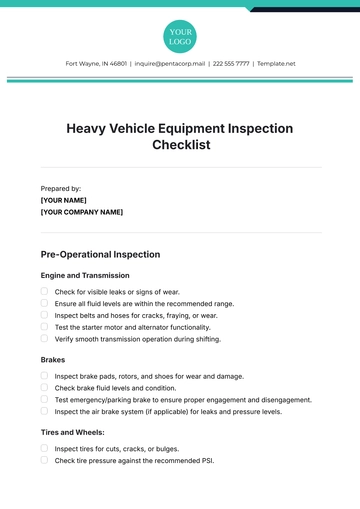

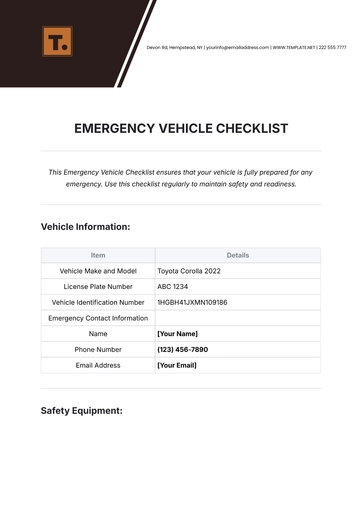

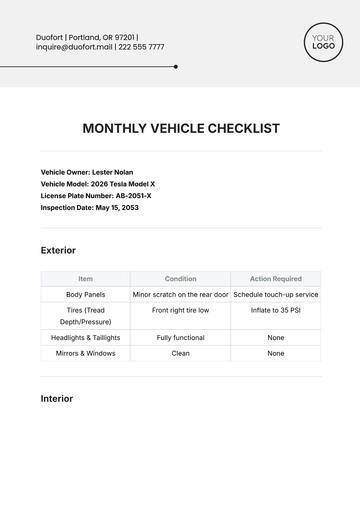

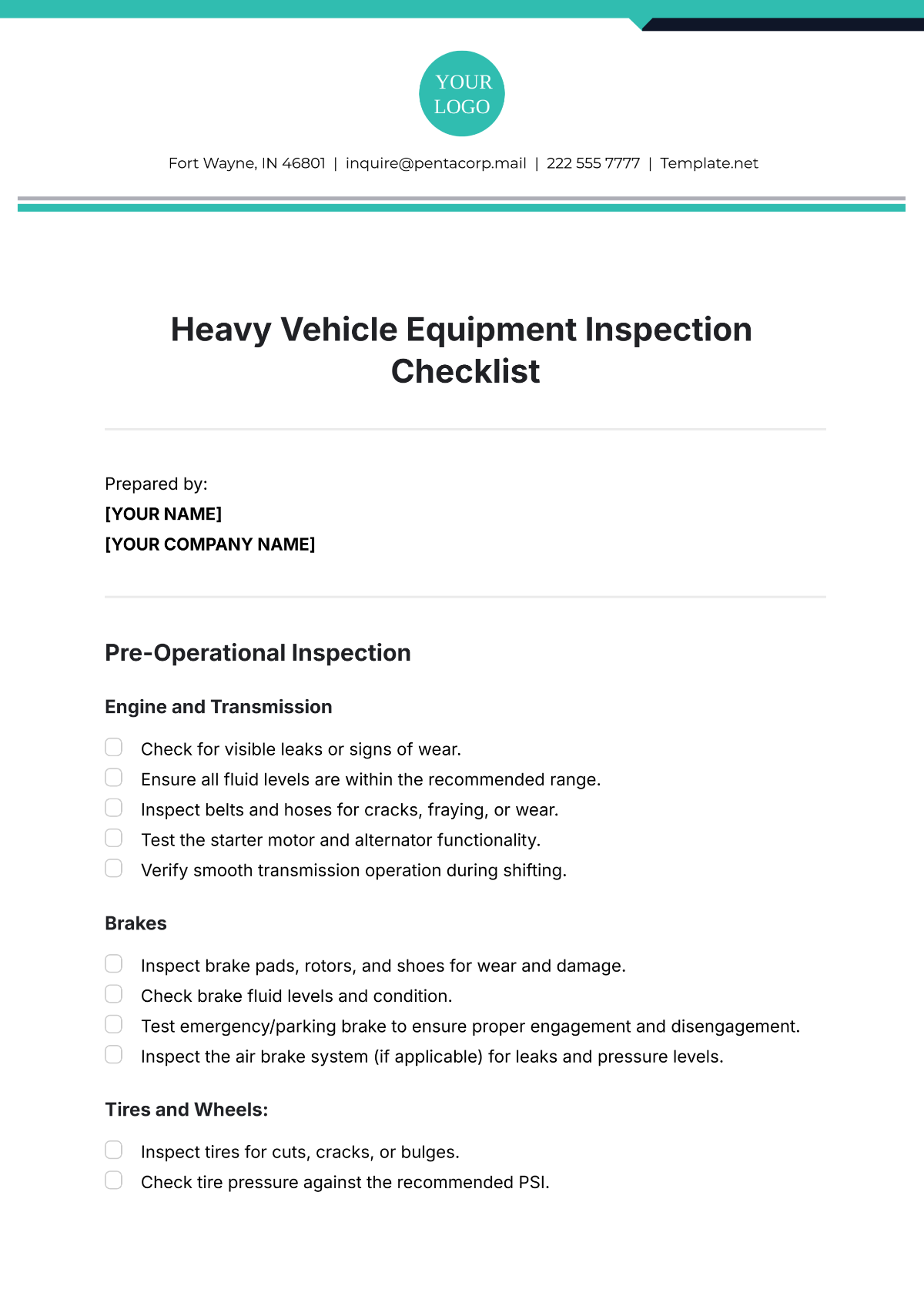

Free Heavy Vehicle Equipment Inspection Checklist

Prepared by:

[YOUR NAME]

[YOUR COMPANY NAME]

Pre-Operational Inspection

Engine and Transmission

Check for visible leaks or signs of wear.

Ensure all fluid levels are within the recommended range.

Inspect belts and hoses for cracks, fraying, or wear.

Test the starter motor and alternator functionality.

Verify smooth transmission operation during shifting.

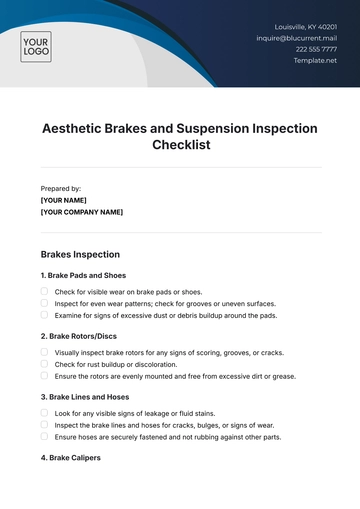

Brakes

Inspect brake pads, rotors, and shoes for wear and damage.

