Cost Benefit Analysis with NPV

I. Executive Summary

This document provides a comprehensive Cost-Benefit Analysis (CBA) for the implementation of the Automated Logistics Optimization System (ALOS). The purpose of this analysis is to evaluate the economic viability of the project by comparing the projected benefits and costs over its lifespan. Using the Net Present Value (NPV) methodology, this analysis incorporates both quantitative and qualitative factors to ensure a well-rounded assessment.

II. Objective of the Analysis

The objective is to determine whether implementing the Automated Logistics Optimization System (ALOS) will provide financial and operational advantages to [YOUR COMPANY NAME] in the year 2084 and beyond.

Key Considerations:

Enhancing operational efficiency by automating logistics processes.

Reducing transportation costs and delays.

Improving data accuracy and decision-making.

III. Project Description

The Automated Logistics Optimization System (ALOS) aims to streamline [YOUR COMPANY NAME]’s supply chain by using cutting-edge AI to automate route planning, inventory management, and real-time shipment tracking. This project addresses inefficiencies in the current logistics framework, ultimately contributing to cost savings, increased productivity, and enhanced customer satisfaction.

IV. Methodology

Identification of Costs and Benefits

Costs include hardware, software, implementation, and maintenance.

Benefits include direct savings, increased revenue, and enhanced operational performance.

Calculation of Net Present Value (NPV)

Formula:

NPV=∑(Benefit−Cost / (1+r)t)

Where:r=8% (Discount Rate)r = 8\% \text{ (Discount Rate)}r=8% (Discount Rate)

t=Years 1-5t = \text{Years 1-5}t=Years 1-5

Sensitivity Analysis

Examined the impact of fluctuating benefits and costs on NPV.

V. Assumptions

Discount Rate: 8%

Project Duration: 5 years (2084–2088).

Cost Data Source: Vendor quotes and historical data.

Benefit Data Source: Simulated efficiency gains and industry benchmarks.

