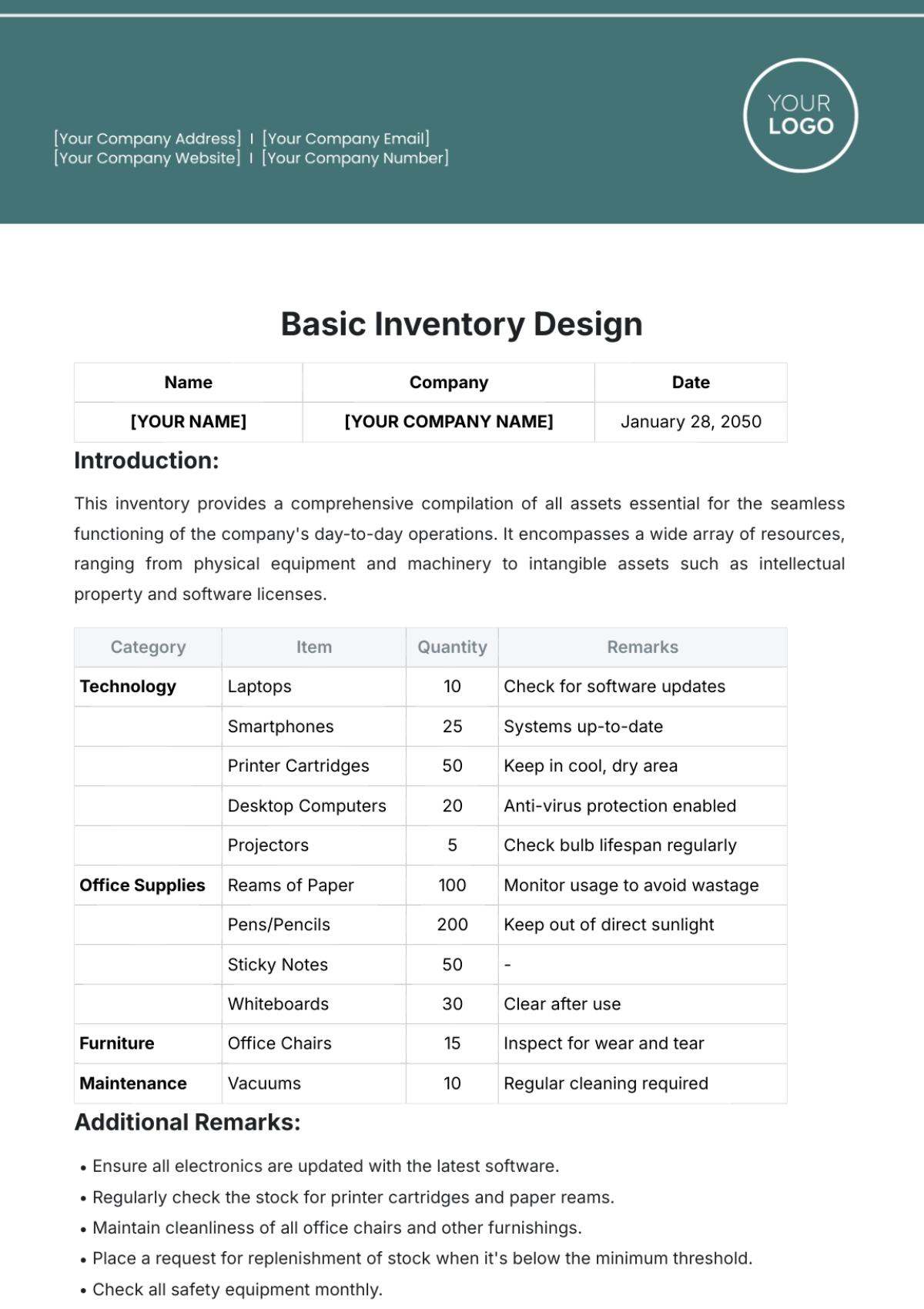

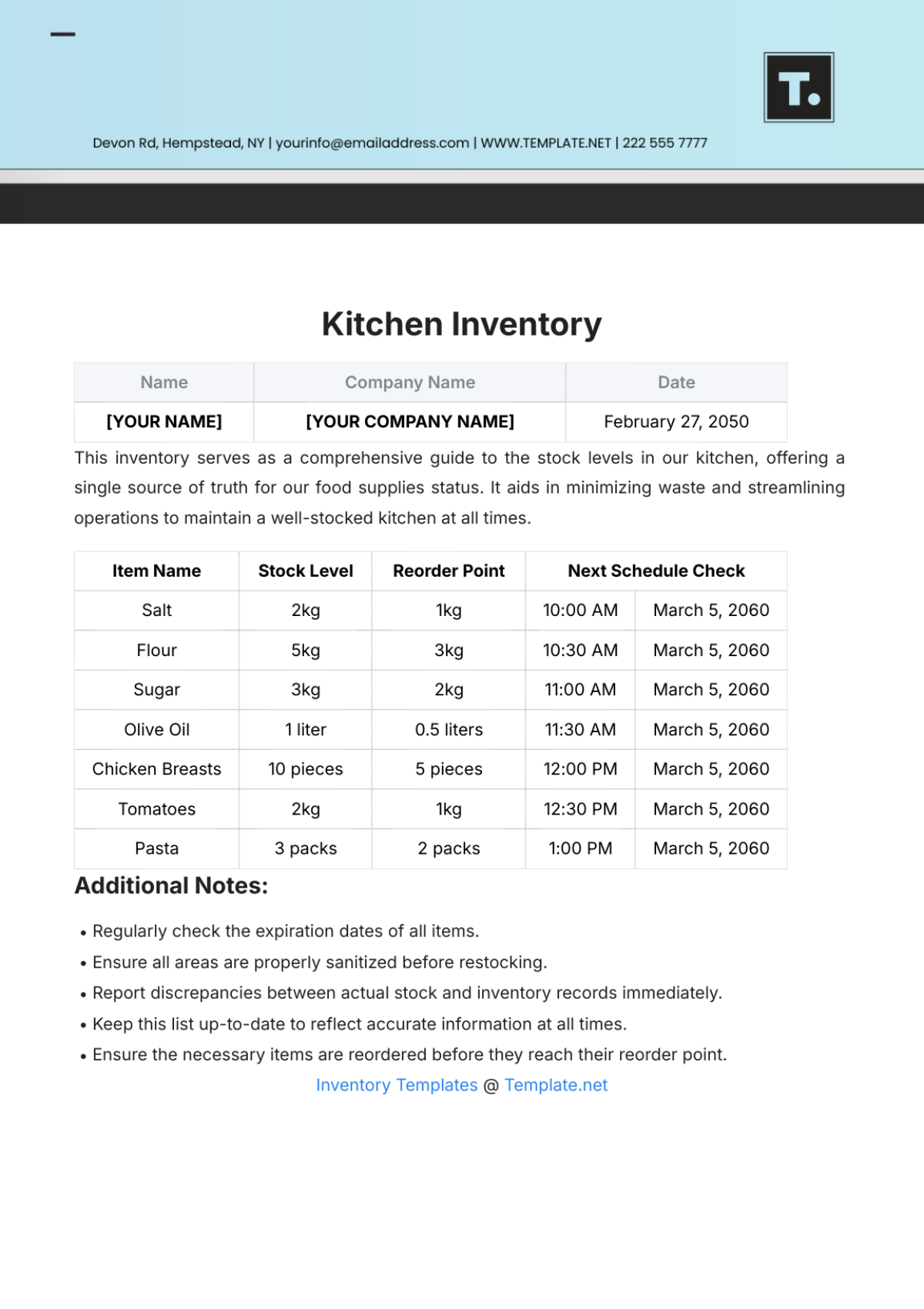

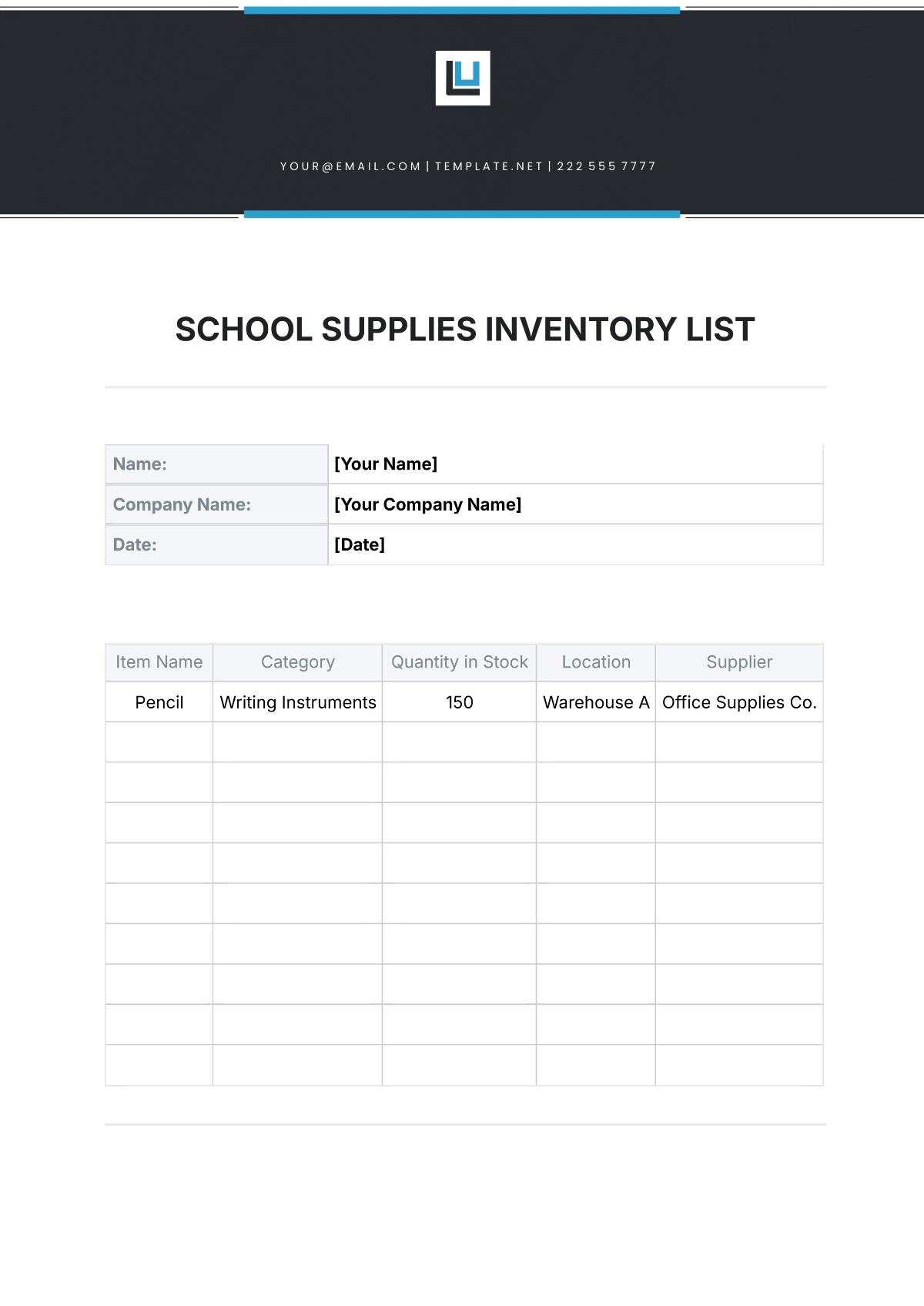

III. Inventory Tracking and Monitoring

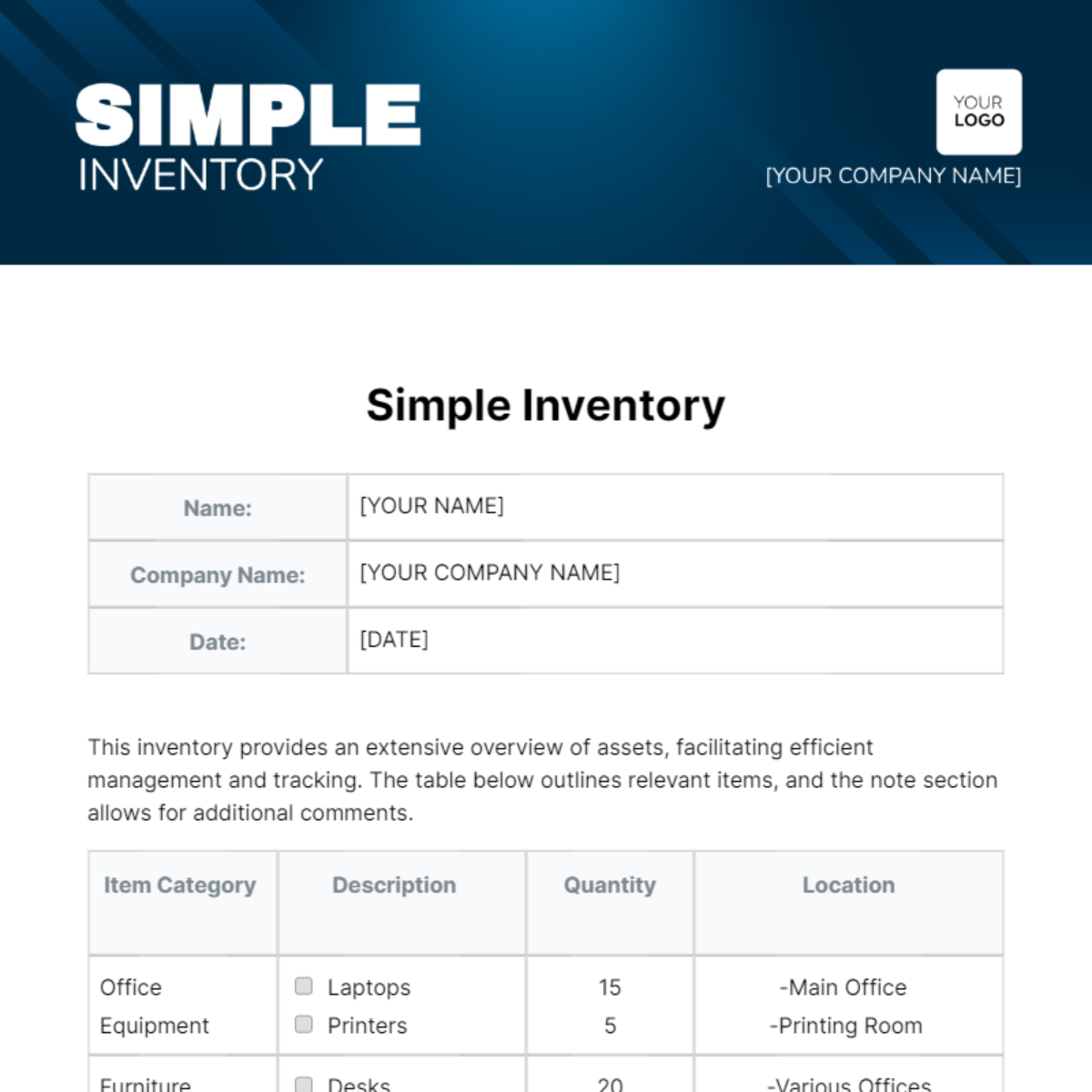

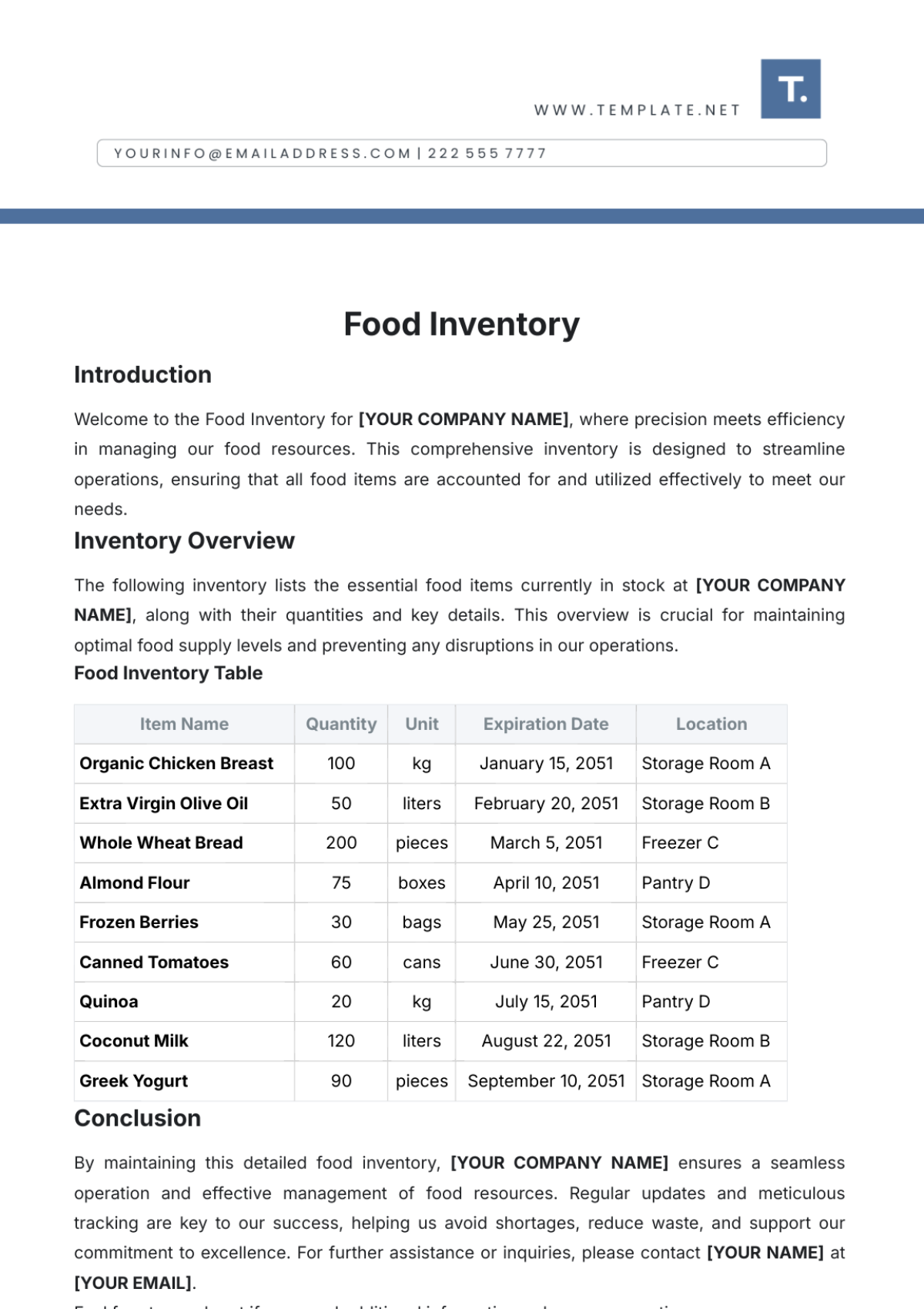

Tracking and monitoring inventory levels ensure that the company maintains optimal stock while avoiding overstocking or shortages. This section highlights the tools and methods used for precise inventory control.

Barcode Scanning: A system to scan products in and out of inventory, reducing errors and improving speed.