Check brake fluid levels and condition.

Test emergency/parking brake to ensure proper engagement and disengagement.

Inspect the air brake system (if applicable) for leaks and pressure levels.

Tires and Wheels:

Inspect tires for cuts, cracks, or bulges.

Check tire pressure against the recommended PSI.

Examine rims for cracks or damage.

Verify proper tire tread depth.

Ensure all lug nuts are properly tightened.

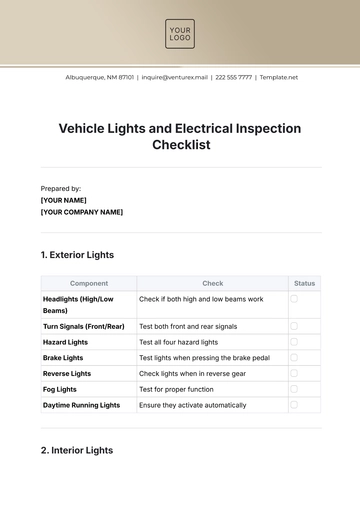

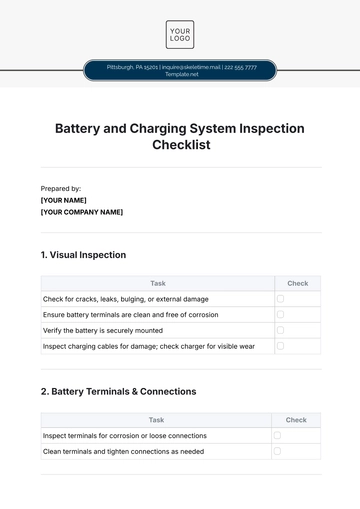

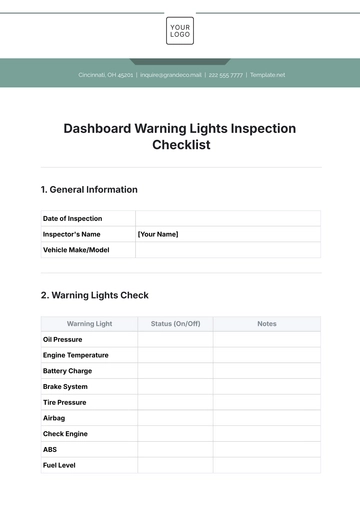

Lights and Electrical Systems

Test all exterior lights (headlights, taillights, turn signals, brake lights).

