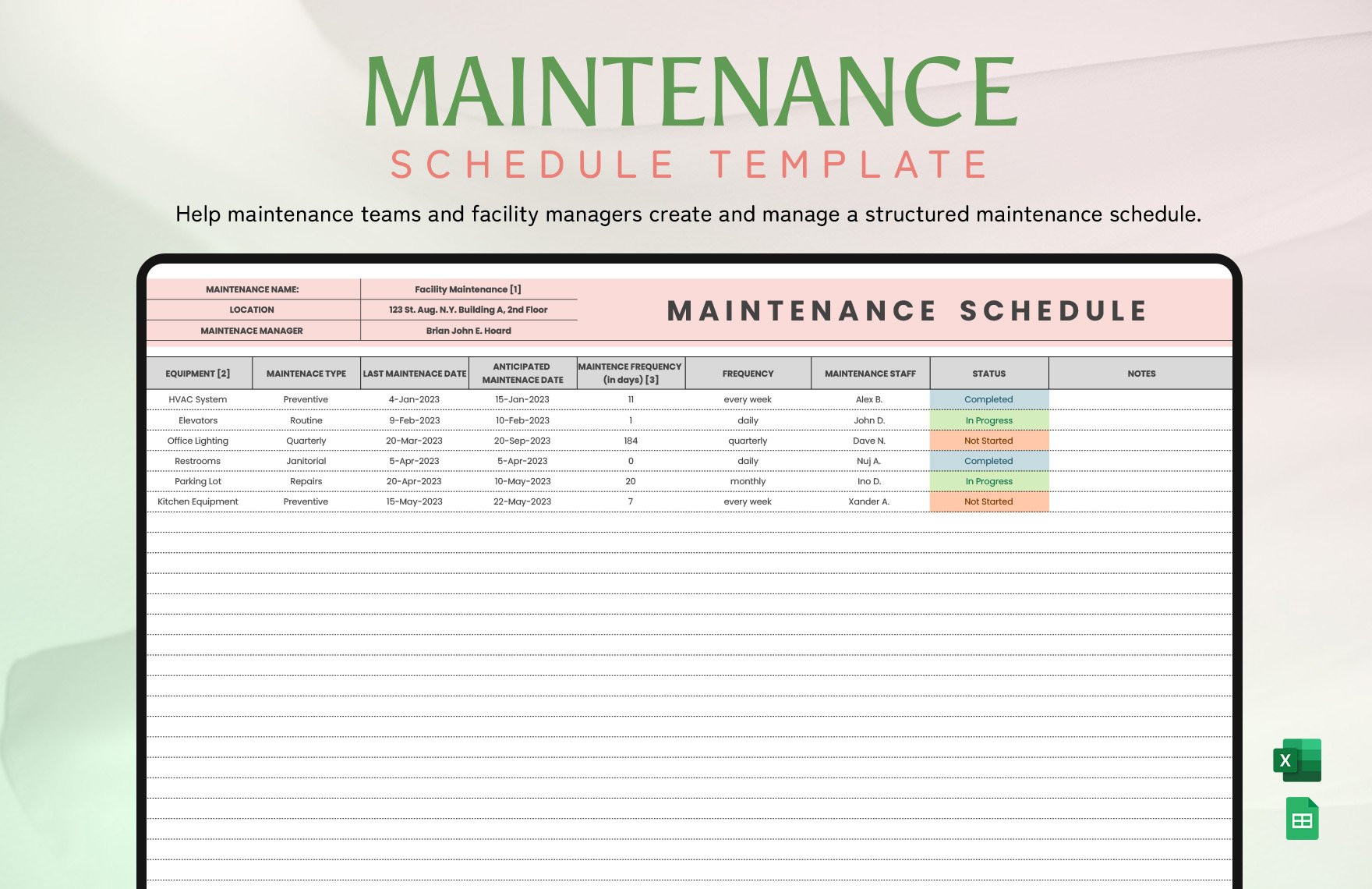

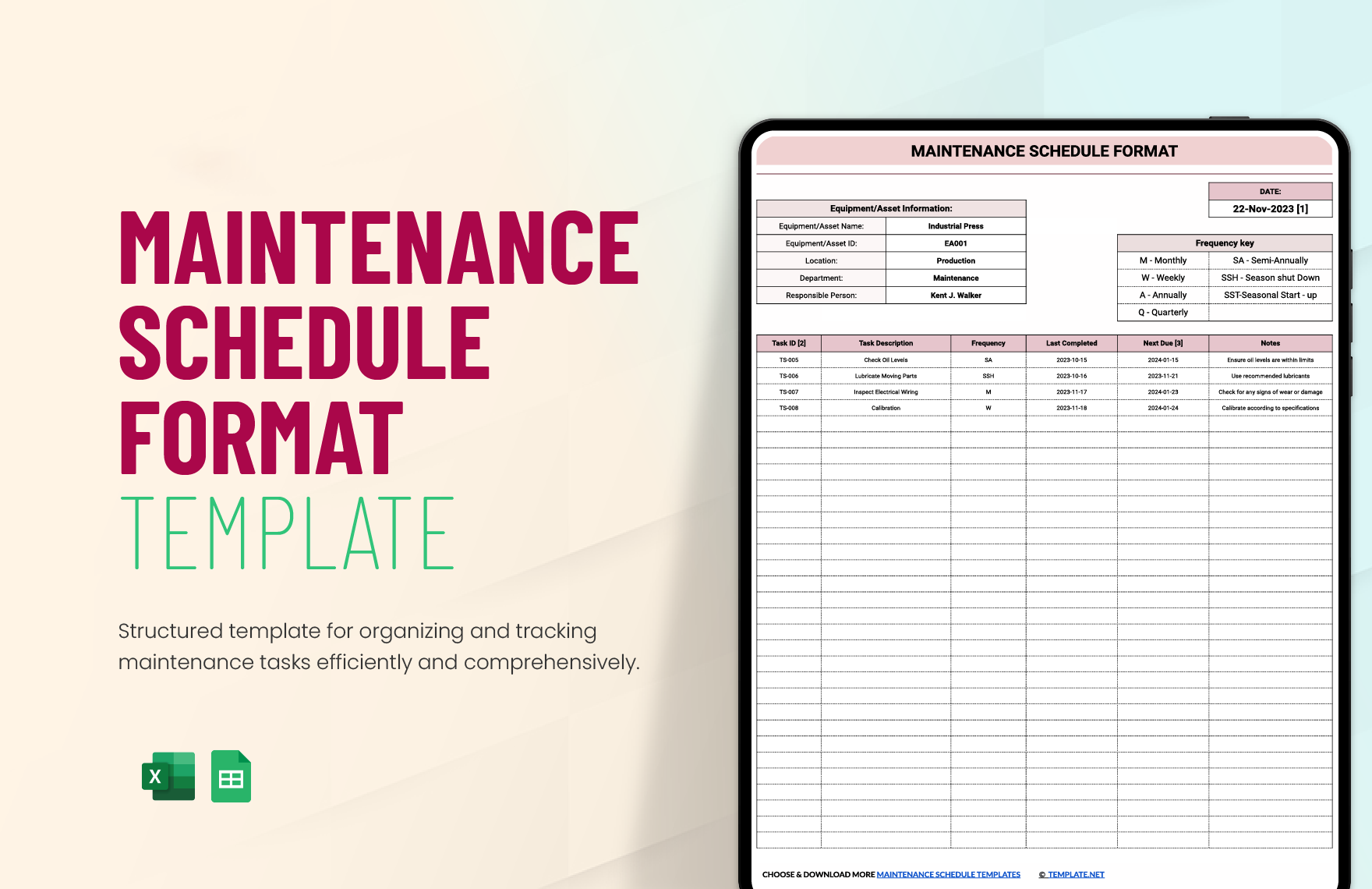

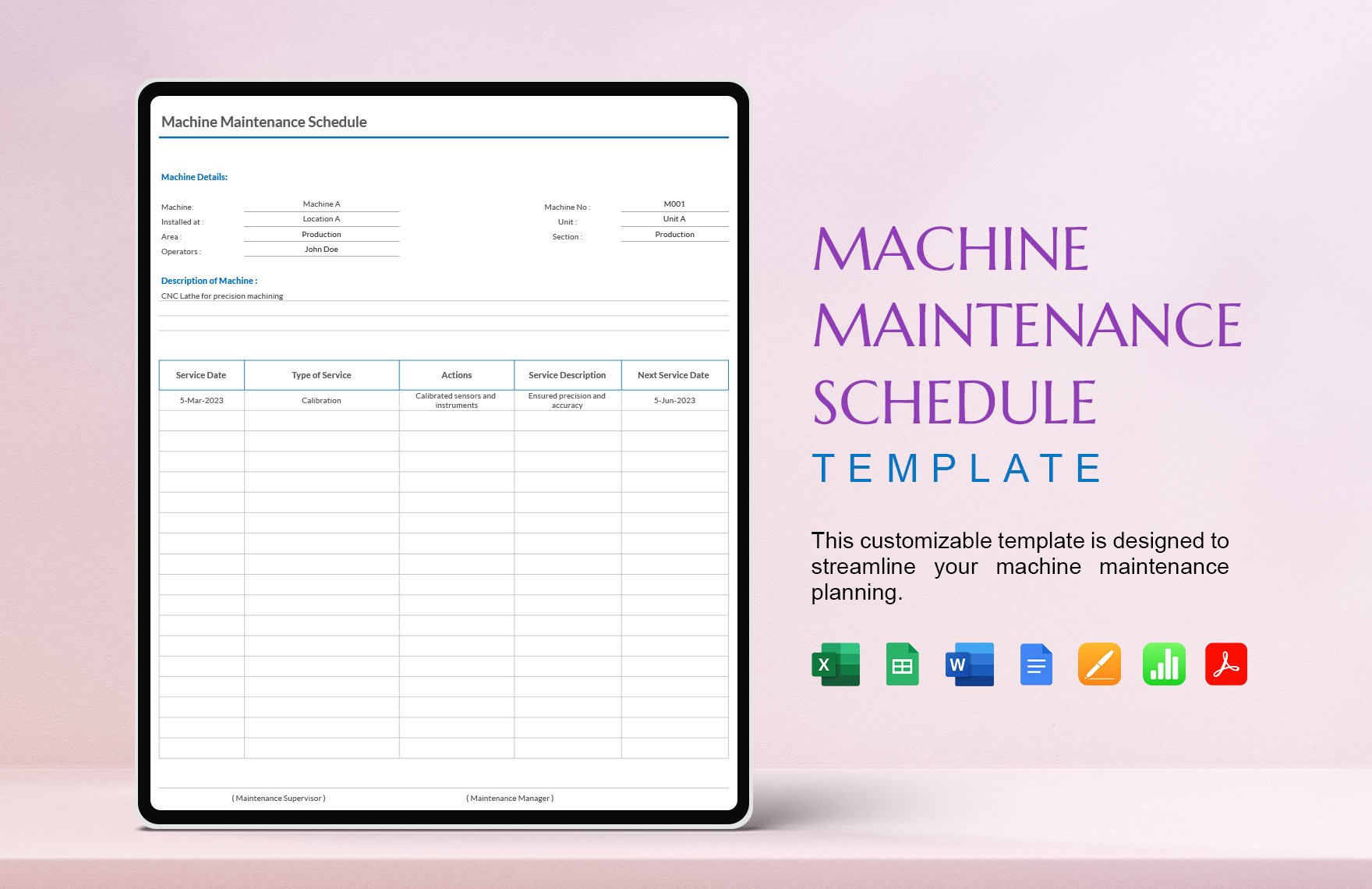

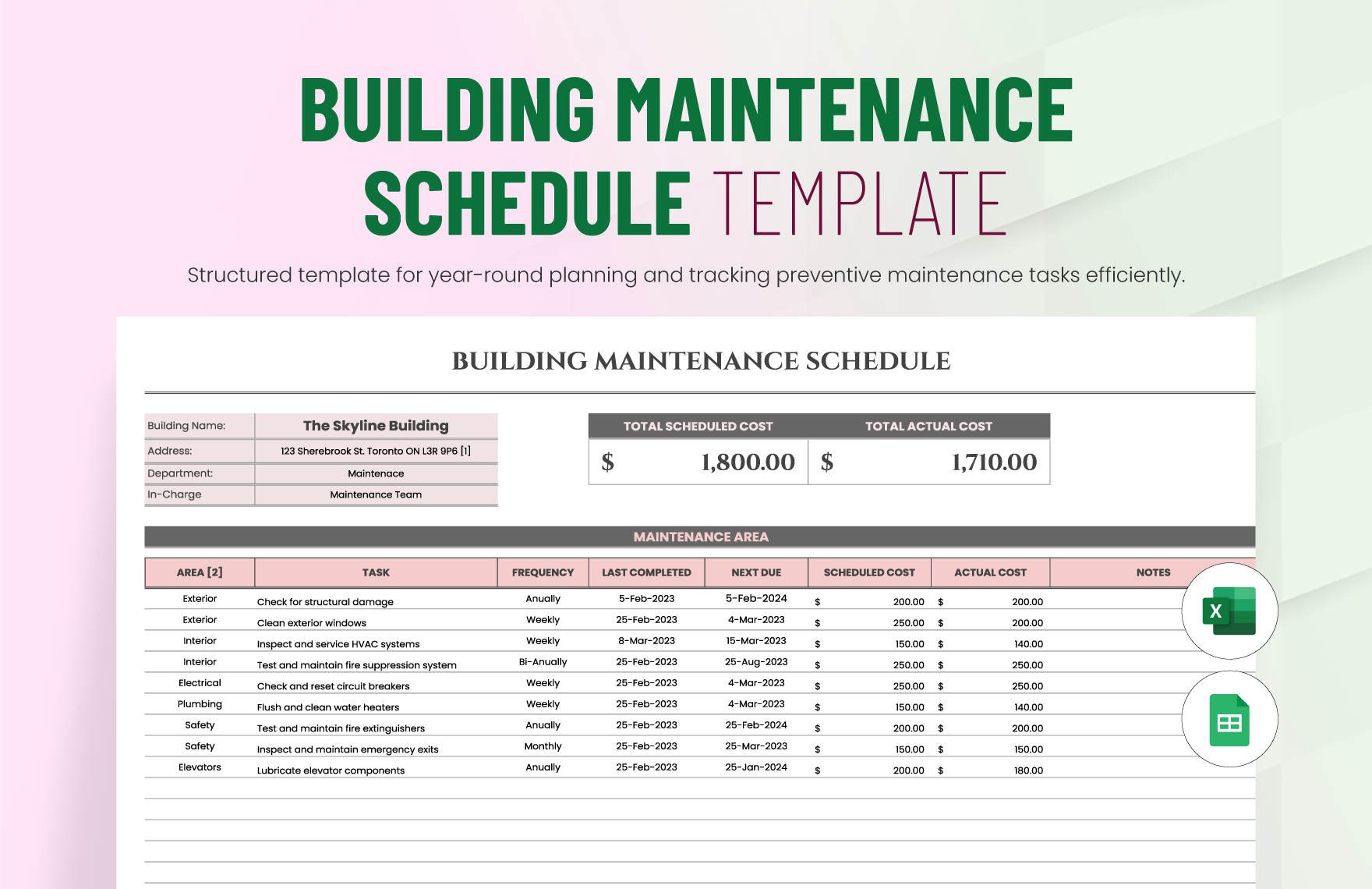

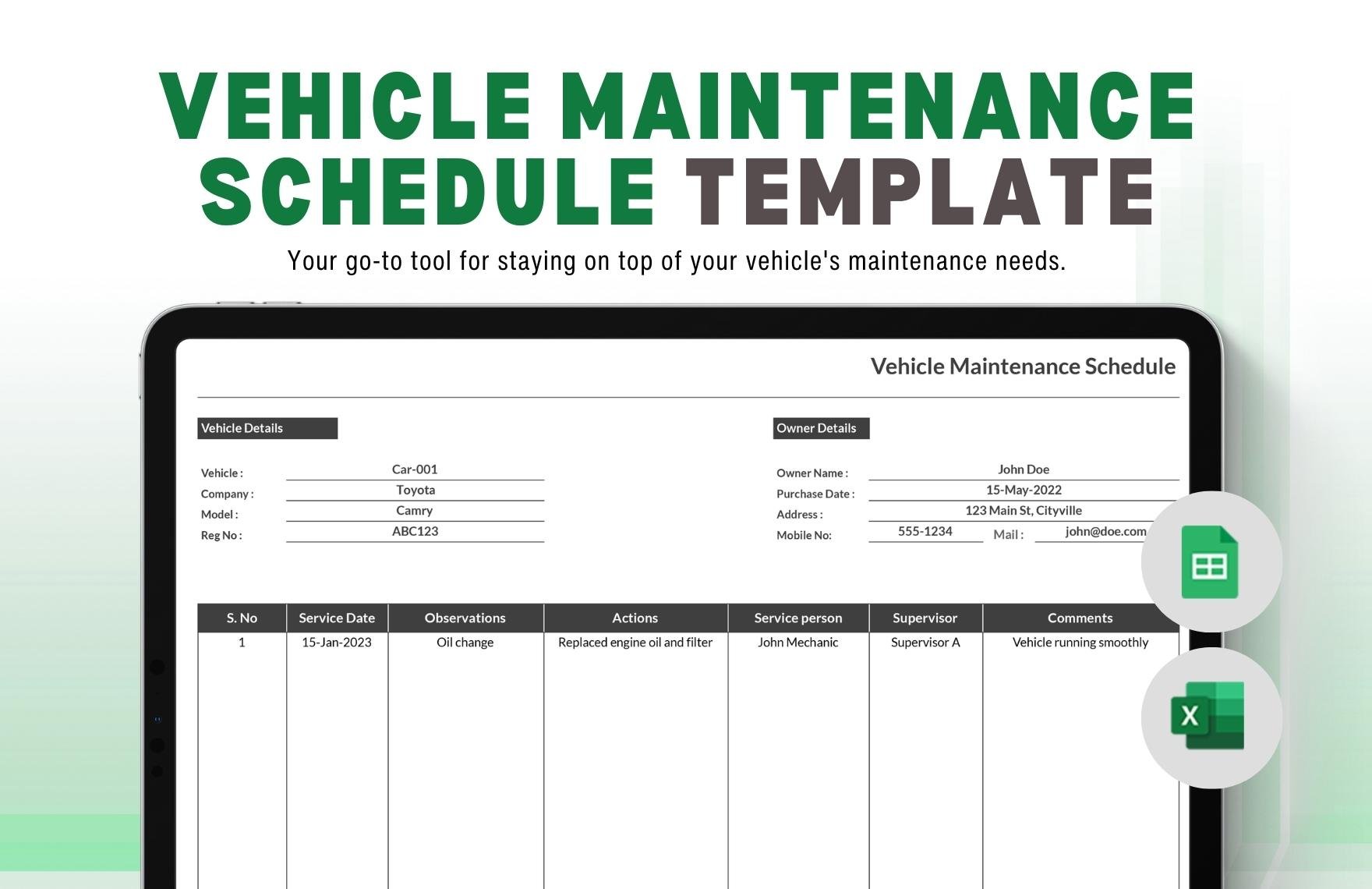

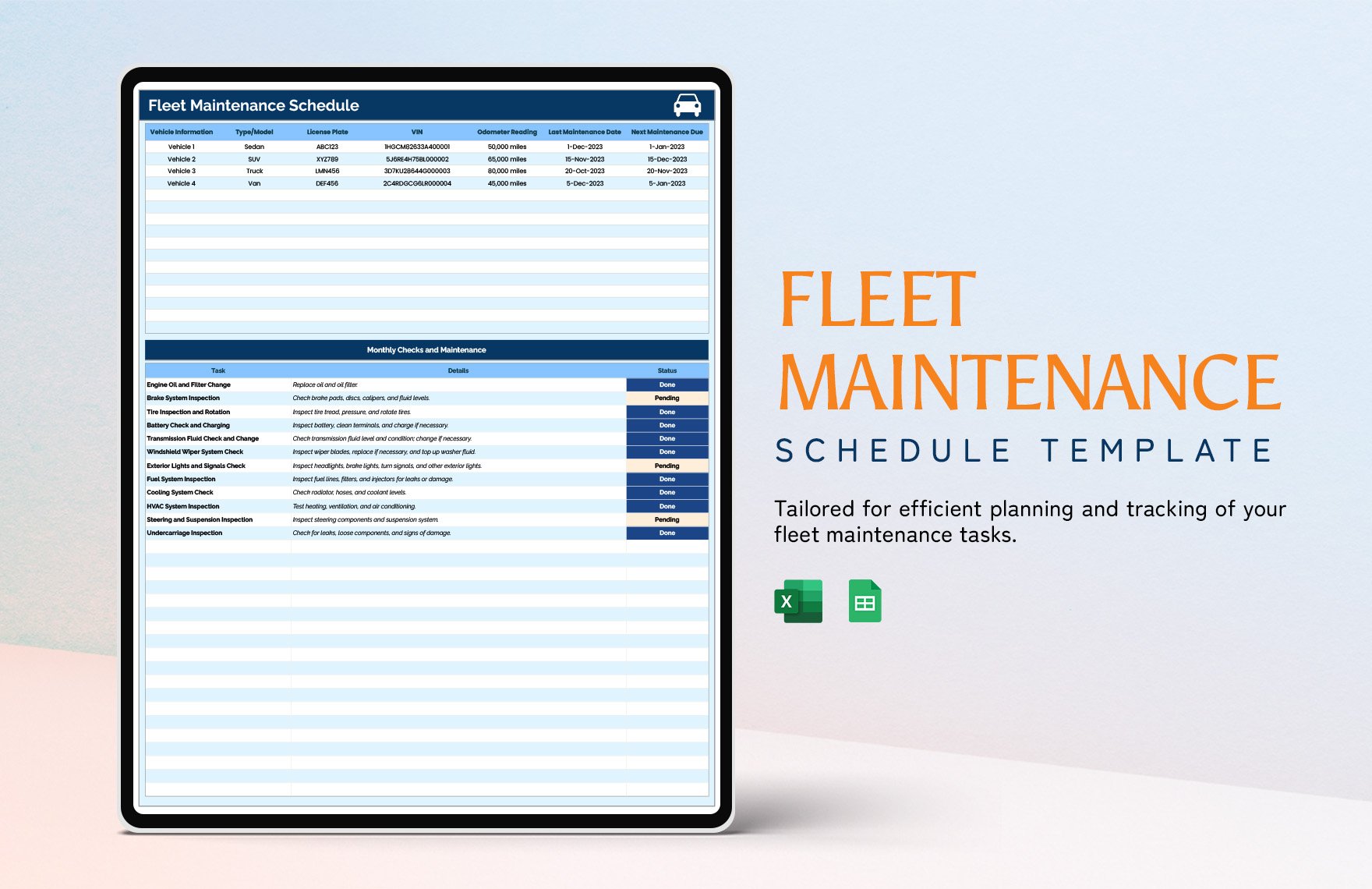

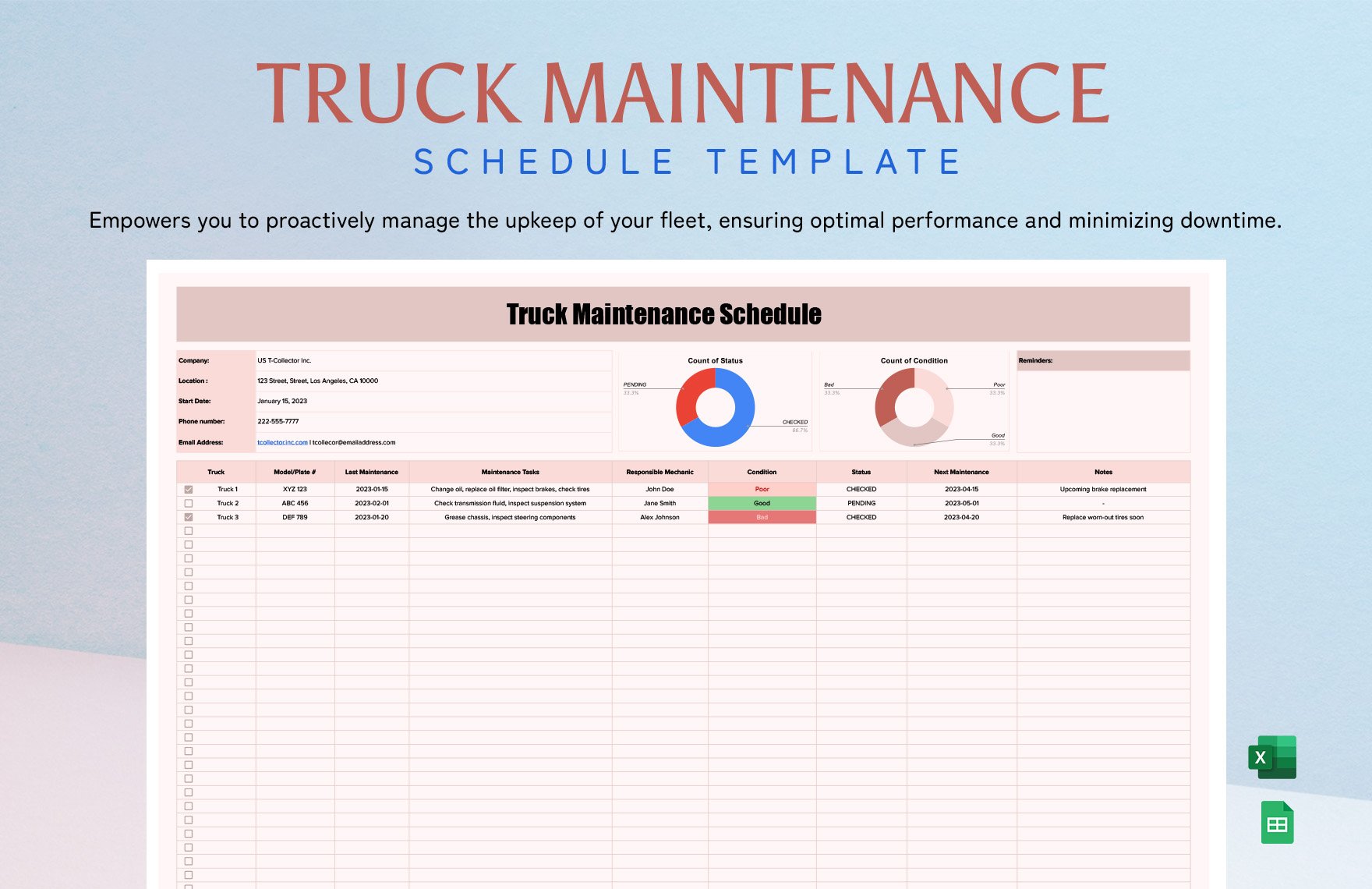

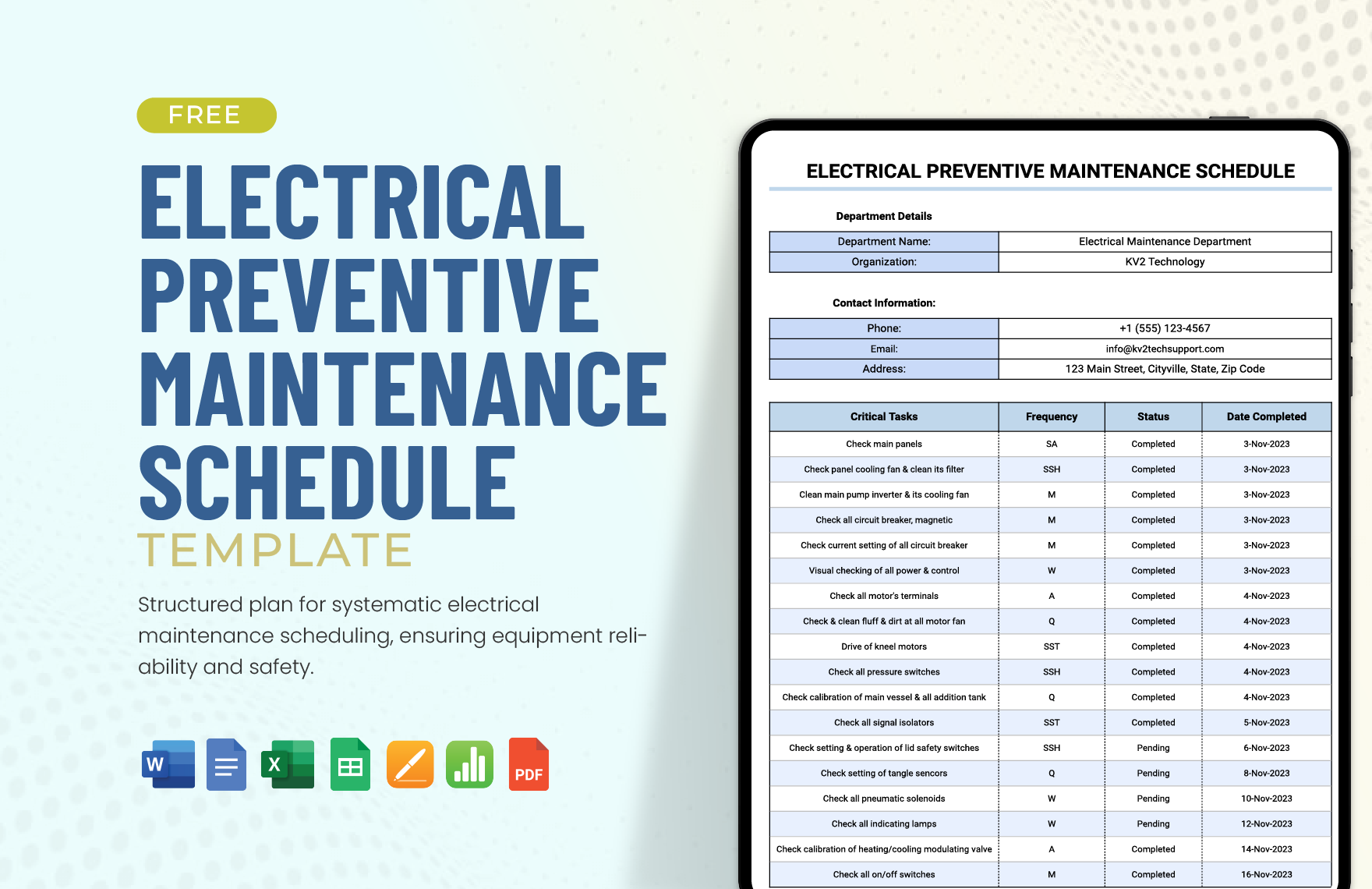

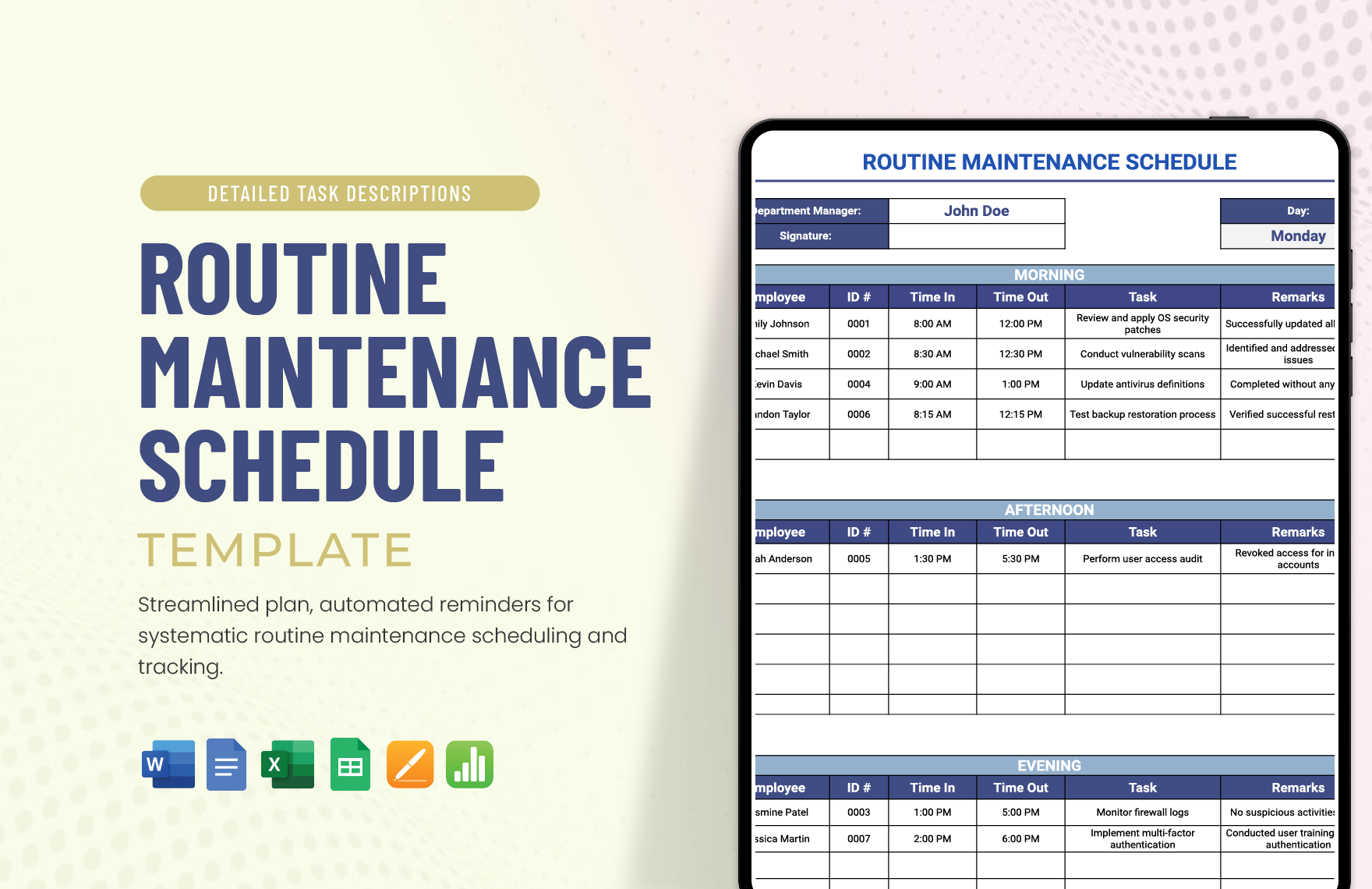

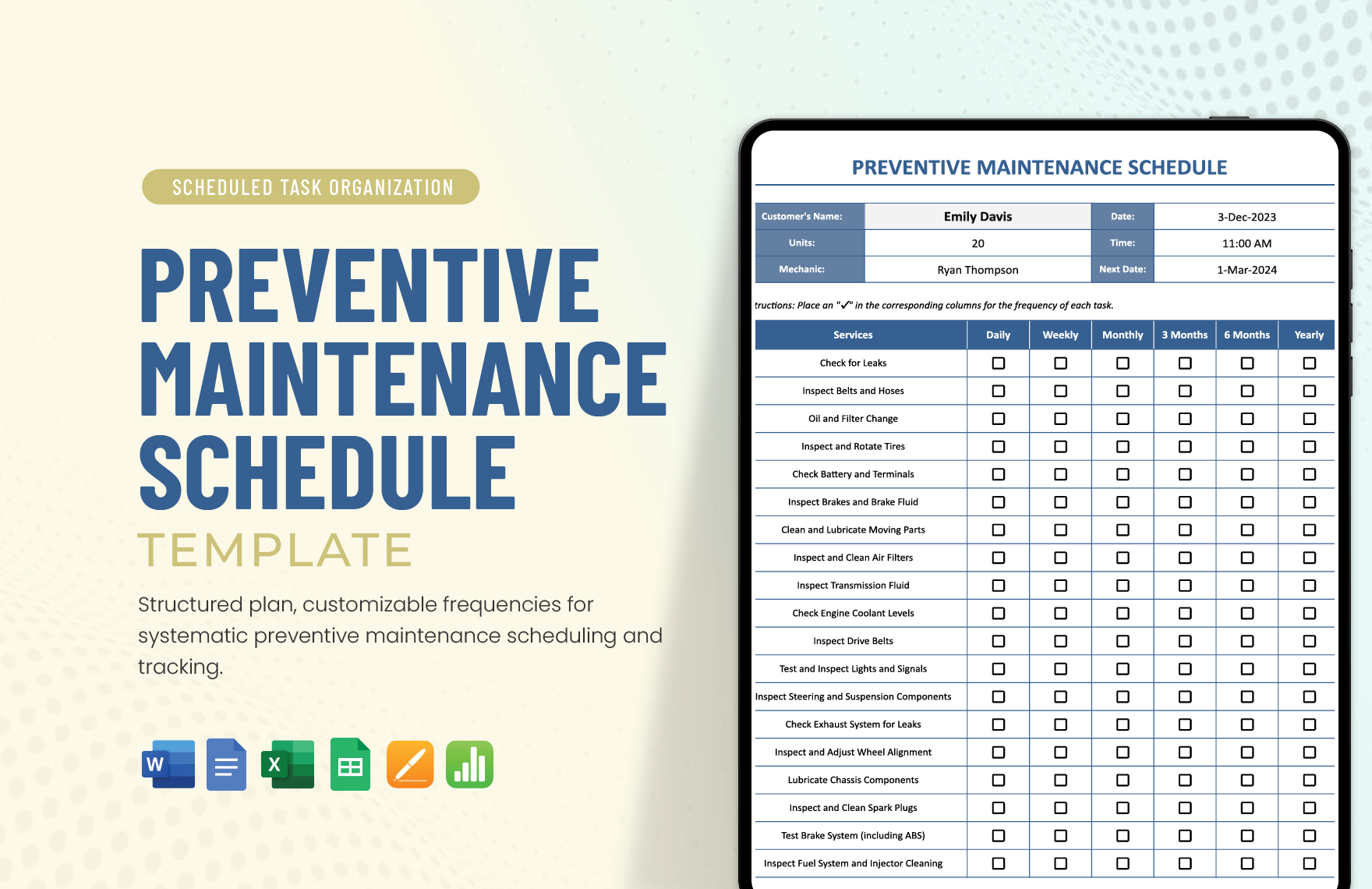

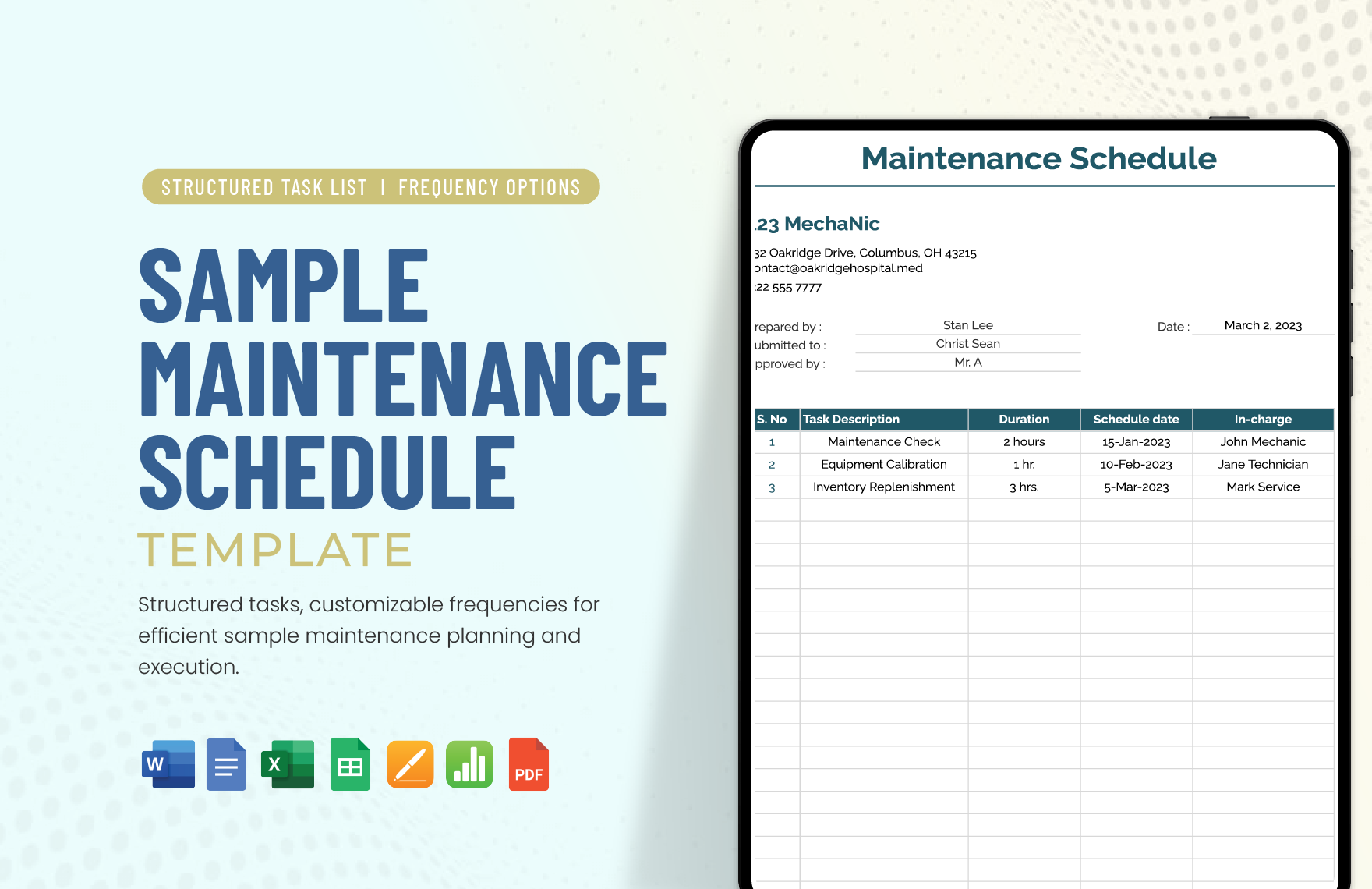

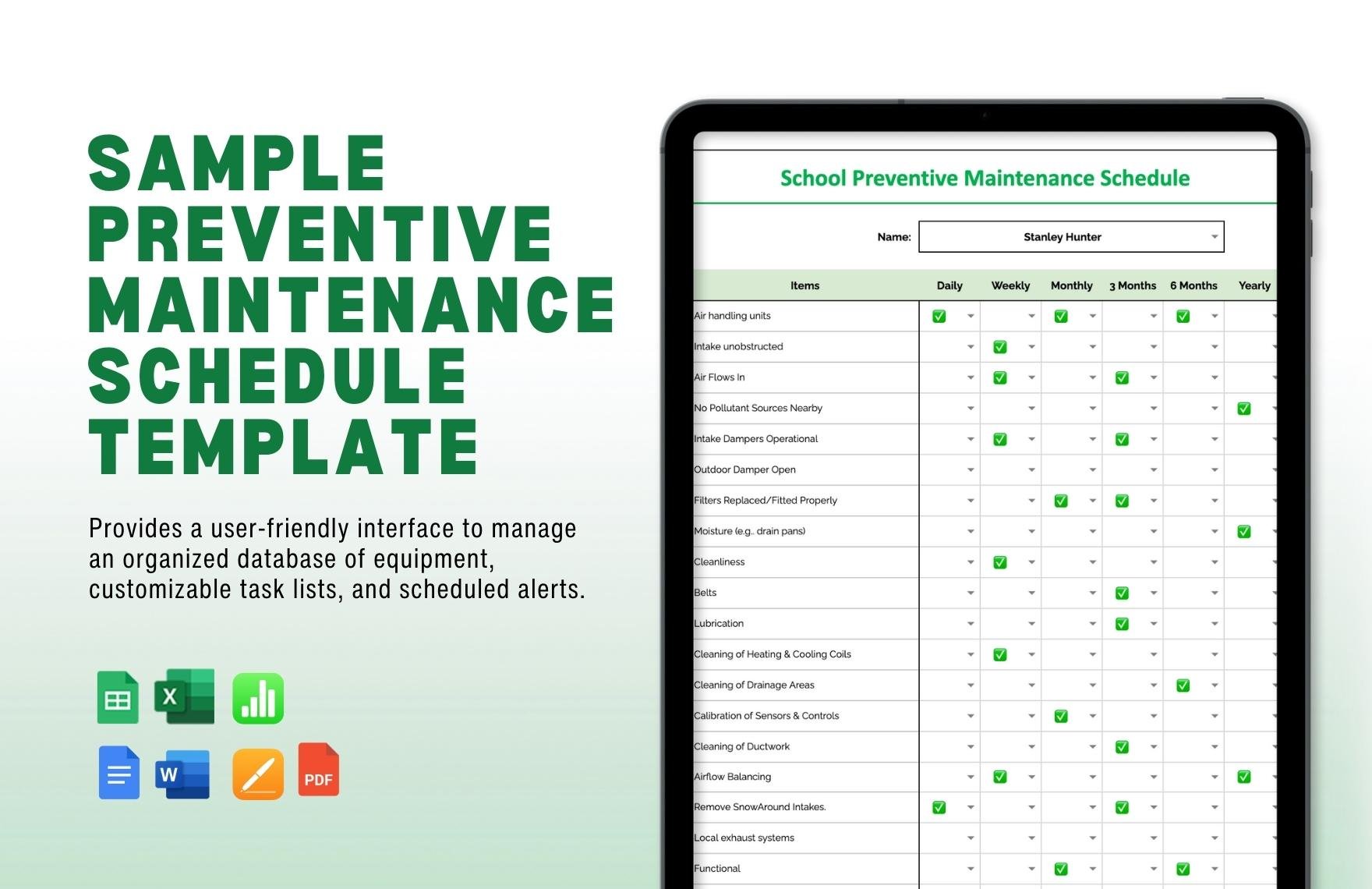

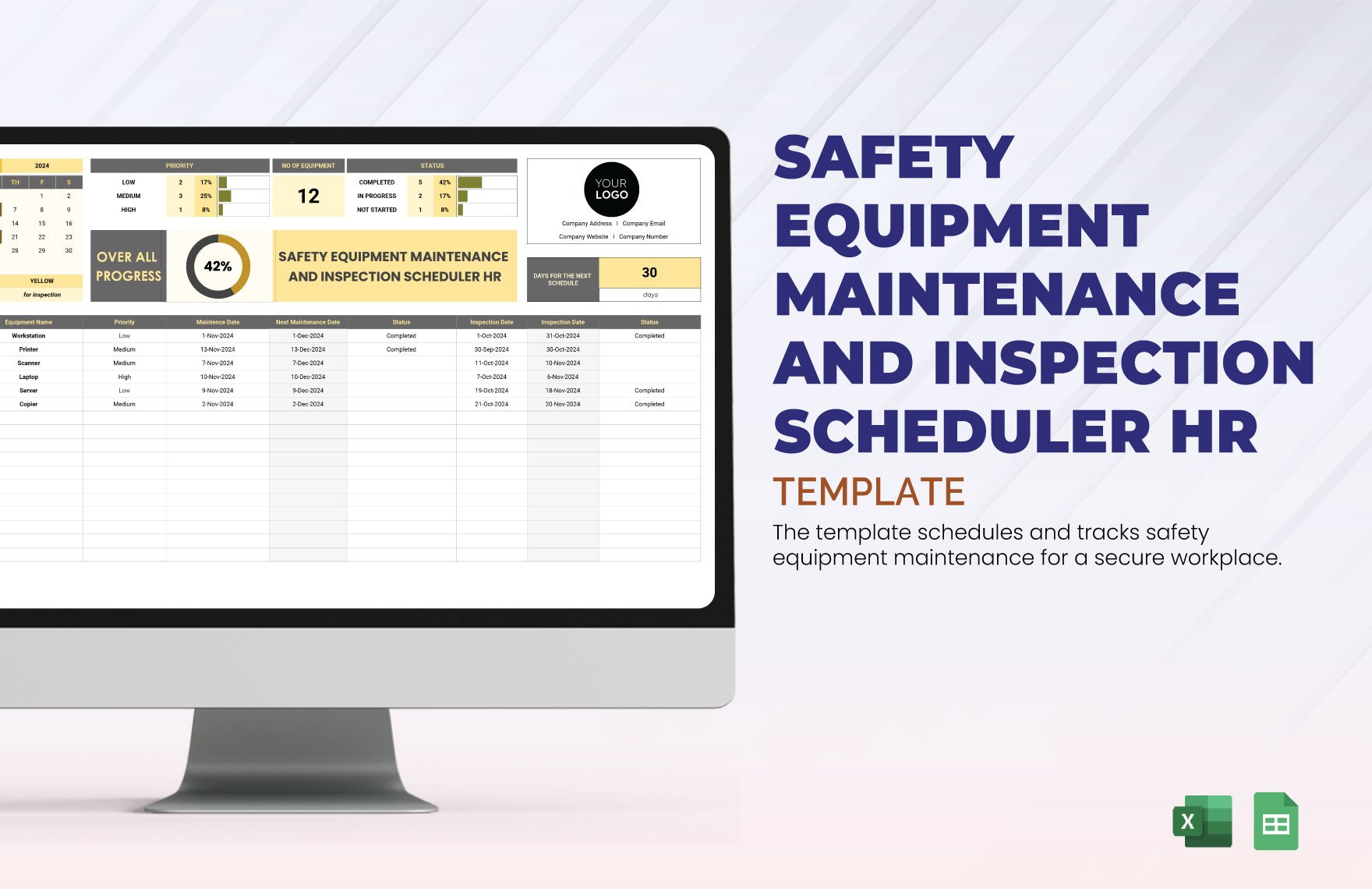

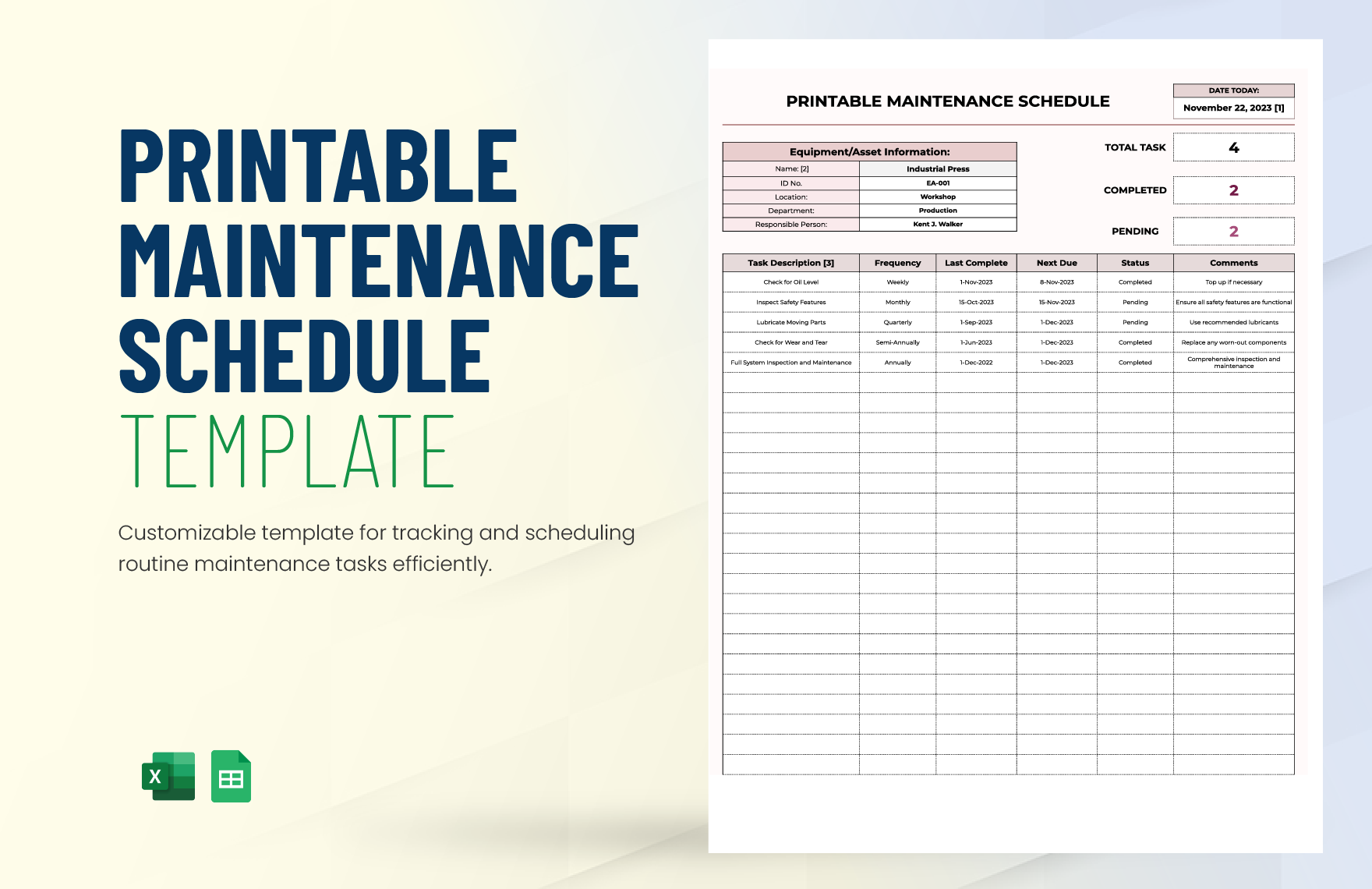

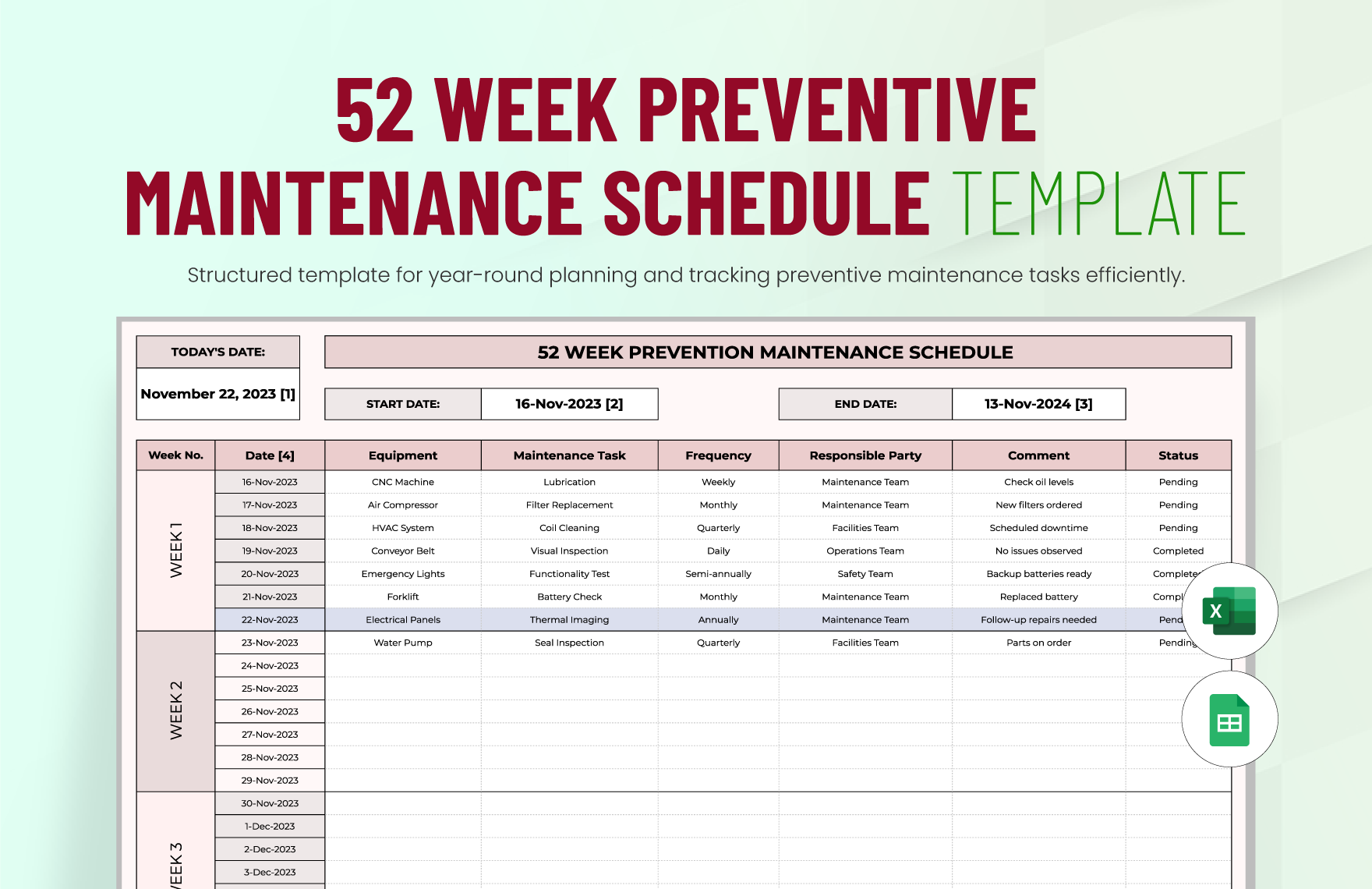

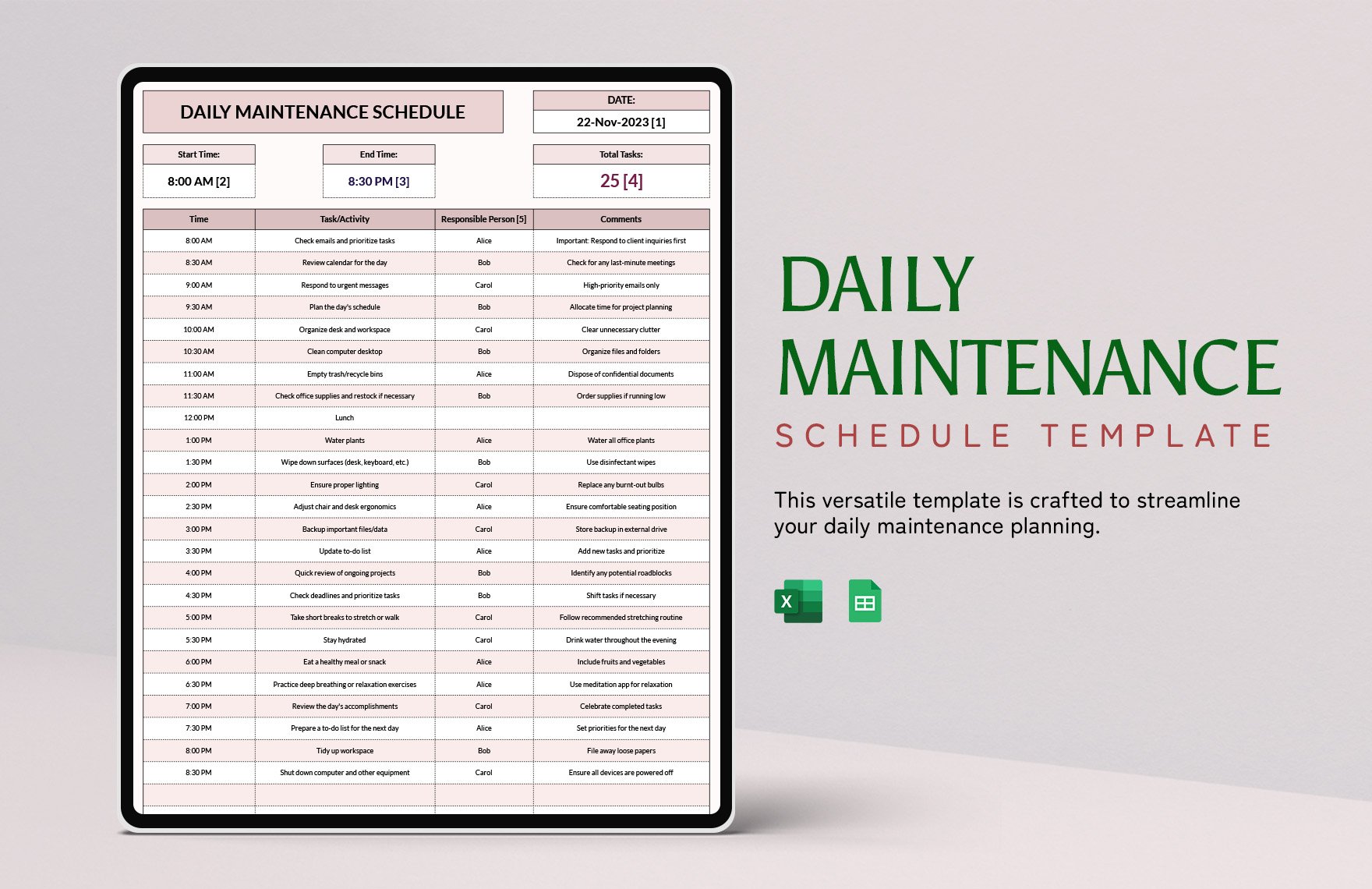

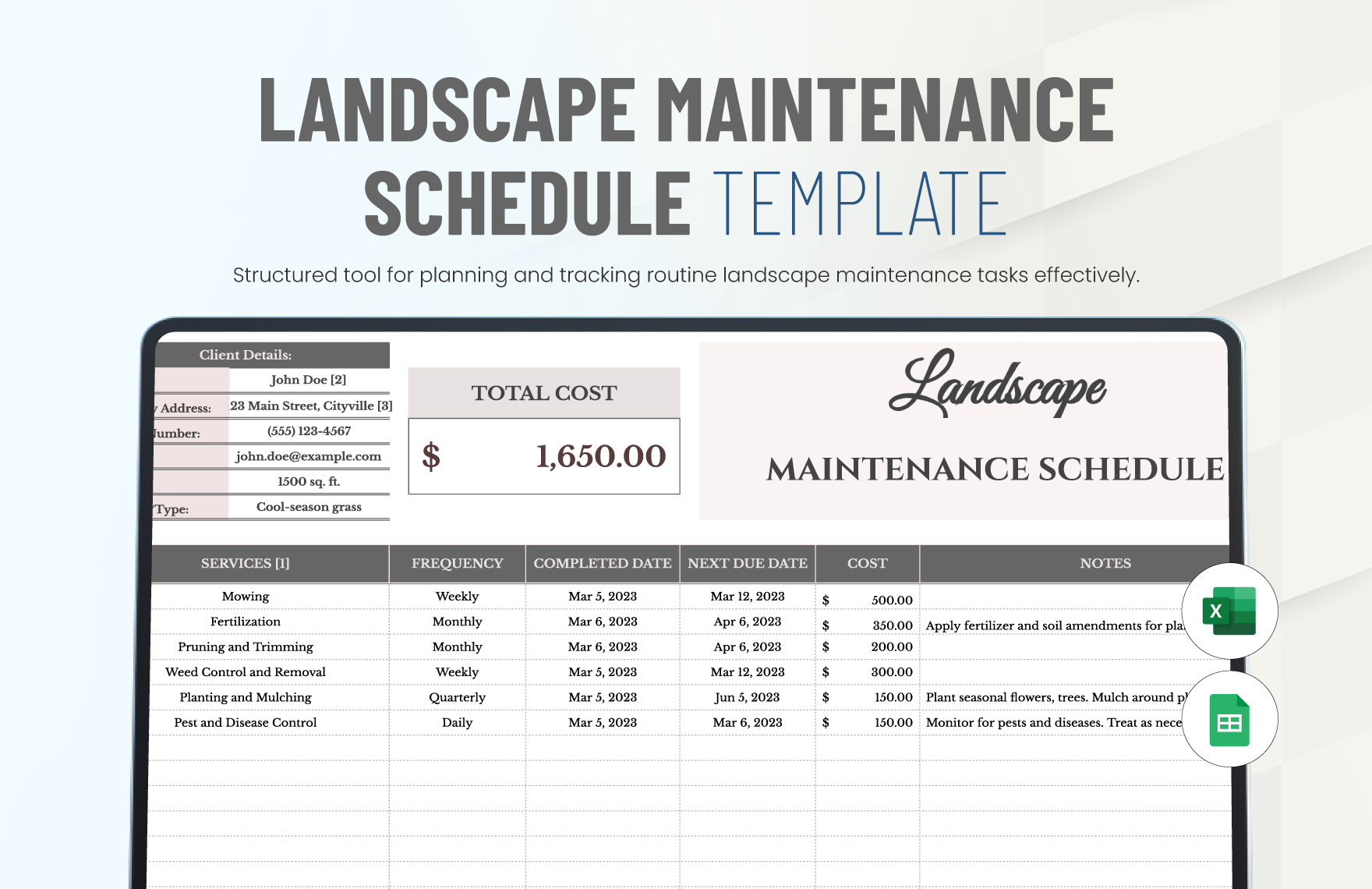

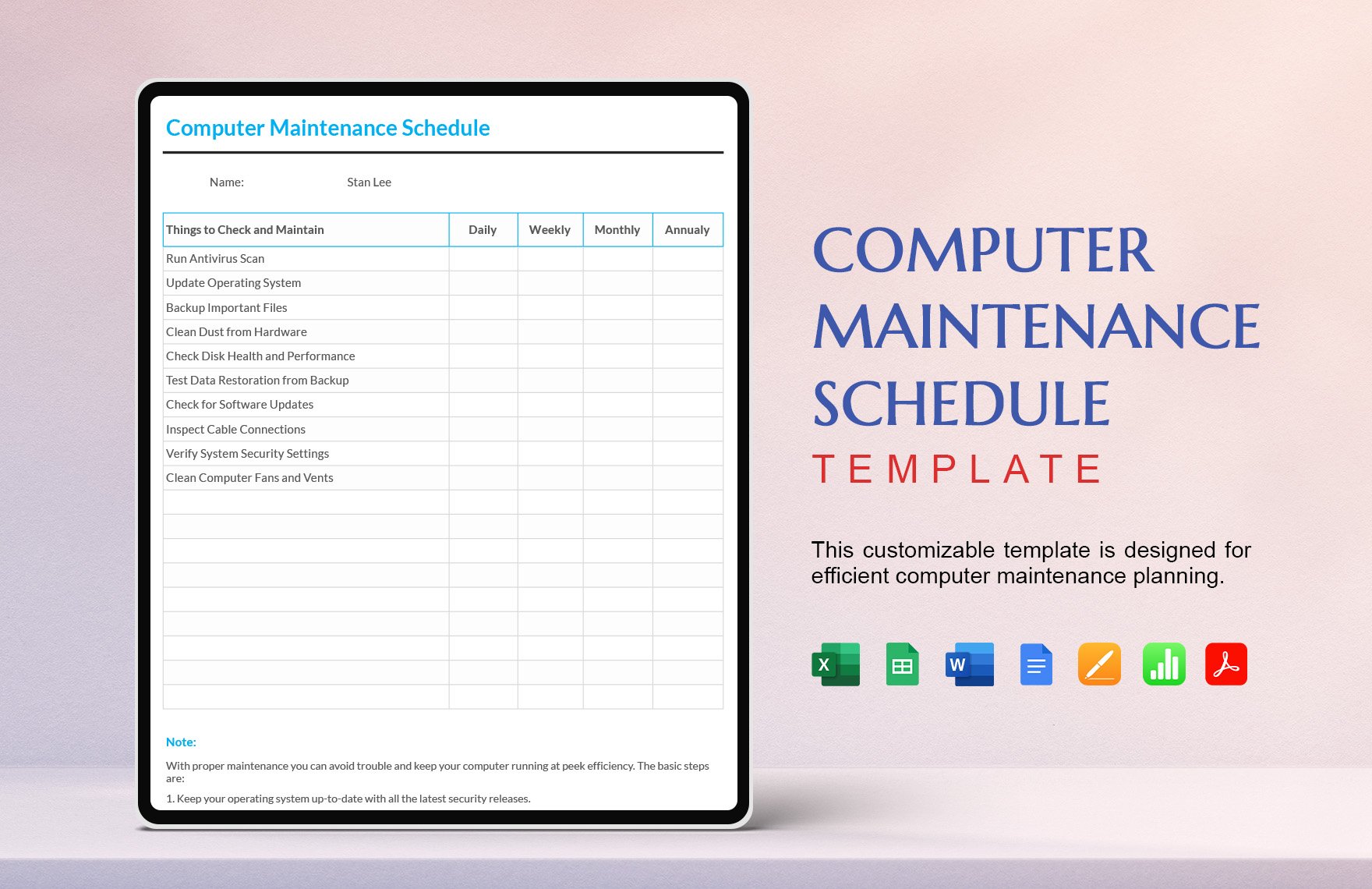

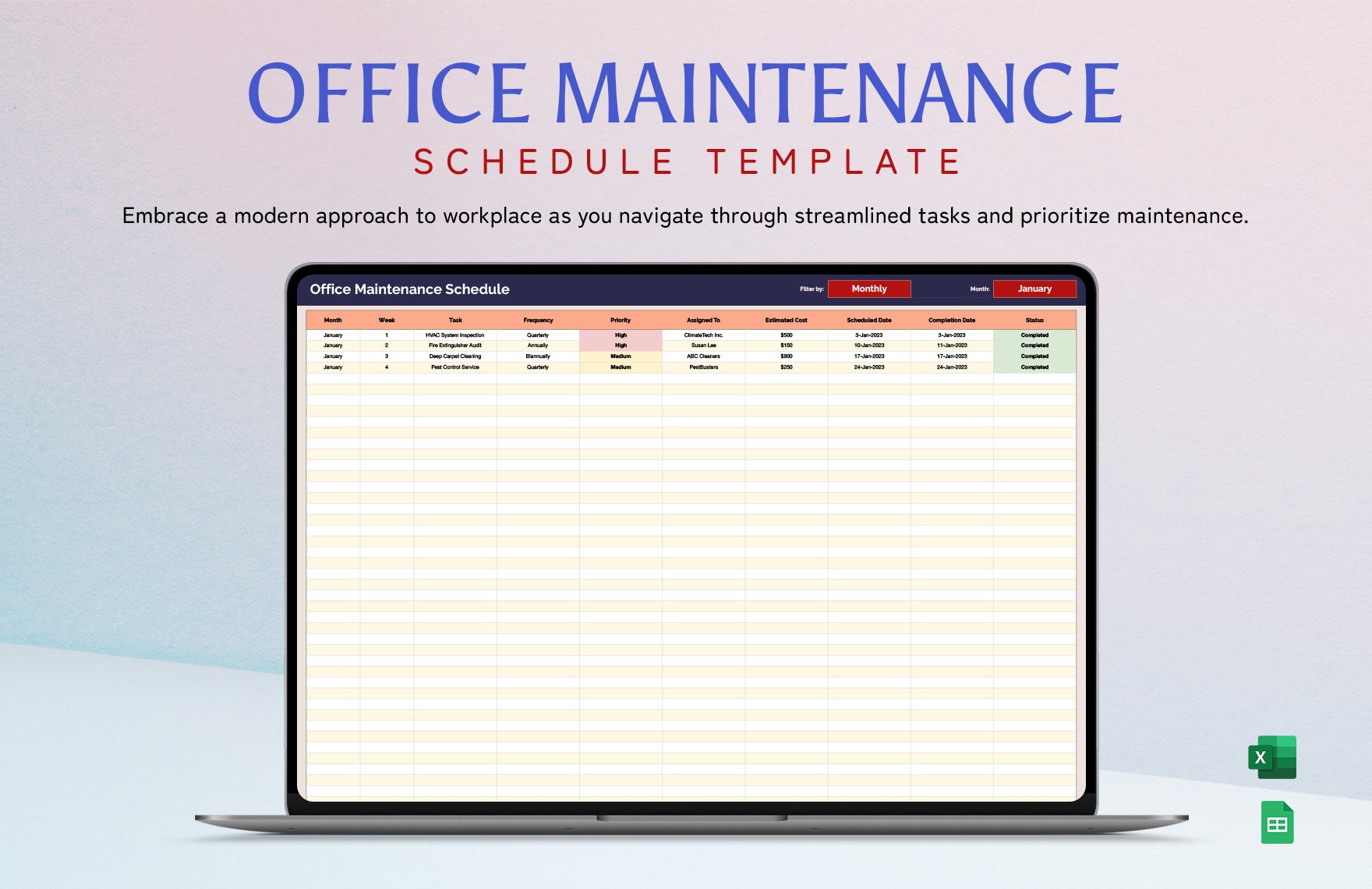

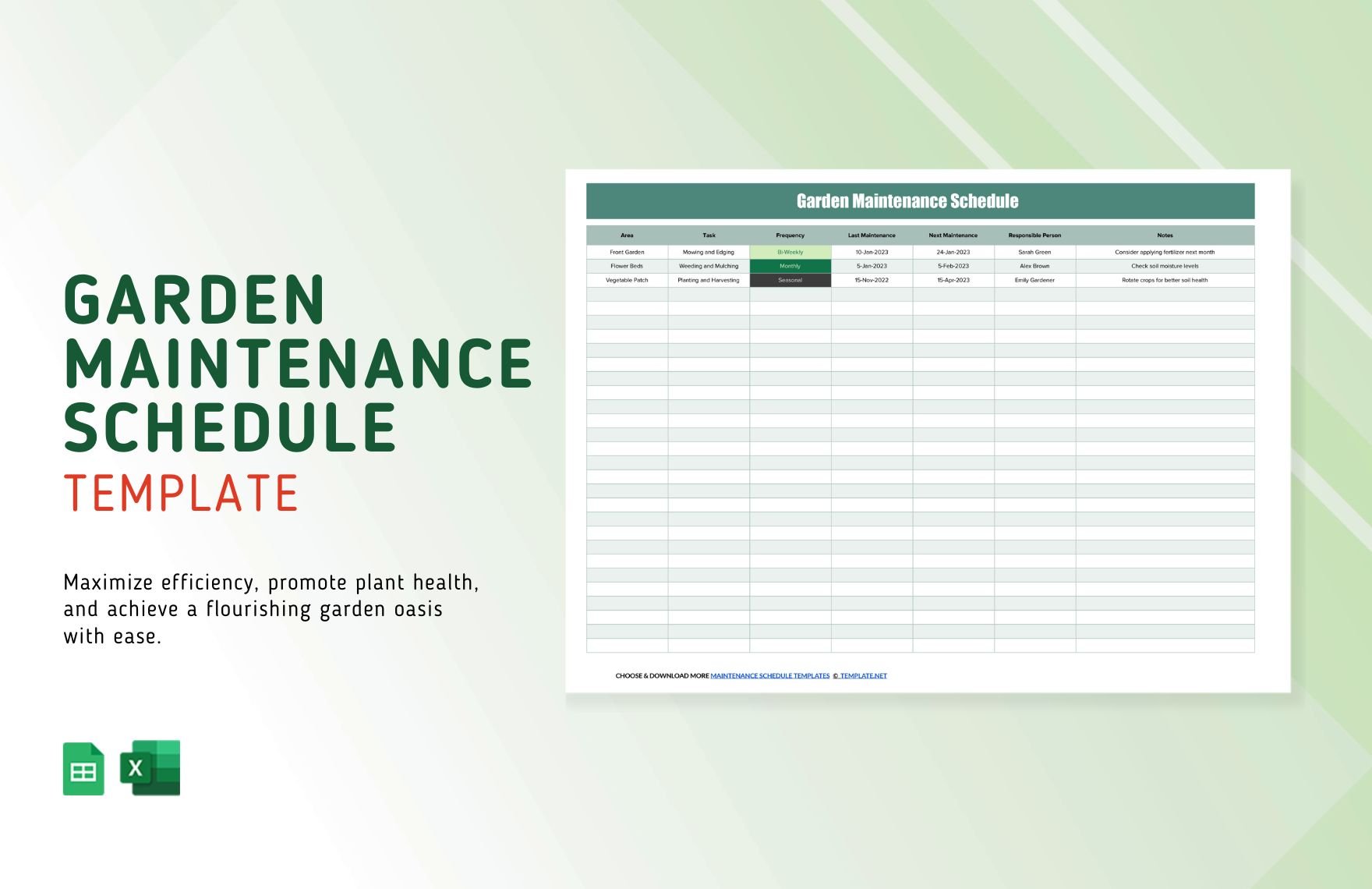

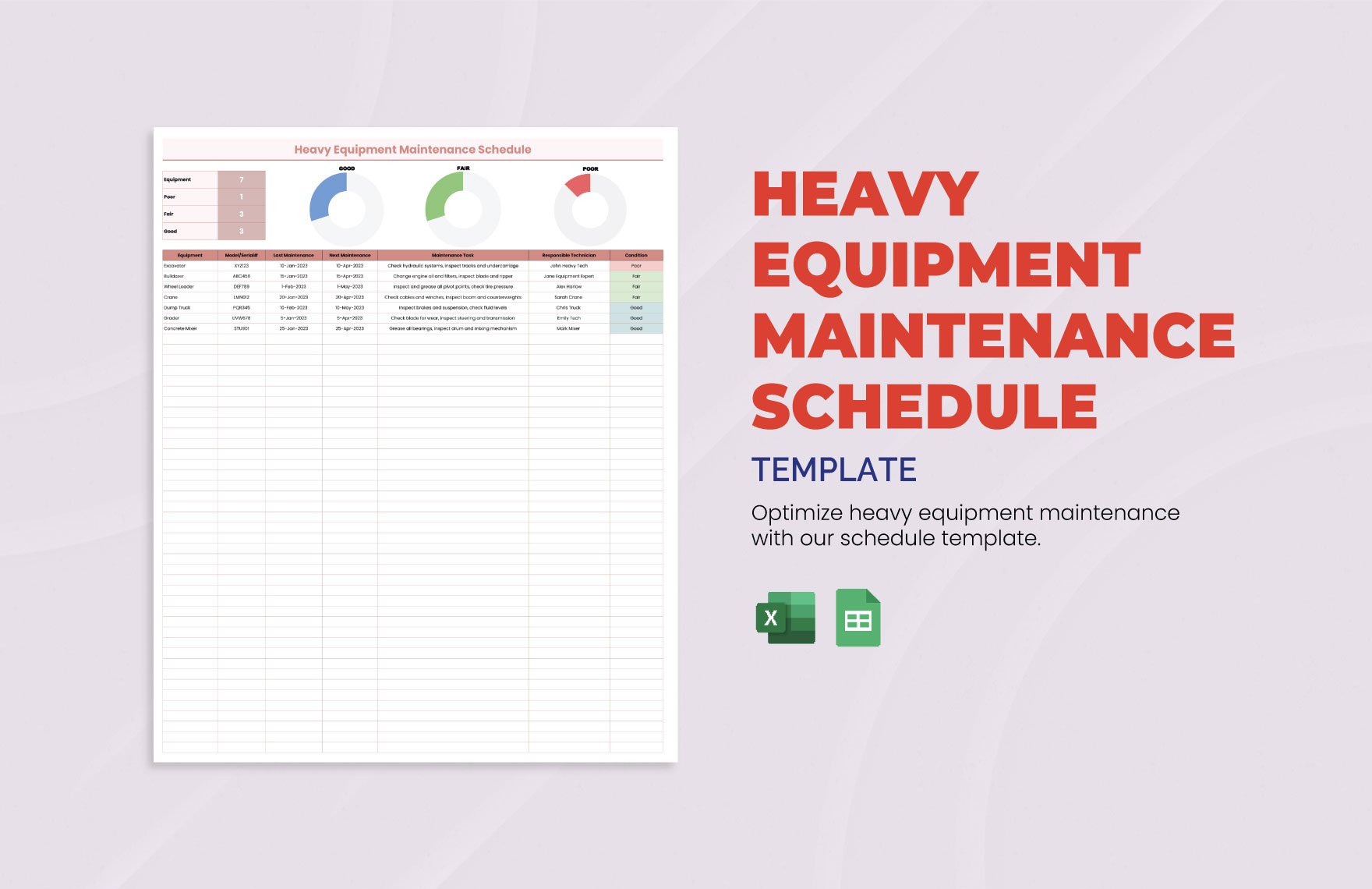

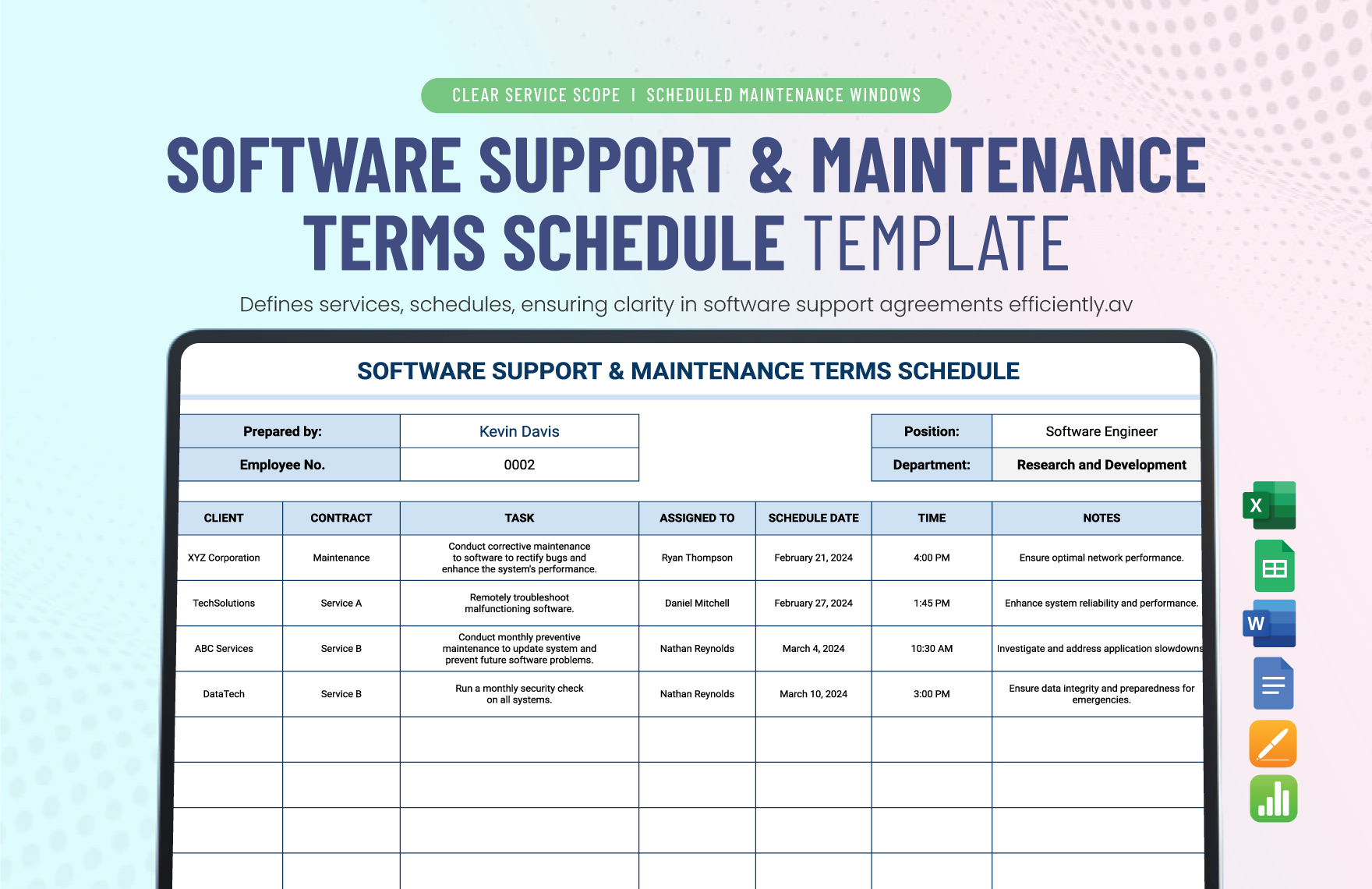

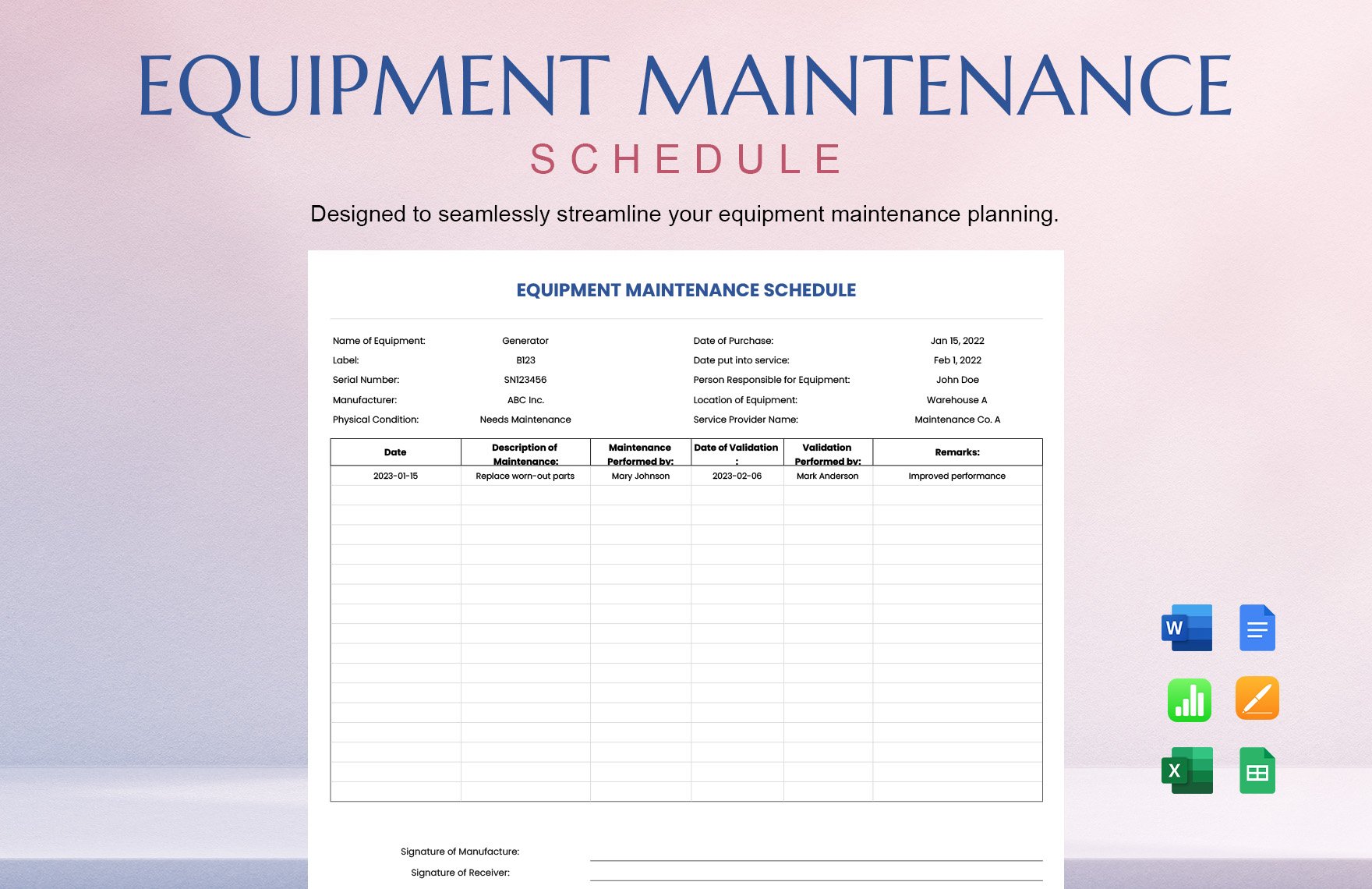

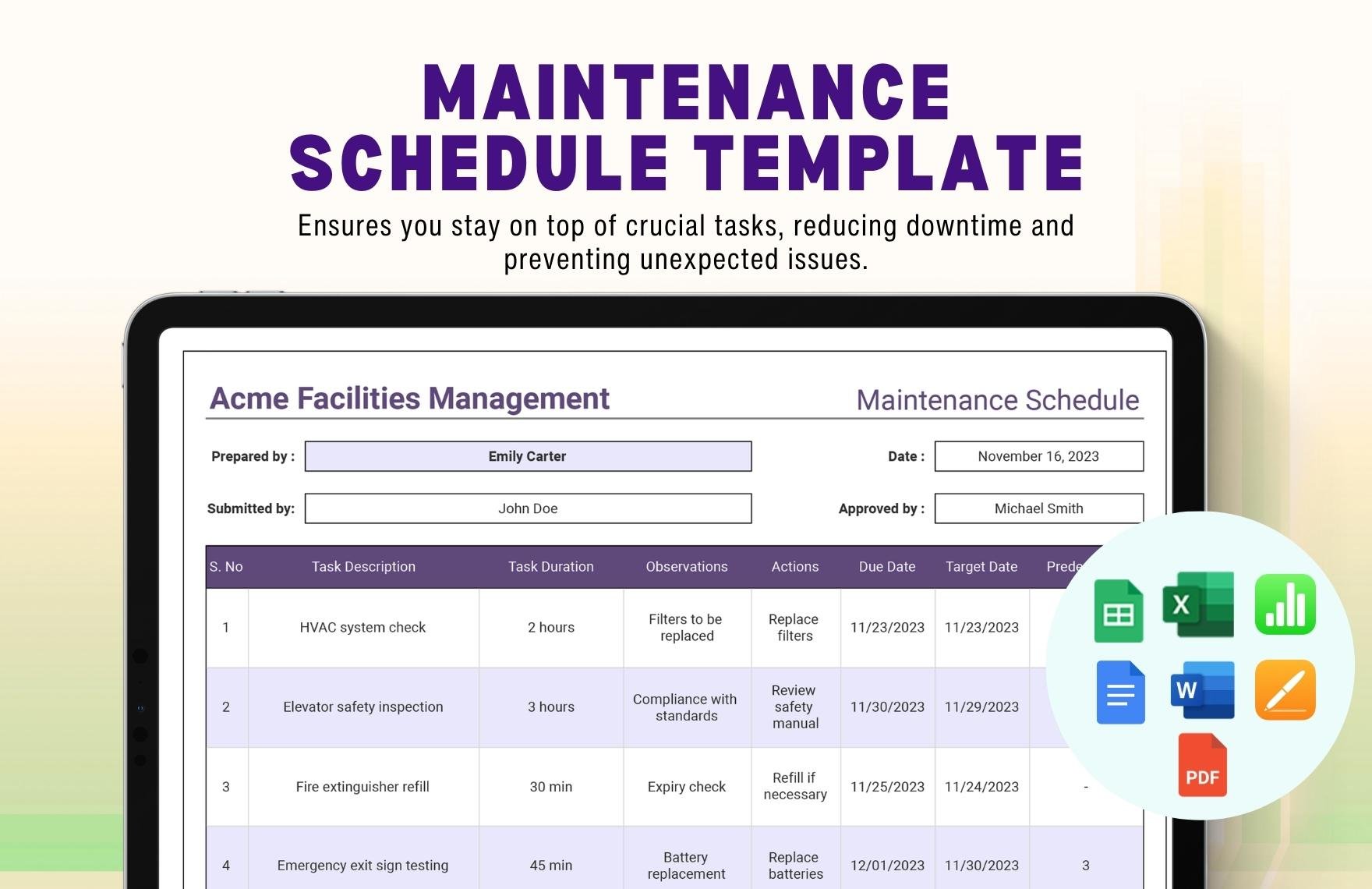

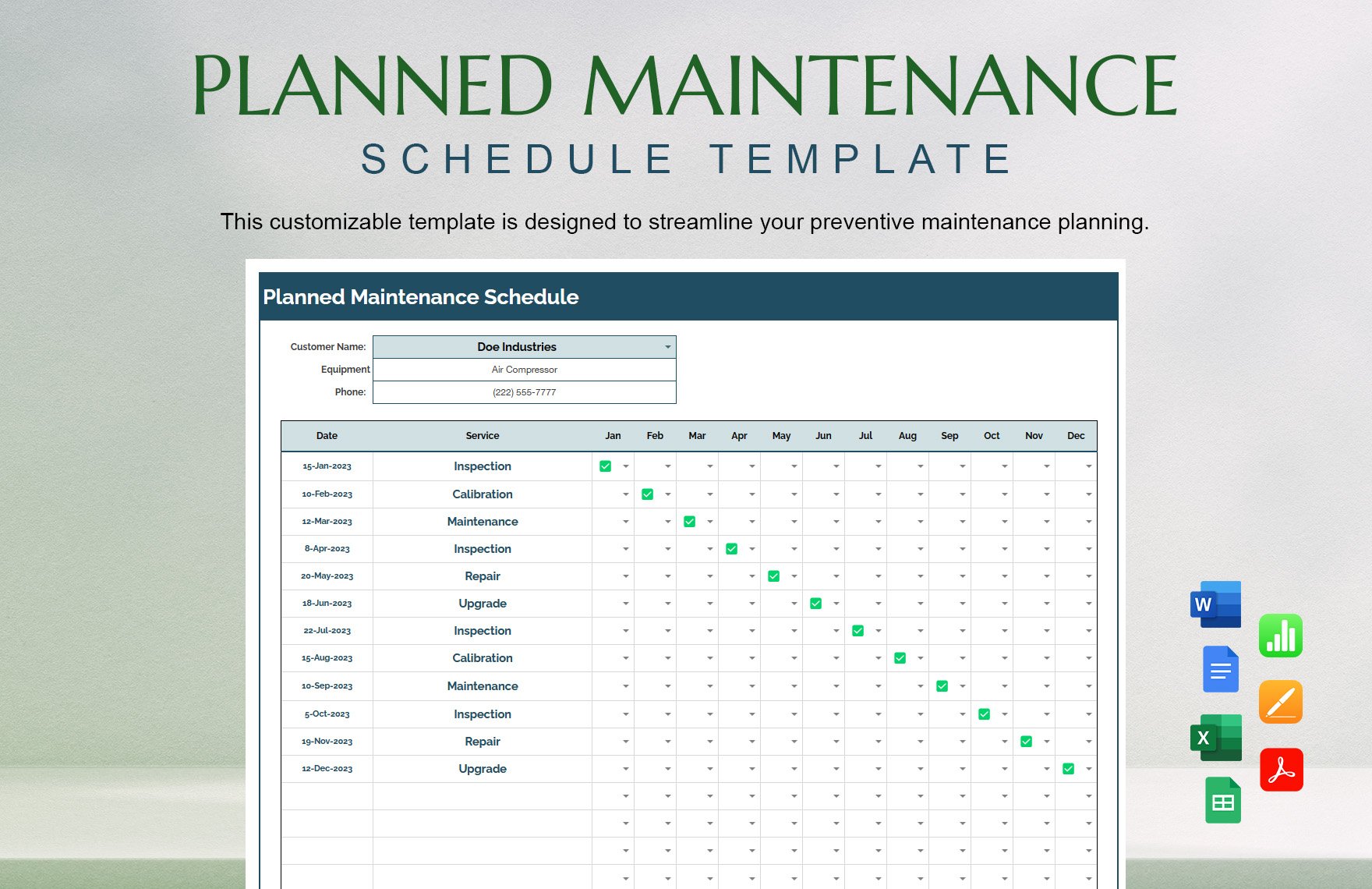

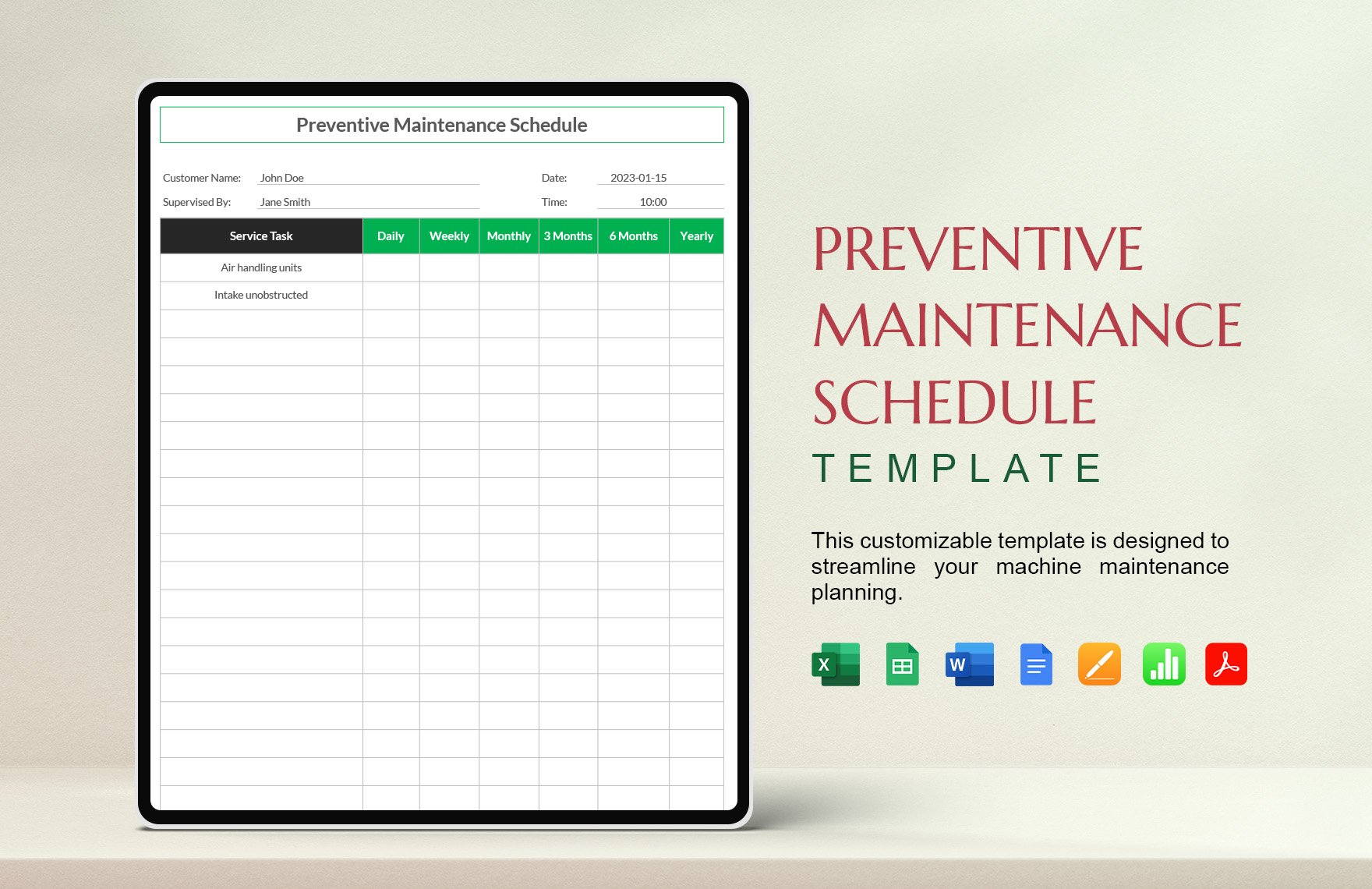

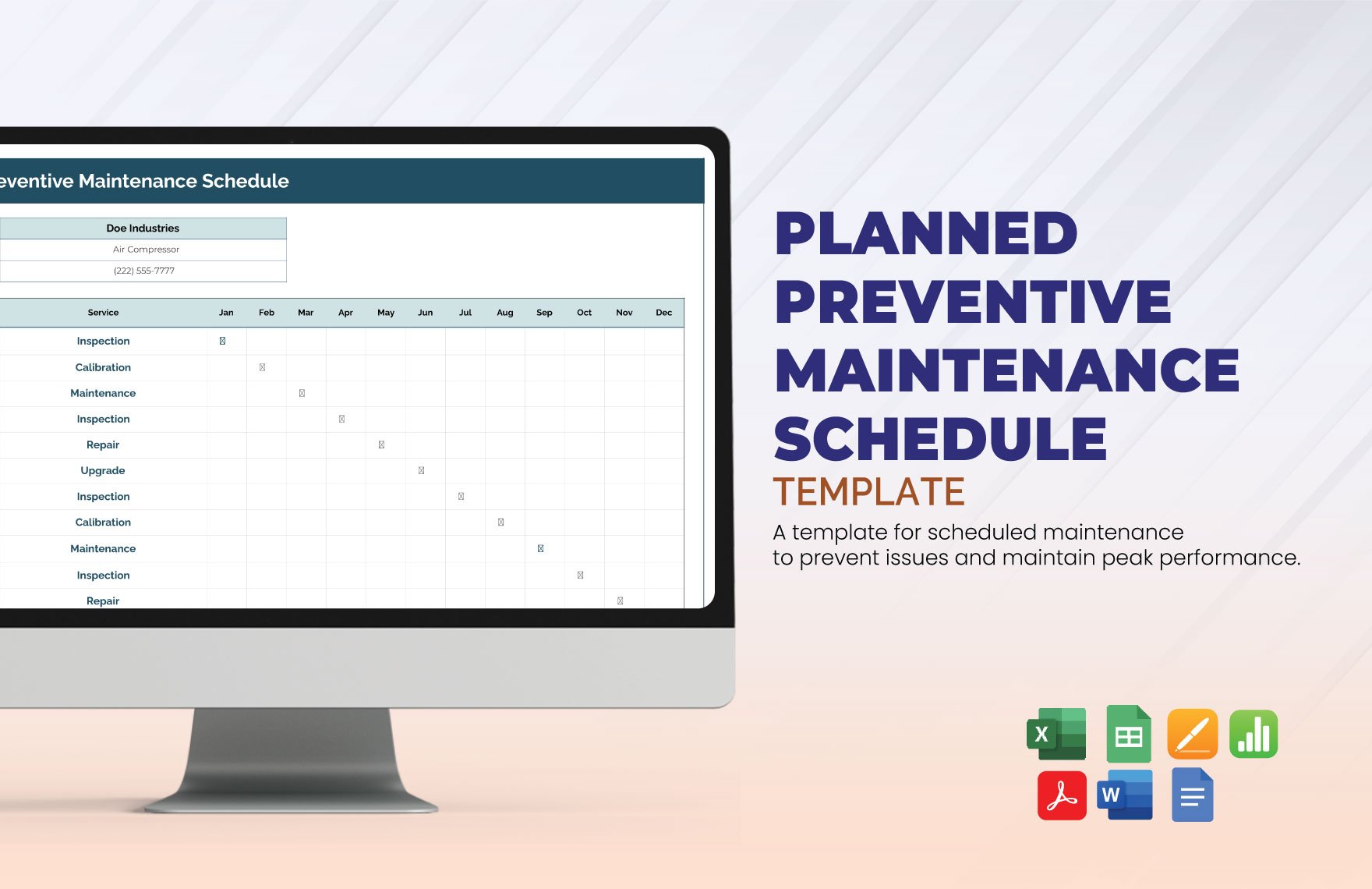

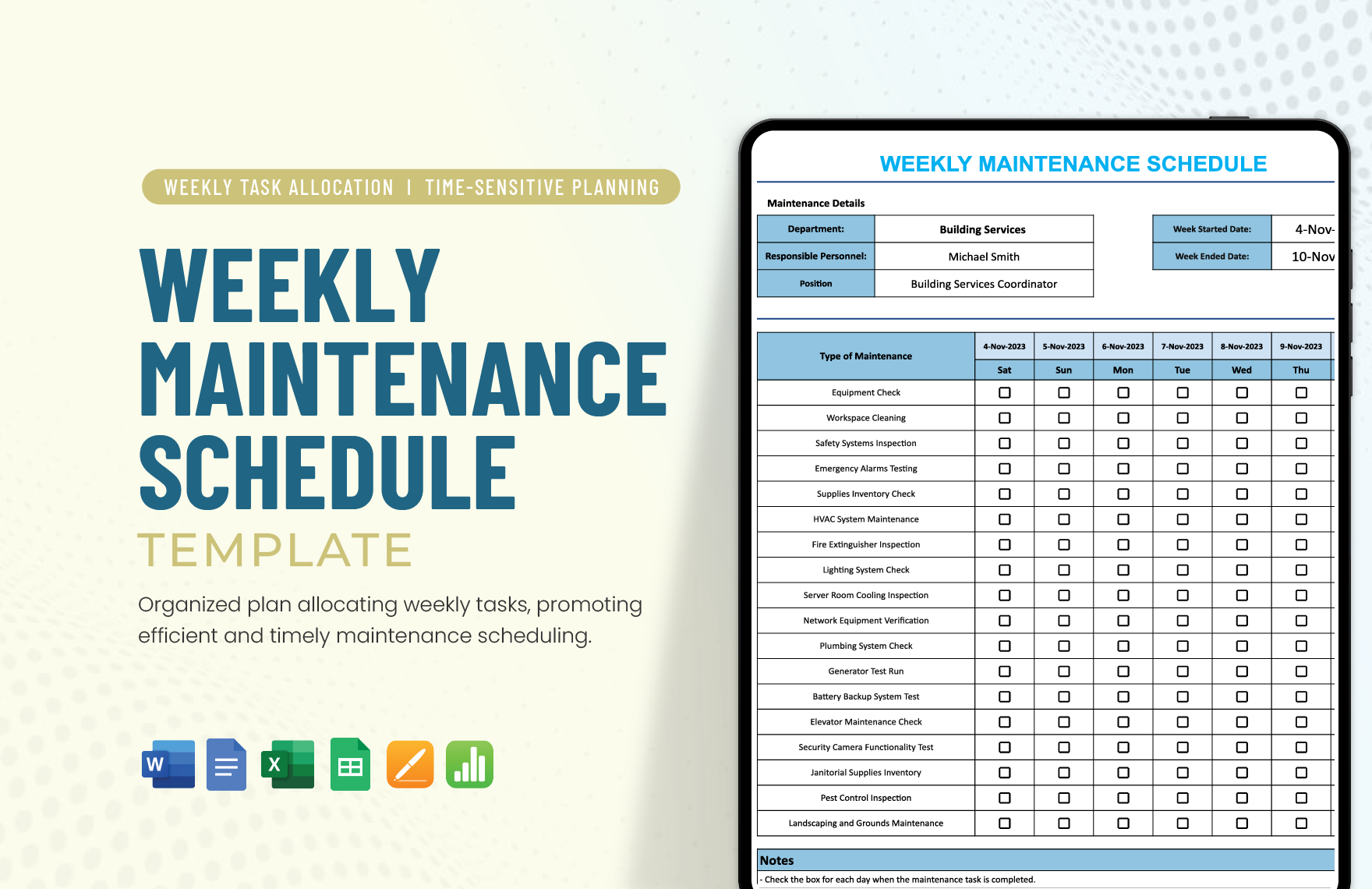

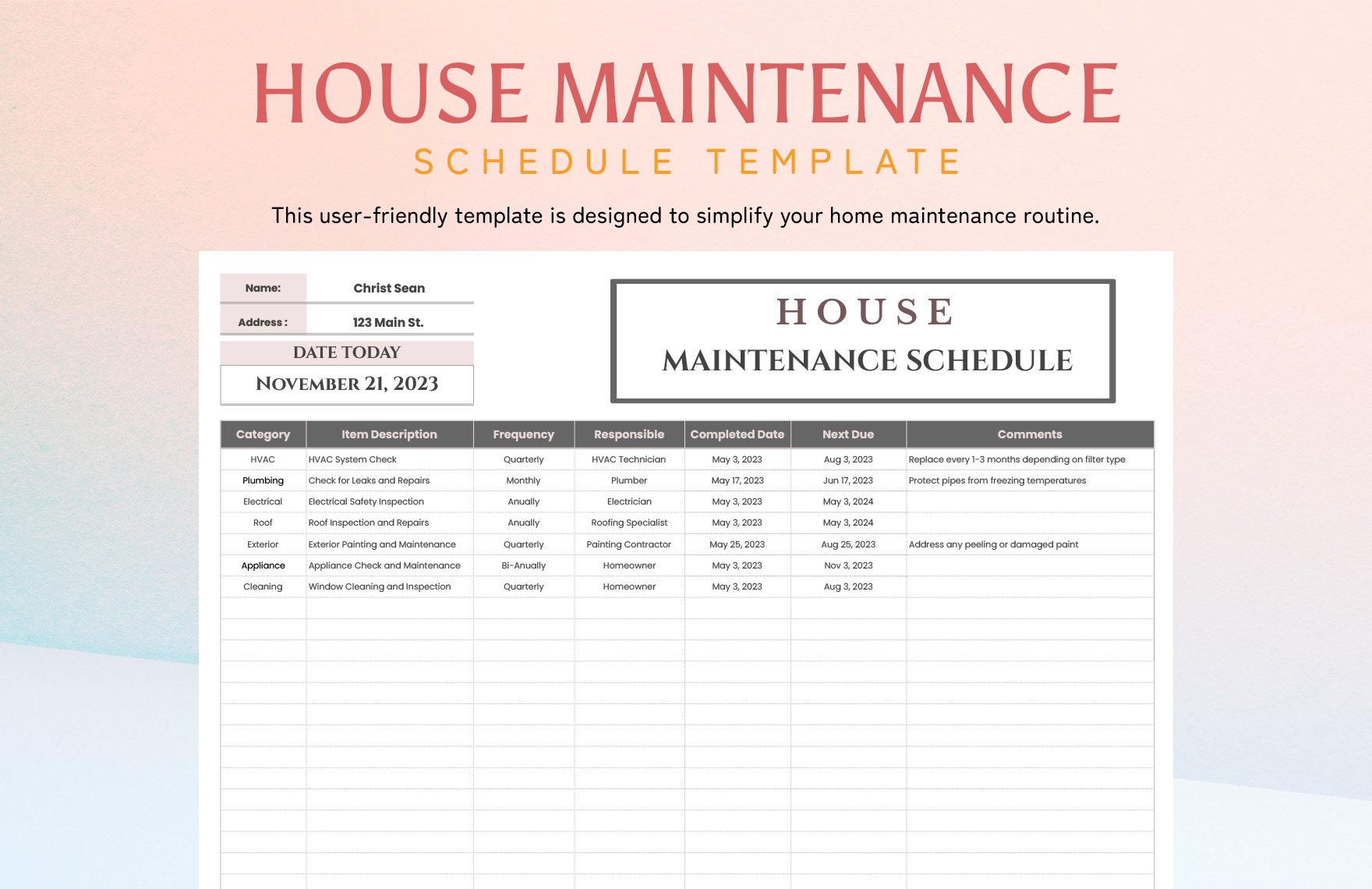

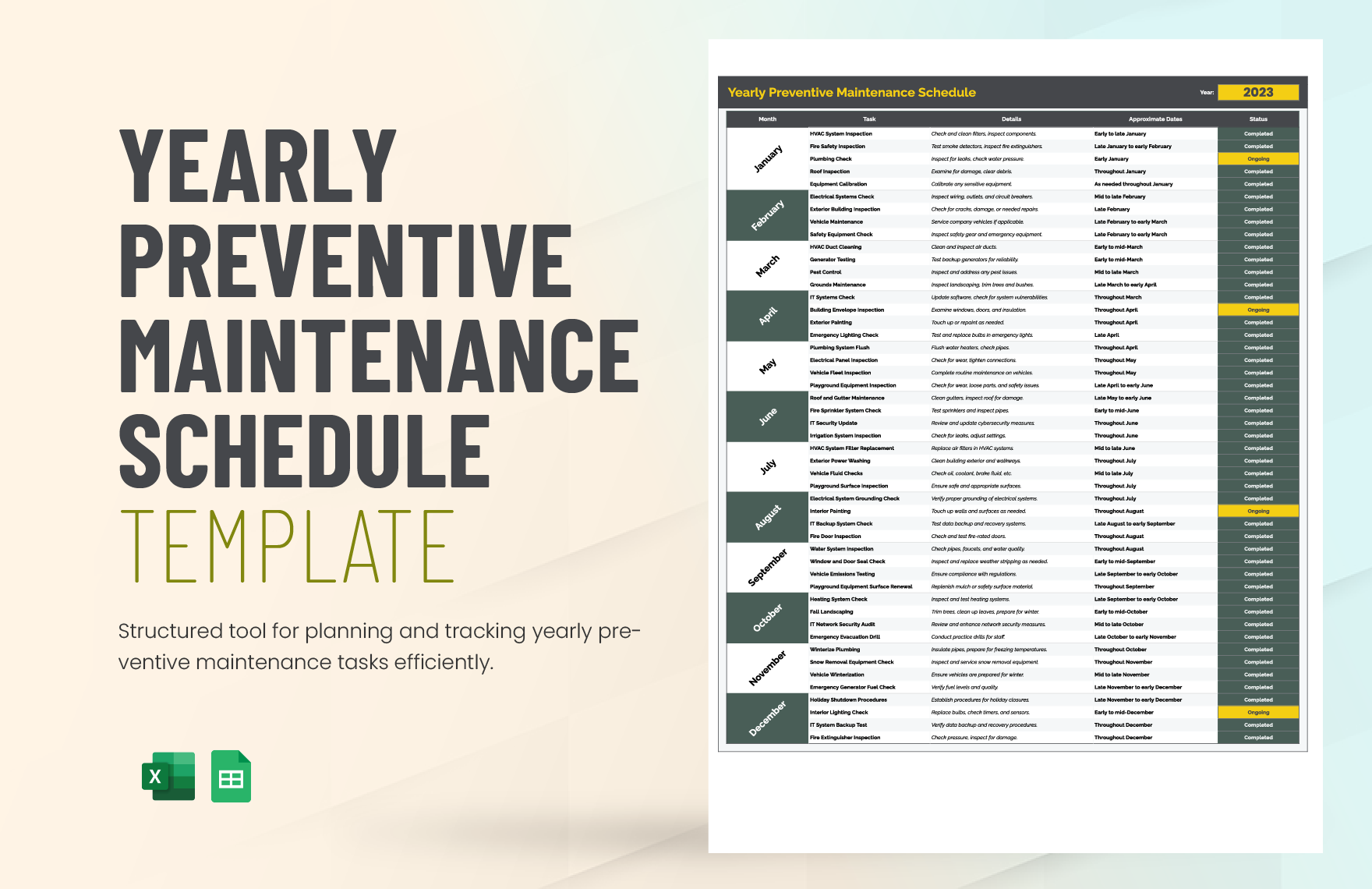

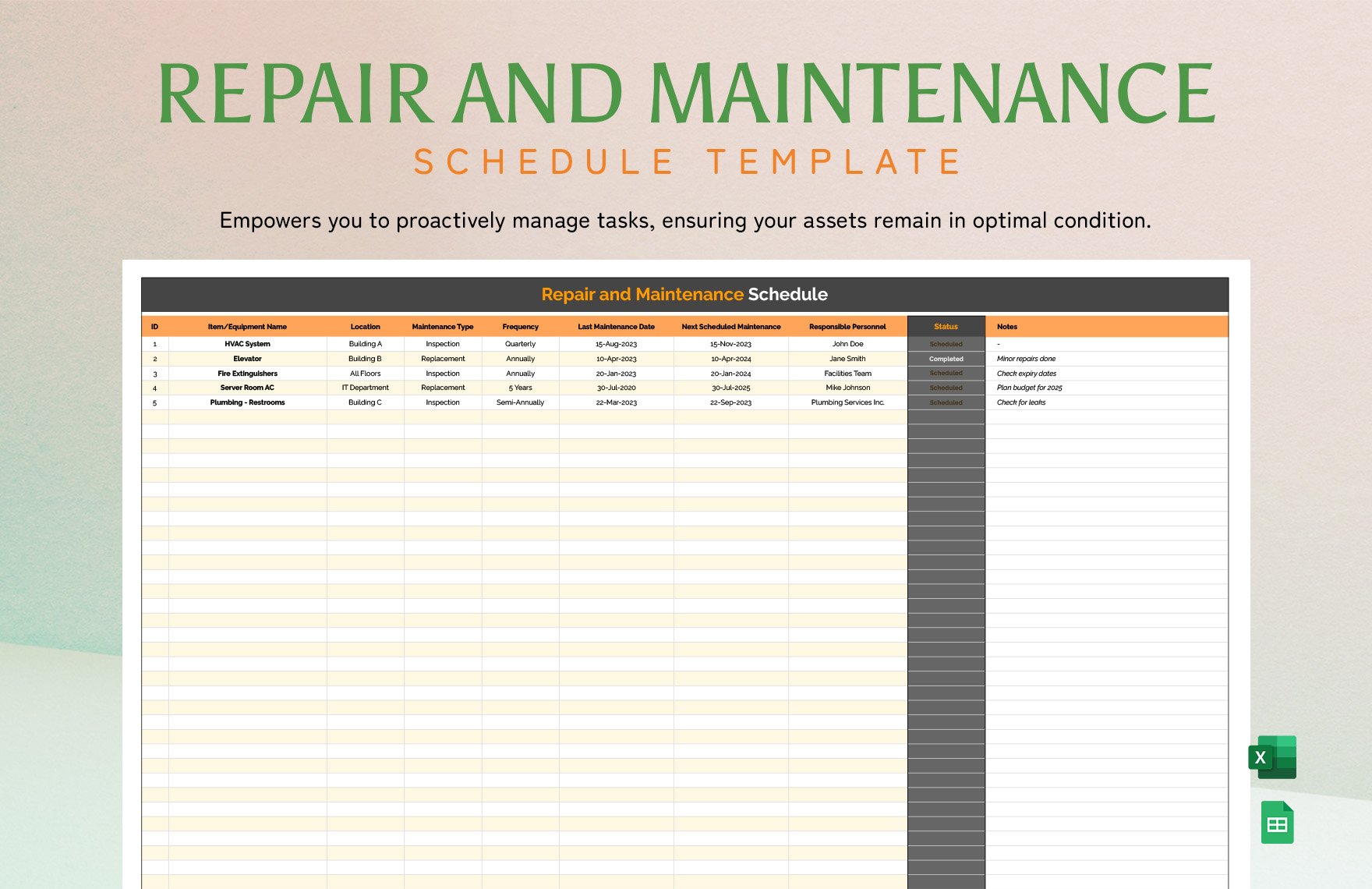

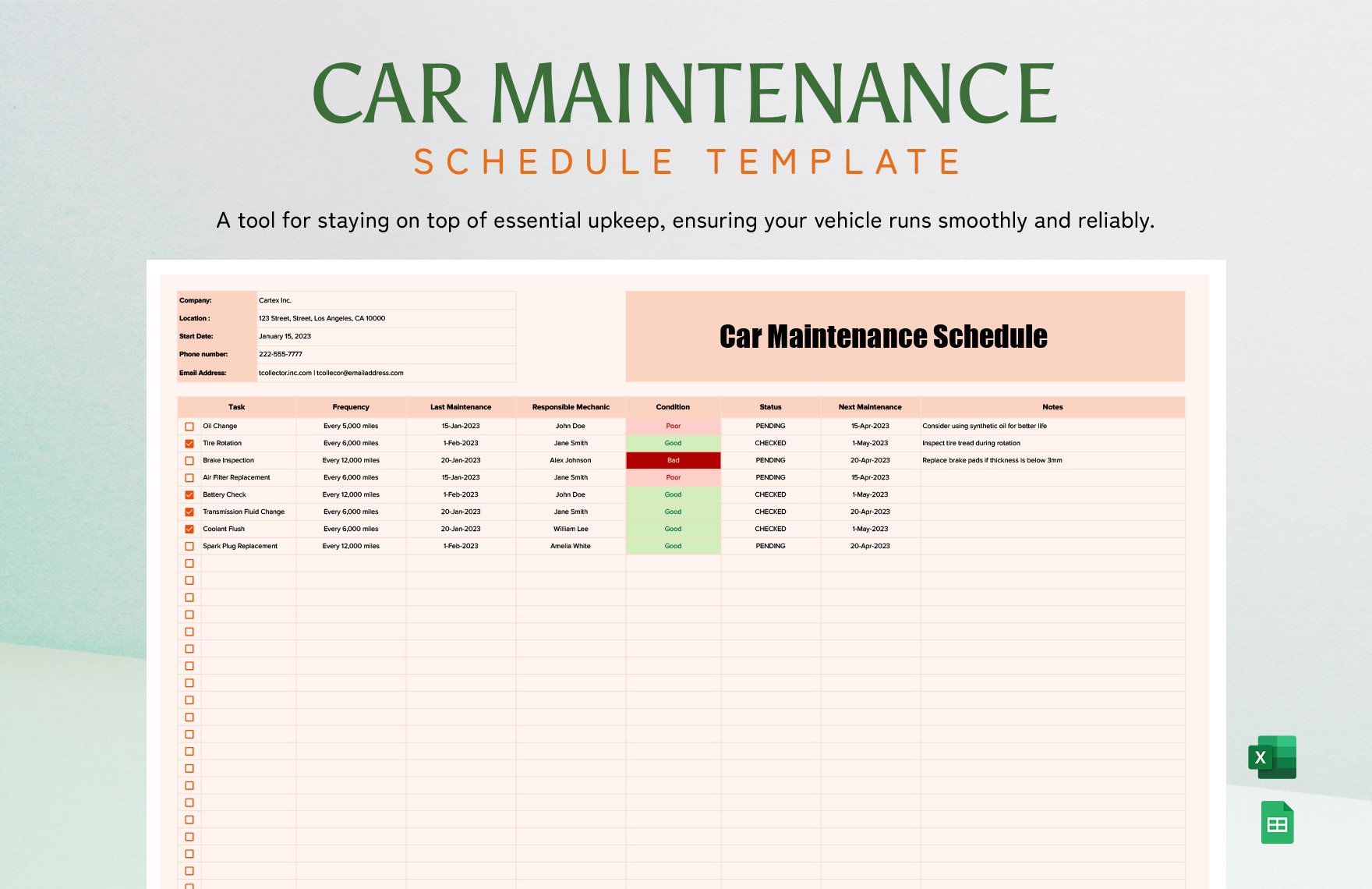

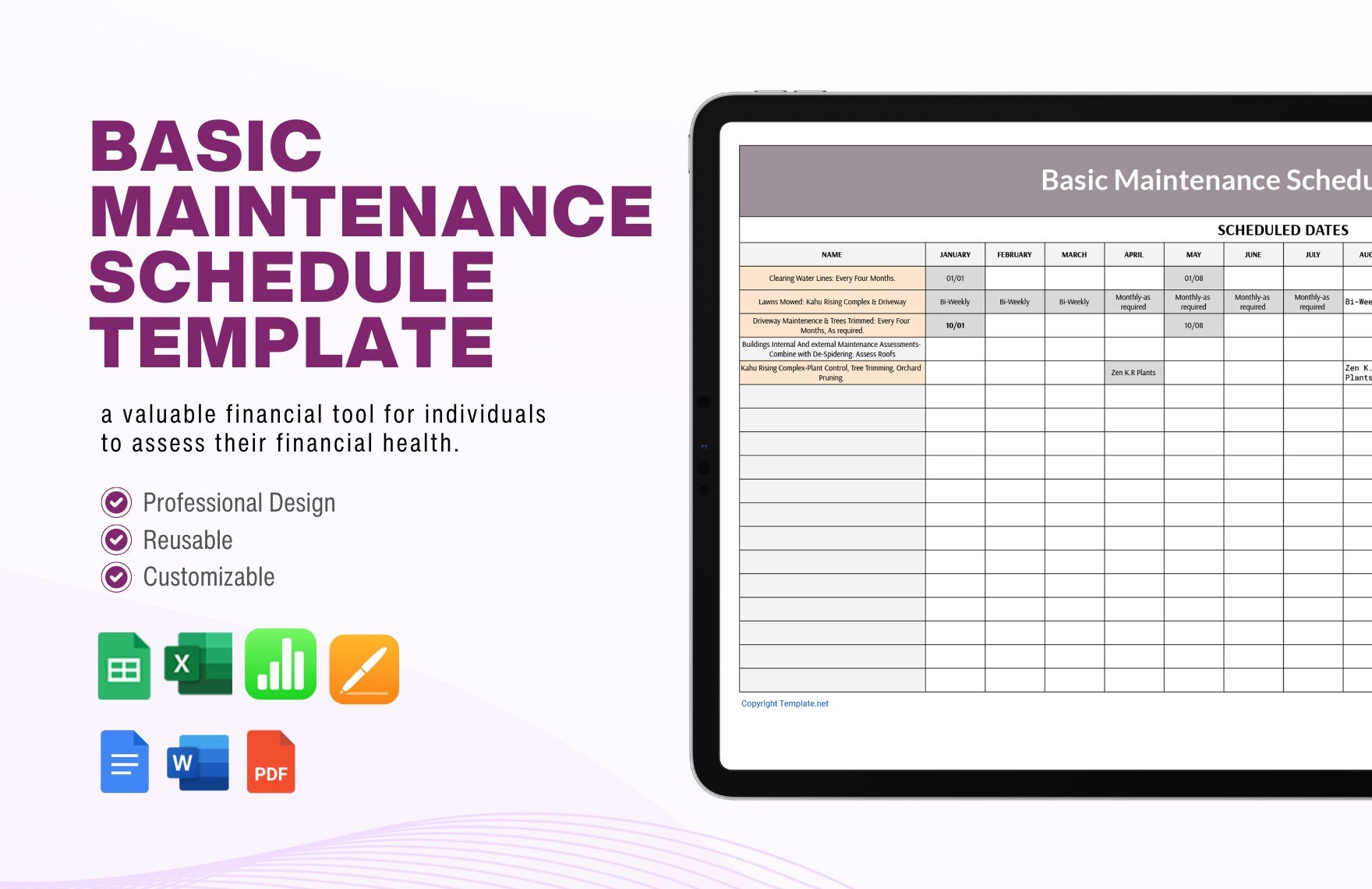

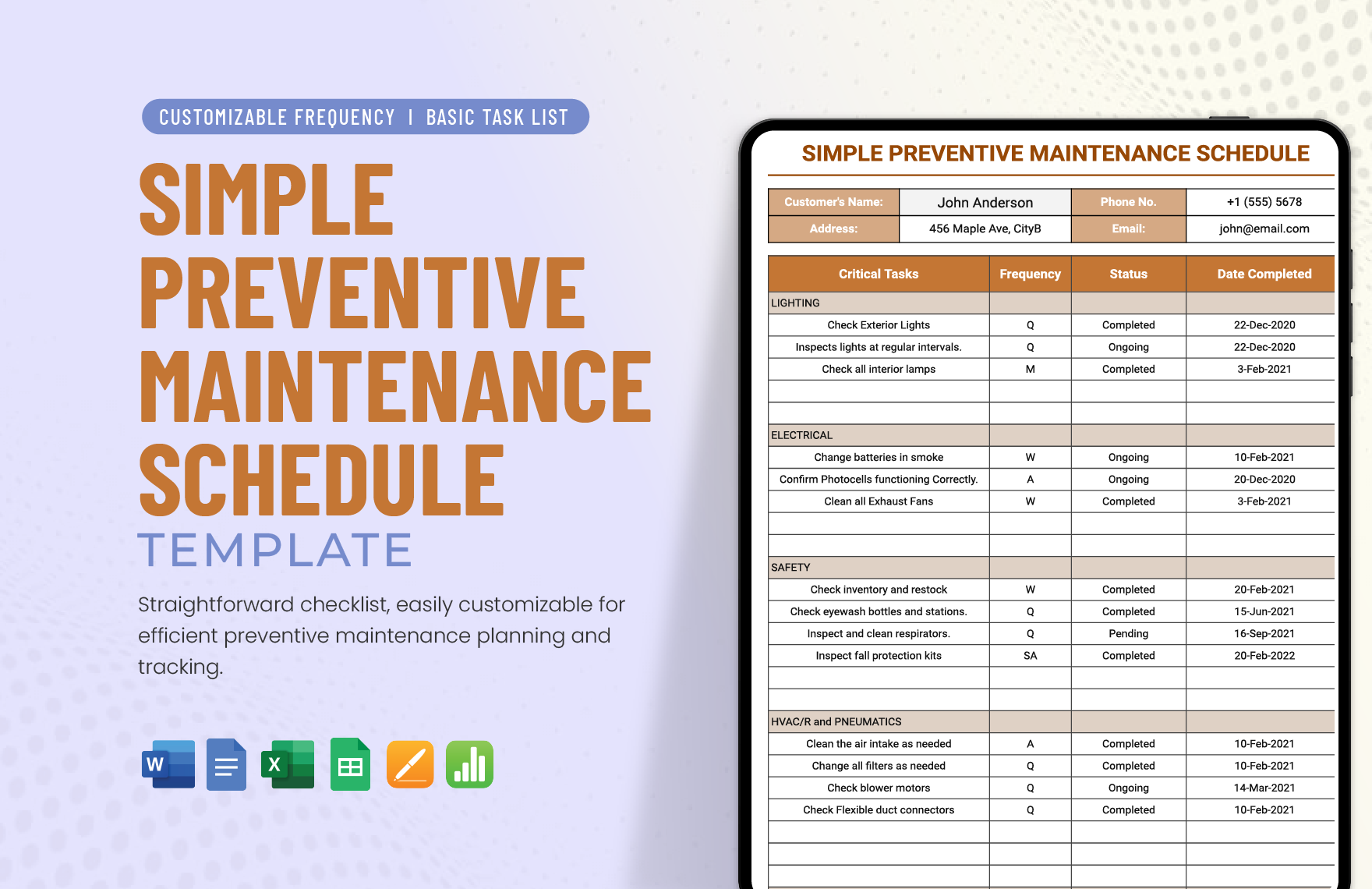

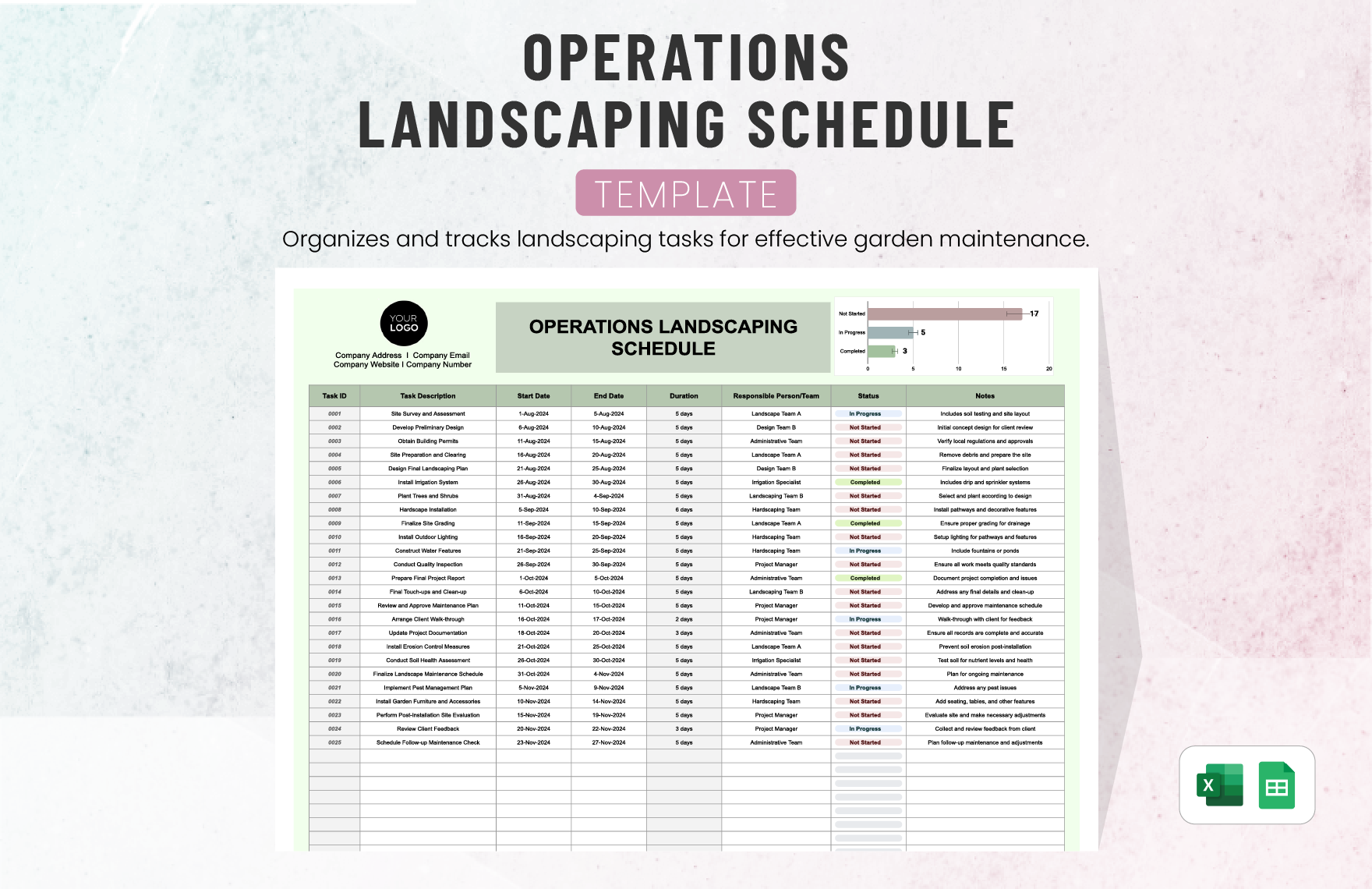

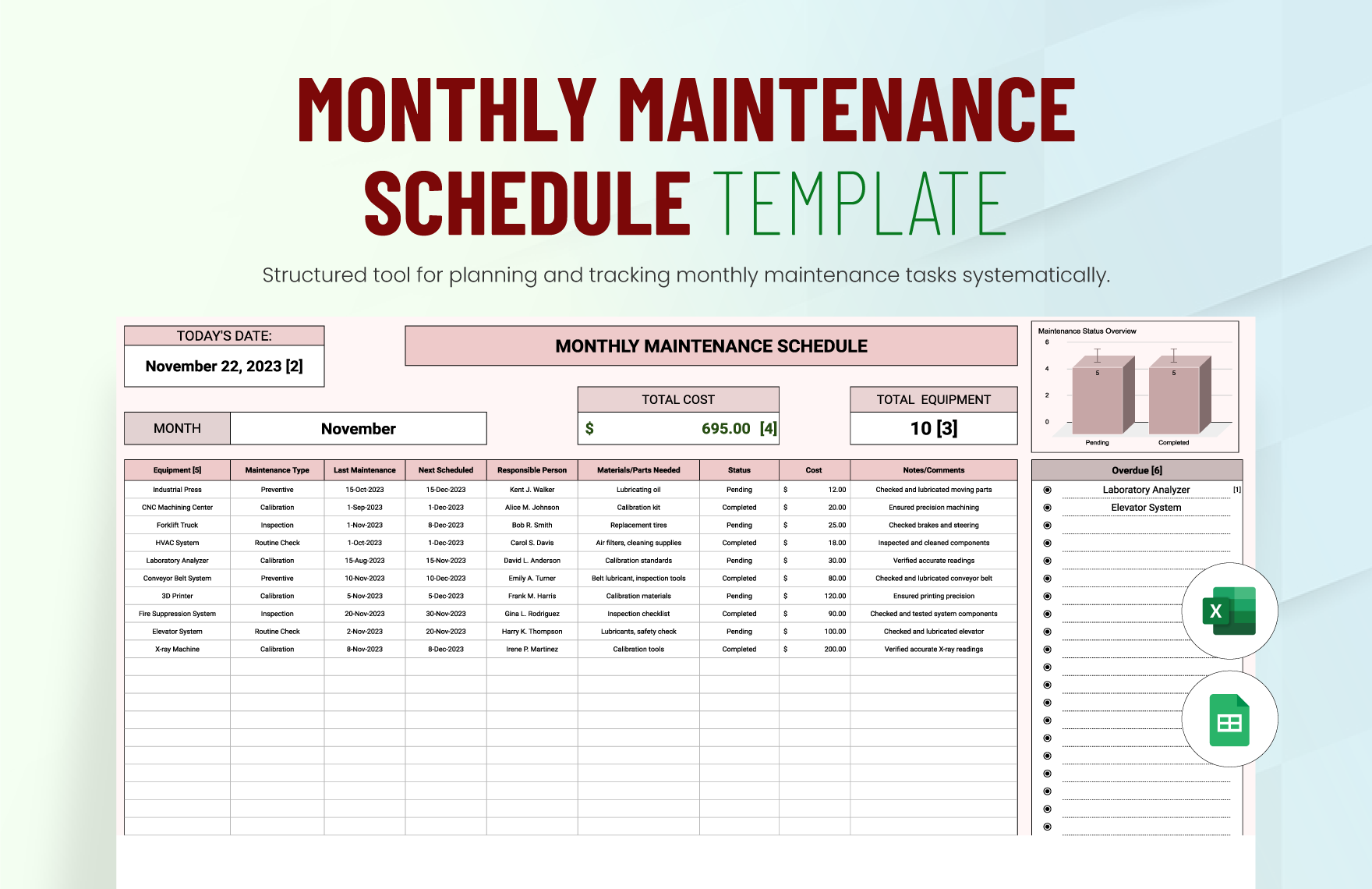

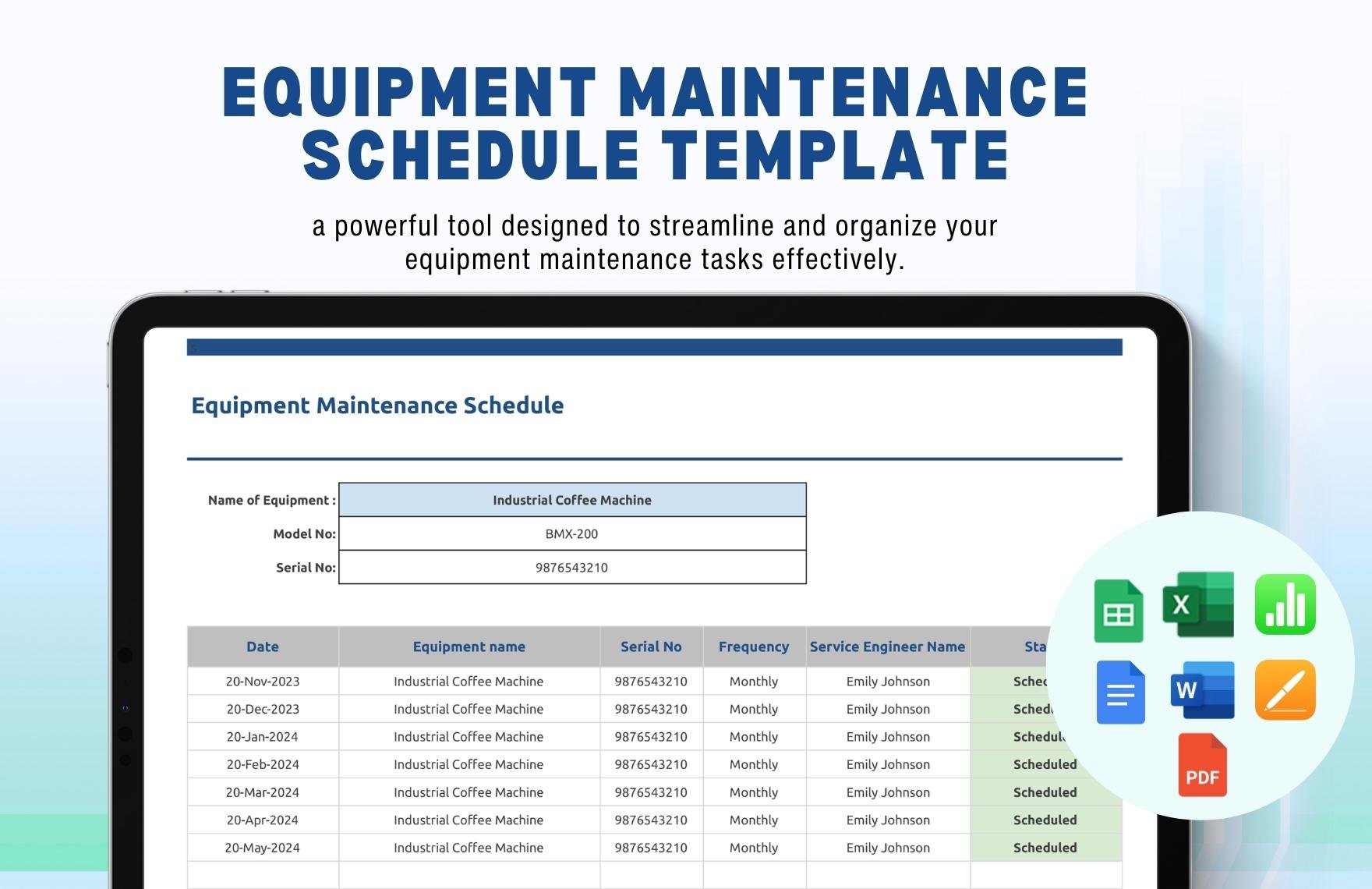

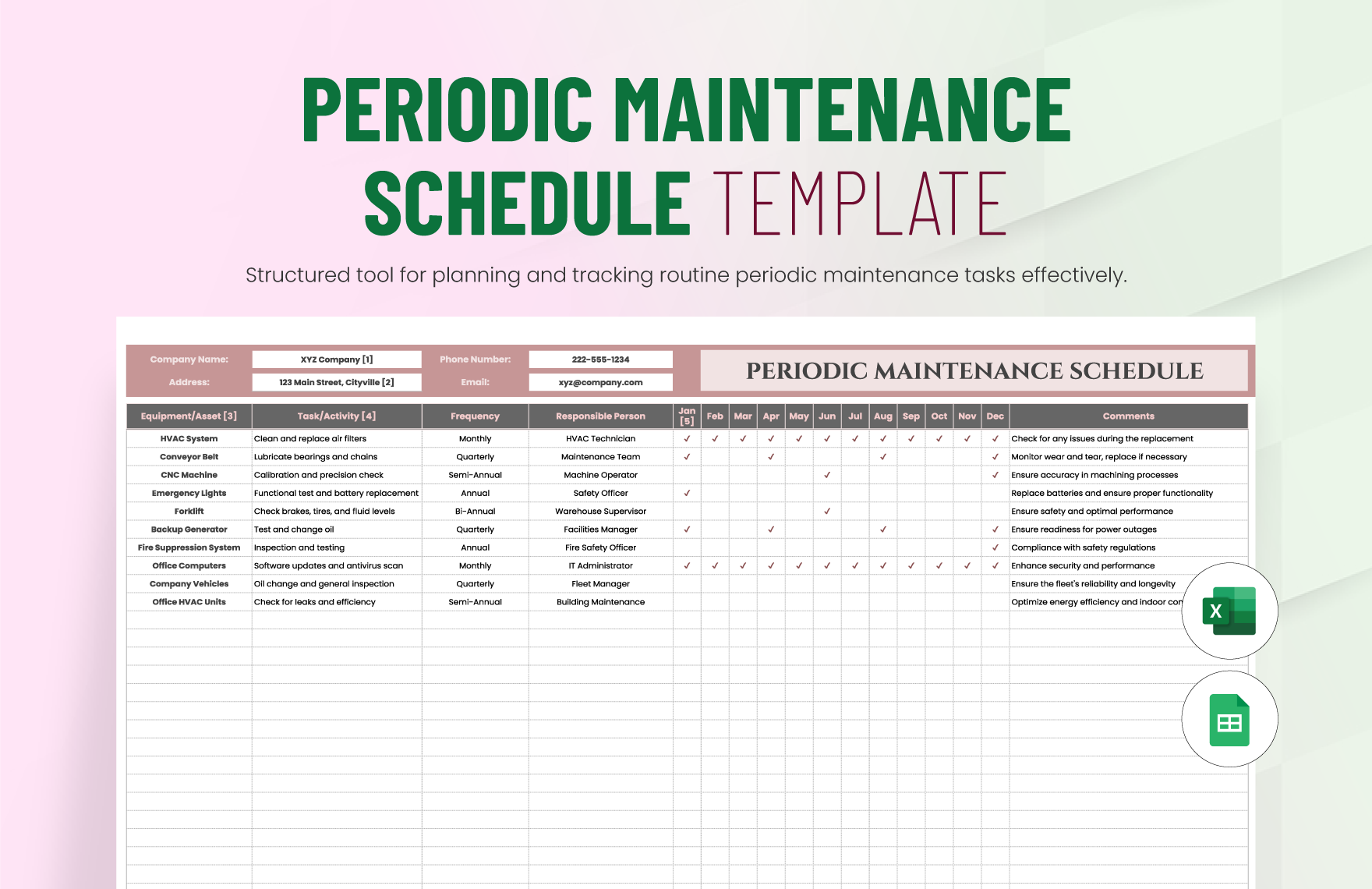

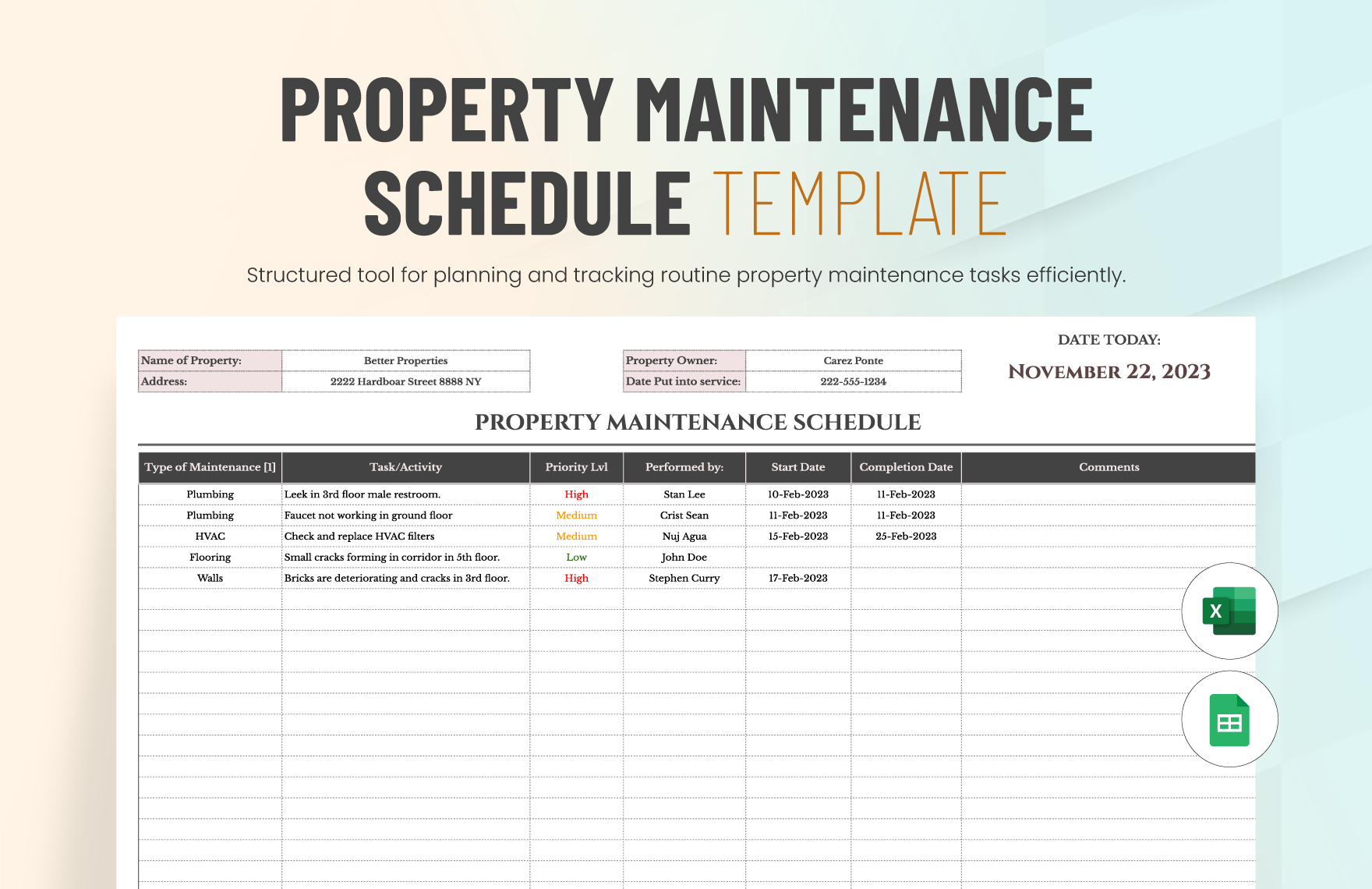

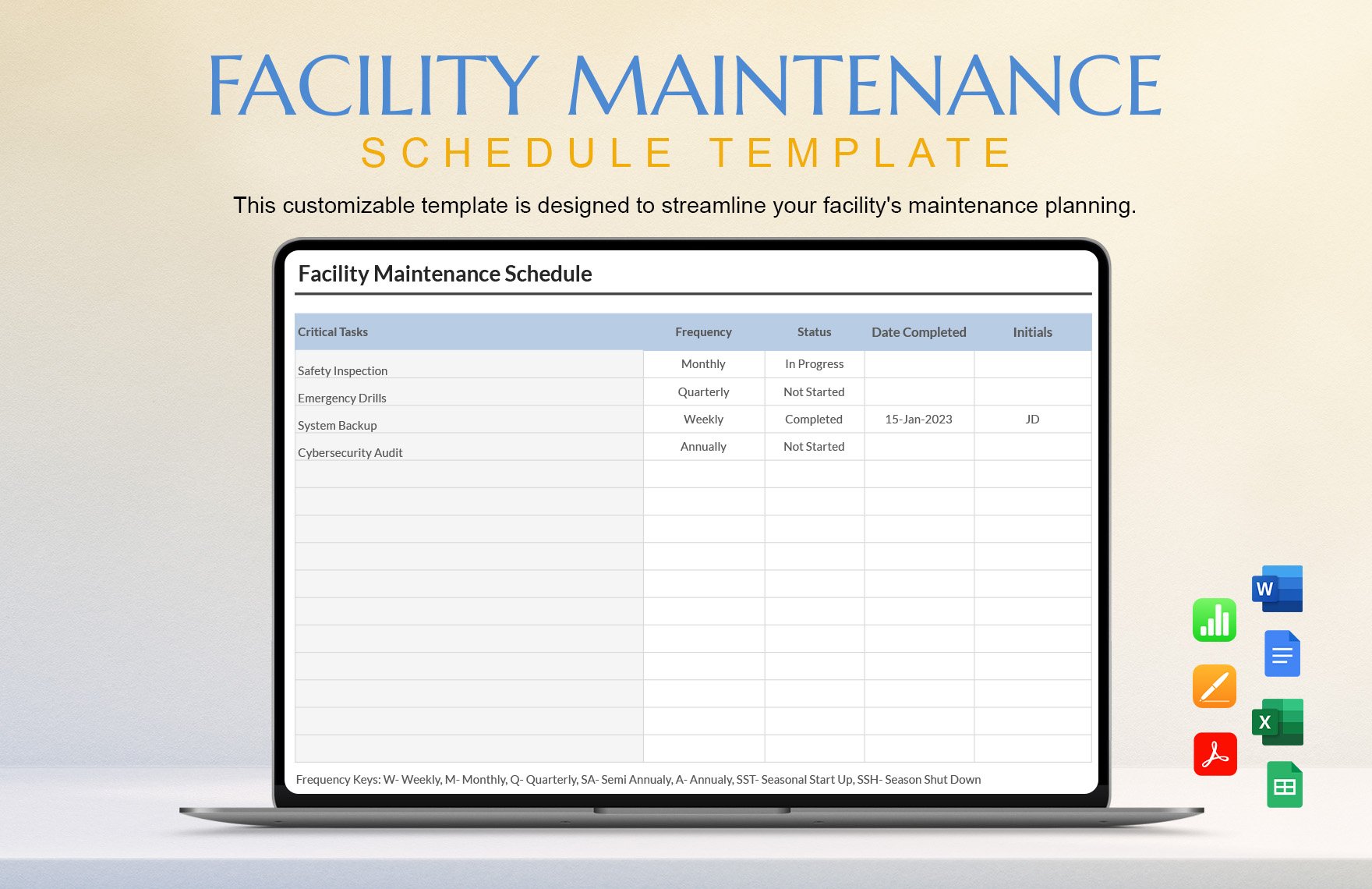

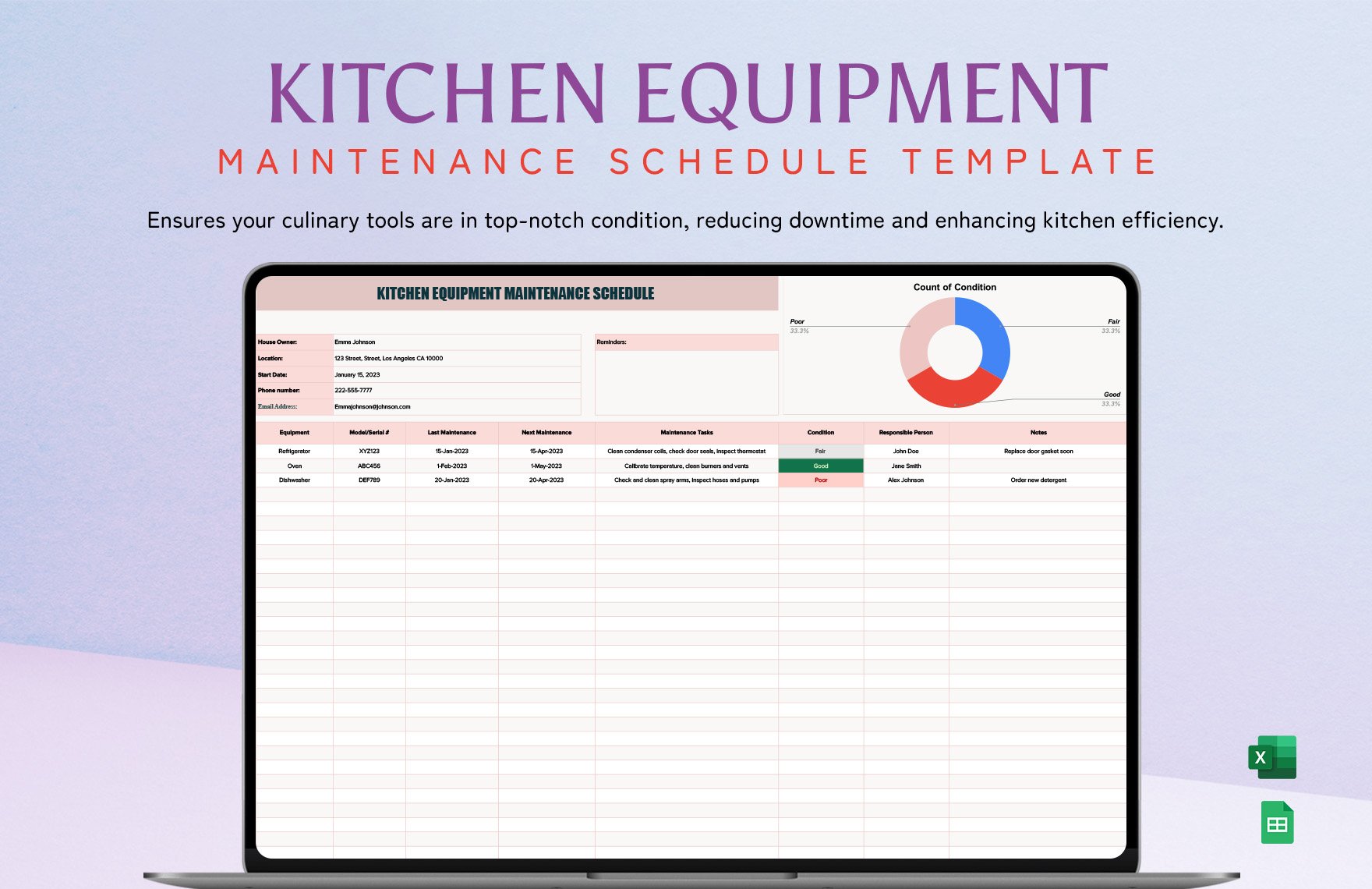

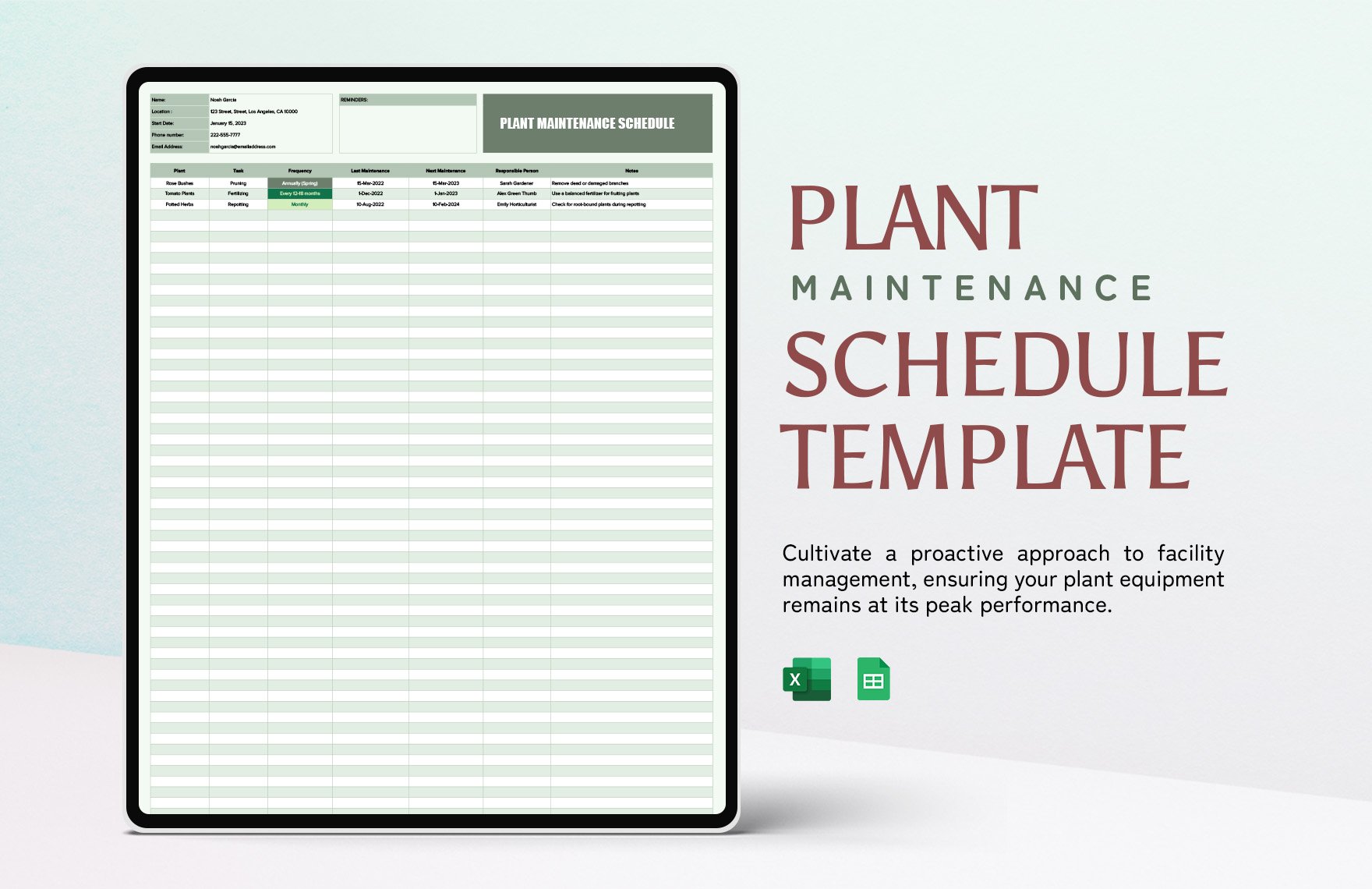

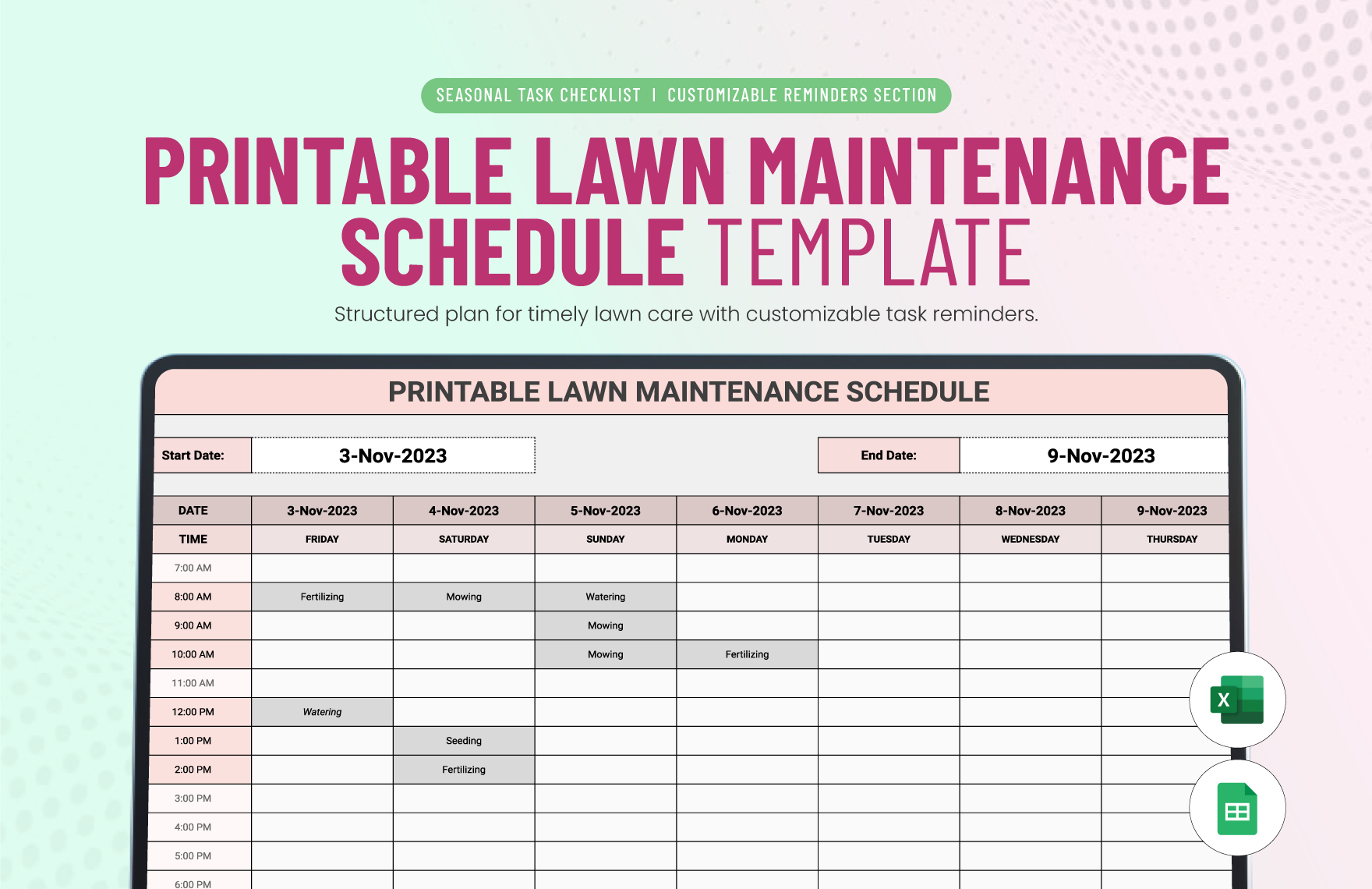

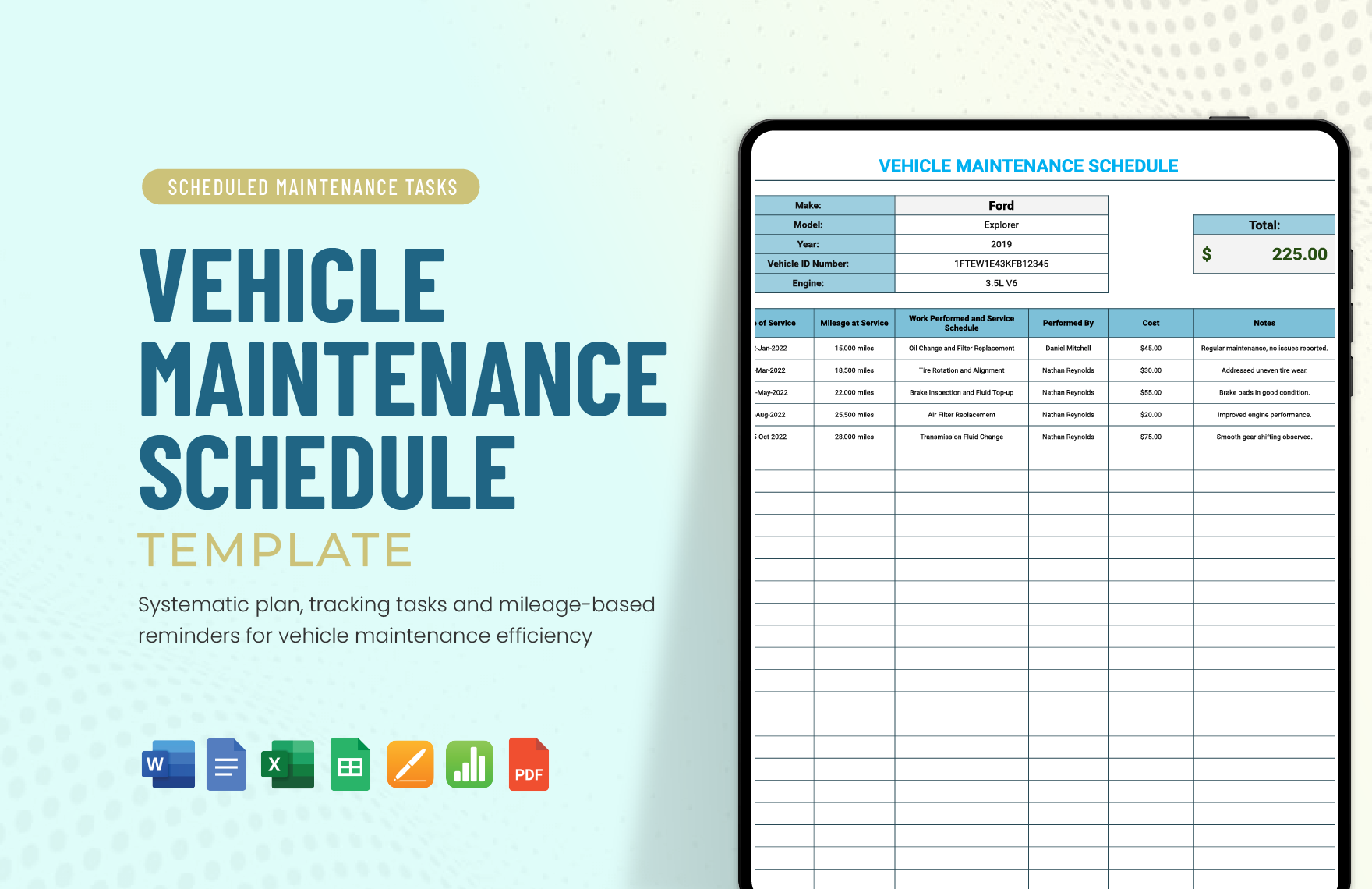

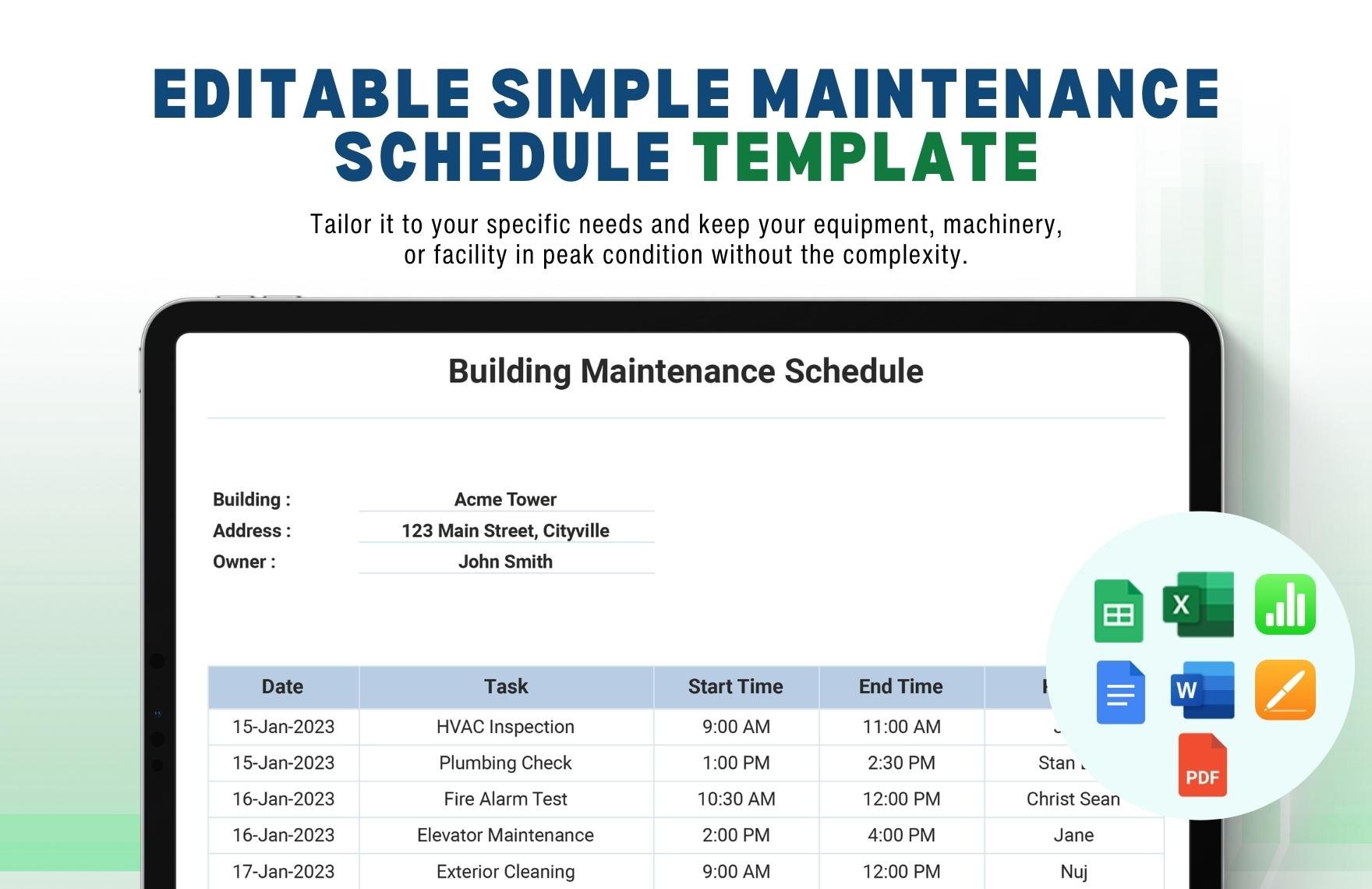

Creating a maintenance schedule with the use of Microsoft Excel is undeniably the best and the most logical way of creating one. And with that, we provide you with our ready-made Maintenance Schedule Templates that you can not only view and edit using Microsoft Excel, but you can also download and get for free! To make things even more convenient on your end, all of these templates include a professionally made format that allows you to simply input your preferred details and your maintenance schedule is already good to go. Easy to download and just as easy to customize and print, these ready-made Maintenance Schedule Templates are indeed a deal you should not miss out on. Download these in Microsoft Excel for free today!

What Is a Maintenance Schedule?

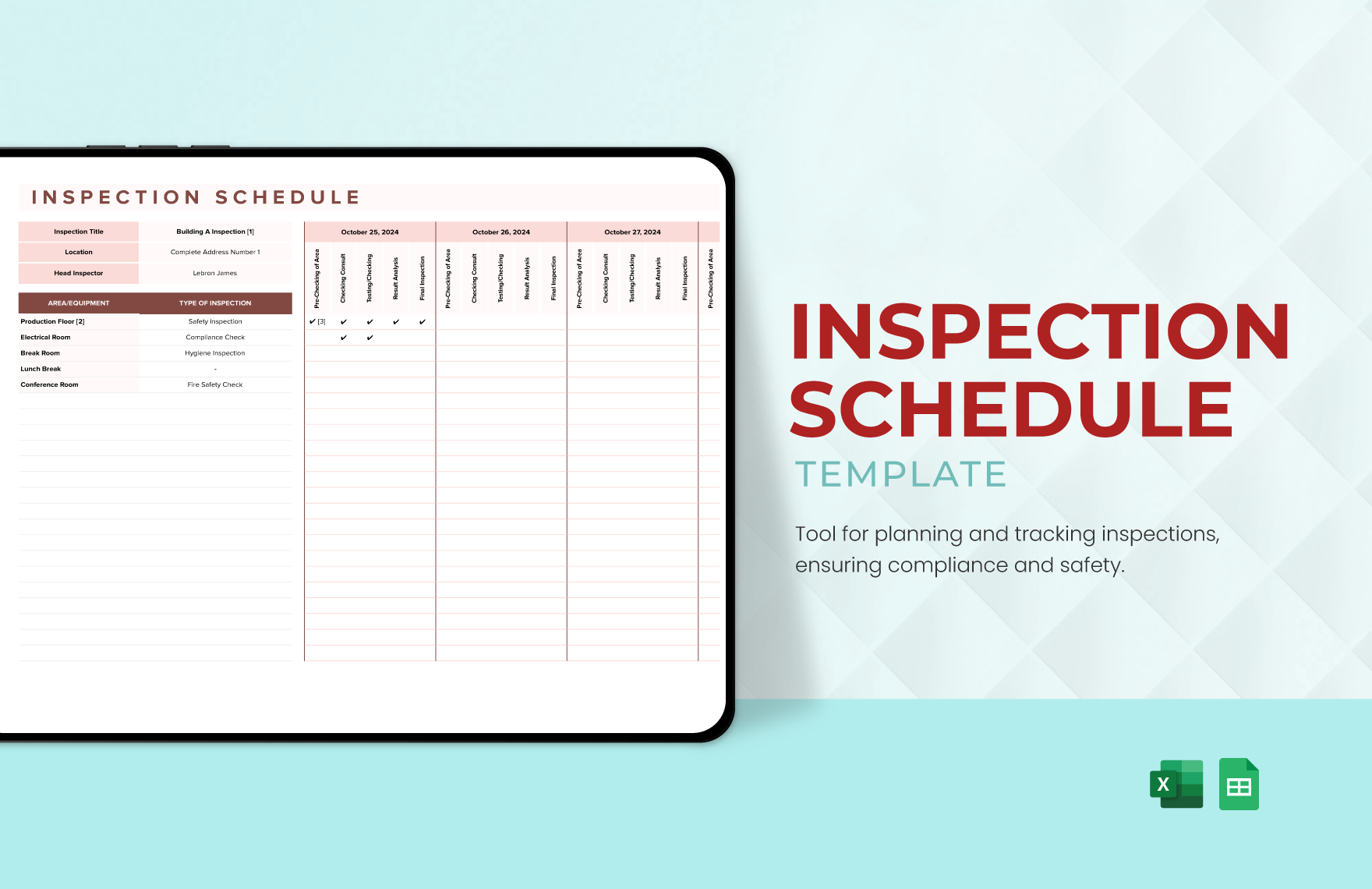

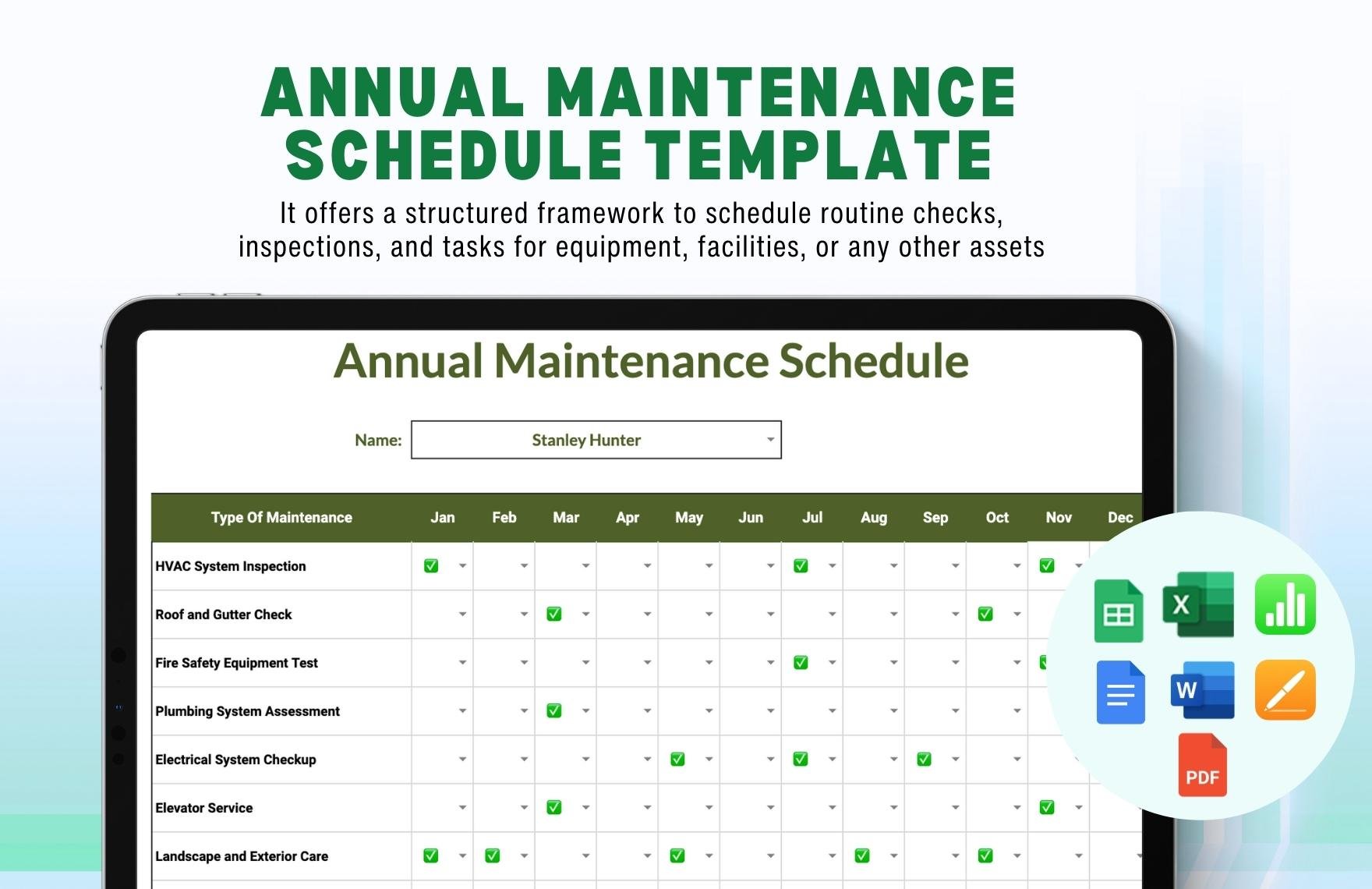

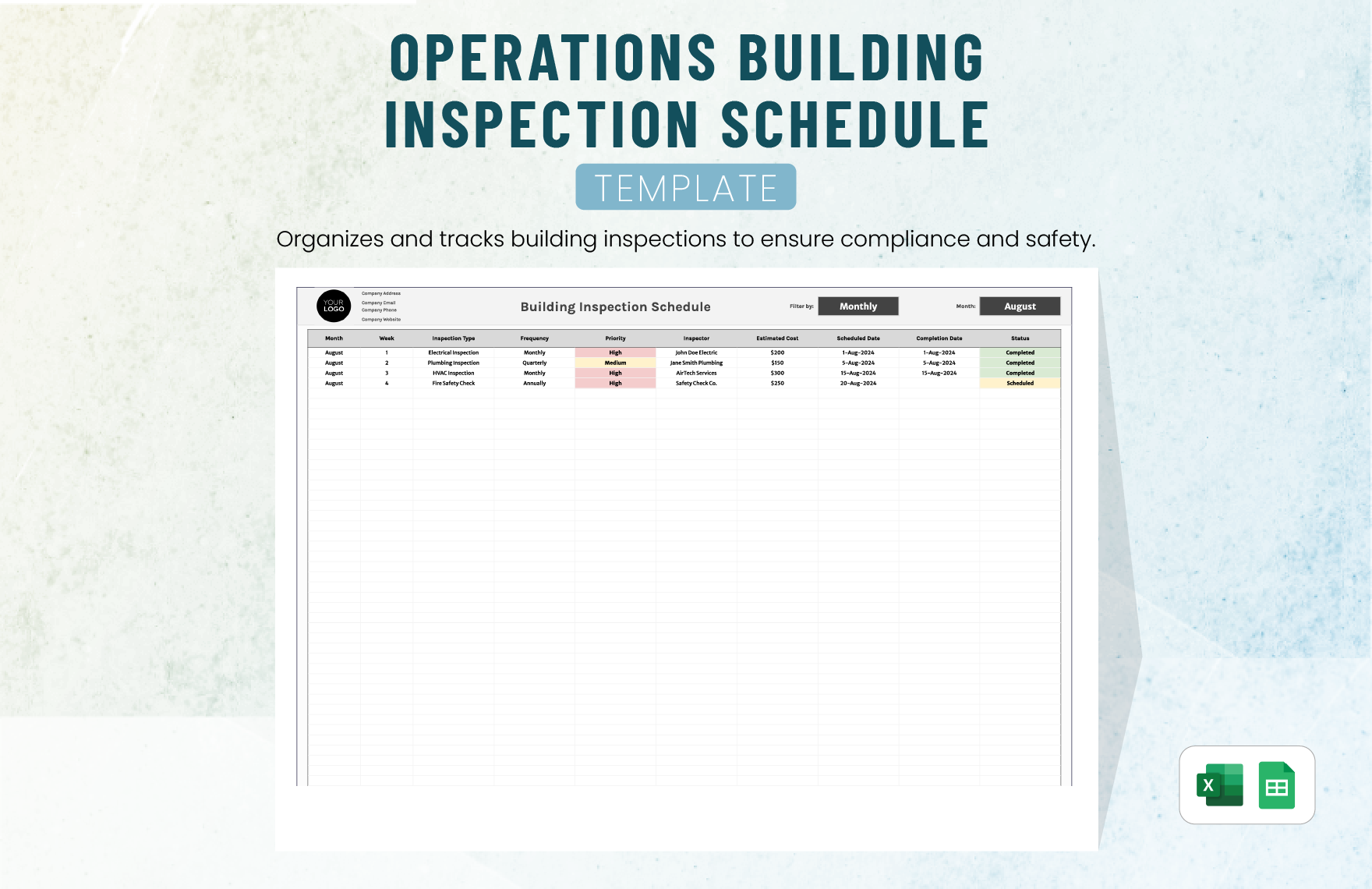