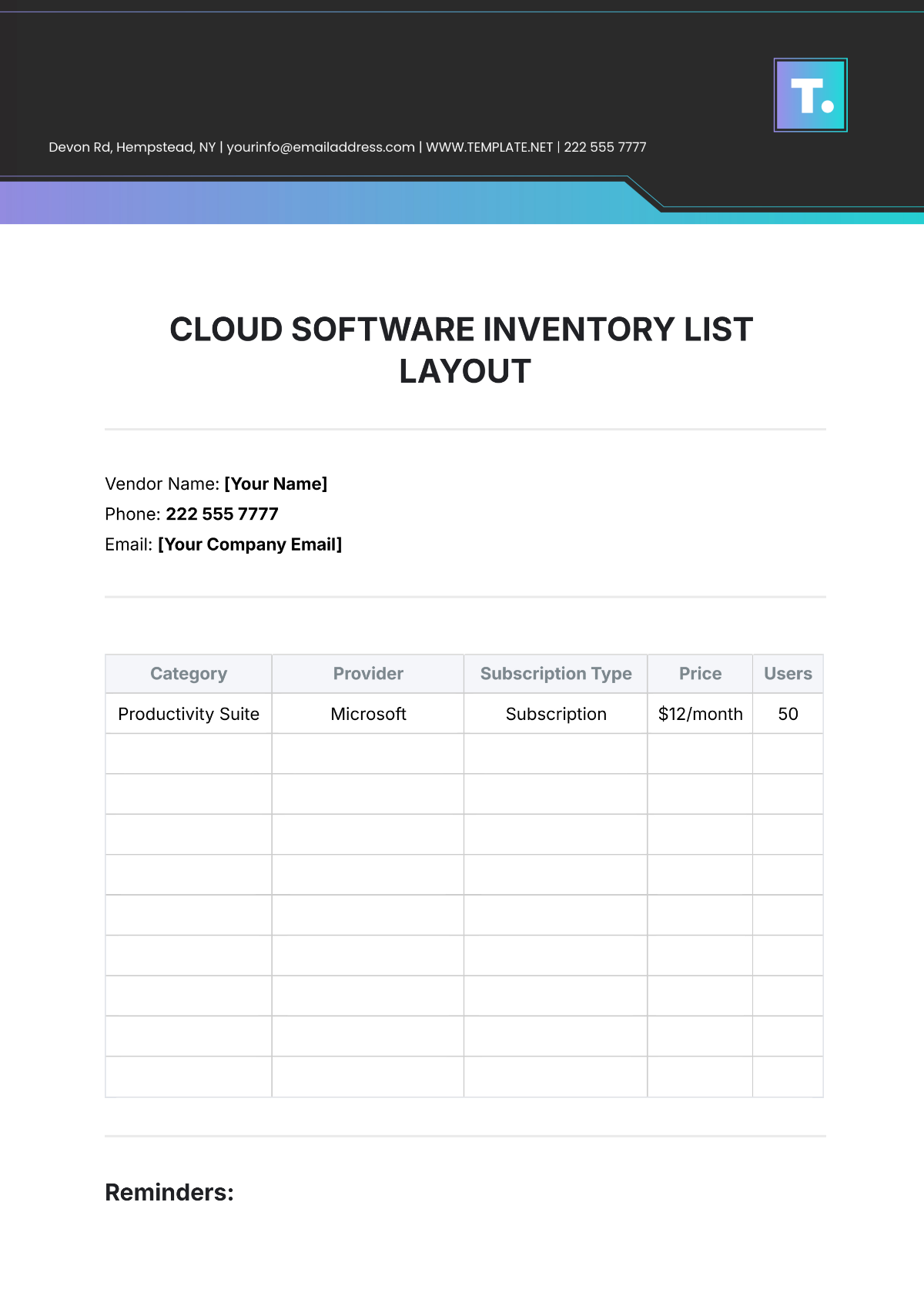

Digital Inventory System: Cloud-based software that tracks stock levels, automates reordering, and generates reports for analysis.

Physical Stock Audits: Periodic checks to validate digital records and ensure accuracy.

Automated Alerts: System-generated notifications for low stock or upcoming expirations, enabling timely action.

Seasonal Demand Forecast: Predictive analytics to adjust inventory levels based on historical trends, ensuring readiness for peak demand.

Tracking Method | Frequency |

|---|---|

Barcode Scanning | Continuous |

Digital Inventory System | Daily Updates |

Physical Stock Audits | Monthly |

Automated Alerts | As Triggered |

Seasonal Demand Forecast | Quarterly |

Utilizing a combination of manual and automated tracking methods ensures accuracy and adaptability. Automated alerts and forecasting further streamline operations by preempting issues, while regular audits maintain trust in the system’s data.

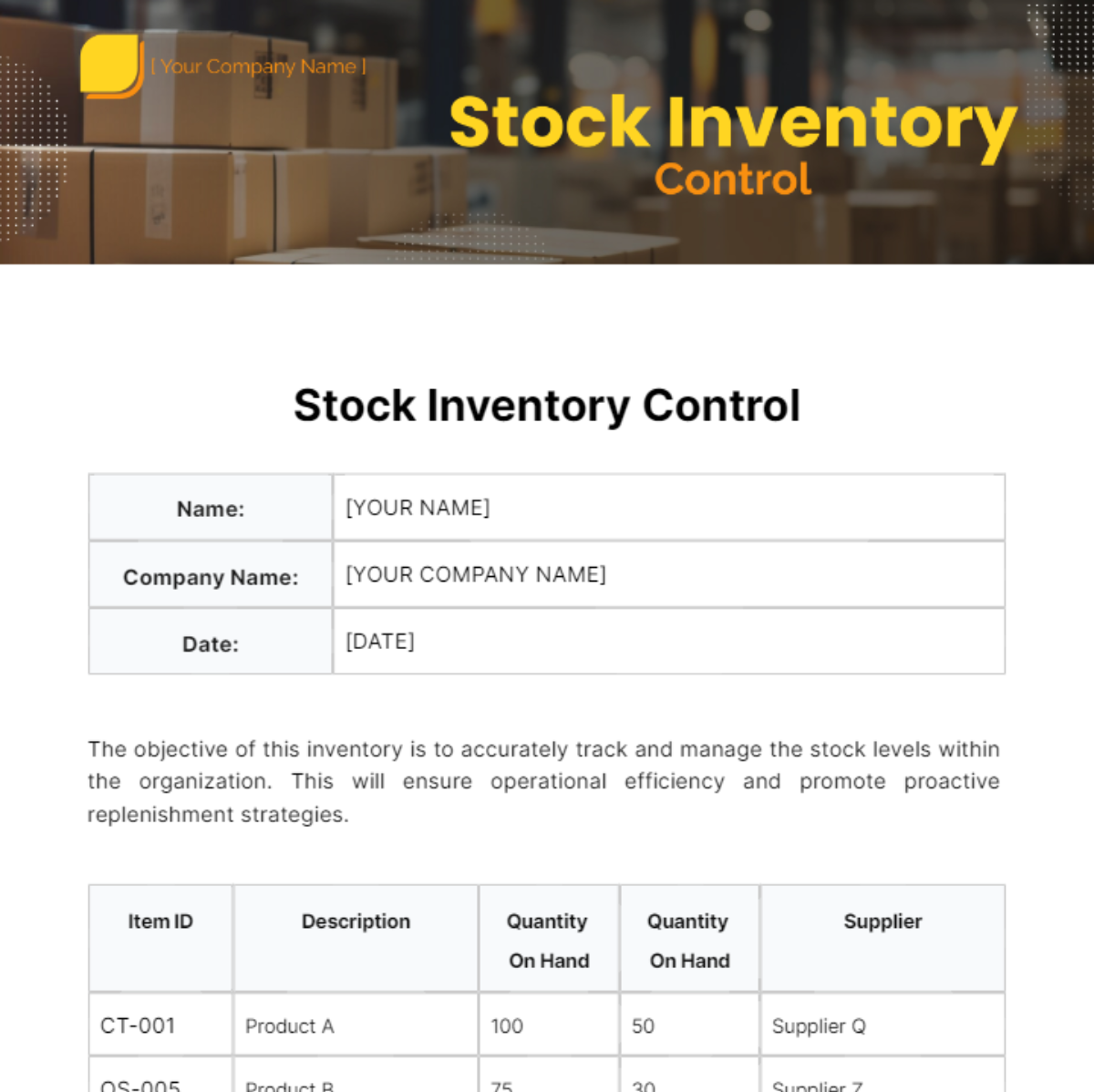

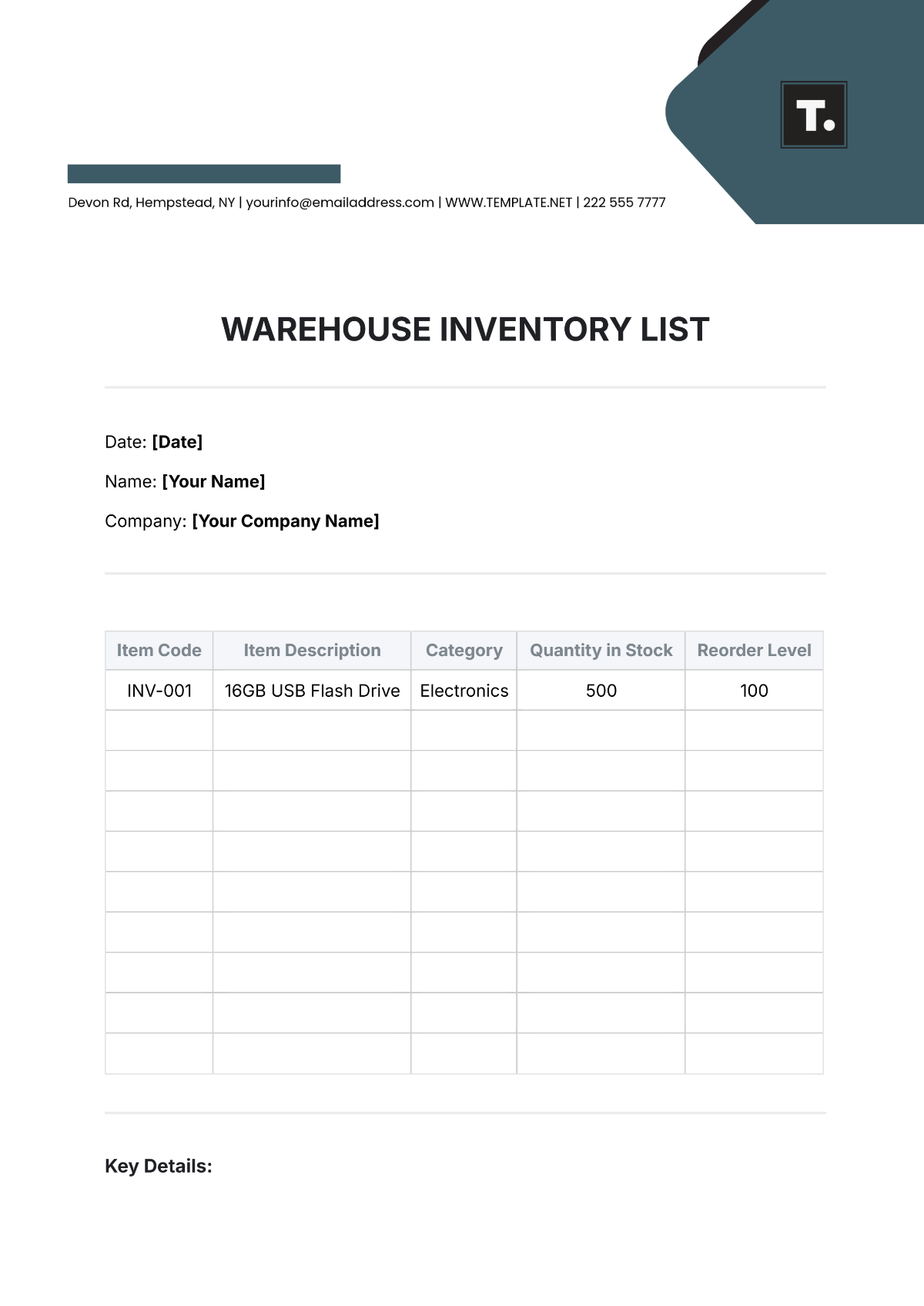

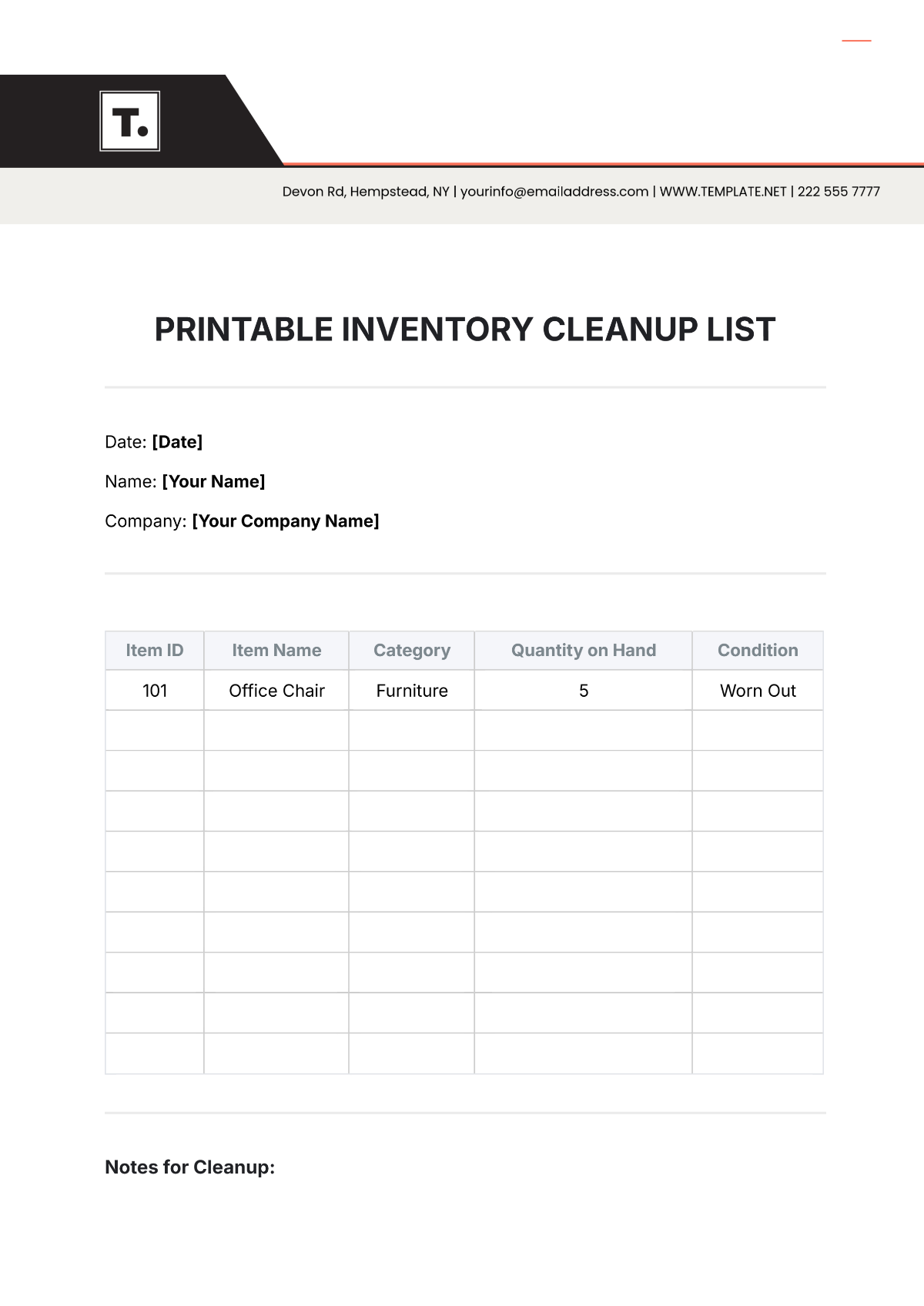

IV. Stock Reordering Policies

Establishing clear reordering policies helps maintain inventory levels that meet operational demands without overburdening storage or capital resources.