Check battery condition and ensure connections are clean and secure.

Inspect fuses for damage or wear.

Ensure the horn is functioning properly.

Hydraulic and Pneumatic Systems

Inspect hydraulic lines, cylinders, and hoses for leaks or wear.

Check fluid levels in hydraulic systems.

Verify pneumatic lines and valves are secure and free of damage.

Test hydraulic/pneumatic functions for responsiveness.

Operational Inspection

Performance Testing

Verify smooth acceleration and effective braking.

Test steering responsiveness for vibrations or noises.

Assess suspension system operation.

Ensure smooth shifting in the transmission.

Load Handling (If Applicable)

Test lifting mechanism (e.g., crane, hoist, loader) for proper function.

Inspect load-securing devices for wear or failure.

Verify lifting equipment operates within rated capacity.

Ensure load gauges and indicators are functioning.

Air Conditioning/Heating System

Check the air conditioning or heating system for correct operation.

Ensure air vents are clean and unobstructed.

Verify temperature controls are functioning.

Post-Operational Inspection

Fuel and Fluid Systems

Check fuel levels and inspect for leaks.

Inspect engine oil, coolant, transmission fluid, and hydraulic fluid for contamination.

Clean and check air filters for proper airflow.

Structural Integrity

Inspect chassis, frame, and undercarriage for damage or fatigue.

Check for loose or missing bolts, nuts, or fasteners.

Verify safety guards and covers are secure.

Cabin and Operator’s Area

Inspect seat belts for wear or damage.

Ensure the seat is adjustable and securely fastened.

Check mirrors, windows, and windshield wipers for condition.

Test communication equipment (radio, intercom, etc.) for functionality.

Additional Safety Checks

Fire Safety Equipment

Ensure fire extinguishers are accessible, fully charged, and in working condition.

Check other safety equipment (e.g., first aid kits, emergency signaling devices).

Safety Documentation

Ensure safety inspection logs are up to date.

Verify operator has the necessary training and certifications.

Check for compliance with local regulations or standards.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

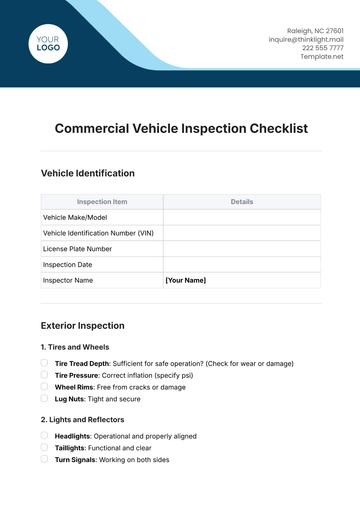

The Heavy Vehicle Equipment Inspection Checklist Template from Template.net is an editable and customizable tool designed for thorough inspections of heavy vehicles and equipment. Easily adjust the checklist to meet your specific needs using our AI Editor Tool. This template ensures safety, reliability, and compliance, making it ideal for heavy equipment maintenance and management.

You may also like

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

- Quality Checklist

- Compliance Checklist

- Audit Checklist

- Registry Checklist

- HR Checklist

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

- Construction Checklist

- Task Checklist

- Professional Checklist

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

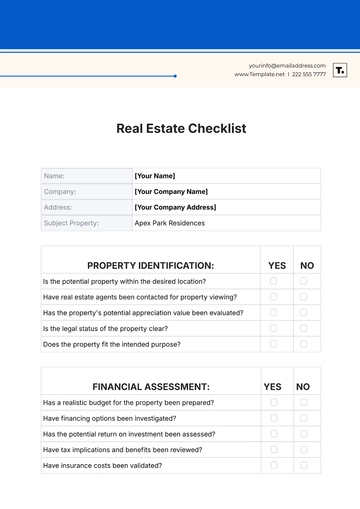

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

- Medical Checklist

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

- School Checklist

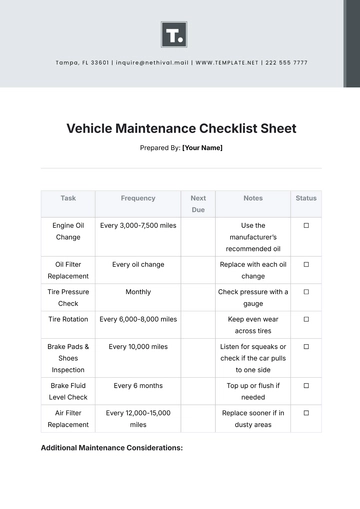

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

- Travel Agency Checklist

- Vehicle Inspection Checklist

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist