Free Automotive Inventory Management

I. Introduction

Inventory management is critical to the success of [Your Company Name], ensuring that operations run smoothly and customer demands are met without unnecessary delays. This document outlines key policies, procedures, and strategies to maintain efficient inventory practices, minimizing costs while maximizing operational efficiency.

Purpose of Inventory Management

The primary purpose is to ensure a consistent supply of materials, parts, and finished products, avoiding disruptions in manufacturing and sales. Effective inventory management directly impacts customer satisfaction and profitability.

II. Inventory Categorization

Proper categorization of inventory ensures clarity and enables efficient allocation of resources for procurement and storage. The automotive company must recognize and manage different inventory types based on their unique requirements.

Work-in-Progress (WIP): Refers to partially completed assemblies awaiting further processing. Regular assessments ensure minimal WIP accumulation, reducing holding costs.

Finished Goods: These are completed vehicles and spare parts ready for distribution. Accurate demand forecasting ensures optimal stock levels.

Maintenance, Repair, and Operating (MRO) Supplies: Includes tools, lubricants, and spare parts used in production machinery. A safety stock of MRO items prevents delays caused by equipment breakdowns.

Obsolete Inventory: Items no longer usable or in demand, such as outdated spare parts. Effective disposal policies reduce storage costs and free up warehouse space.

Raw Materials

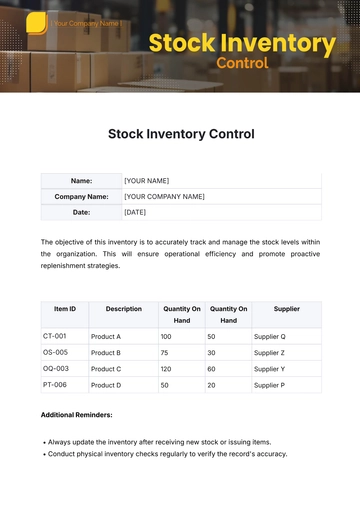

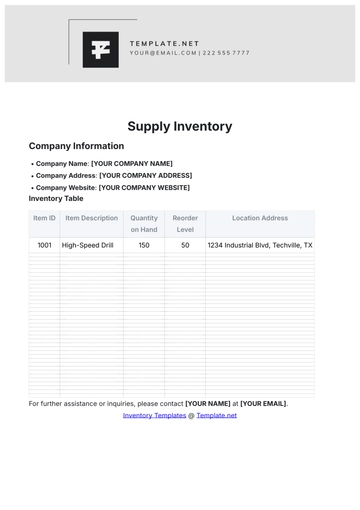

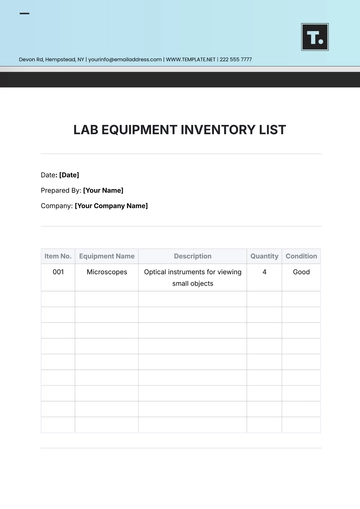

Proper categorization of raw materials ensures streamlined procurement and inventory management, critical for uninterrupted production. Below is a table outlining key aspects of raw materials used in the company.

Material Type | Procurement Lead Time | Storage Requirements | Criticality Level |

|---|---|---|---|

Metals | 2-4 weeks | Dry, temperature-controlled areas to prevent corrosion. | High |

Plastics | 3-6 weeks | Cool, dark storage to prevent degradation. | Medium |

Rubber | 4-8 weeks | Humidity-controlled storage to prevent cracking. | High |

Glass | 3-5 weeks | Fragile, needs protective packaging and careful handling. | Medium |

Electronic Components | 8-12 weeks | Anti-static, temperature-controlled storage. | High |

III. Inventory Monitoring and Control

Monitoring and controlling inventory involves systematic processes to track quantities, ensure accuracy, and optimize costs. This section outlines practices to maintain inventory reliability and responsiveness.

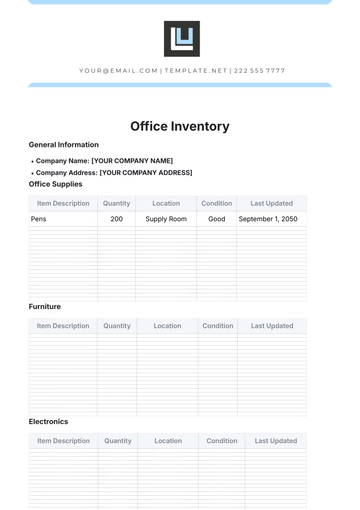

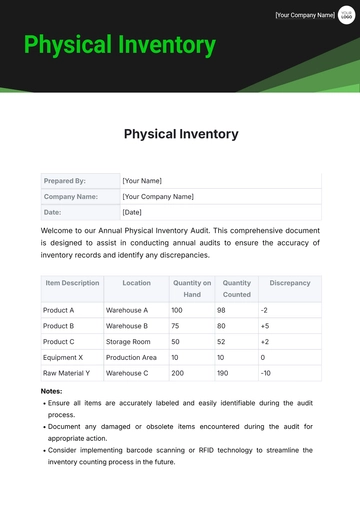

Inventory Auditing: Conduct regular physical counts and reconcile with system records to identify discrepancies. Auditing prevents shrinkage and ensures data accuracy.

ABC Analysis: Classify inventory based on value and usage frequency to prioritize management efforts. Focus more on high-value or high-demand items for enhanced control.

Reorder Point System: Set thresholds for automatic replenishment of stock, avoiding overstock or stock outs. Regularly review these points to align with demand changes.

Cycle Counting: Conduct partial counts of selected inventory items periodically instead of annual audits. This ensures ongoing accuracy without disrupting operations.

Key Performance Indicators (KPIs): Monitor metrics like inventory turnover ratio, carrying costs, and order accuracy. These KPIs provide insights into efficiency and areas for improvement.

IV. Technological Solutions

Leveraging technology can streamline inventory management processes, reducing errors and enhancing efficiency. This section highlights digital tools and systems suitable for an automotive company.

Enterprise Resource Planning (ERP) Systems: Integrate inventory data with production, procurement, and sales functions. ERP systems enable real-time tracking and better decision-making.

Barcode and RFID Technologies: Use these tools for precise identification and tracking of inventory. They minimize human error and accelerate warehouse operations.

Automated Storage and Retrieval Systems (AS/RS): Implement robotics to optimize space utilization and reduce labor costs. These systems are especially beneficial for large warehouses.

Inventory Management Software: Use specialized software for forecasting, ordering, and reporting. Such software reduces manual tasks and improves accuracy.

Internet of Things (IoT): Sensors and connected devices provide real-time data on inventory conditions, such as temperature or location. IoT enhances inventory visibility and control.

V. Inventory Performance Assessment

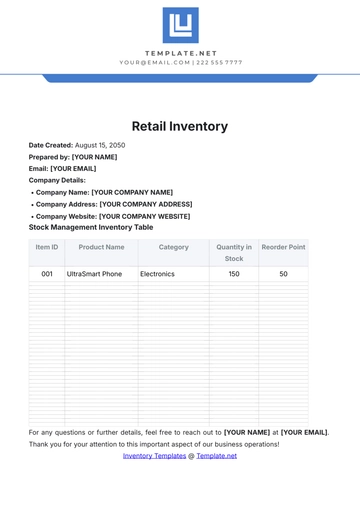

Assessing inventory performance involves analyzing metrics to identify strengths and areas needing improvement. The table below summarizes key performance indicators (KPIs) for effective inventory evaluation.

KPI | Definition | Target |

|---|---|---|

Inventory Turnover Ratio | Measures how many times inventory is sold and replaced over a period. | 8-12 times/year |

Order Accuracy Rate | Percentage of orders delivered without errors. | 98% or higher |

Carrying Cost Percentage | Cost of holding inventory as a percentage of its value. | < 20% |

Stock Out Rate | Percentage of times items are unavailable when needed. | < 5% |

Lead Time | Time taken to replenish inventory from order placement to receipt. | < 2 weeks |

VI. Supplier Relationship Management

Strong relationships with suppliers are fundamental to efficient inventory management, ensuring timely delivery of quality materials. Proactive supplier management minimizes risks and supports the company’s ability to adapt to changing demands.

Supplier Selection Criteria: Establish clear standards for selecting suppliers, including quality, reliability, and cost-effectiveness. Choosing the right partners reduces delays and ensures consistent material supply.

Supplier Performance Evaluation: Regularly assess supplier performance using metrics like on-time delivery, quality compliance, and responsiveness. Feedback sessions help maintain high standards and address any concerns.

Long-Term Partnerships: Develop strategic alliances with key suppliers to foster mutual trust and commitment. Such partnerships encourage suppliers to prioritize the company’s needs during high-demand periods.

Collaborative Planning: Engage suppliers in demand forecasting and inventory planning to improve synchronization. Shared insights lead to better resource allocation and reduced supply chain disruptions.

Risk Mitigation Strategies: Work with suppliers to establish contingency plans for potential disruptions, such as alternative shipping routes or backup production facilities. Collaboration enhances the company’s resilience to unforeseen challenges.

VII. Contingency Planning

Unexpected events like supplier disruptions or demand surges can impact inventory levels. A contingency plan ensures the company remains prepared to respond effectively to such scenarios.

Safety Stock Management: Maintain buffer stock for critical components to manage supply chain uncertainties. This practice minimizes risks of production downtime.

Supplier Diversification: Establish relationships with multiple suppliers for key materials. Diversification reduces dependence on a single source, ensuring continuity.

Emergency Procurement Processes: Develop expedited procedures for sourcing items during crises. These processes should include pre-approved vendors and quick payment options.

Scenario-Based Simulations: Conduct regular drills to test the inventory management system’s response to hypothetical disruptions. This helps identify and address potential gaps.

Communication Protocols: Define clear communication channels and responsibilities for handling emergencies. Rapid information sharing enables swift and coordinated action.

This document serves as a guide to best practices, offering strategies for optimizing inventory processes and ensuring readiness for unforeseen challenges. Regular performance assessments, as detailed here, will enable [Your Company Name] to identify inefficiencies and adapt swiftly to industry changes.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Optimize inventory tracking with the Automotive Inventory Management Template available on Template.net. This editable and customizable tool enables businesses to monitor stock levels, and inventory needs effectively. The Ai Editor Tool allows customization to suit specific operational workflows. Integrate this template into your operations to achieve better control over your automotive inventory.