Reorder Thresholds: Minimum stock levels are established for each item to trigger reordering, ensuring no interruptions in operations or sales.

Supplier Lead Time: Accounting for supplier delivery times when placing orders ensures timely replenishment without risking stock outs.

Bulk Order Discounts: Taking advantage of discounts for bulk orders when feasible reduces per-unit costs and maximizes profitability.

Dynamic Reorder Adjustments: Reorder points are adjusted based on sales trends, seasonal demand, and market fluctuations.

Emergency Procurement Plans: Backup plans are in place for urgent restocking needs, including secondary suppliers or expedited shipping options.

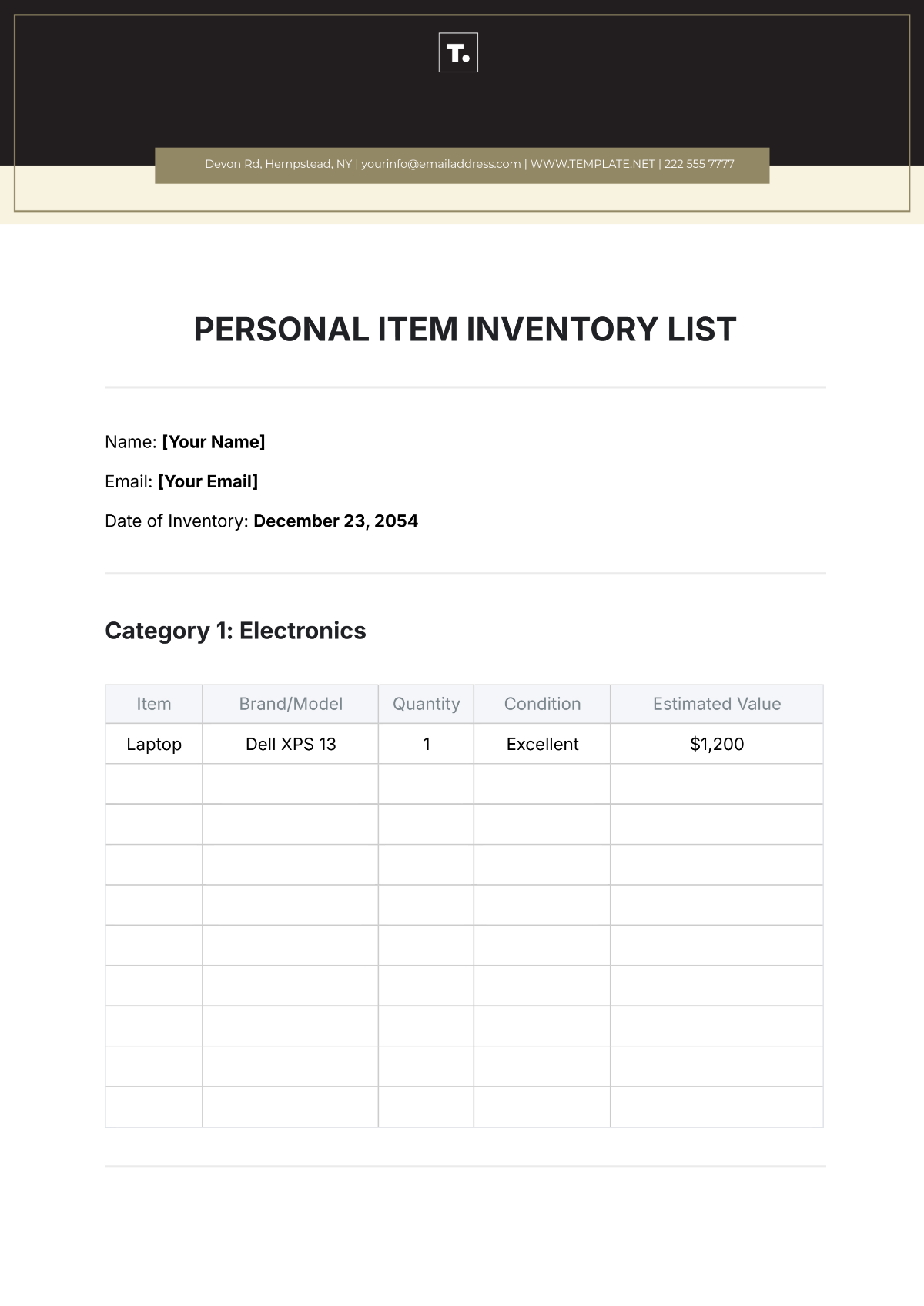

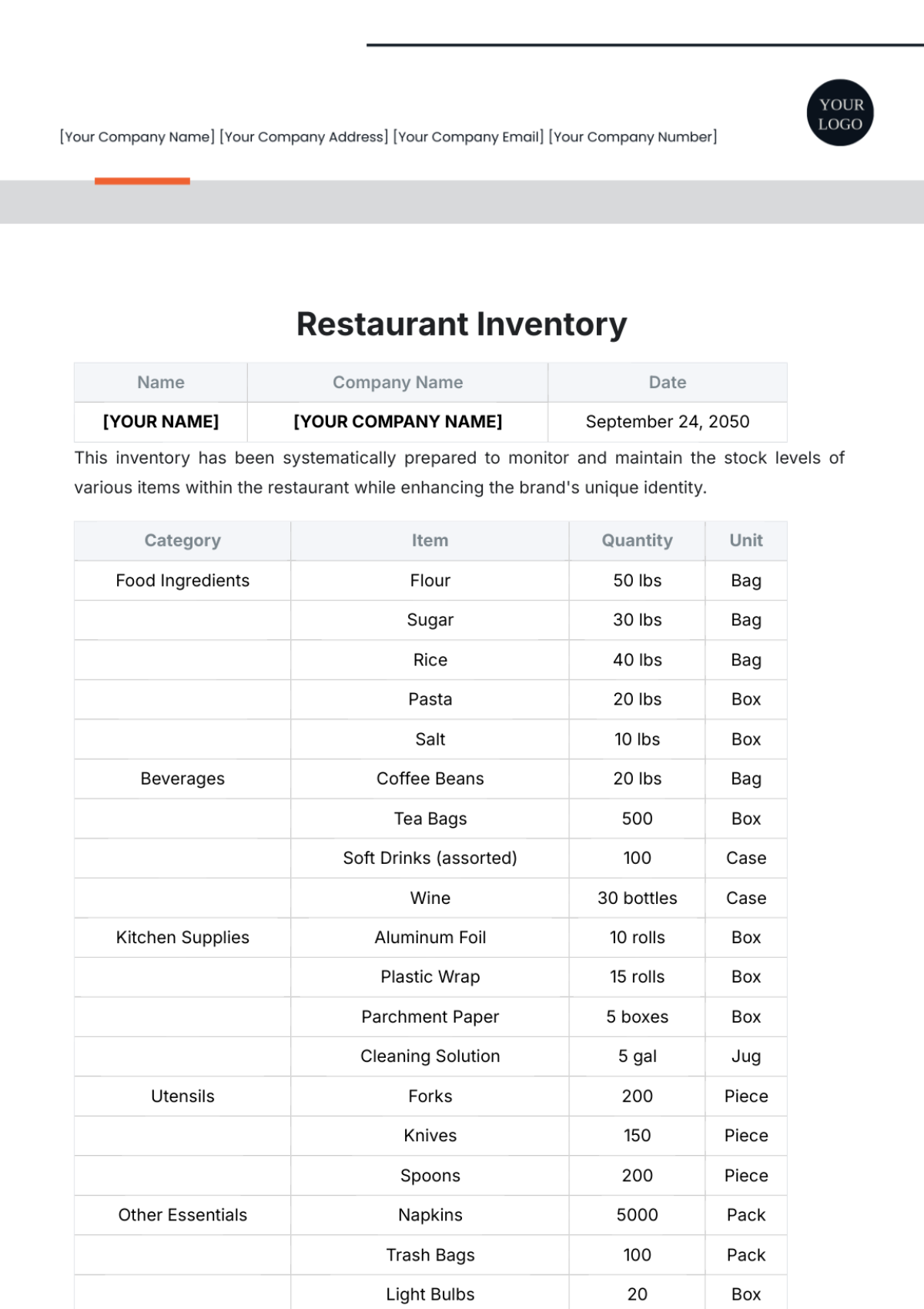

V. Inventory Storage Guidelines

Proper storage of inventory ensures product integrity, maximizes space utilization, and reduces the risk of damage or obsolescence.