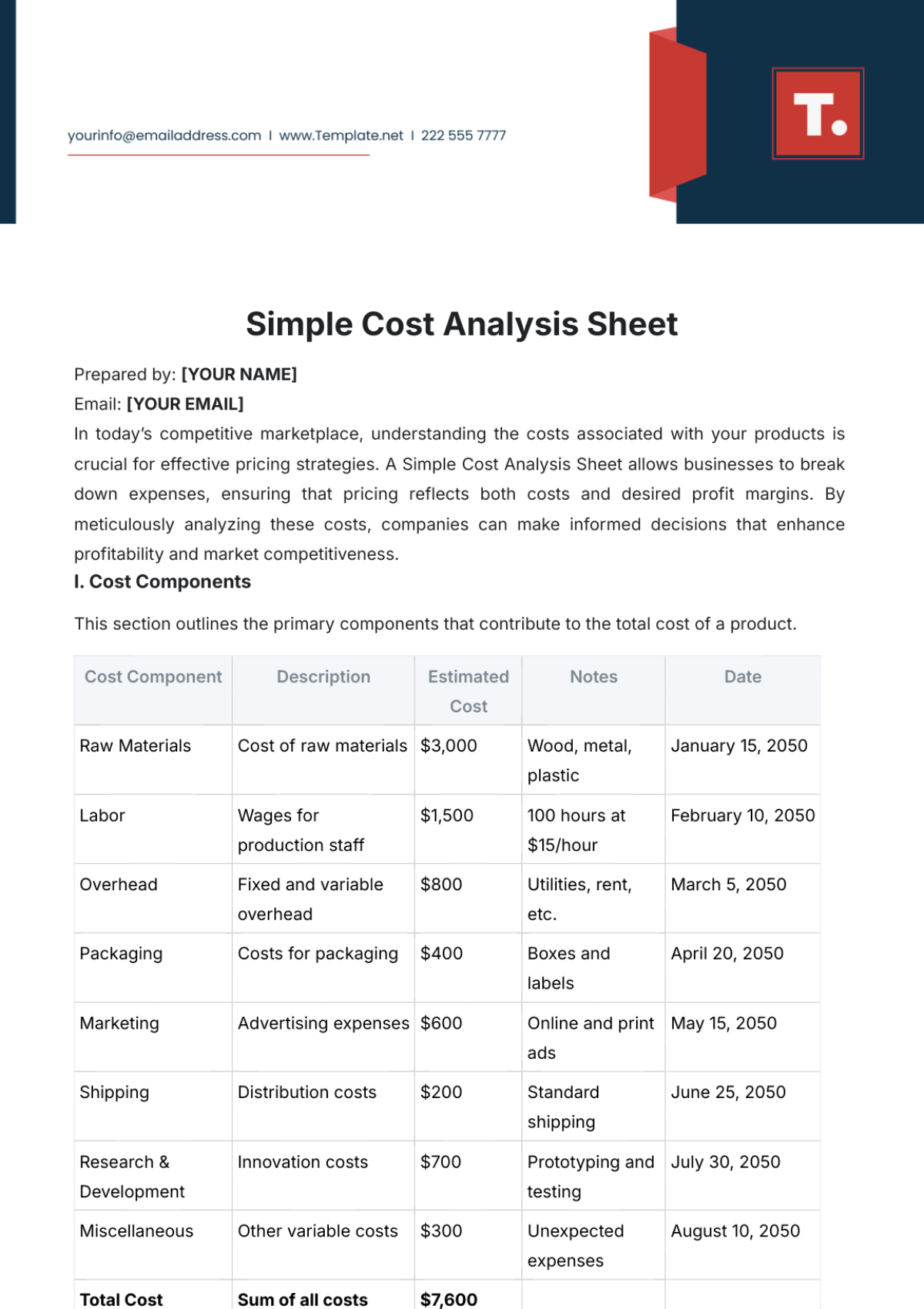

VI. Cost Analysis

A. Upfront Costs

AI Software Development: $500,000

Hardware Acquisition: $200,000

Installation and Setup: $100,000

B. Recurring Costs

System Maintenance: $50,000/year

Licensing Fees: $25,000/year

Training Costs: $10,000/year

C. Total Costs

Total Over 5 Years: $925,000

VII. Benefit Analysis

A. Financial Benefits

Reduction in Transportation Costs: $300,000/year

Inventory Optimization Savings: $200,000/year

Revenue Increase from Faster Deliveries: $100,000/year

B. Non-Financial Benefits

Enhanced customer satisfaction by 15%.

Reduction in manual errors by 25%.

C. Total Benefits

Total Over 5 Years: $3,000,000

VIII. Net Present Value (NPV) Calculation

A. Discounted Benefits and Costs (Over Time)

Year | Benefits ($) | Costs ($) | Net Benefits ($) | Discount Factor | Discounted Net Benefits ($) |

|---|---|---|---|---|---|

2084 | 600,000 | 725,000 | -125,000 | 0.93 | -116,250 |

2085 | 600,000 | 85,000 | 515,000 | 0.86 | 442,900 |

2086 | 600,000 | 85,000 | 515,000 | 0.79 | 407,850 |

2087 | 600,000 | 85,000 | 515,000 | 0.74 | 381,100 |

2088 | 600,000 | 85,000 | 515,000 | 0.68 | 350,200 |

B. Total NPV

Total NPV: $1,465,800

IX. Sensitivity Analysis

Scenarios Modeled:

Scenario 1: Discount Rate Increased to 10%.

Resulting NPV: $1,302,000

Scenario 2: Reduction in Benefits by 20%.

Resulting NPV: $940,800

Results of Sensitivity Analysis

The analysis shows that the project remains viable under varying assumptions, though profitability decreases with higher discount rates or reduced benefits.

X. Conclusion

The Automated Logistics Optimization System (ALOS) demonstrates a Net Present Value (NPV) of $1,465,800, indicating significant financial viability. Additionally, the project aligns with strategic goals to enhance supply chain efficiency and customer satisfaction.

Recommendation: Proceed with the implementation of ALOS to capitalize on the outlined benefits.

XI. Appendices

Detailed Cost Breakdown

Detailed Benefit Breakdown

Sensitivity Analysis Charts

Supporting Documentation