A maintenance schedule is a written document that is used to organize a program plan for important tasks such as inspection, prevention, and repair. It is used to keep track of maintenance on a daily schedule, weekly schedule, monthly schedule, or yearly basis. The schedule is used by clients who either work in buildings or homes or large or small equipment.

How to Create a Maintenance Schedule on Microsoft Excel?

Whether it's to create a document such as a letter, report, or schedule, Microsoft offers a variety of programs that can help you. Although Microsoft Word is the most common tool used, schedules are best utilized with the program Microsoft Excel. This article will act as a guide and give you tips to creating your very own maintenance schedule.

1. Types of Maintenance Schedule

Before you start making your schedule, you need to know the different types there are. There are four types: corrective, predetermined, condition-based, and preventive. Corrective maintenance is implemented once a defect has been found on a piece of equipment. Predetermined maintenance is applied according to the programs that come with the status of the equipment. It is usually to anticipate any possible failures. Condition-based maintenance is the aims to prevent failures which requires regular check-ups. The last is preventive maintenance which is planned based on programs and hard facts.

2. Create a Project Plan

Once you know what kind of schedule you want to make, you need to organize a project plan. Gather the members of your team to discuss your end goals and what you need to do to ensure that the plan is successful.

3. Make an Inventory

Next thing you need to do is create an inventory checklist of all the materials and equipment. This stage in creating a maintenance schedule is most likely the longest one. However, it is important to be careful in doing so as it is one of the most critical stages of the process. You need to take note of the equipment model, the specifications, serial numbers, asset identification number, and the current condition of the machine.

4. Create the Procedures and Schedules

When you've had your inventory set up, you're going to have to distribute tasks to assigned members who maintain the equipment frequently. The schedule can be a weekly schedule, monthly, or even yearly. You need to address possible scenarios and estimate the amount of time the procedure will take. It's best to have a backup plan in the event of the first one failing. Your plan will need to prioritize the tasks accordingly so the person in charge will be able to estimate the time they need to invest on the job.

5. Review and Revise

When you complete your schedule, take some time to go through it and review. Make sure that your content doesn't leave out anything important and check for any error in your spelling, grammar, and punctuation. Change what you can and when you finish, save the file so you can have it ready for printing.