Item Type | Storage Requirements |

|---|---|

Perishable Goods | Temperature-controlled environments to prevent spoilage. |

Fragile Items | Secured and padded shelves to minimize breakage during storage or handling. |

Bulky or Oversized Items | Dedicated storage areas with appropriate lifting and handling equipment. |

High-Value Stock | Secured locations with restricted access and monitoring systems to prevent theft or loss. |

Frequently Accessed Items | Storage near workstations or delivery points for easy retrieval and improved workflow efficiency. |

Categorized storage reduces inefficiencies and risks, ensuring every type of stock is handled according to its specific needs. This systematic approach improves inventory lifespan, accessibility, and safety.

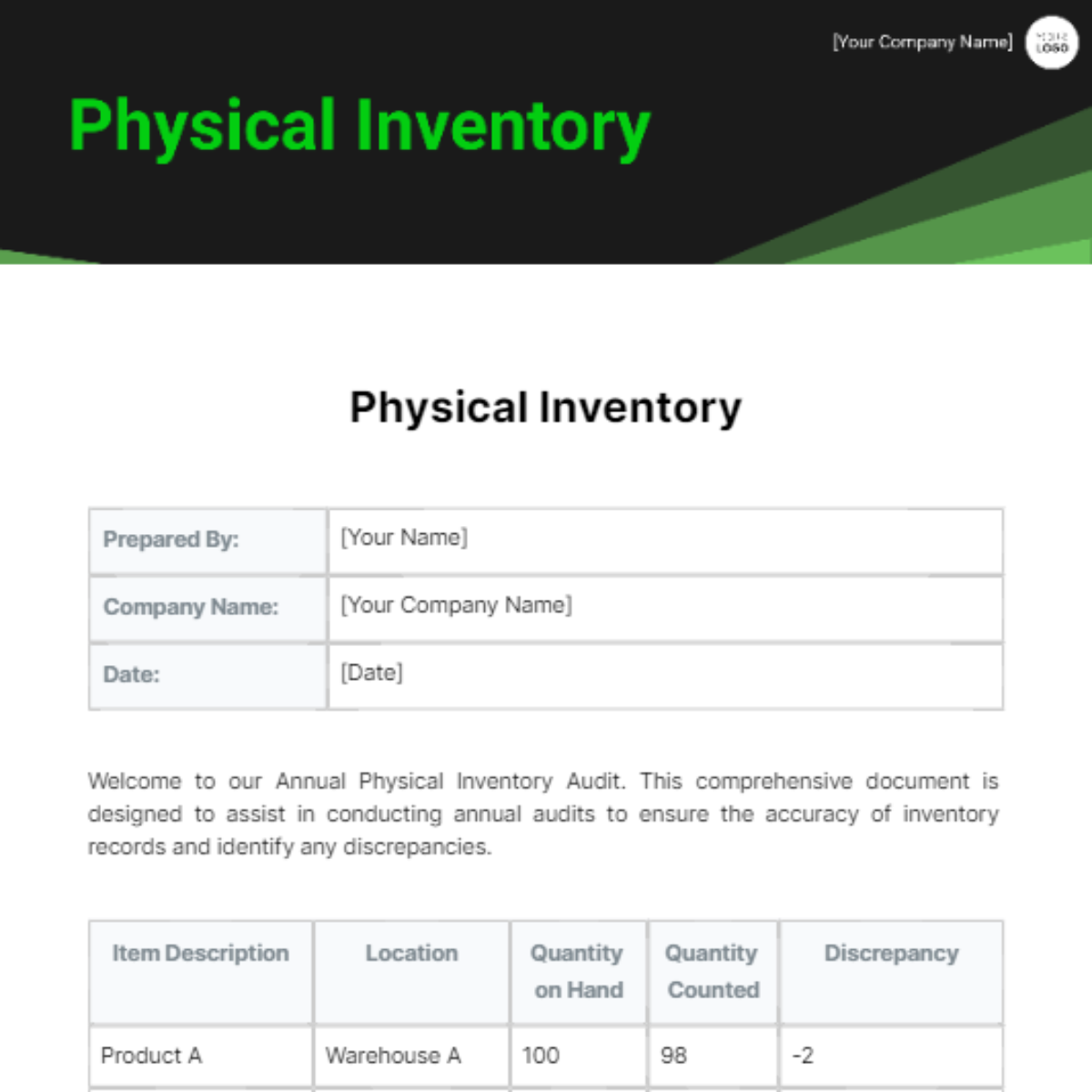

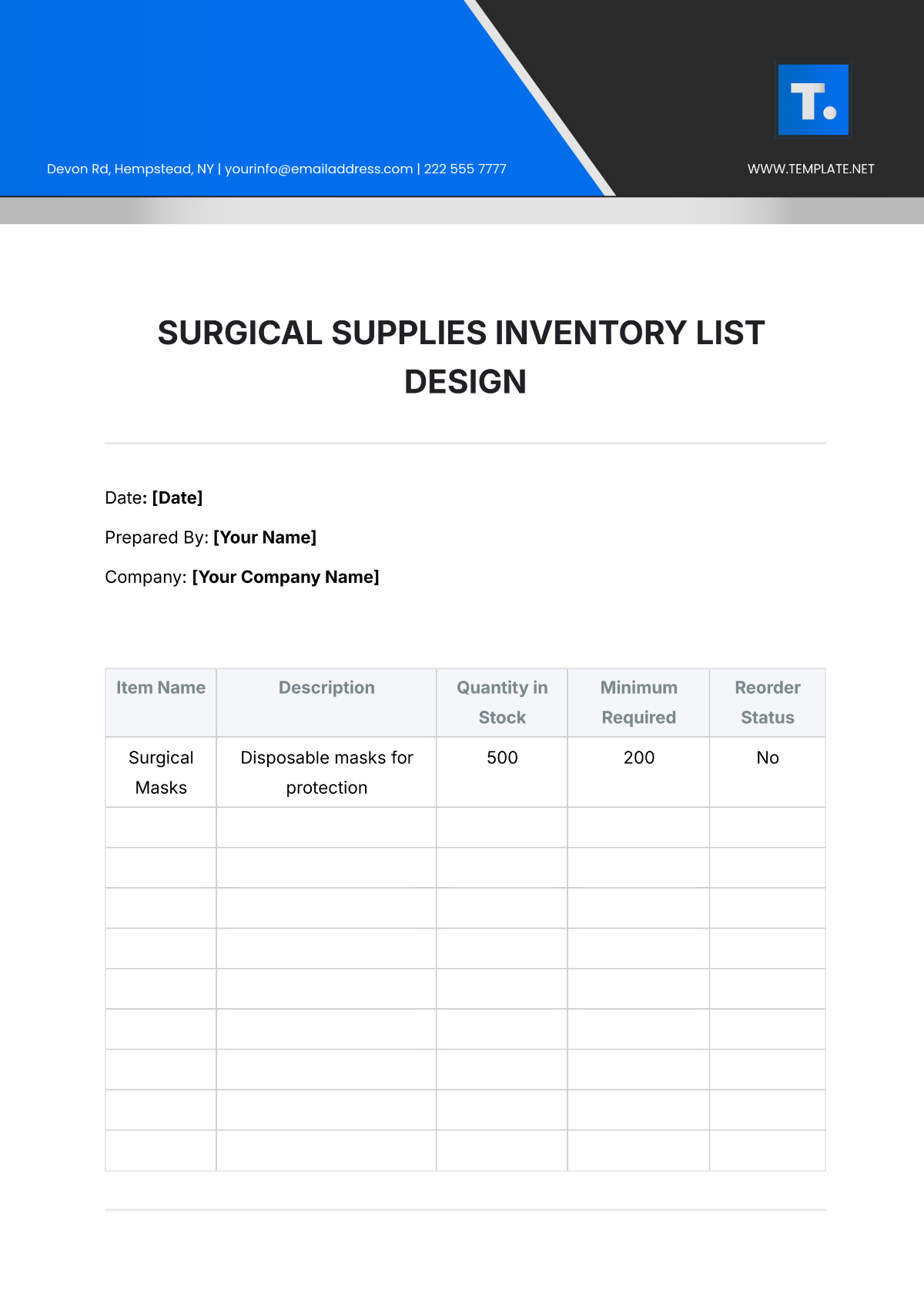

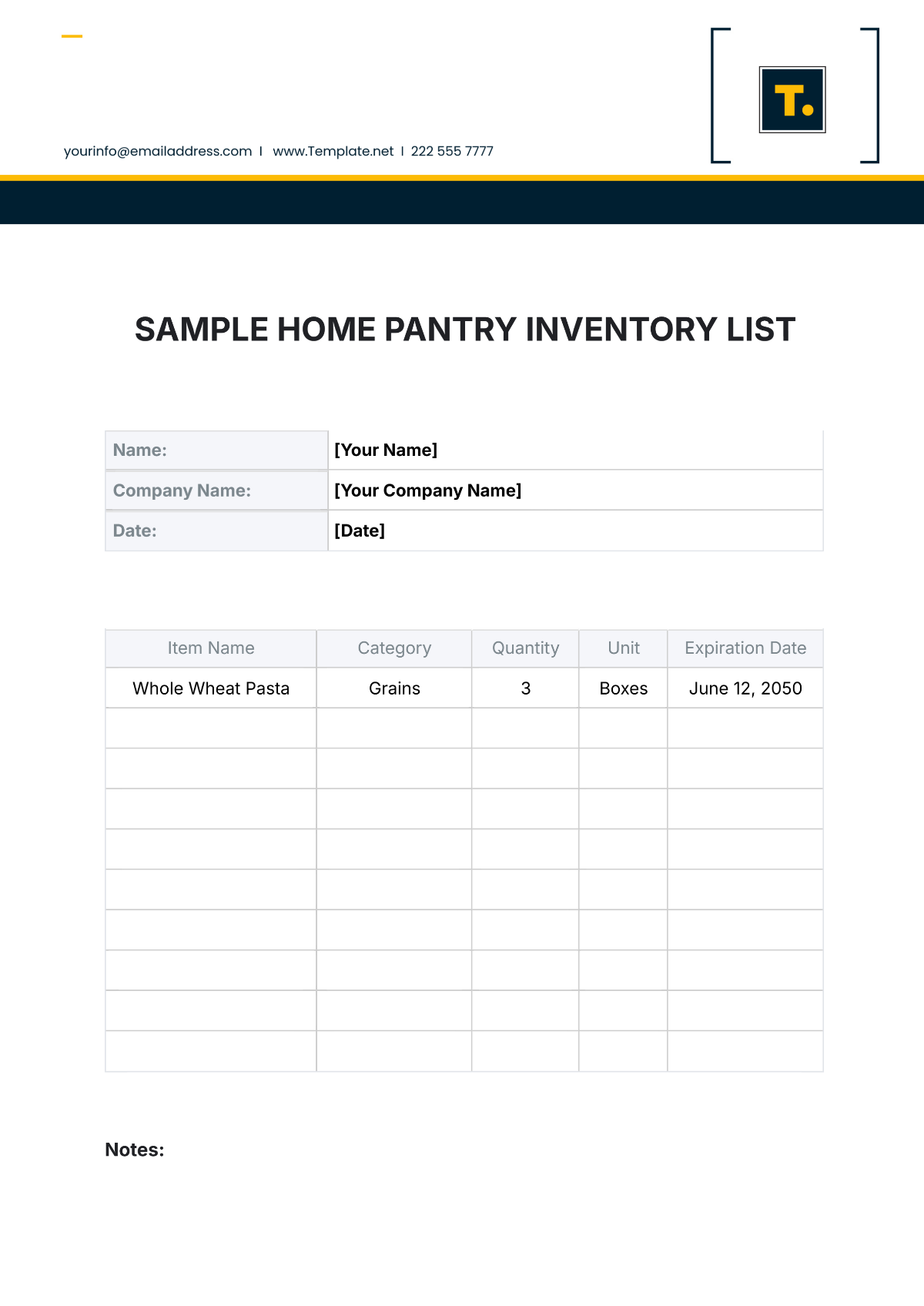

VI. Loss Prevention and Quality Control

Minimizing loss and maintaining quality are essential to inventory management. This section outlines preventative strategies to protect inventory from theft, damage, or obsolescence.

Regular Inspections: Periodic checks are performed to detect issues like damage or spoilage early, preserving product quality and reducing losses.

Employee Training: Staff is trained in proper handling techniques and loss prevention measures, ensuring accountability at all levels.

Security Measures: Surveillance systems, access controls, and inventory audits are implemented to deter theft and unauthorized access.

Expiration Tracking: Items with expiration dates are monitored closely to prioritize their use or sale, reducing waste.

Incident Documentation: Losses or quality issues are logged and reviewed to identify trends and implement corrective actions.

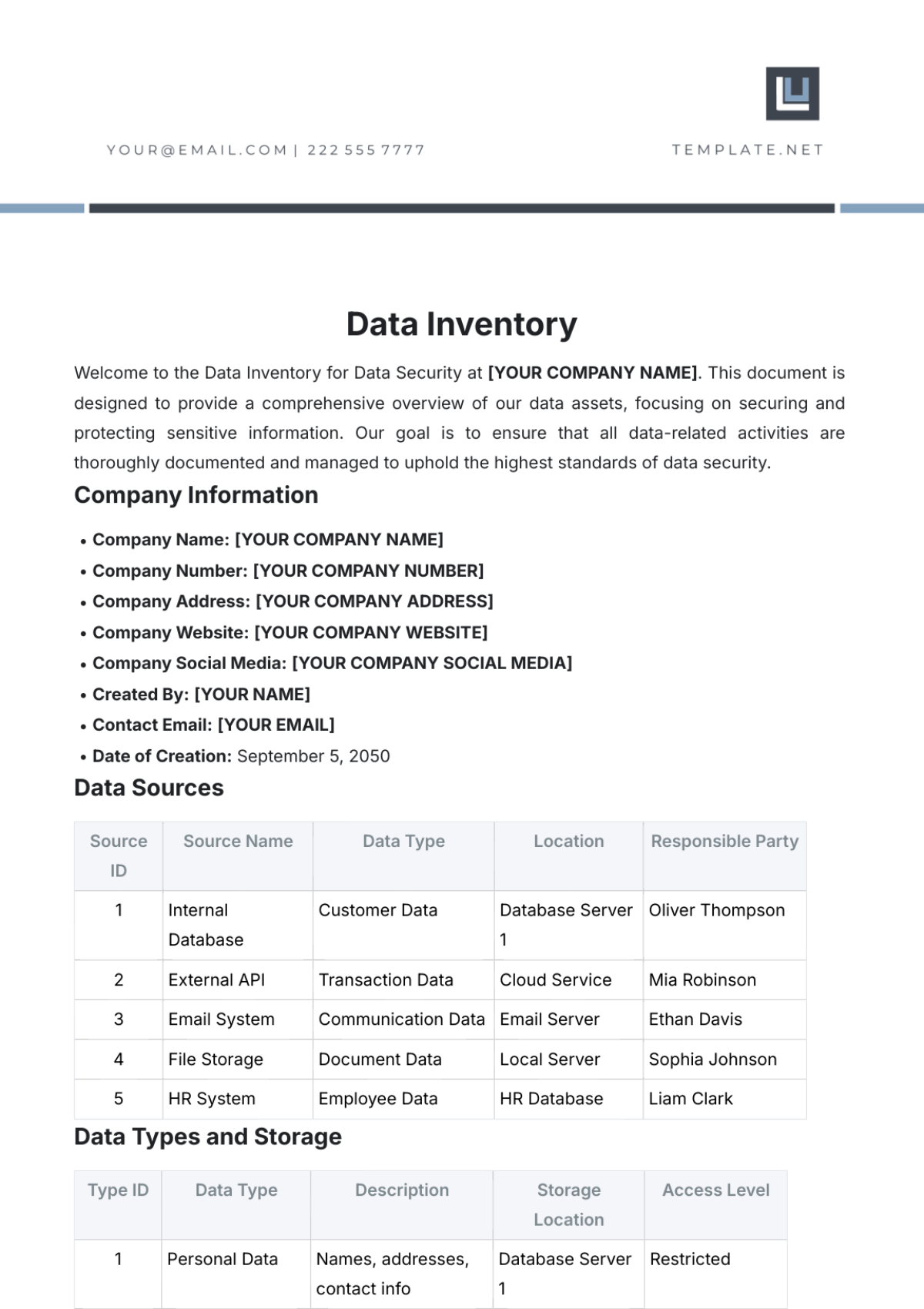

VII. Training and Development

Continuous training equips staff with the knowledge and skills needed to manage inventory effectively, adapt to technological changes, and maintain operational excellence.

Training Program | Schedule |

|---|---|

Inventory Management Basics | Bi-Annually |

Digital System Training | Quarterly |

Quality Assurance Procedures | Annually |

Supplier Coordination Skills | As Needed |

A regular training schedule ensures employees are always prepared to handle evolving inventory challenges. By investing in education, [Your Company Name] strengthens its operational foundation and reduces errors.

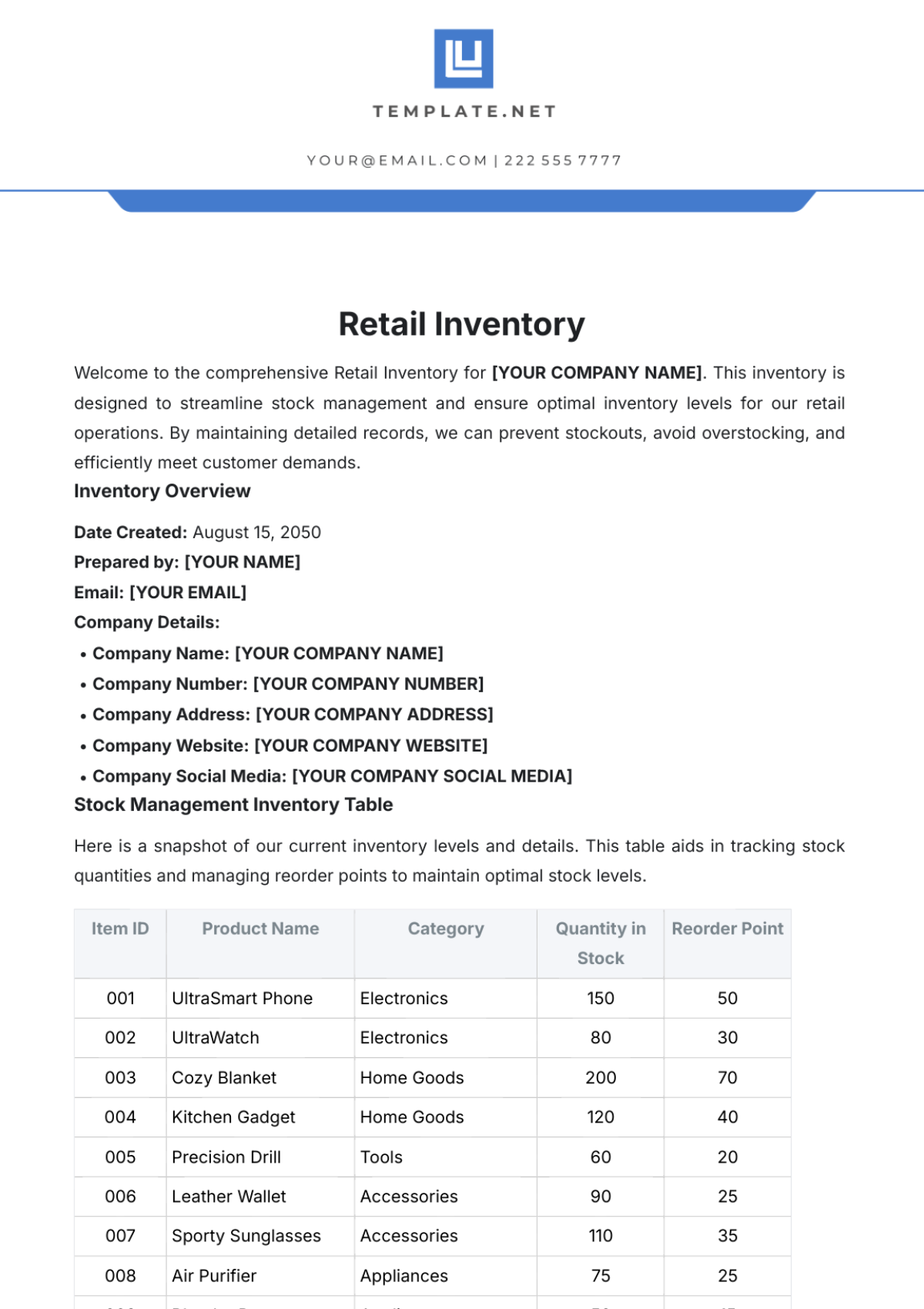

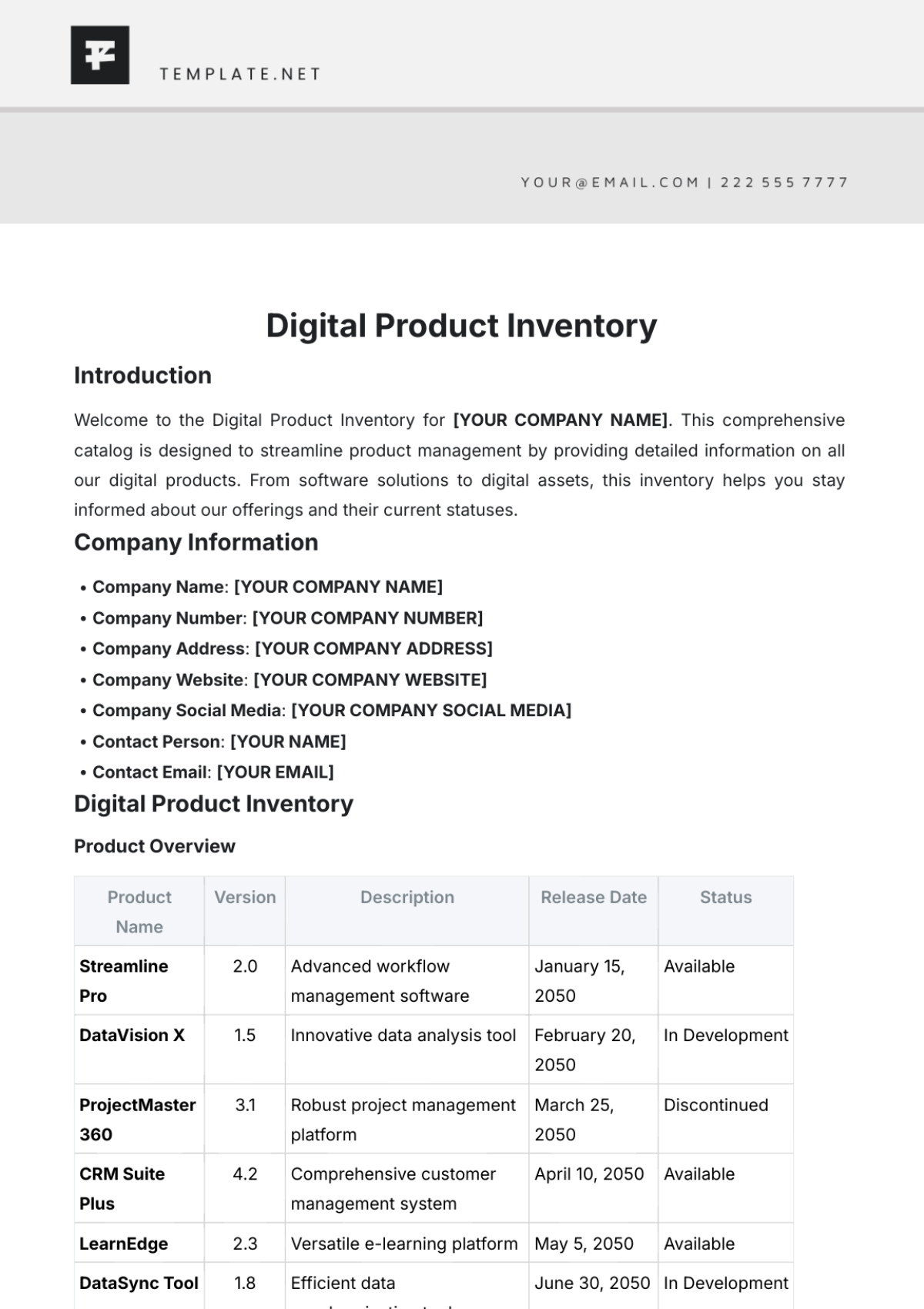

VIII. Performance Metrics and Reporting

To continuously improve inventory management, performance must be measured and reported regularly. This section defines key metrics and reporting processes.

Turnover Rates: Measures how quickly inventory is sold or used, indicating efficiency in stock management.

Accuracy Rate: Compares recorded inventory levels to actual stock during audits to identify discrepancies.

Cost of Holding Inventory: Tracks storage expenses, ensuring cost-effectiveness in maintaining stock levels.

Order Fulfillment Rate: Reflects the company’s ability to meet customer demand without delay or shortages.

Loss Ratios: Monitors the percentage of inventory lost due to theft, damage, or obsolescence, prompting corrective action.

IX. Continuous Improvement Strategies

Inventory management requires ongoing refinement to adapt to market changes and technological advancements.

Implementing AI Tools: Explore AI-based inventory forecasting systems to improve accuracy and reduce manual labor.

Supplier Relationship Building: Strengthen partnerships with suppliers to negotiate better terms and improve delivery reliability.

Feedback Loops: Use data and employee feedback to identify areas for improvement in inventory policies and practices.

Sustainability Practices: Introduce eco-friendly storage and procurement practices to reduce environmental impact.

Regular Policy Updates: Revise inventory management guidelines annually to reflect current trends and operational learnings.

The Inventory Management Guide serves as a roadmap to effective inventory control, emphasizing accuracy, organization, and adaptability. By adhering to these practices, the company ensures efficient operations, customer satisfaction, and long-term sustainability. Regular reviews and improvements will keep the system dynamic and aligned with future needs.