Operational Strategy Gap Analysis

Prepared By: [YOUR NAME]

Date: March 1, 2050

I. Current State Assessment

A. Overview of Operational Processes

The organization currently employs a set of operational processes that have organically evolved over time. These processes are characterized by a mix of manual and automated tasks, largely dependent on legacy systems. The workflow from initiation to delivery involves multiple checkpoints, requiring approvals that slow down the throughput. A lack of standardization in documentation and process execution has resulted in variability in output quality.

B. Performance

Key Performance Indicators (KPIs) such as lead time, cycle time, and first-pass yield are currently below industry benchmark standards.

Employee productivity metrics suggest inefficiencies in task allocation and resource utilization, leading to potential underperformance.

Customer satisfaction scores are moderate, heavily influenced by delayed delivery and inconsistent product/service quality.

C. Resources

The organization relies heavily on a labor-intensive model with limited investment in optimized technology solutions. The workforce is skilled but not adequately trained in lean methodologies or continuous improvement strategies. Resource allocation is often reactive rather than proactive, impacting overall operational efficiency.

II. Desired Future State

A. Goals and Operational Targets

The organization aspires to be a leader in its sector by enhancing operational efficiency and achieving a customer satisfaction rating of 95% or higher. Key goals include:

Reducing lead times by 30% within the next fiscal year.

Achieving a first-pass yield of 98% through improved quality control processes.

Increasing the adoption of technology-driven solutions to streamline operations.

Enhancing employee skill sets and promoting a culture of continuous improvement.

B. Strategic Initiatives

To reach these targets, strategic initiatives involve the integration of new technologies, process re-engineering, and the implementation of a robust training and development program. These initiatives are designed to align resources, optimize processes, and elevate the organization's market position.

III. Gap Identification

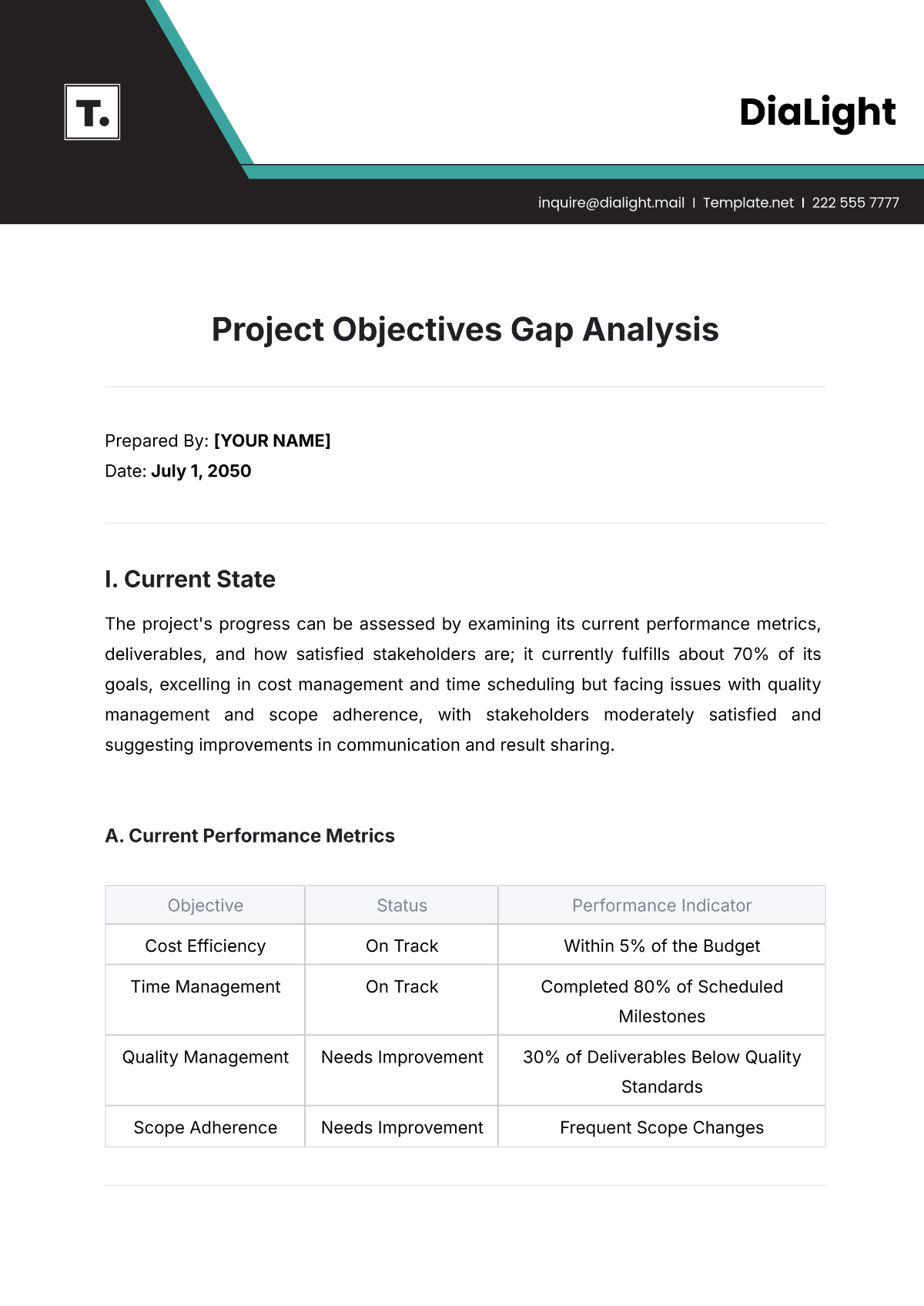

A. Performance Gaps

Current performance metrics indicate a gap in efficiency and quality, with existing processes failing to meet target benchmarks. Employee output and engagement are also areas that require attention.

B. Process Gaps

Lack of standard operating procedures, leading to inconsistencies.

Minimal automation, resulting in slower process execution.

C. Resource Gaps

Insufficient training in modern operational strategies and underutilization of available technologies are significant resource gaps. The organization lacks a structured framework for continuous improvement, leading to stagnation in process enhancement.

IV. Root Cause Analysis

A. Identifying Underlying Causes

Several root causes have been identified as contributors to the operational gaps:

Category | Root Cause |

|---|---|

Process Inefficiencies | Outdated systems and unclear workflow definitions. |

Technology Deficiencies | Lack of investment in and integration of new technologies. |

Resource Allocation | Poor training programs and misallocation of skilled employees. |

V. Action Plan

A. Recommendations for Addressing Gaps

To address the identified gaps, the following strategic actions are recommended:

Process Optimization: Implement standardized operating procedures and introduce automation where feasible within the next six months.

Technology Investment: Increase investment in state-of-the-art technology to improve process speed and accuracy, targeting completion within one year.

Training and Development: Develop a comprehensive training program focusing on lean and agile methodologies, rolling out over the next quarter.

Continuous Improvement Framework: Establish a framework to regularly review and refine operational processes, launching within three months.

B. Timeline

A detailed timeline will be structured with milestones set at three-month intervals to assess progress and make necessary adjustments. Regular reviews with stakeholders will ensure alignment with the overall strategic vision.