Free Pharmaceutical Inventory Management

I. Introduction

A. Purpose and Scope

The purpose of [Your Company Name]'s Pharmaceutical Inventory Management system is to ensure a consistent supply of medications while minimizing wastage, theft, and stockouts. It covers the processes for purchasing, storing, tracking, and distributing pharmaceutical products in a healthcare setting. This system supports the broader goal of providing safe, effective, and timely access to medications for patients.

B. Objectives of Inventory Management

The primary objectives are to optimize stock levels, improve medication availability, and ensure that drugs are stored safely and efficiently. It aims to reduce operational costs associated with overstocking or stockouts. Additionally, it ensures compliance with regulatory requirements for pharmaceutical handling, safety, and distribution.

C. Importance of Inventory Management in Pharmacy

Effective inventory management ensures that pharmacies can meet patient needs without delay or risk to patient safety. By keeping precise records, pharmacies reduce the likelihood of dispensing errors and medication wastage. This is particularly important in hospital pharmacies where patients rely on timely access to critical medications.

D. Regulatory and Compliance Considerations

Pharmacies must adhere to a variety of regulations, including those related to controlled substances and expiration dates. Inventory systems must support accurate reporting and auditing for compliance with local, state, and federal regulations. Additionally, pharmacies must ensure that all records are properly maintained for inspection by regulatory authorities.

II. Inventory Management System Overview

A. Manual vs. Automated Systems

Manual inventory uses paper and spreadsheets, prone to errors, while automated systems use barcoding and software for real-time tracking, enhancing accuracy and efficiency. The choice depends on the pharmacy's operational size and complexity.

Aspect | Manual Systems | Automated Systems |

|---|---|---|

Efficiency | Time-consuming, requires manual data entry | Fast, real-time updates, reduces human error |

Accuracy | Prone to human error and inconsistencies | Highly accurate with automated tracking and updates |

Cost | Low upfront cost but labor-intensive | Higher initial investment, but long-term cost savings |

Tracking & Visibility | Limited tracking capabilities, more reliant on physical checks | Provides real-time tracking, instant visibility |

Flexibility | Flexible for small operations with less tech support | Scalable for large operations, integrates with other systems |

Integration | Limited or no integration with other systems | Seamless integration with purchasing, accounting, and POS |

B. Key Components of an Inventory Management System

Key components include stock categorization, real-time tracking, reordering mechanisms, and expiry date management. Additionally, a reliable inventory system integrates seamlessly with purchasing, accounting, and patient care systems. These components work together to maintain an efficient flow of pharmaceutical products.

C. Role of Technology in Inventory Management

Technology plays a vital role in modernizing inventory processes, from tracking stock levels using barcode scanners to utilizing cloud-based software for real-time updates. Automation tools help forecast demand and optimize reordering cycles, reducing human error. Integration with other healthcare systems improves accuracy and ensures that pharmacists have up-to-date information for decision-making.

D. System Integration with Other Healthcare Functions

An effective inventory system must be integrated with pharmacy management, point-of-sale (POS) systems, and patient care software. Integration ensures that stock levels are updated in real-time as medications are dispensed. This interconnection also enhances medication safety and improves patient care by providing accurate medication history and availability data.

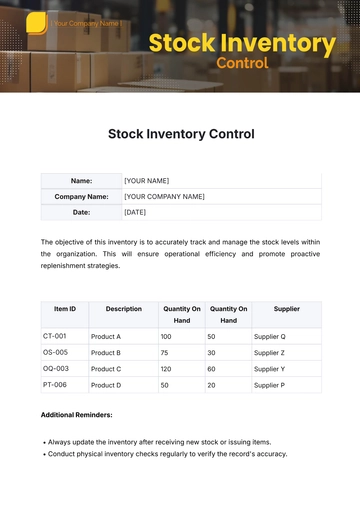

III. Stock Control Procedures

A. Stock Categorization

Medications are categorized by type, usage, and regulation: controlled substances need strict tracking and storage, emergency stock must be always available, and regular medications are replenished based on demand.

Aspect | Manual Systems | Automated Systems |

|---|---|---|

Regular Stock | Medications that are regularly in demand, with consistent usage | Pain relievers, antibiotics |

Controlled Substances | Drugs that require stricter monitoring and security due to abuse potential | Opioids, narcotics |

Emergency Stock | Critical medications needed for urgent care or emergency situations | EpiPens, adrenaline, insulin |

Short-Life Medications | Drugs with shorter shelf lives that need more frequent monitoring | Vaccines, biologics, certain IV drugs |

Special Order Items | Products not frequently needed but must be available for specific cases | Chemotherapy drugs, rare antibiotics |

B. Minimum and Maximum Stock Levels

Establishing minimum and maximum stock levels helps prevent both overstocking and stockouts. Minimum levels ensure that the pharmacy always has enough stock to meet demand, while maximum levels prevent excessive stock that could lead to waste. These thresholds are based on historical usage patterns, lead times, and expected demand fluctuations.

C. Replenishment Triggers and Reordering Policies

Replenishment triggers activate automatic reordering or notify staff when stock hits the minimum level, based on policies detailing order frequency, suppliers, and bulk options for cost savings, while considering lead times and delivery schedules for timely stock.

Trigger Type | Description | Reordering Action |

|---|---|---|

Reorder Point | When stock falls below a predetermined threshold, the system triggers a reorder | Generate purchase order or notification to restock |

Lead Time | The time between placing an order and receiving the goods | Order should be placed in advance to allow for delivery time |

Safety Stock | Extra stock kept to avoid running out due to demand surges or delays in supply | Add a buffer to the reorder quantity to prevent stockouts |

Seasonal Demand | Changes in demand based on seasons, trends, or promotions | Adjust reorder quantities based on past seasonal usage |

Bulk Purchases | Ordering in larger quantities to take advantage of discounts or ensure availability | Place bulk orders with longer shelf life or lower cost per unit |

D. Stock Rotation: FIFO and Expiry Management

The First-In-First-Out (FIFO) method ensures that the oldest stock is used first, reducing the likelihood of expired medications. Expiry dates are regularly monitored and flagged for attention, ensuring that products nearing expiration are used or returned. This approach minimizes waste and ensures that only effective medications are dispensed to patients.

IV. Inventory Tracking and Control

A. Barcode and RFID Technologies

Barcodes and RFID (Radio Frequency Identification) tags are used to track the movement of pharmaceutical products through the supply chain. Scanning barcodes during stock intake and dispensing ensures accuracy and reduces human error. RFID technology further enhances tracking by providing real-time visibility into the location and status of each product.

B. Stock Movement Tracking (In, Out, and Transfer)

Tracking the movement of inventory, including stock received, dispensed, and transferred between locations, is crucial for maintaining accurate records. Inventory systems log each movement to create a clear audit trail. This process helps prevent discrepancies and ensures that stock is where it is needed when it is needed.

C. Real-Time Inventory Updates and Reporting

A modern inventory management system updates stock levels in real-time, reflecting any changes immediately across all relevant departments. This allows pharmacy managers and staff to access the most current data when making decisions about stock levels, ordering, and dispensing. Real-time updates also improve patient safety by reducing the chances of dispensing the wrong medication due to outdated stock data.

D. Use of Inventory Management Software

Inventory management software is essential for automating stock control, tracking, and reporting. It allows users to monitor stock levels, generate reports, and manage reordering with minimal manual intervention. Additionally, these systems can integrate with other software platforms, enhancing overall pharmacy workflow efficiency.

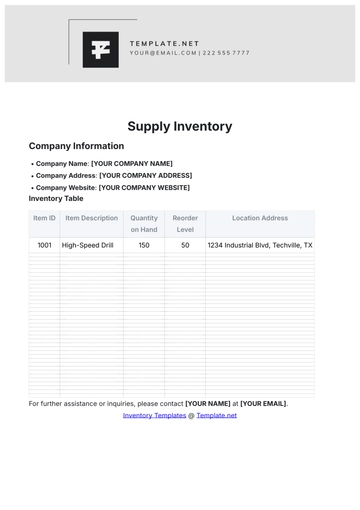

V. Procurement and Supplier Management

A. Vendor Selection and Evaluation

Pharmacy managers should carefully select vendors based on product quality, reliability, and cost-effectiveness. Evaluation criteria may include delivery times, supplier reputation, and their ability to handle urgent orders. Long-term relationships with reputable suppliers are vital for maintaining a steady and reliable supply of pharmaceuticals.

B. Order Planning and Purchasing Procedures

Order planning involves predicting future medication needs based on historical usage data and seasonal trends. Purchasing procedures ensure that medications are ordered on time, in the right quantities, and at the best prices. Bulk purchasing or negotiated discounts with suppliers can help reduce costs while maintaining adequate stock levels.

C. Receipt of Goods

Upon receiving pharmaceutical orders, it is essential to inspect shipments for accuracy and damage. Staff must verify that the correct products, quantities, and lot numbers match the order details. Any discrepancies should be documented and reported to the supplier promptly for resolution.

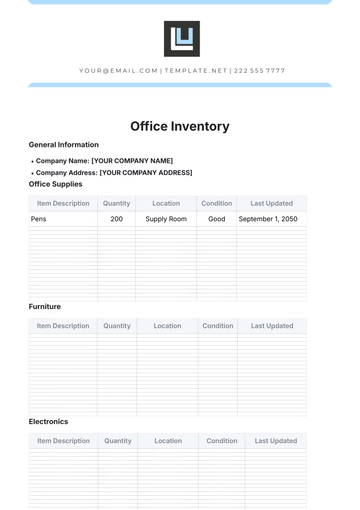

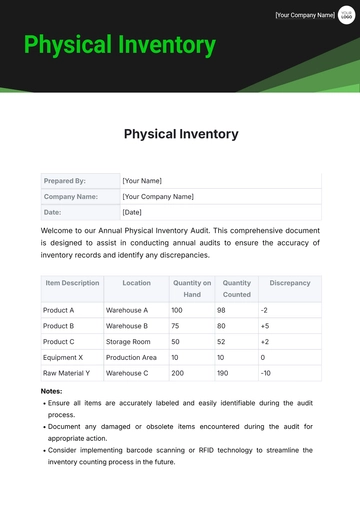

VI. Inventory Auditing and Reconciliation

A. Periodic Physical Inventory Checks

Periodic audits are conducted to physically verify the inventory in stock and ensure that it matches the records in the inventory system. These audits are typically done annually, quarterly, or as required based on the pharmacy’s size and the volume of products handled. Physical counts help detect any discrepancies, such as missing items or incorrect stock levels.

B. Reconciliation Process

Reconciliation involves comparing the physical inventory count with the digital records in the system to identify any discrepancies. If differences are found, they should be thoroughly investigated to determine their cause, whether it's due to theft, miscounting, or system errors. Corrective actions are then taken, such as updating inventory records or reporting incidents to the appropriate authorities.

C. Role of Audit Trails in Compliance

Audit trails are essential for tracking all changes made to the inventory system, providing a clear record of actions and approvals. These logs ensure accountability and transparency, which are crucial for regulatory compliance. In the event of an audit, these trails provide a defensible record of inventory practices and discrepancies.

VII. Security and Loss Prevention

A. Securing Controlled Substances

Controlled substances must be stored in secure, locked environments such as safes or cabinets that meet regulatory standards. Access to these substances should be restricted to authorized personnel only, with clear procedures for logging every transaction. Regular audits and inspections should be performed to ensure compliance with security regulations and prevent unauthorized access.

B. Preventing Theft and Diversion

The pharmacy should implement robust loss prevention measures, such as surveillance cameras and employee training on recognizing suspicious activities. Stock levels should be regularly monitored, and discrepancies should be investigated promptly. By establishing clear policies and protocols for handling high-risk medications, pharmacies can significantly reduce the chances of theft or diversion.

C. Inventory Loss Reporting and Investigation

In the event of inventory loss or theft, a formal reporting and investigation process must be followed. Detailed records should be kept of all incidents, and investigations should aim to identify the root cause of the loss, whether it is due to human error or intentional theft. Corrective actions should be taken to prevent future losses, and the findings should be reported to relevant regulatory authorities when necessary.

VIII. Expiry Management and Disposal

A. Monitoring Expiry Dates

A key element of pharmaceutical inventory management is closely monitoring the expiration dates of medications. Automated systems can send alerts as products approach their expiration dates, ensuring that staff are aware of the need to rotate stock or use products before they become unfit for use. Regular manual checks complement these alerts to ensure no product is overlooked.

B. Safe Disposal of Expired or Unwanted Medications

Expired medications should be disposed of in a manner that adheres to environmental and legal guidelines. Many medications require specialized disposal processes to prevent contamination or misuse, such as incineration or secure collection bins. Compliance with local regulations regarding drug disposal is essential to ensure safety and avoid fines or legal consequences.

C. Record-Keeping of Expired Products

Proper documentation of expired or disposed medications is necessary for regulatory compliance and auditing purposes. Records should include details of the medication, its expiration date, the reason for disposal, and the method used. These records should be kept for a specific duration, as stipulated by law, to ensure transparency and accountability in the disposal process.

IX. Reporting and Analytics

A. Inventory Reports

Inventory reports should provide an accurate snapshot of stock levels, identifying any discrepancies or potential issues with supply. Reports should be generated regularly to track usage patterns, monitor stock rotations, and ensure that stock levels are aligned with demand. These reports can help pharmacy managers make data-driven decisions about future stock orders and purchasing strategies.

B. Usage and Consumption Analysis

By analyzing medication consumption trends, pharmacies can forecast demand more accurately and avoid stockouts or overstocking. Usage reports should identify fast-moving and slow-moving medications, helping to optimize inventory and reduce waste. This analysis is crucial for identifying patterns in seasonal demand or changing healthcare needs.

C. Financial Reports

Financial reports, such as Cost of Goods Sold (COGS) and inventory turnover ratios, are vital for assessing the financial health of the pharmacy's inventory. These reports help track the cost-effectiveness of inventory management practices, enabling better budgeting and cost control. Financial insights also inform purchasing decisions, helping to balance cost savings with stock availability.

D. Compliance and Regulatory Reporting

Pharmacies must maintain accurate records for regulatory bodies, especially concerning controlled substances and other regulated drugs. Reporting should include detailed records of drug purchases, usage, and wastage, as well as any incidents of theft or loss. These reports must be prepared in accordance with federal and state laws to ensure compliance and avoid penalties.

X. Training and Staff Management

A. Staff Training on Inventory Procedures

Training staff is essential to ensure that all personnel involved in inventory management understand the correct procedures for ordering, storing, and dispensing medications. Regular training should cover topics such as stock rotation, managing controlled substances, and using inventory software. Well-trained staff are critical to maintaining a smooth and compliant inventory system.

B. Role Assignments and Responsibilities

Clear role assignments help ensure accountability within the inventory management process. Staff should be assigned specific responsibilities, such as receiving stock, auditing inventory, or managing orders, to streamline workflow. This approach helps prevent confusion and ensures that each step in the process is carried out accurately and efficiently.

C. Ongoing Education and Compliance Updates

Pharmacy staff should receive ongoing education to keep up with new regulations, best practices, and technological advancements in inventory management. Regular refresher courses ensure that employees stay informed about any changes to policies or regulations that may affect inventory management. This continuous learning helps prevent errors and ensures compliance with evolving standards.

XI. Regulatory Compliance and Best Practices

A. Adherence to Local and International Laws

Compliance with local, state, and federal laws is a cornerstone of effective pharmaceutical inventory management. Pharmacies must ensure that all inventory practices, from procurement to disposal, align with legal requirements, particularly for controlled substances. Non-compliance can result in fines, legal action, or harm to patients, so adherence to these regulations is non-negotiable.

B. Good Distribution Practices (GDP) and Good Manufacturing Practices (GMP)

Pharmacies must follow Good Distribution Practices (GDP) and Good Manufacturing Practices (GMP) to ensure that medications are stored, handled, and transported safely and effectively. These practices ensure product quality and integrity, reducing the risk of contamination or degradation. Following GDP and GMP guidelines also enhances a pharmacy's reputation for providing safe, reliable medications.

C. Documentation and Reporting Standards

Pharmaceutical inventory management requires meticulous documentation, including records of purchases, stock movements, and disposal. This documentation serves as evidence for regulatory compliance and is essential for audits. Pharmacies must adhere to strict reporting standards to ensure transparency and avoid potential legal issues.

D. Compliance with HIPAA and Other Data Protection Laws

Pharmacies must protect patient data and comply with data protection laws, such as HIPAA, to maintain confidentiality and patient trust. Inventory management systems should be designed to prevent unauthorized access to patient and medication information. Compliance with data protection regulations is critical for safeguarding sensitive information and avoiding penalties.

XII. Continuous Improvement and Feedback

A. Monitoring Performance and Identifying Issues

Regularly monitoring the performance of the inventory management system helps identify areas for improvement. KPIs like stock turnover, order accuracy, and waste levels must be tracked to ensure optimal pharmacy inventory.

B. Feedback Loop with Staff and Stakeholders

Establishing a feedback loop with pharmacy staff and other stakeholders ensures that all parties can contribute to improving inventory management practices. Regular meetings or surveys gather input for improvements, fostering continuous growth and quick issue resolution.

C. Technological Advancements in Inventory Management

Pharmacies should regularly evaluate emerging technologies that can improve inventory management, such as artificial intelligence (AI) or machine learning algorithms. These technologies offer predictive analytics and task automation, easing staff workload. Keeping up with tech advancements helps the pharmacy stay competitive and efficiently manage inventory.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Simplify your Pharmaceutical Inventory Management with Template.net's fully editable and customizable template. Designed to streamline your workflow, this template allows you to effortlessly track, organize, and manage stock. With the AI Editor Tool, you can make real-time adjustments and tailor the template to your specific needs, ensuring efficiency and accuracy in your pharmacy operations.