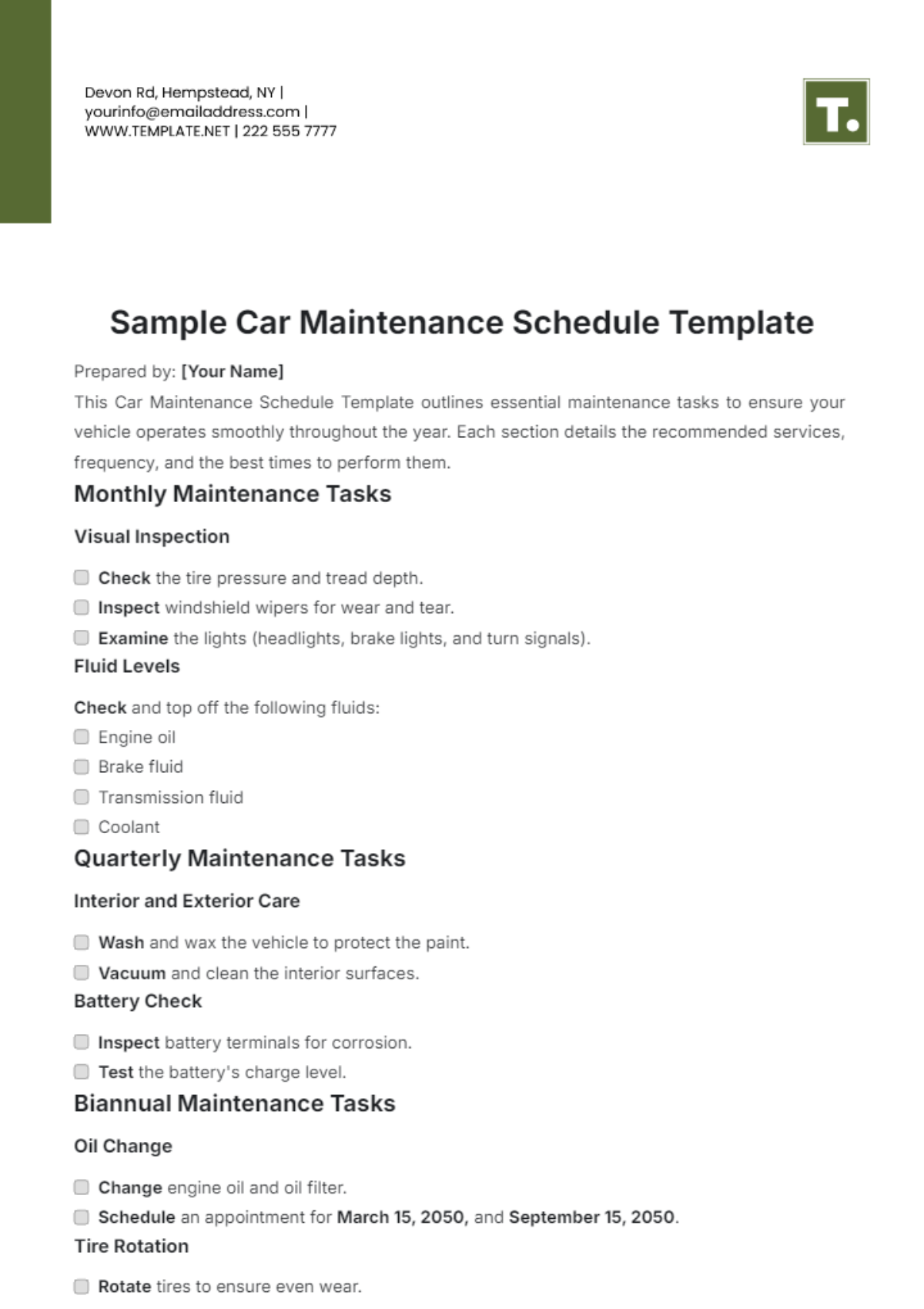

Make your Maintenance Planning to life with Preventive Maintenance Schedule Templates from Template.net.

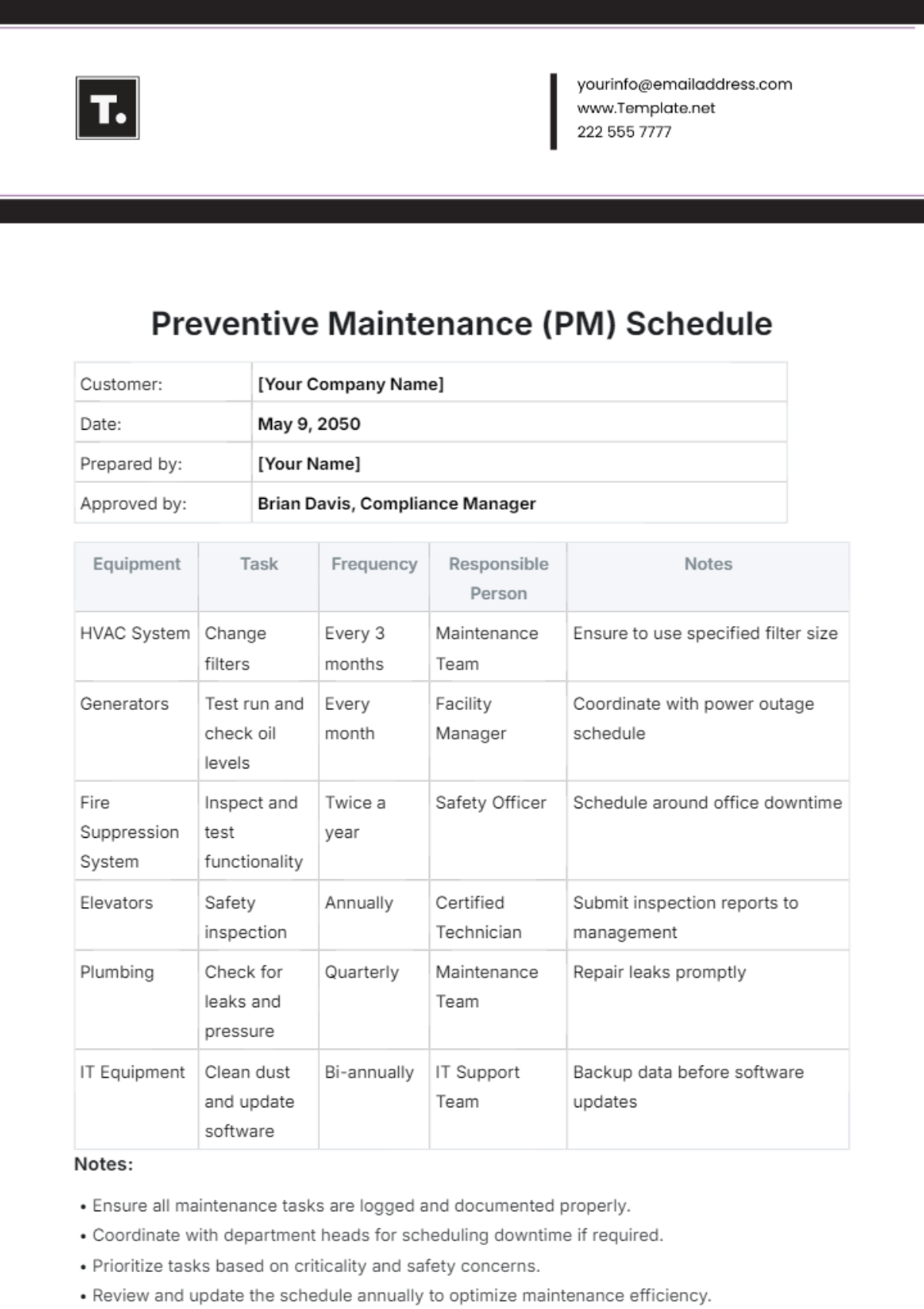

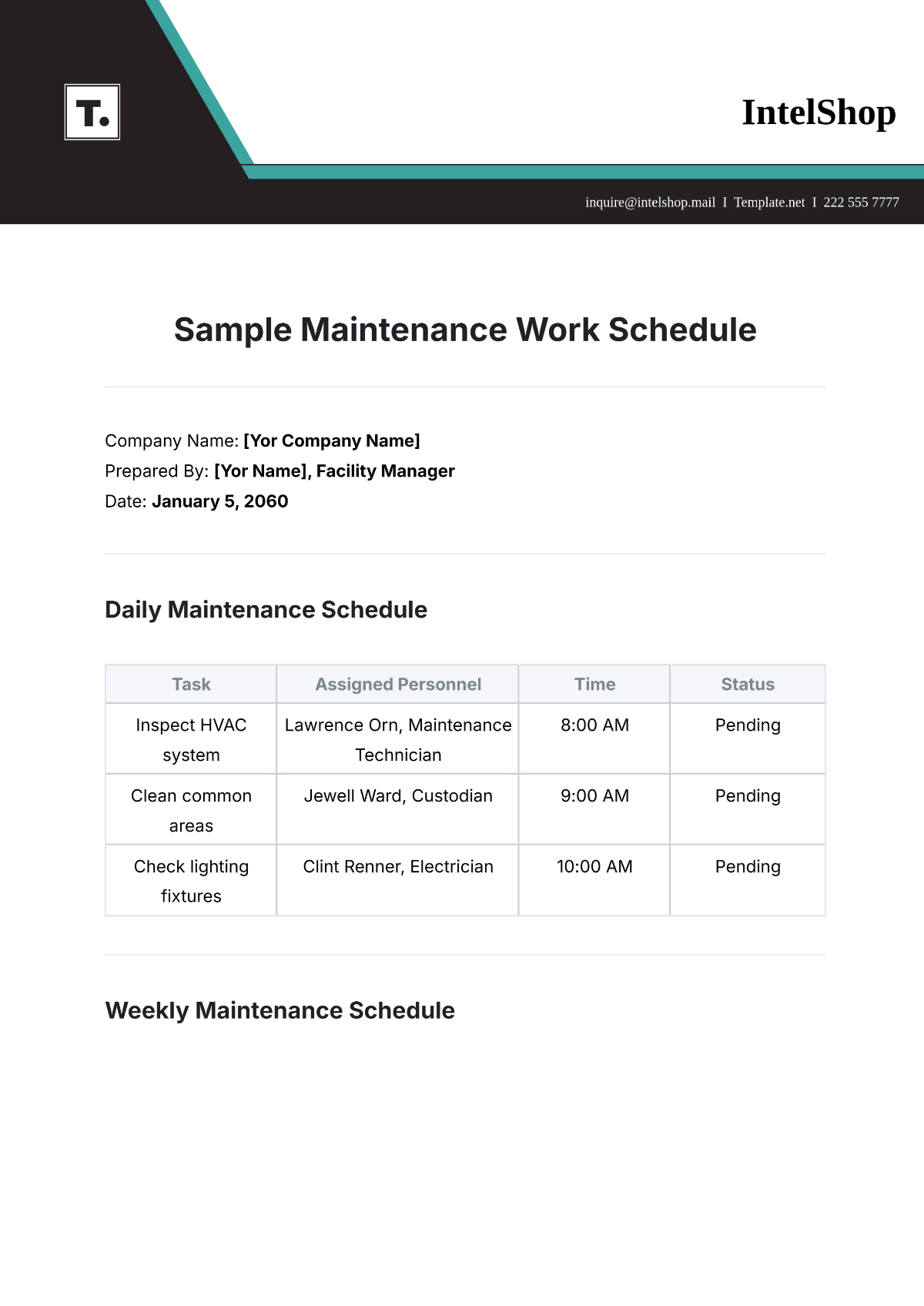

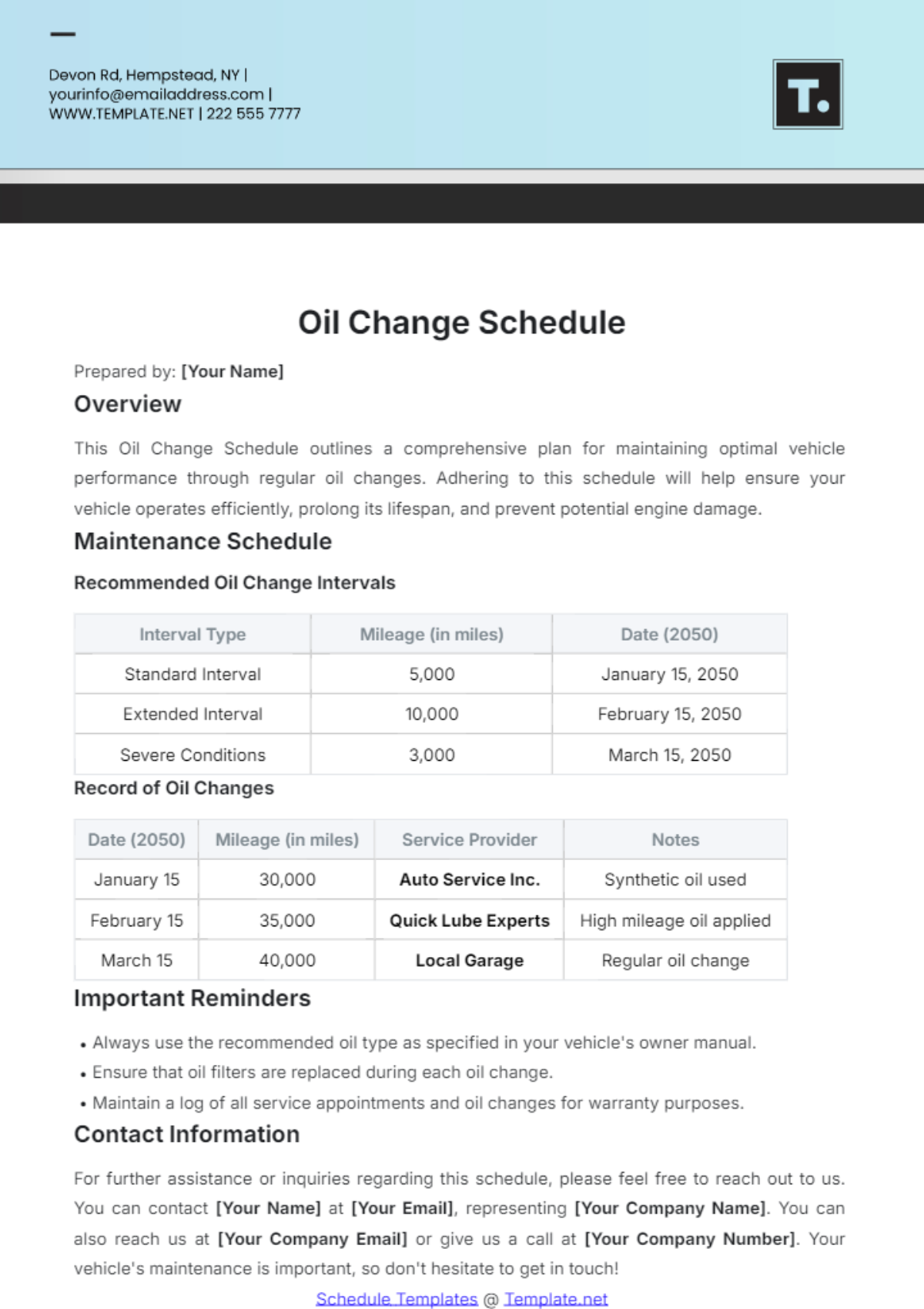

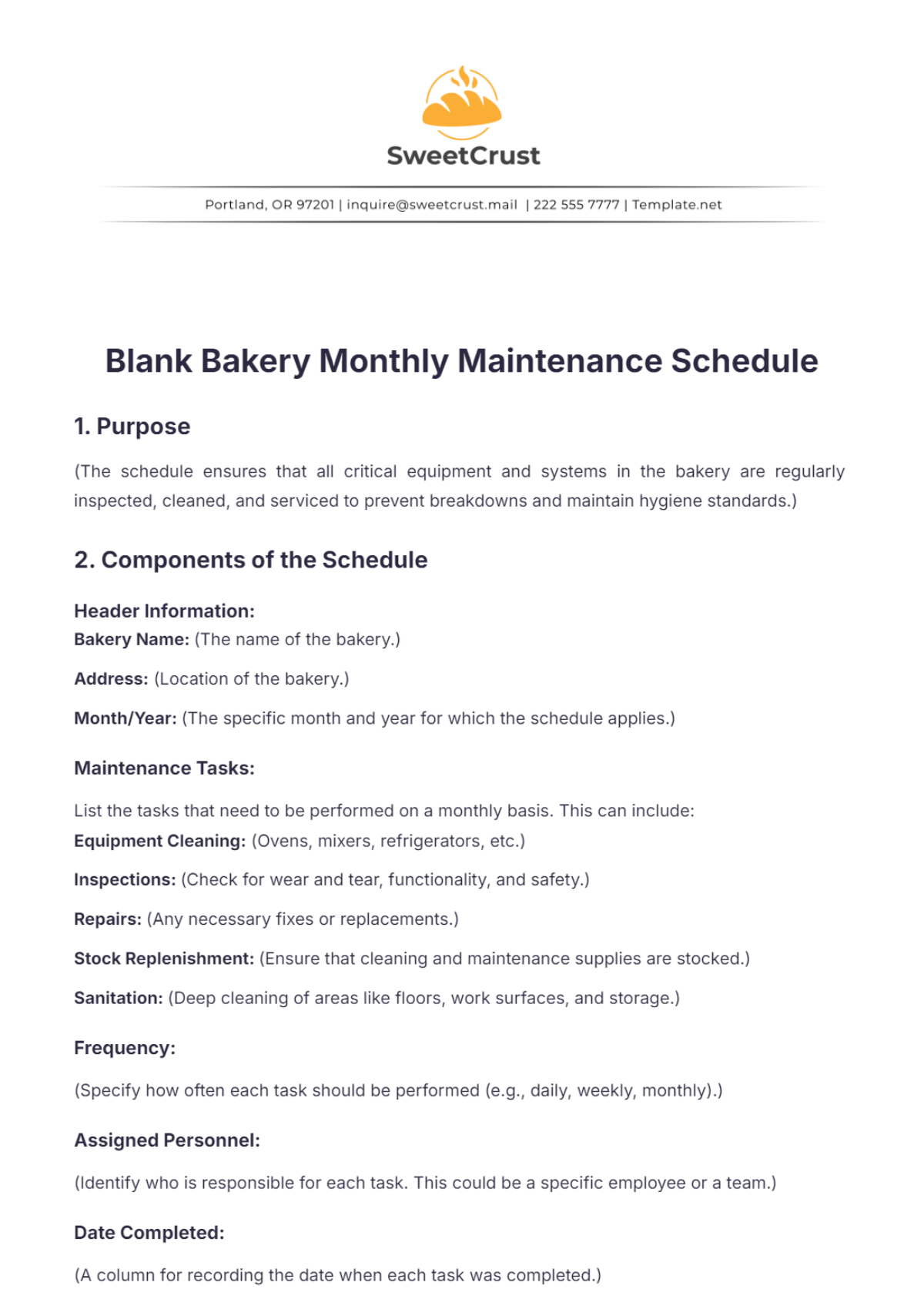

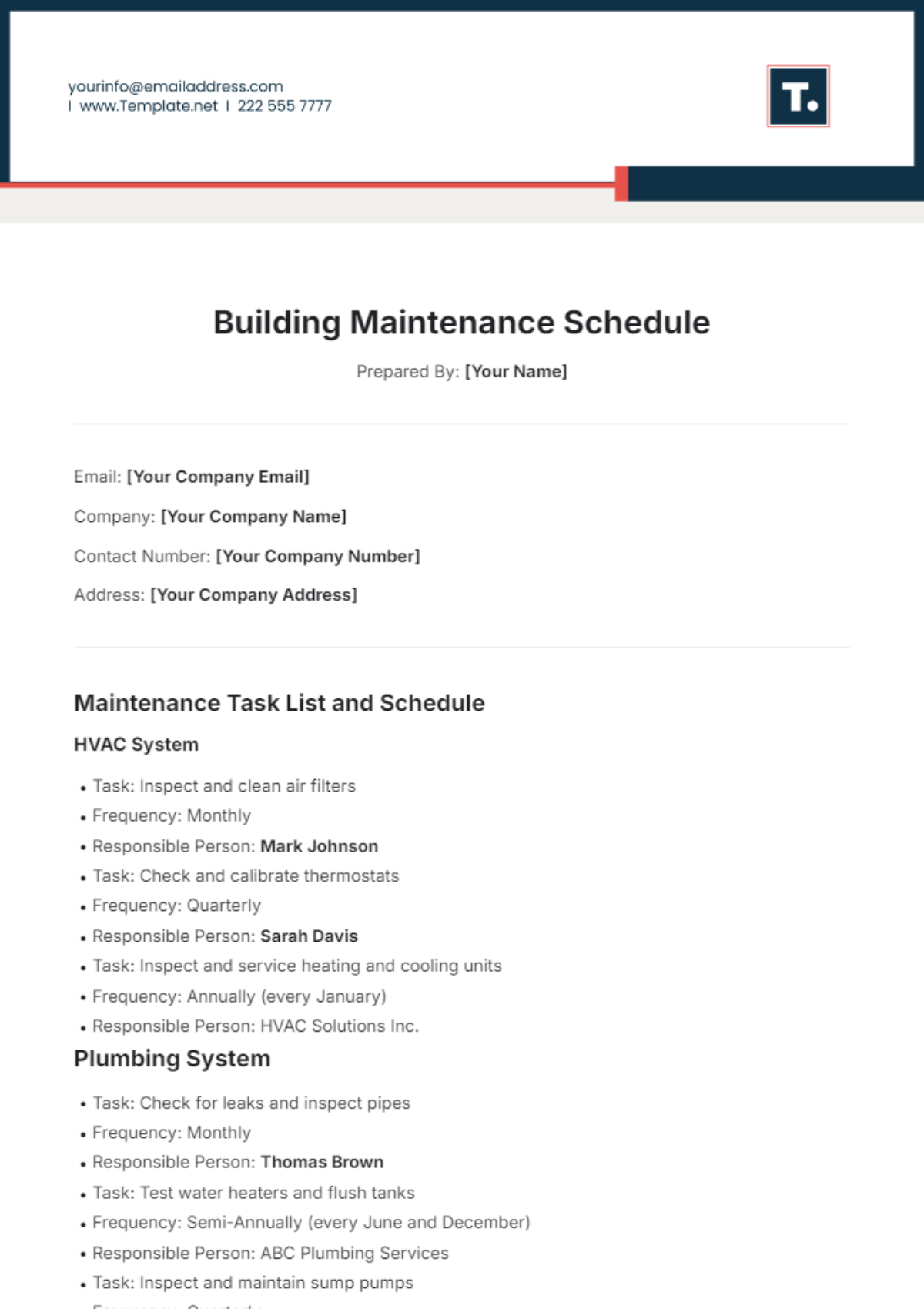

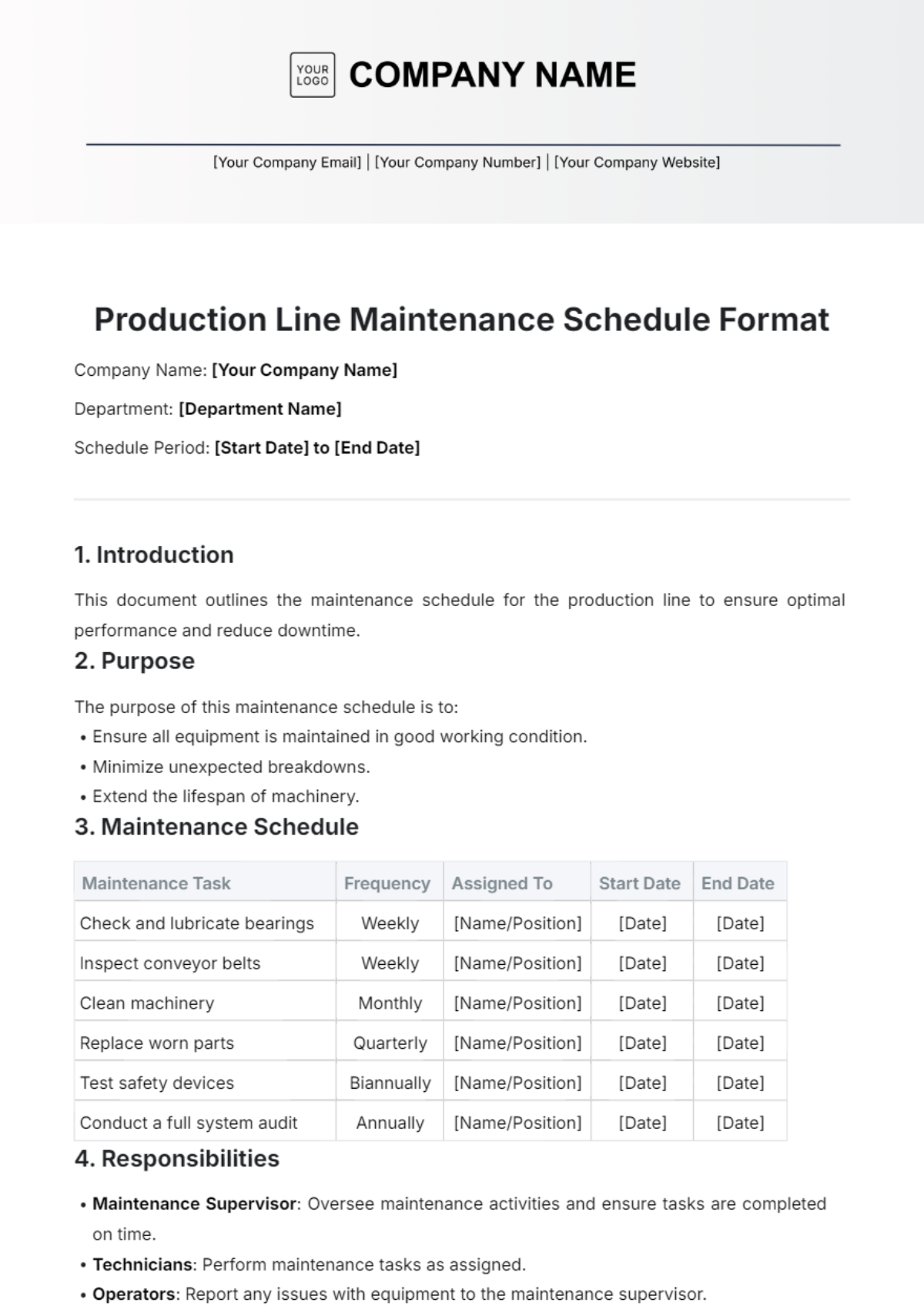

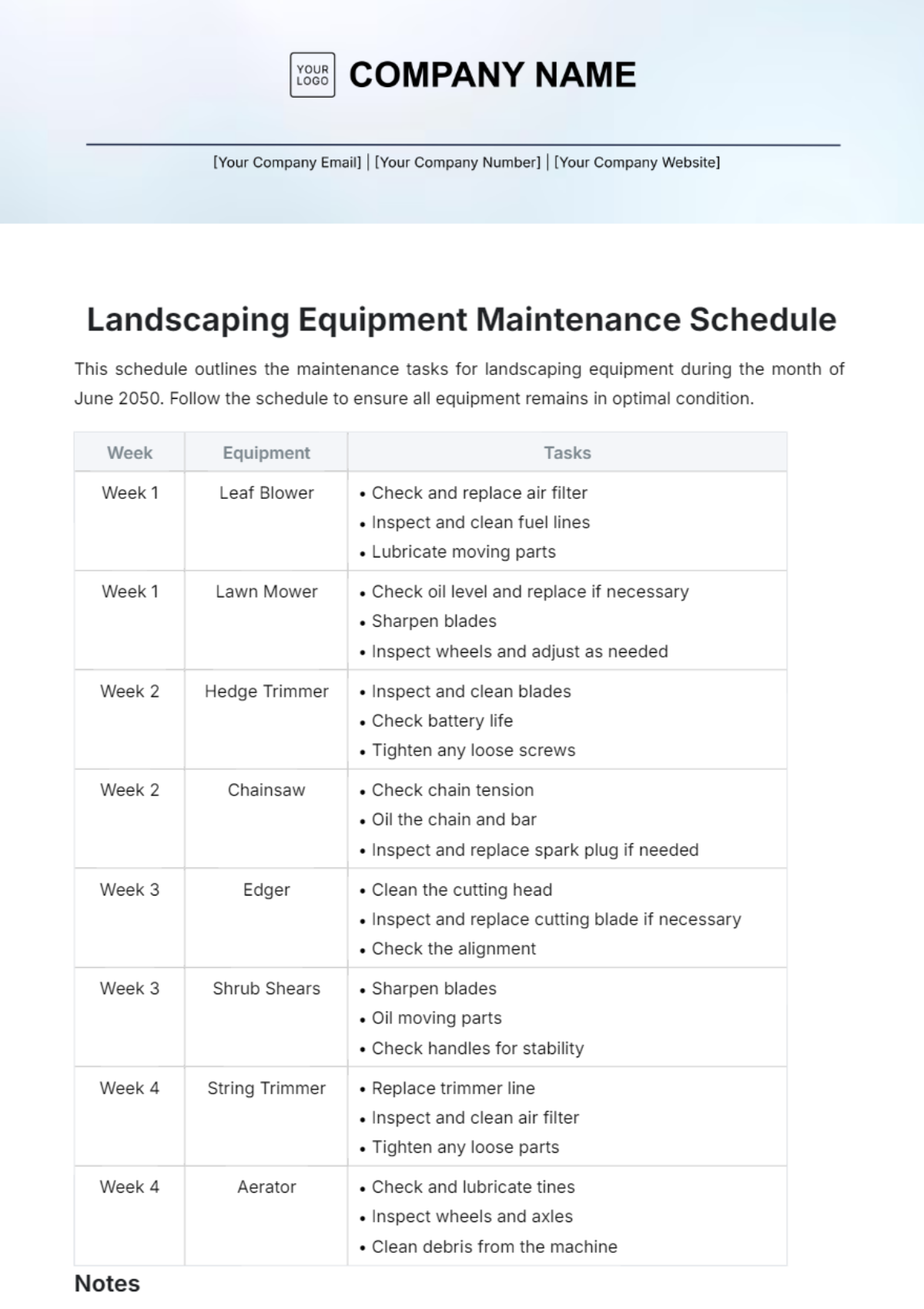

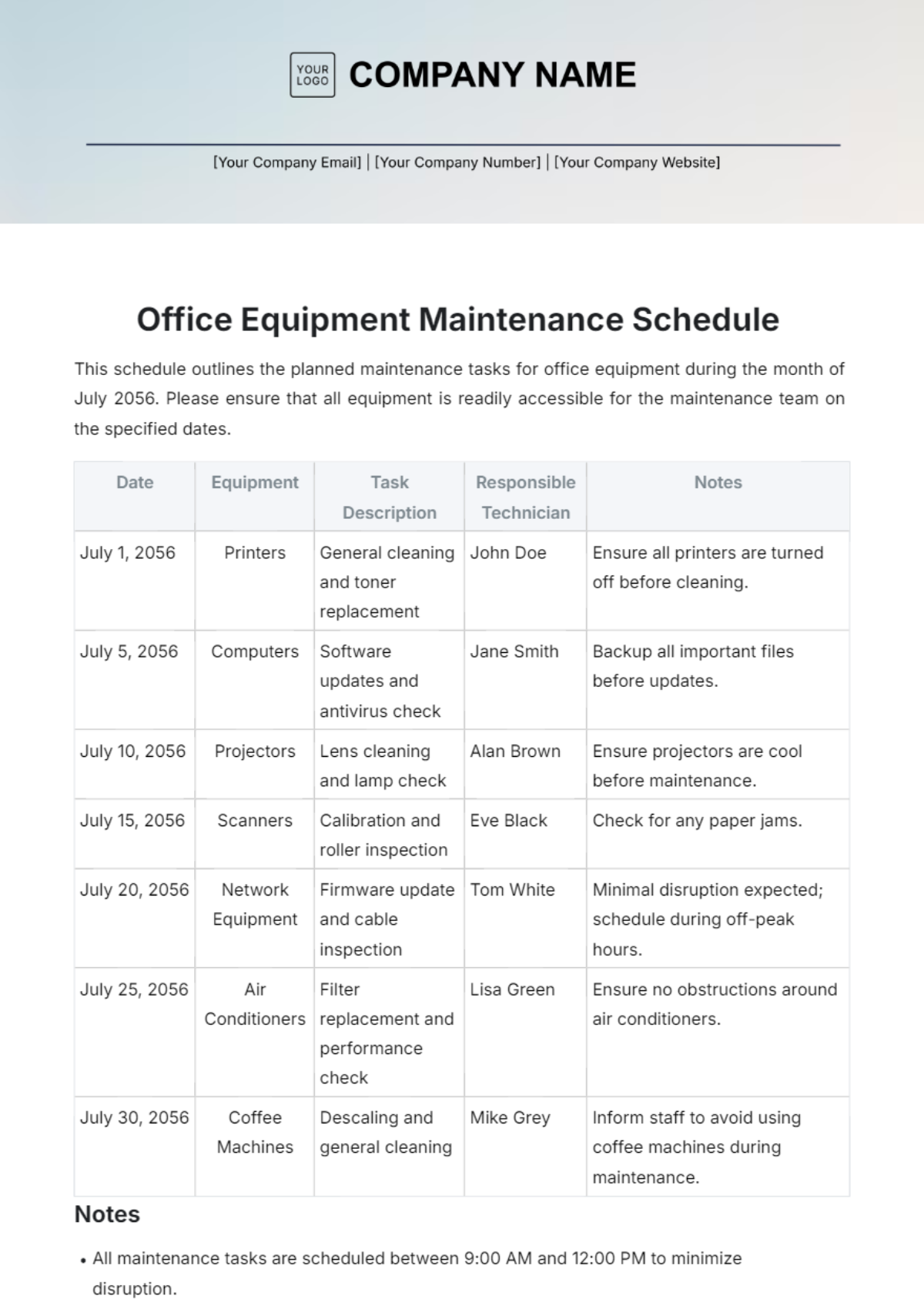

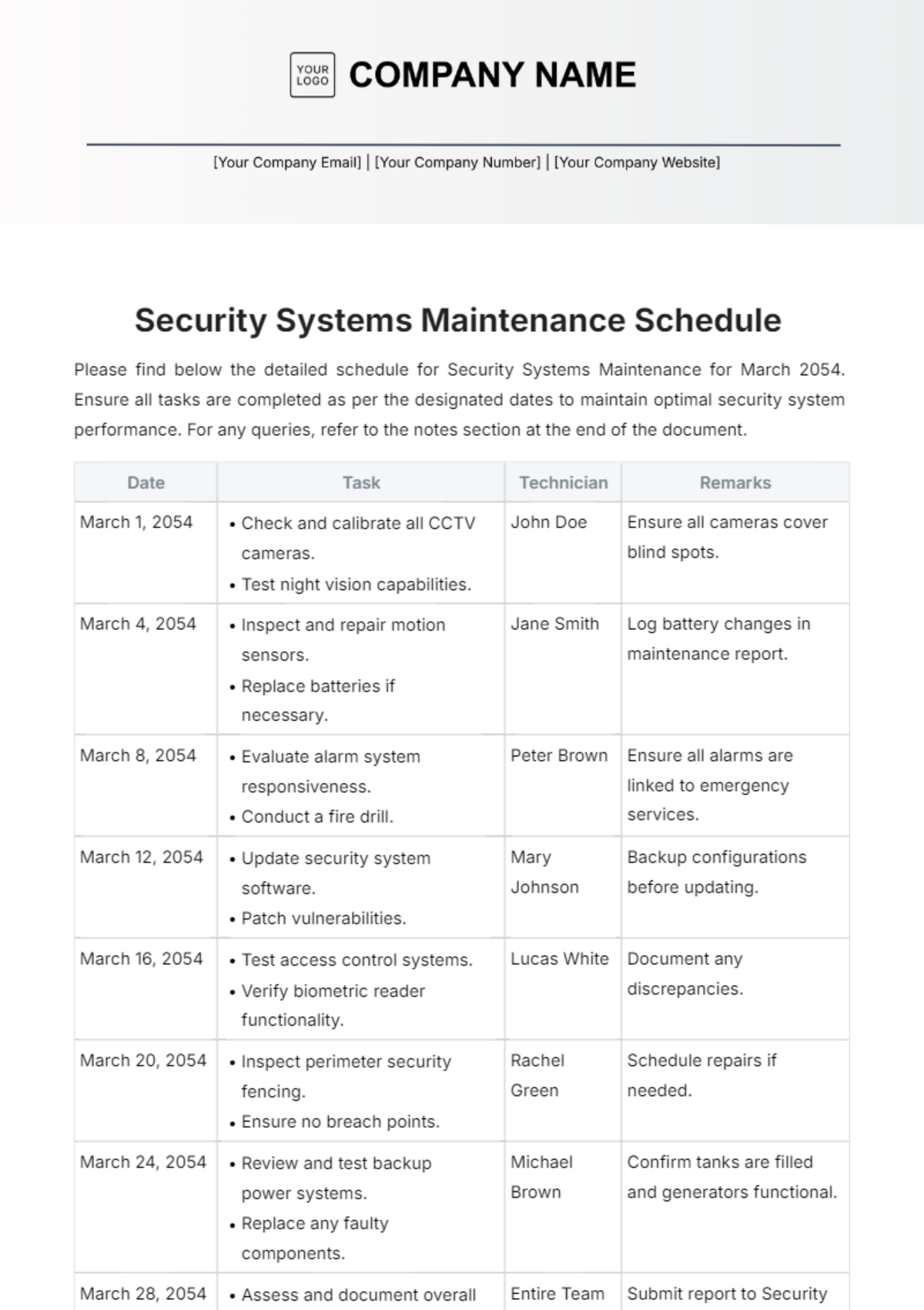

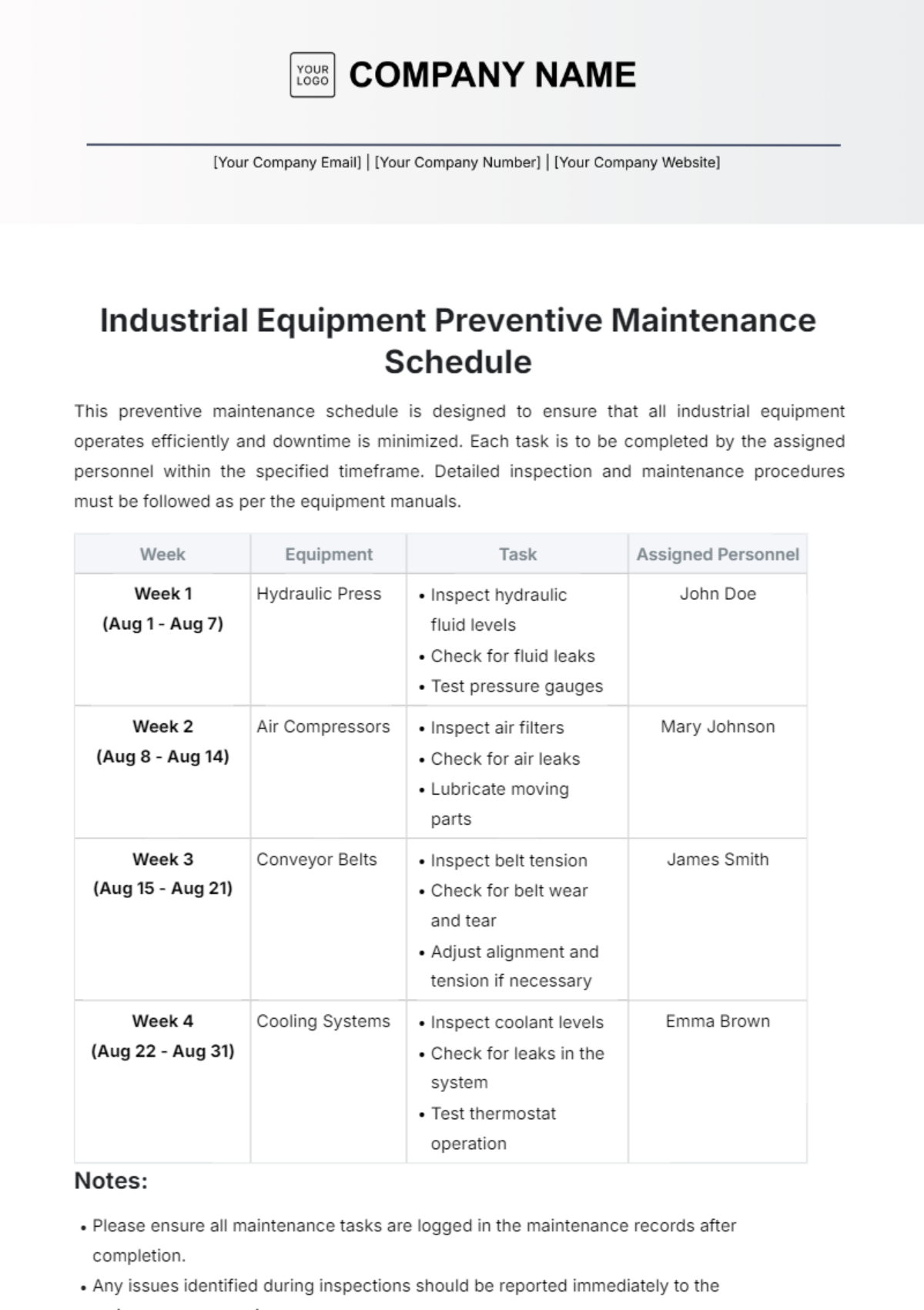

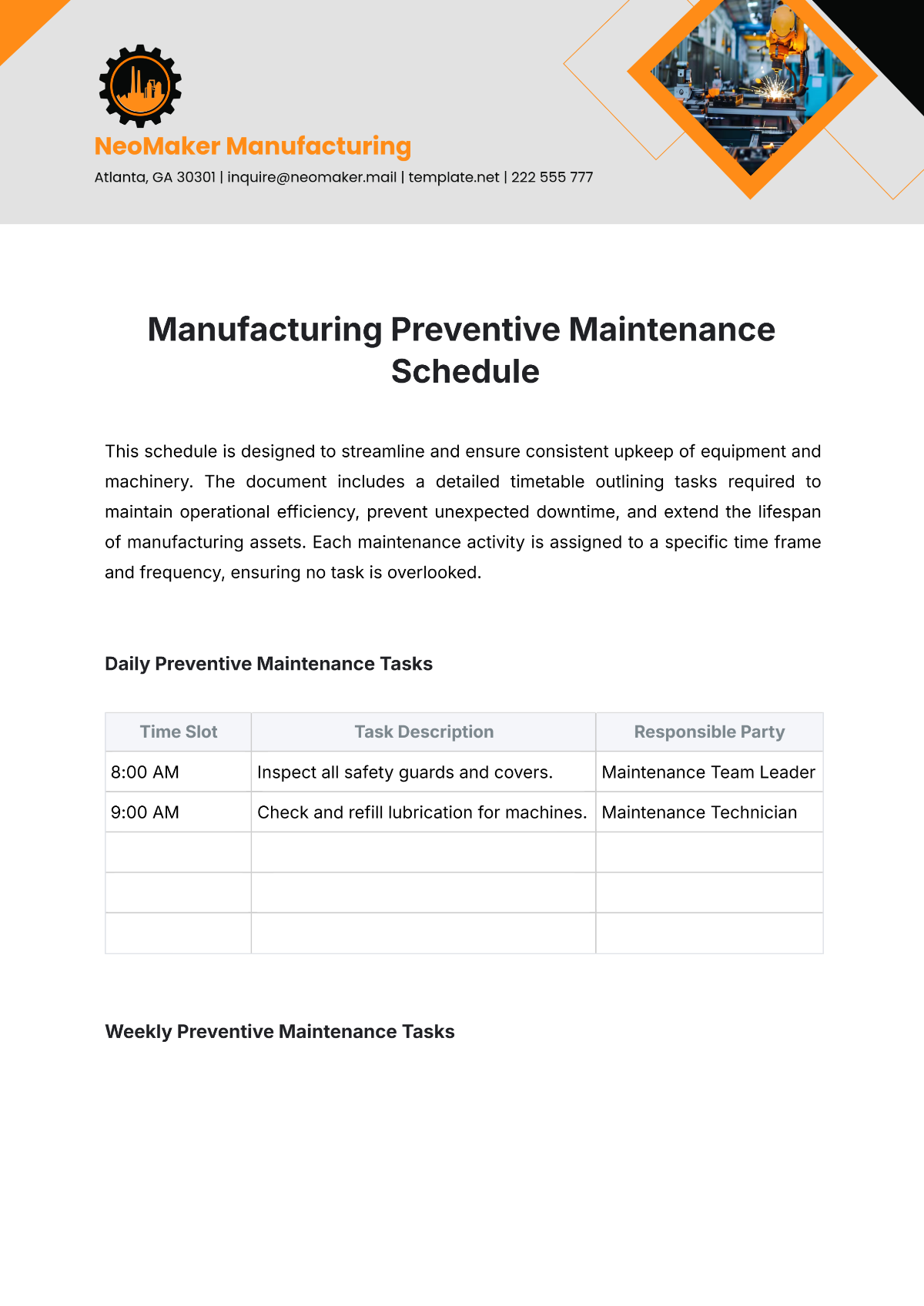

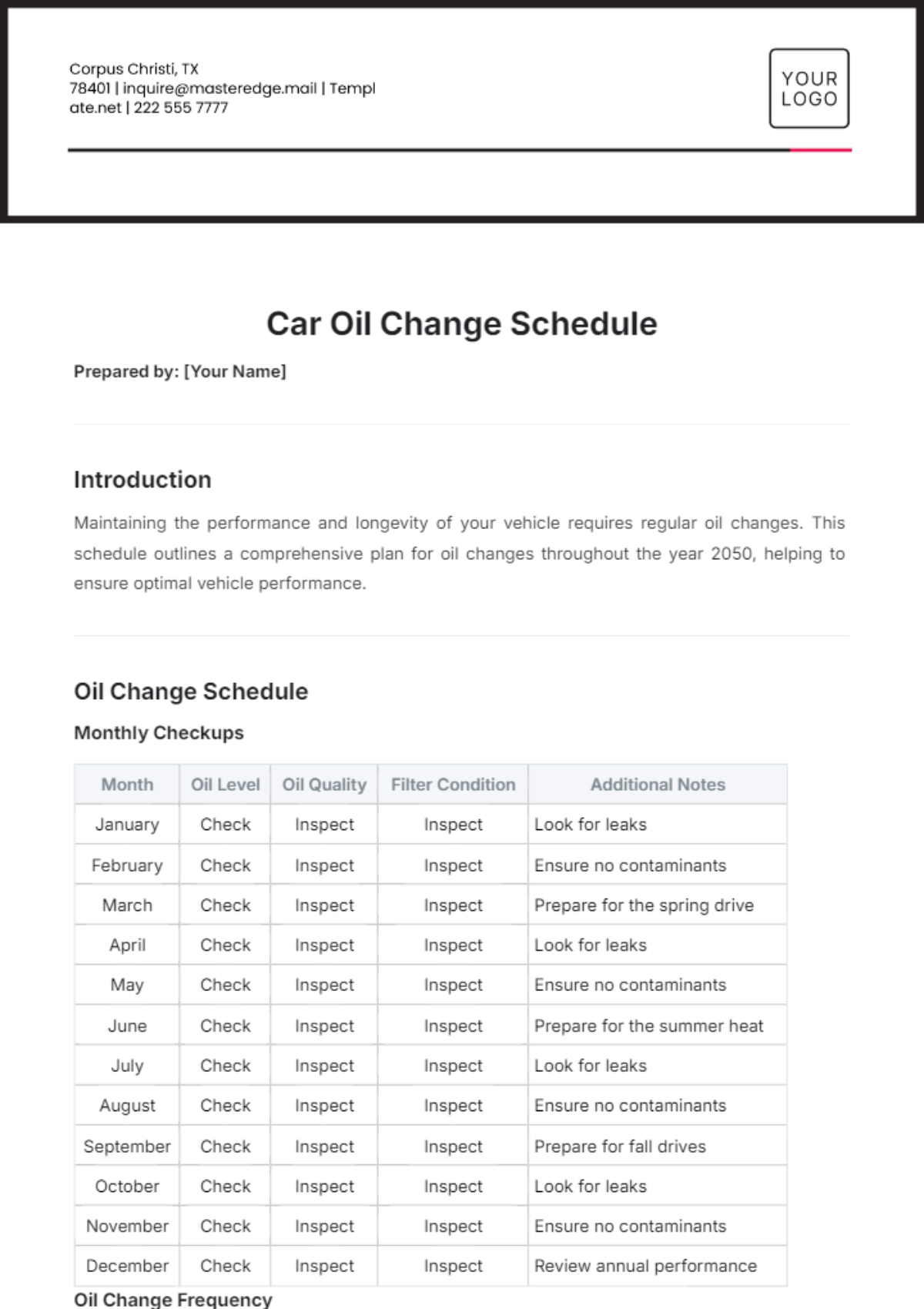

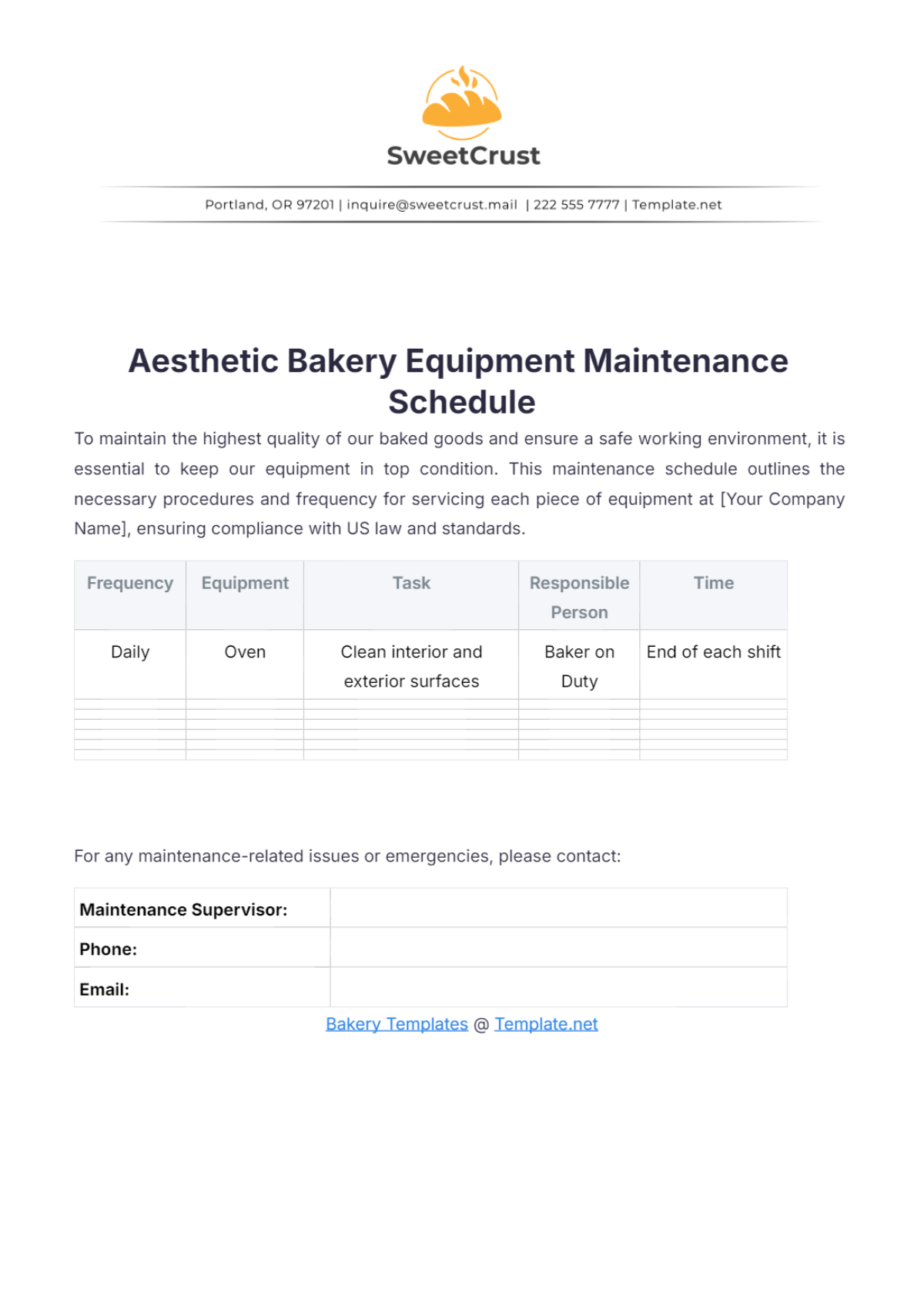

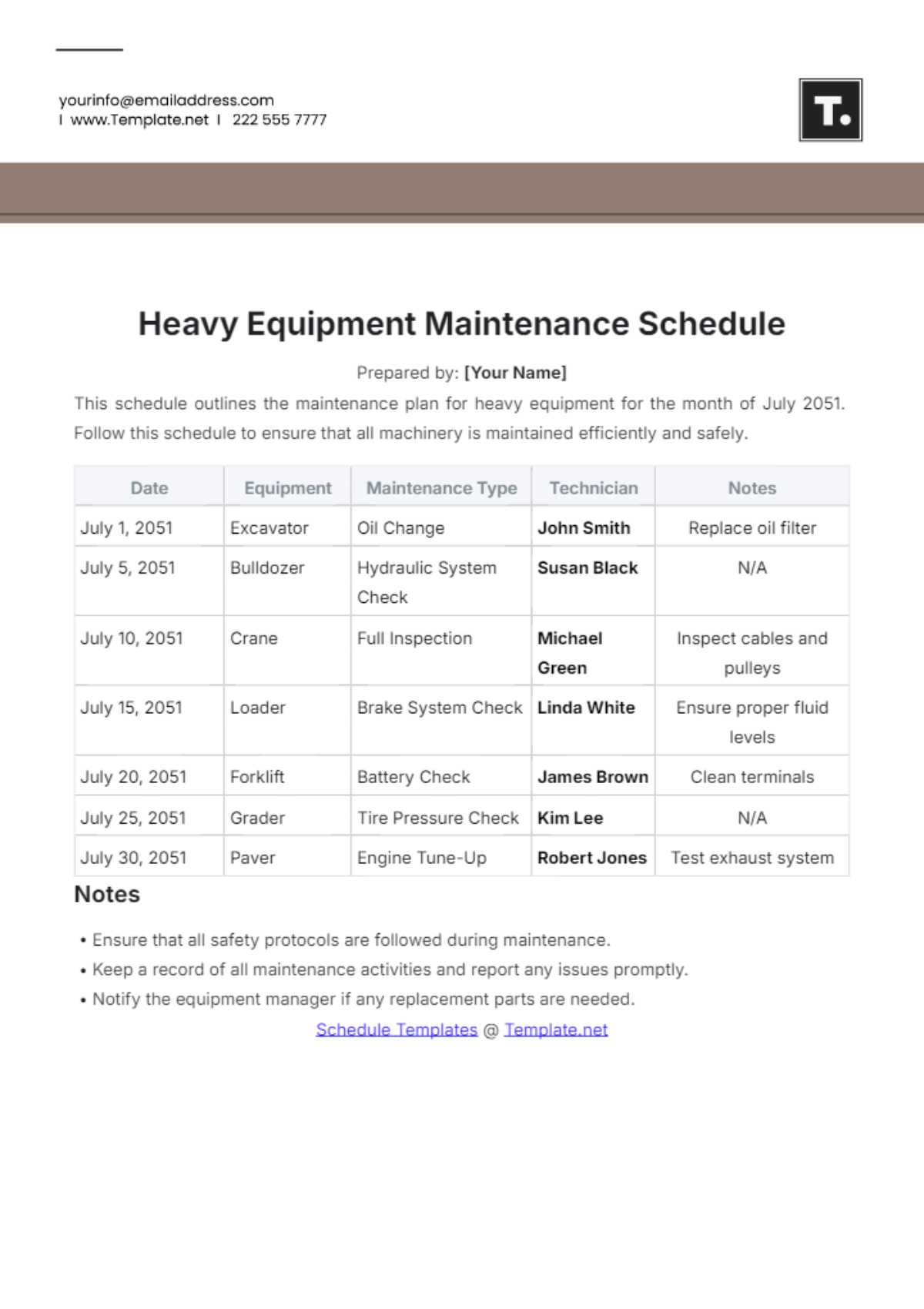

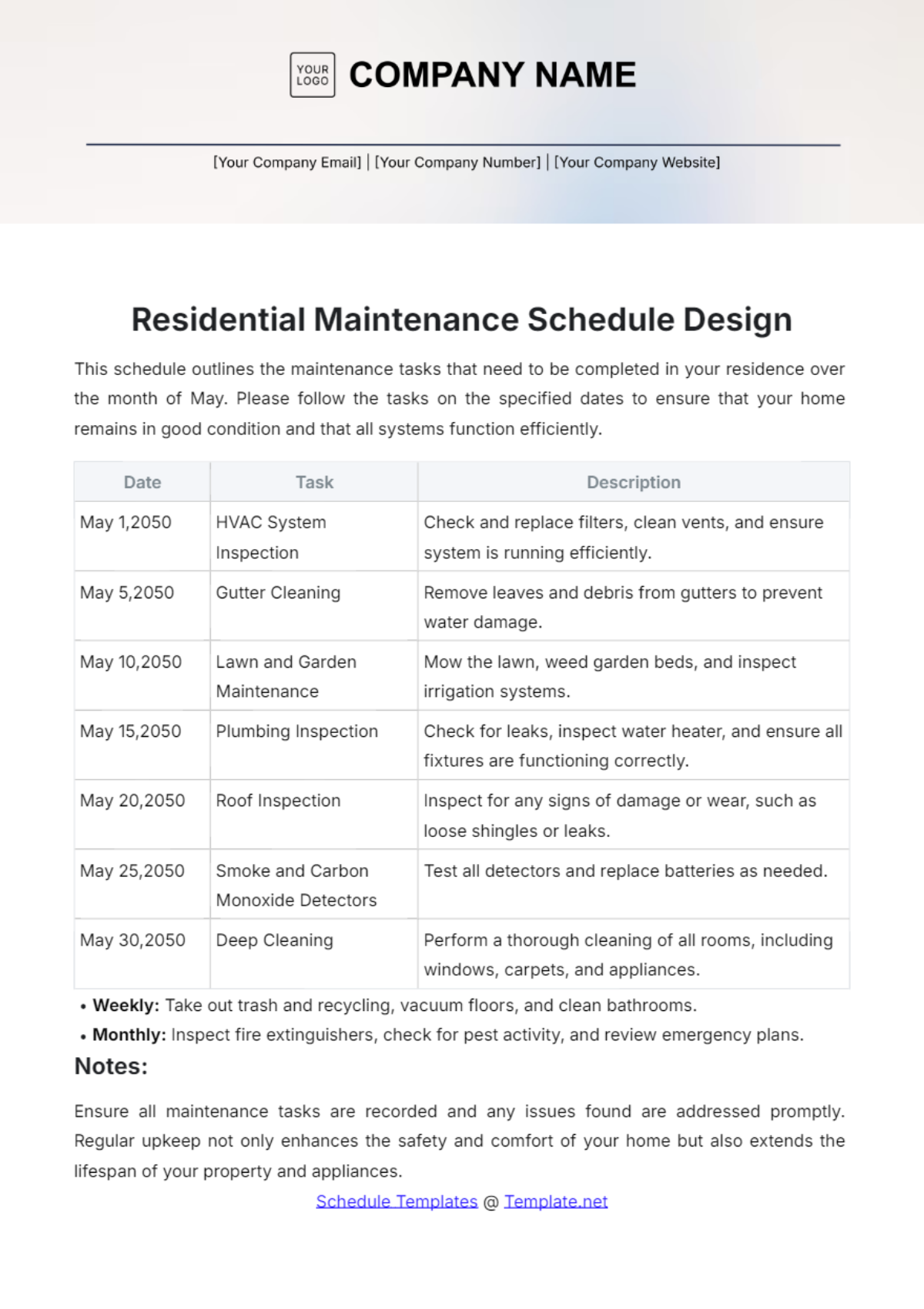

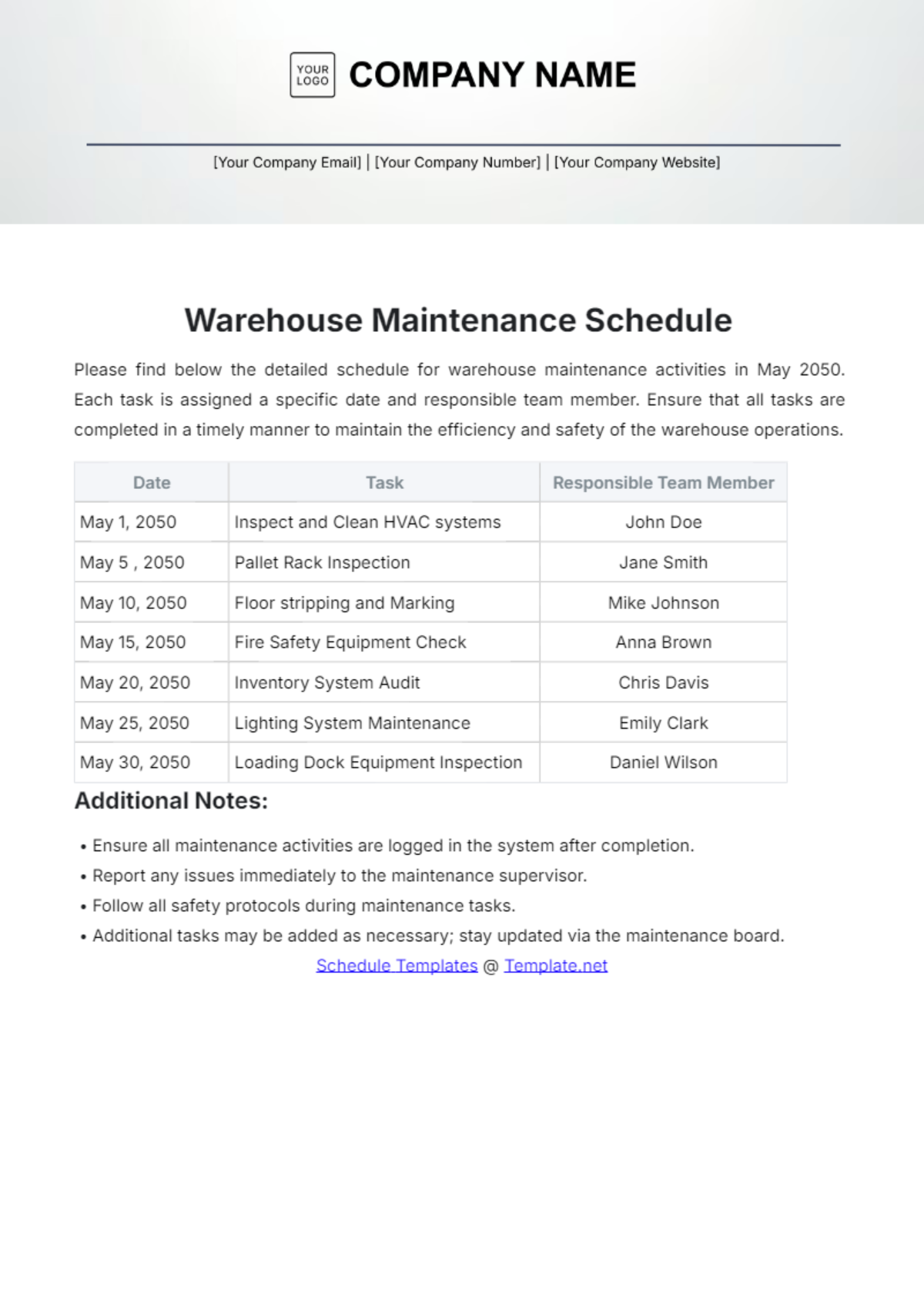

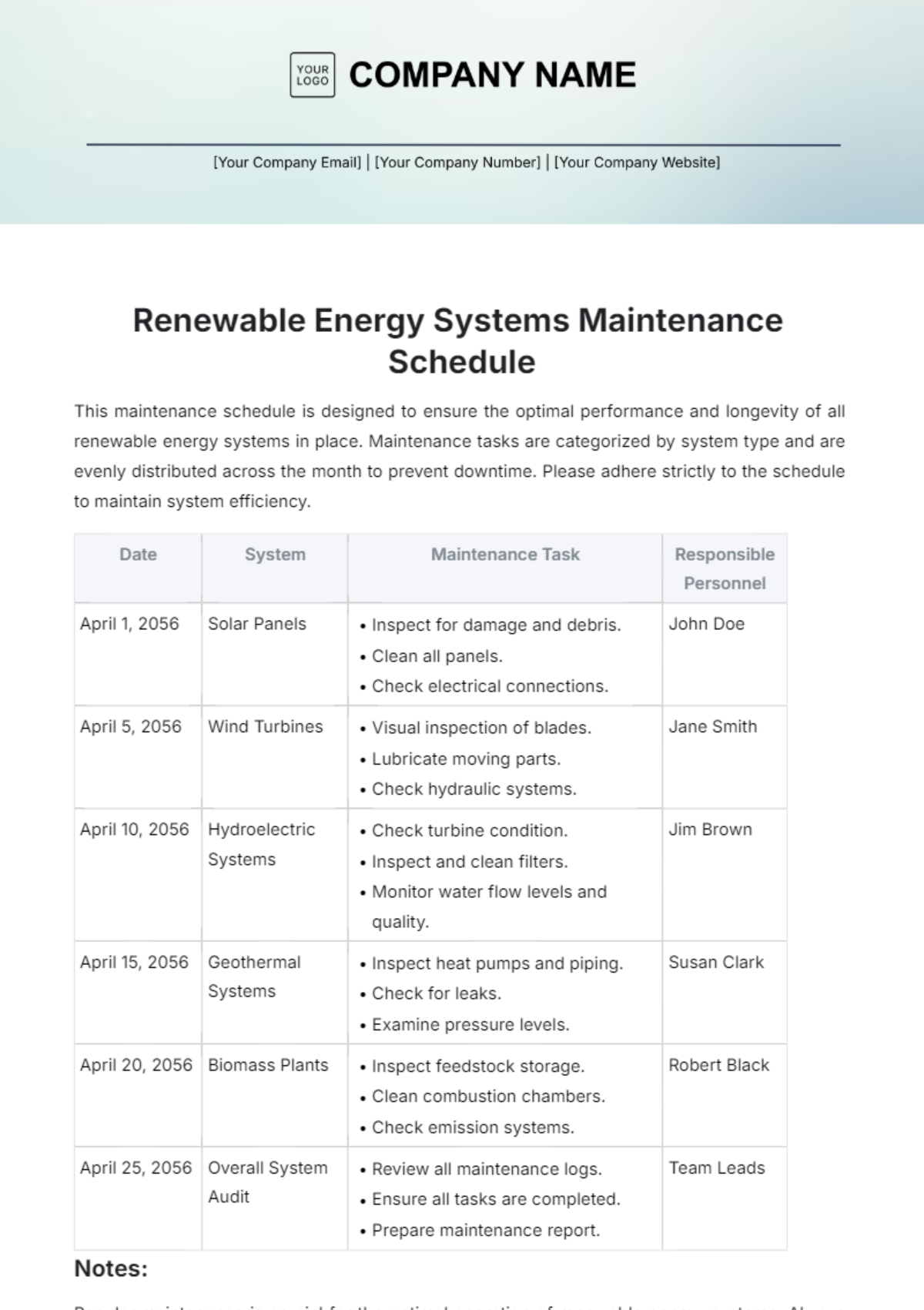

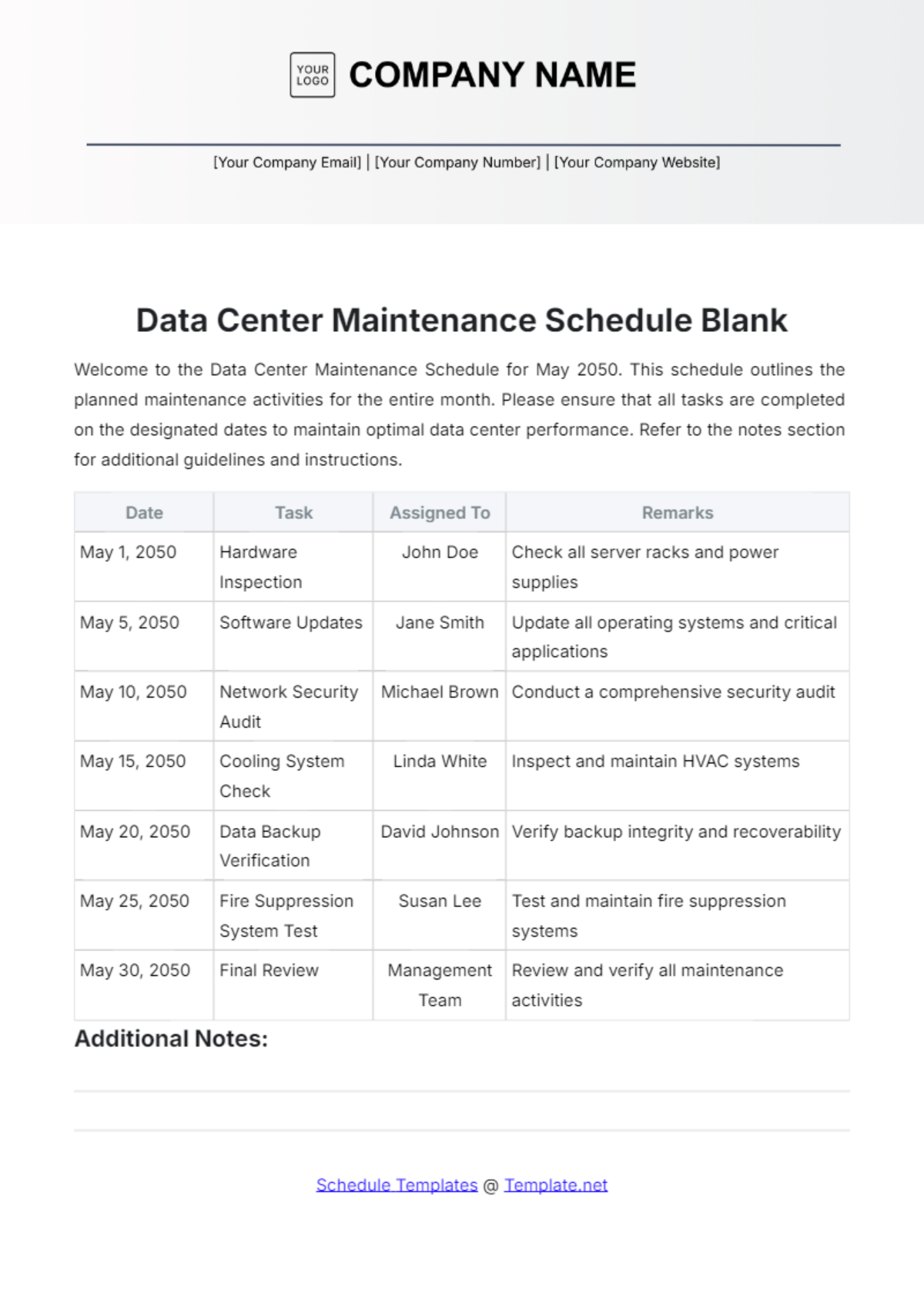

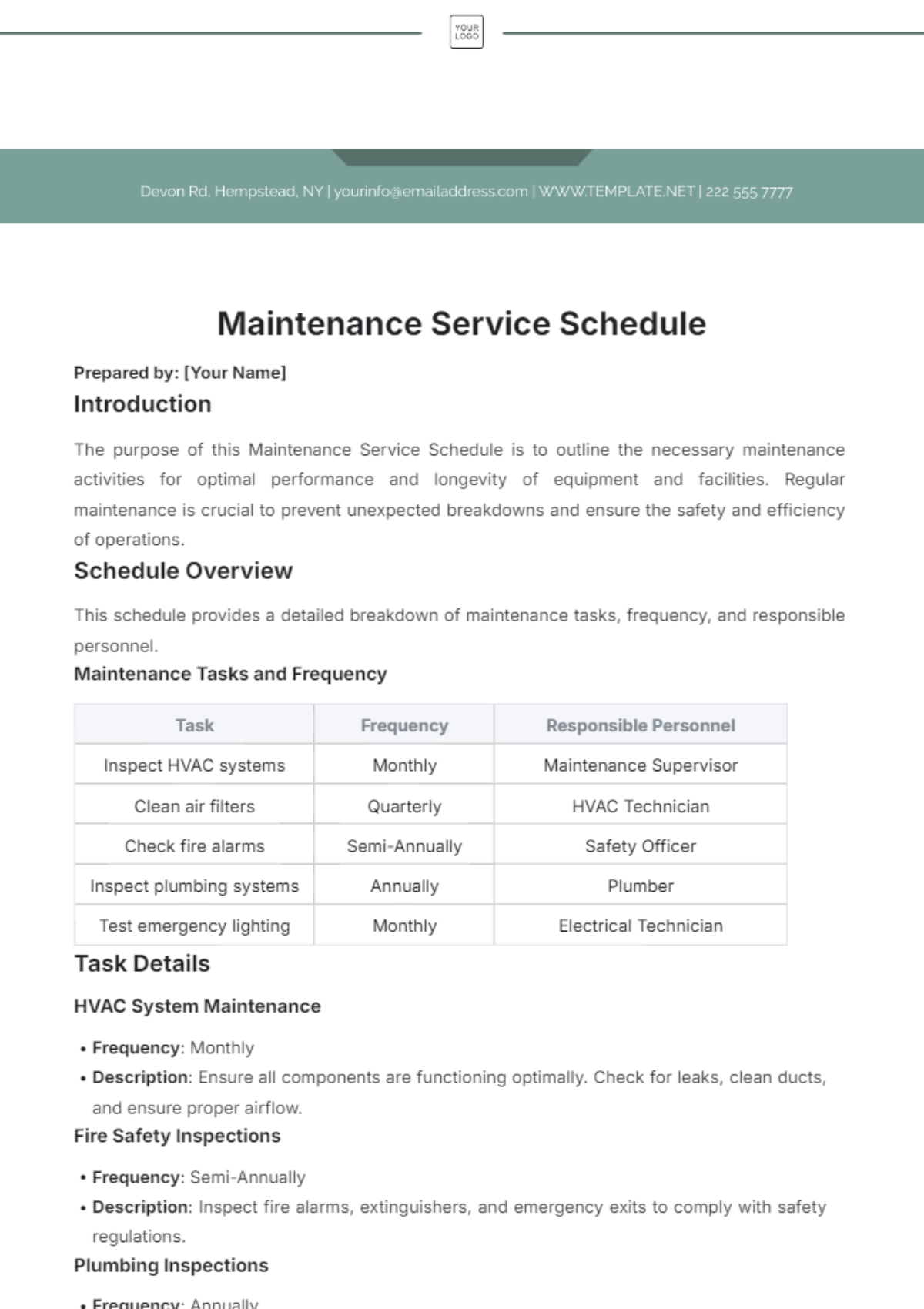

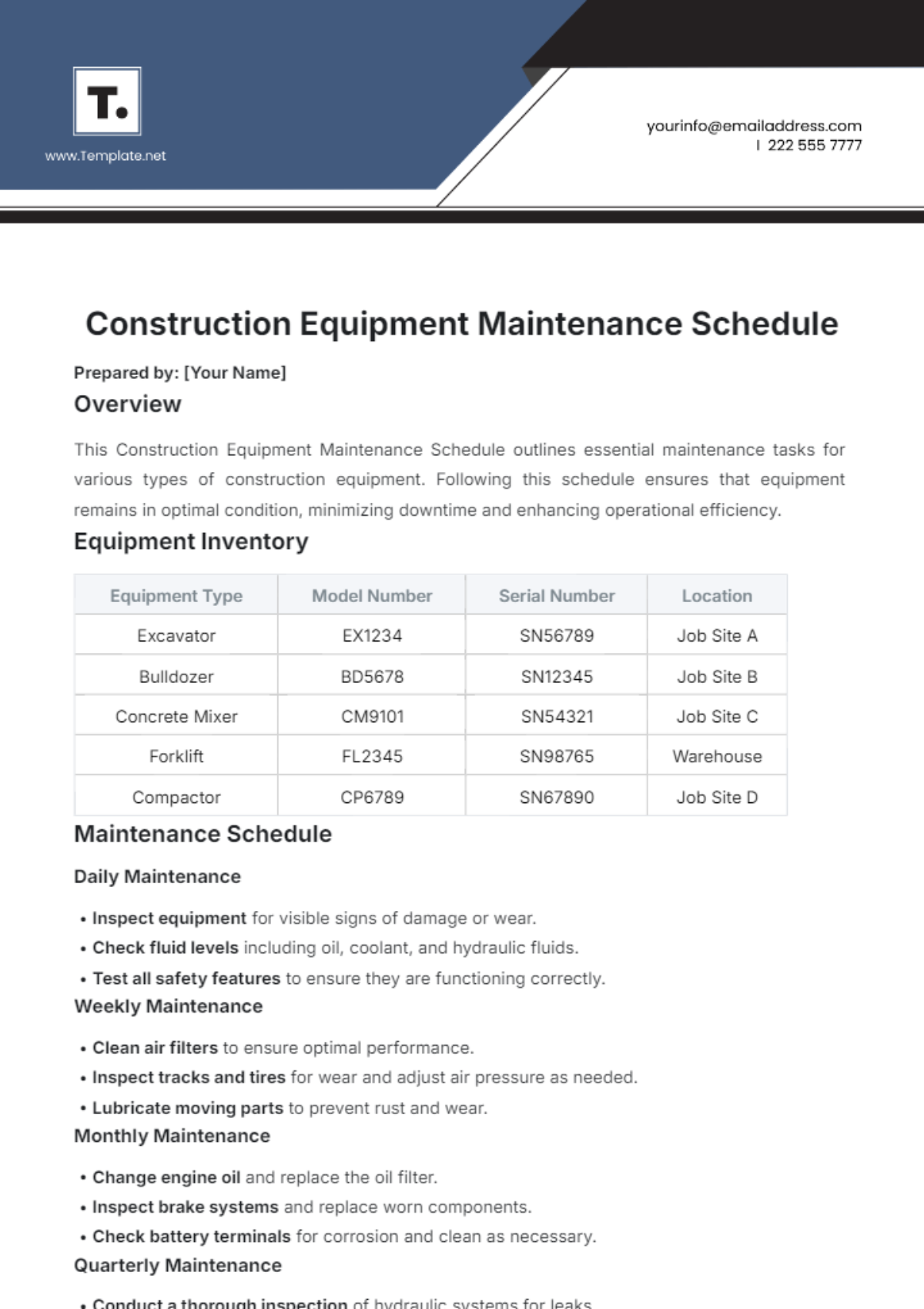

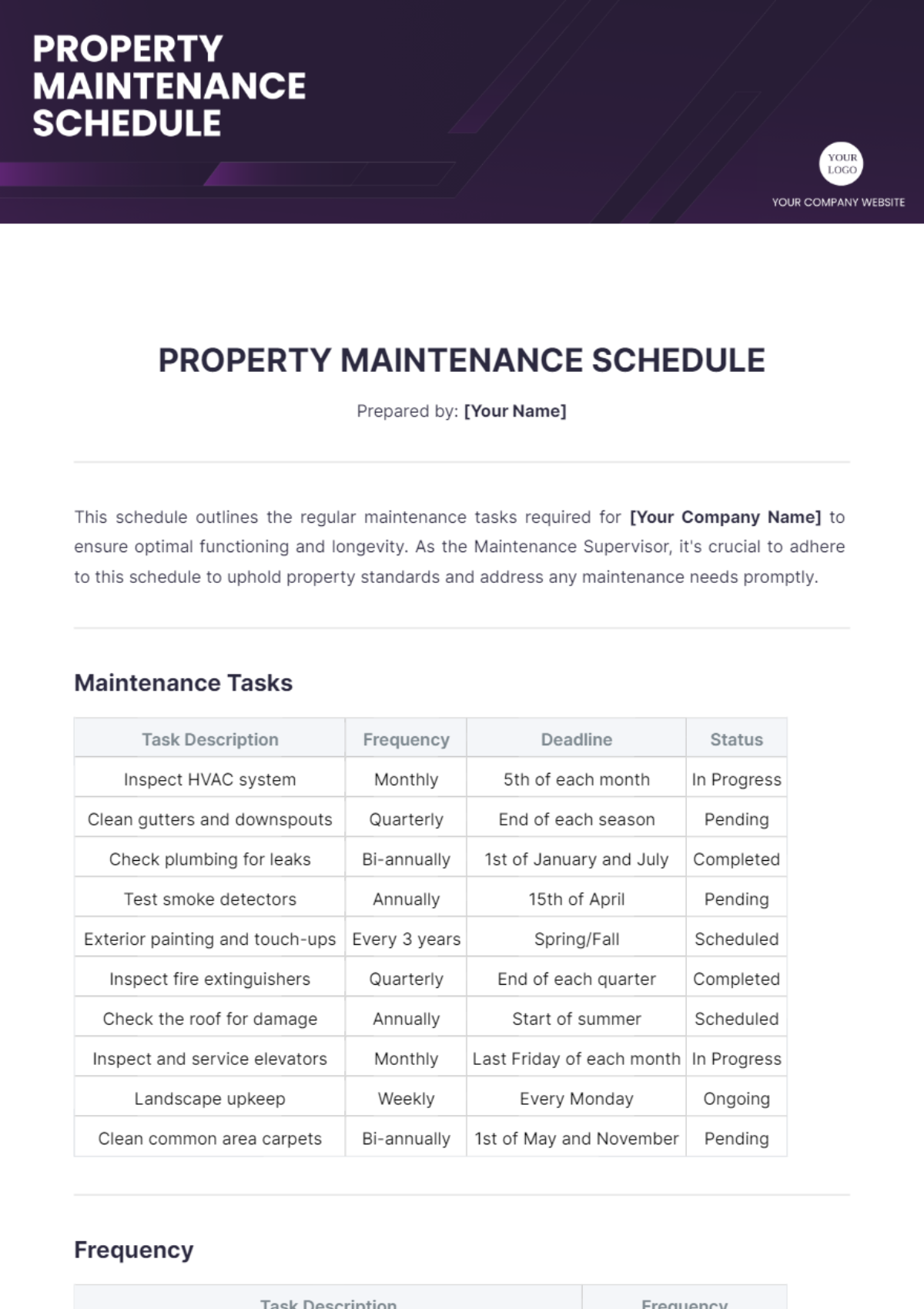

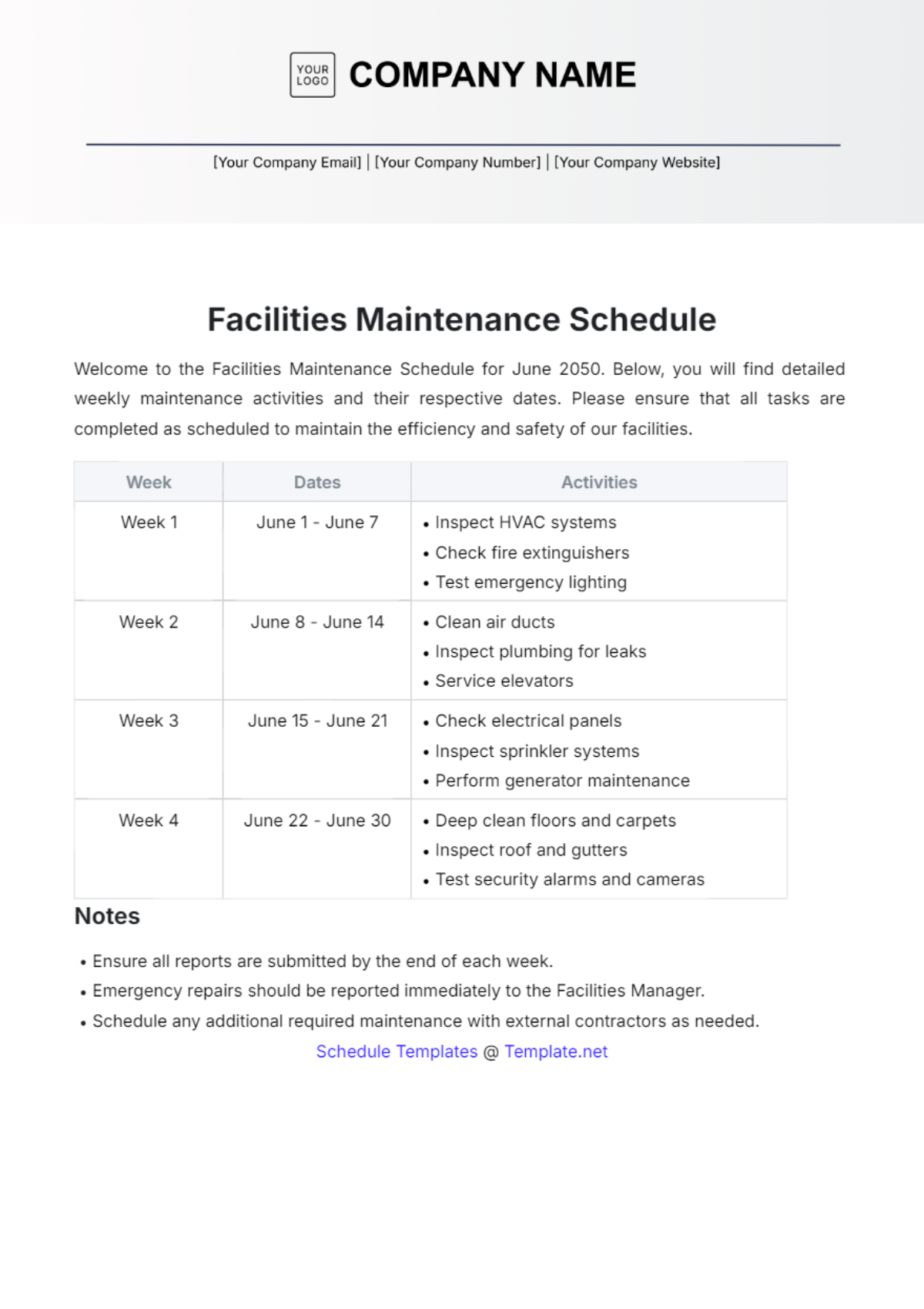

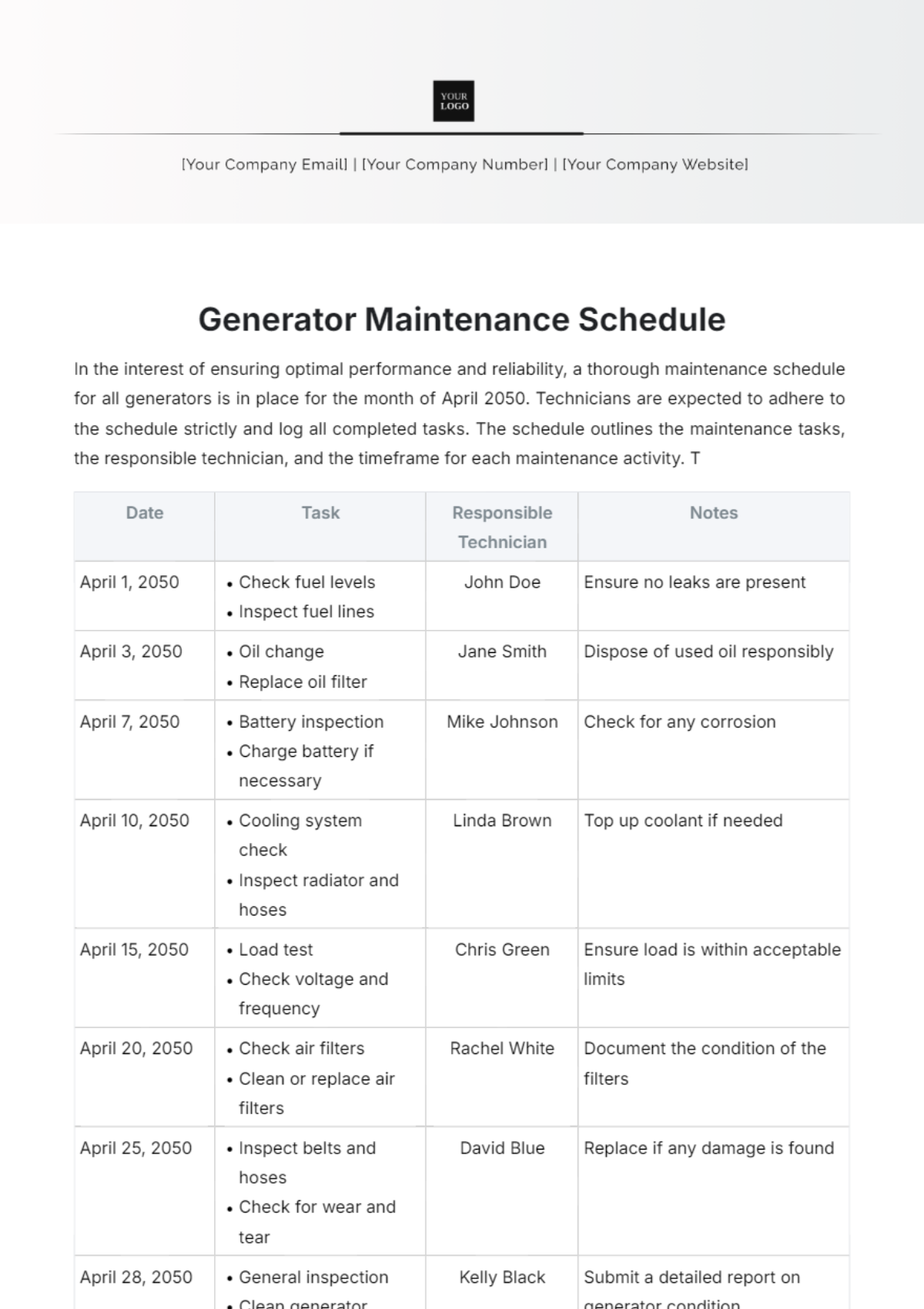

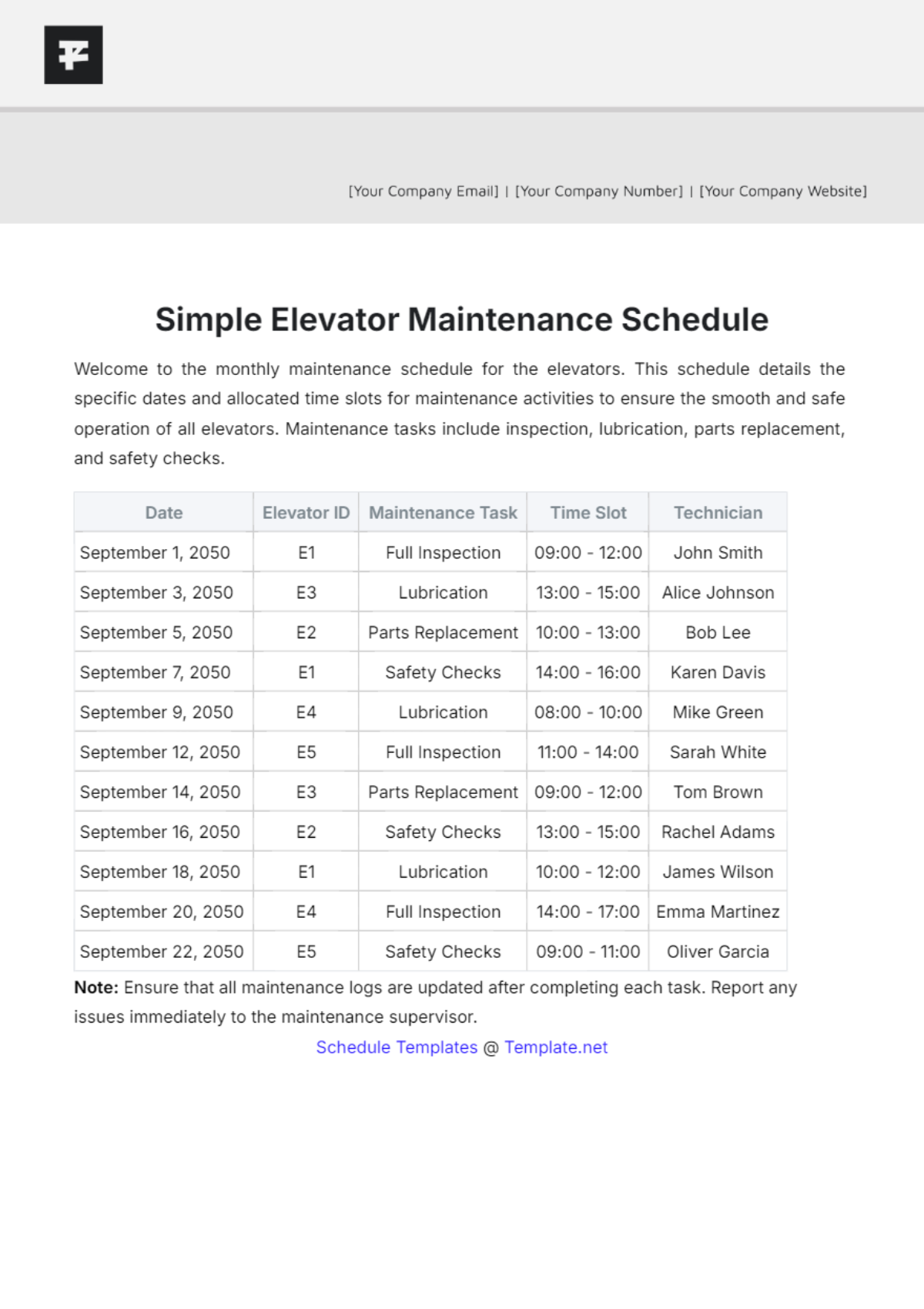

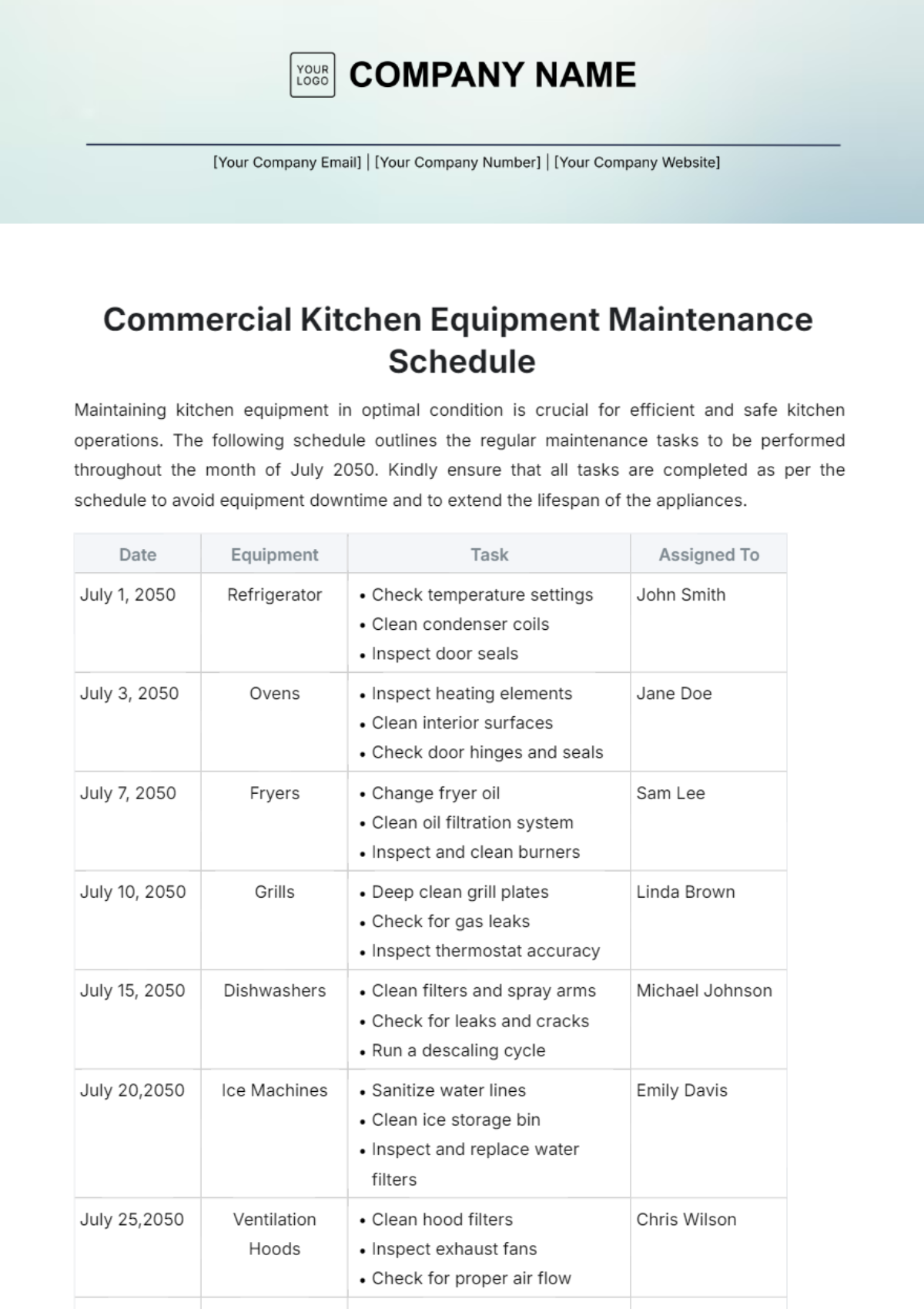

Keep your facility team engaged, reduce downtime, and enhance equipment longevity with our expertly crafted Preventive Maintenance Schedule Templates from Template.net. Designed for facility managers and maintenance professionals, these templates allow you to streamline maintenance activities, ensuring no task is overlooked. Use them to effectively promote a more efficient maintenance department by scheduling routine upkeep or invite team members to training events by planning available time slots. Each template includes essential details such as task descriptions, time frames, and responsible contacts, ensuring all involved parties know their duties. With no specialized software skills required, enjoy professional-grade design elements that are ready to use upon download and come with customizable layouts for either print or digital distribution, saving you valuable time and resources in the process.

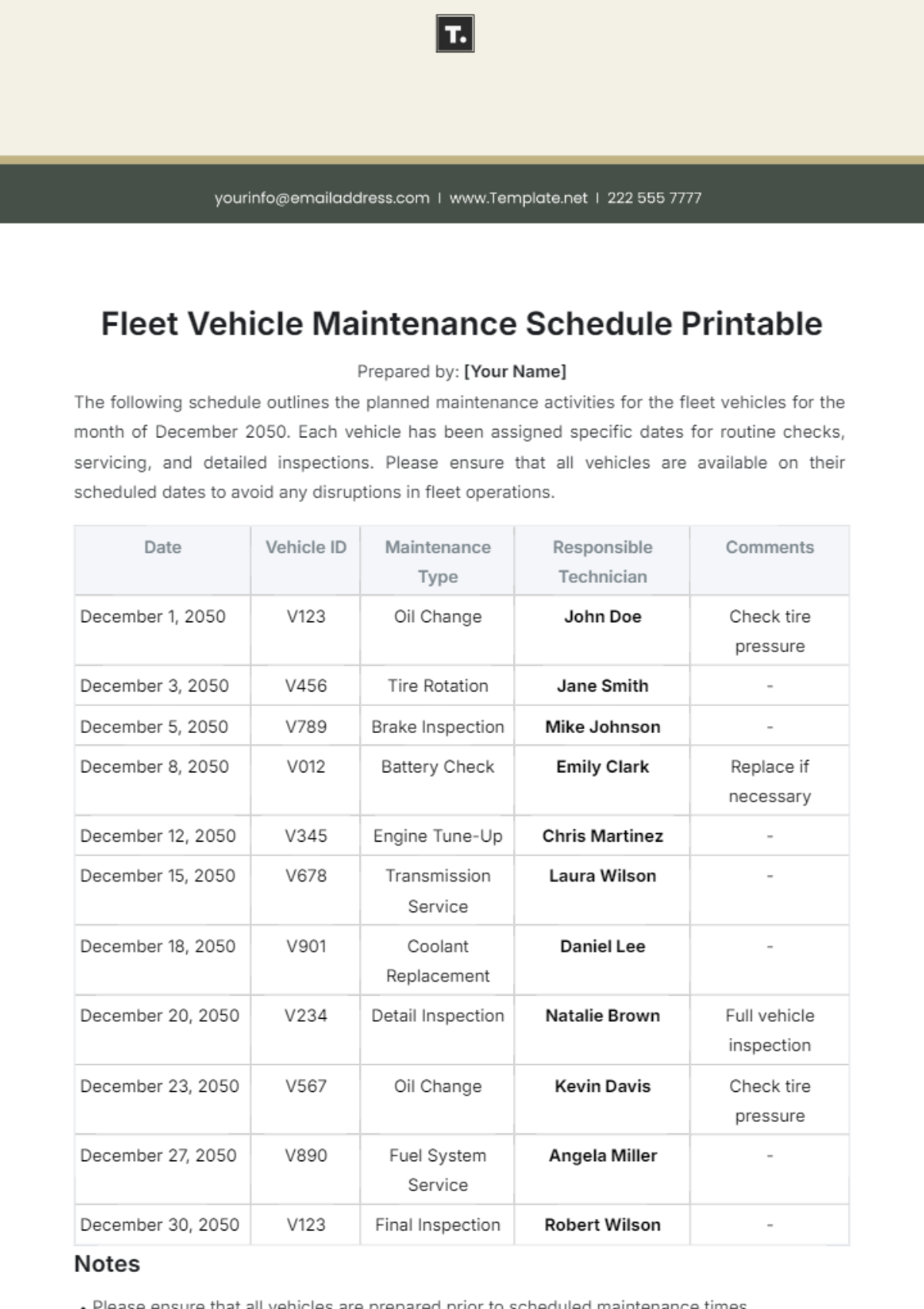

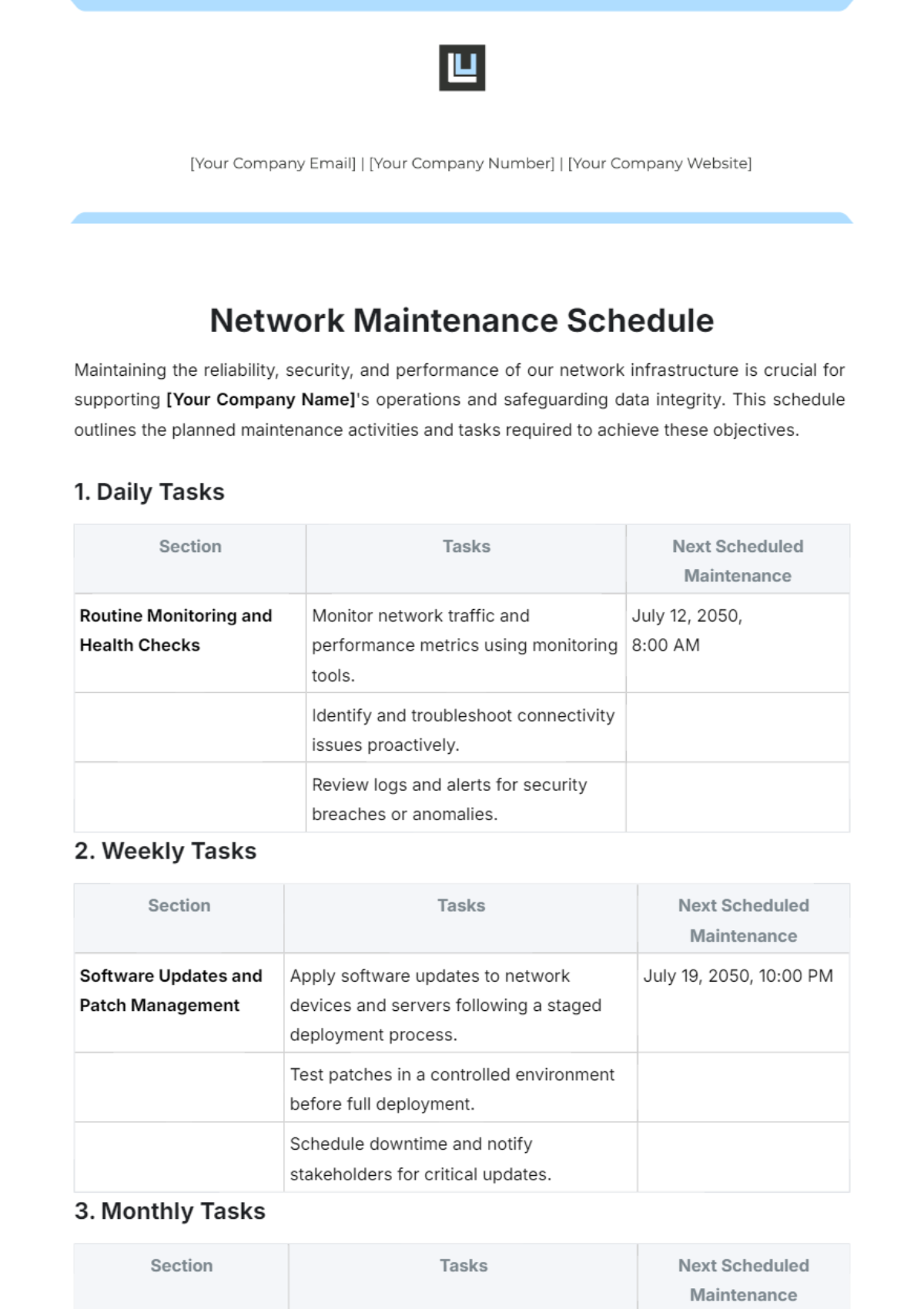

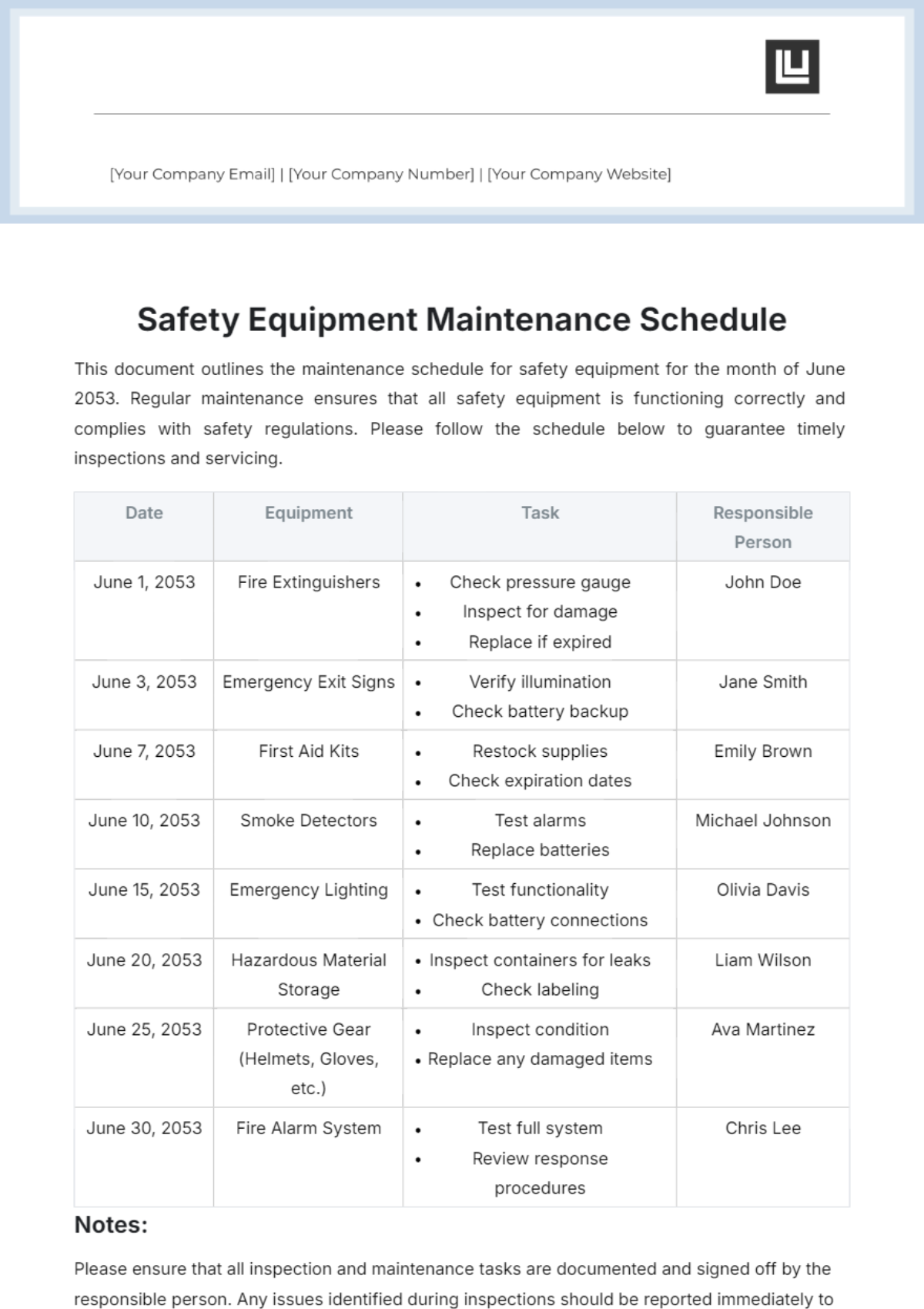

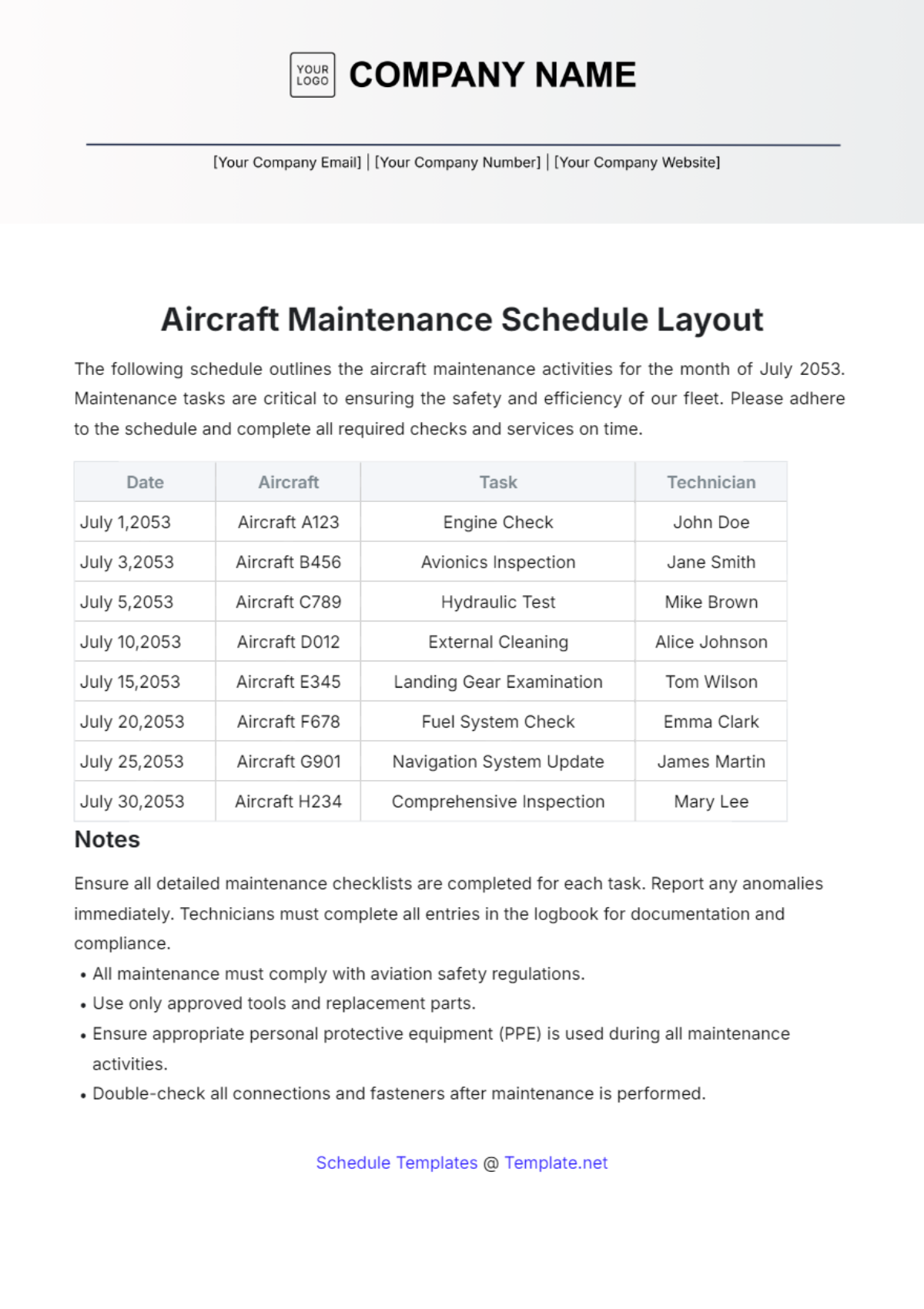

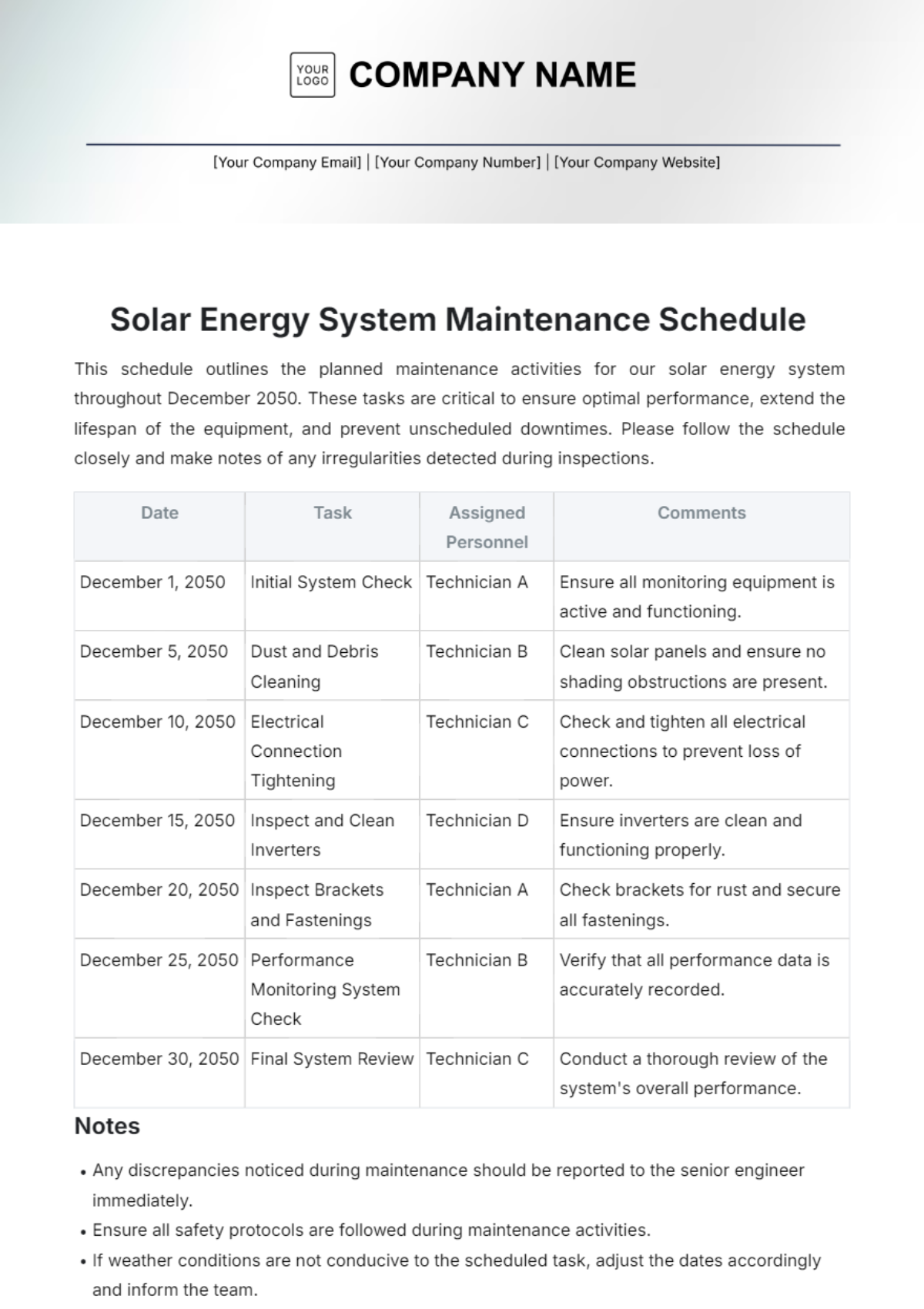

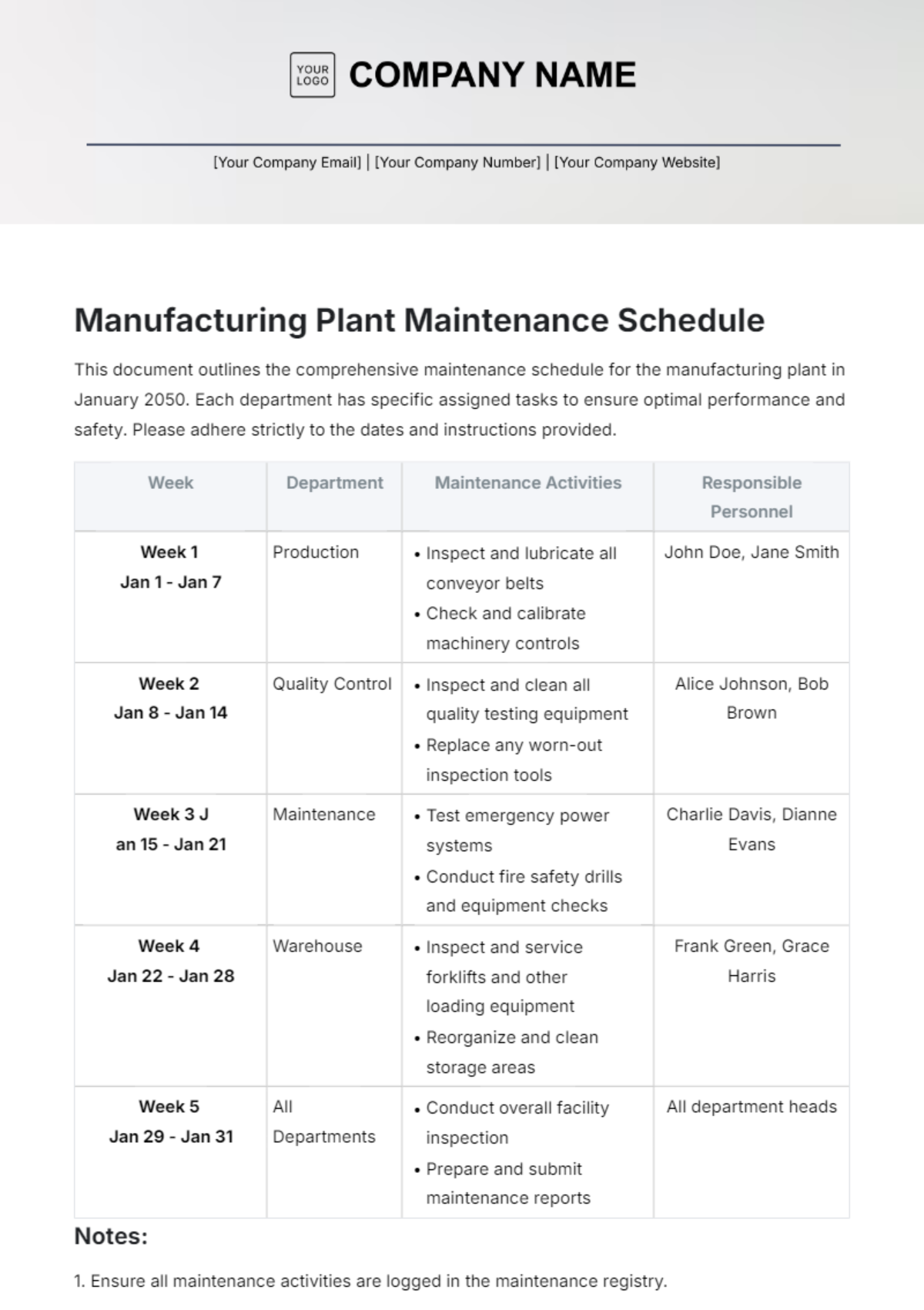

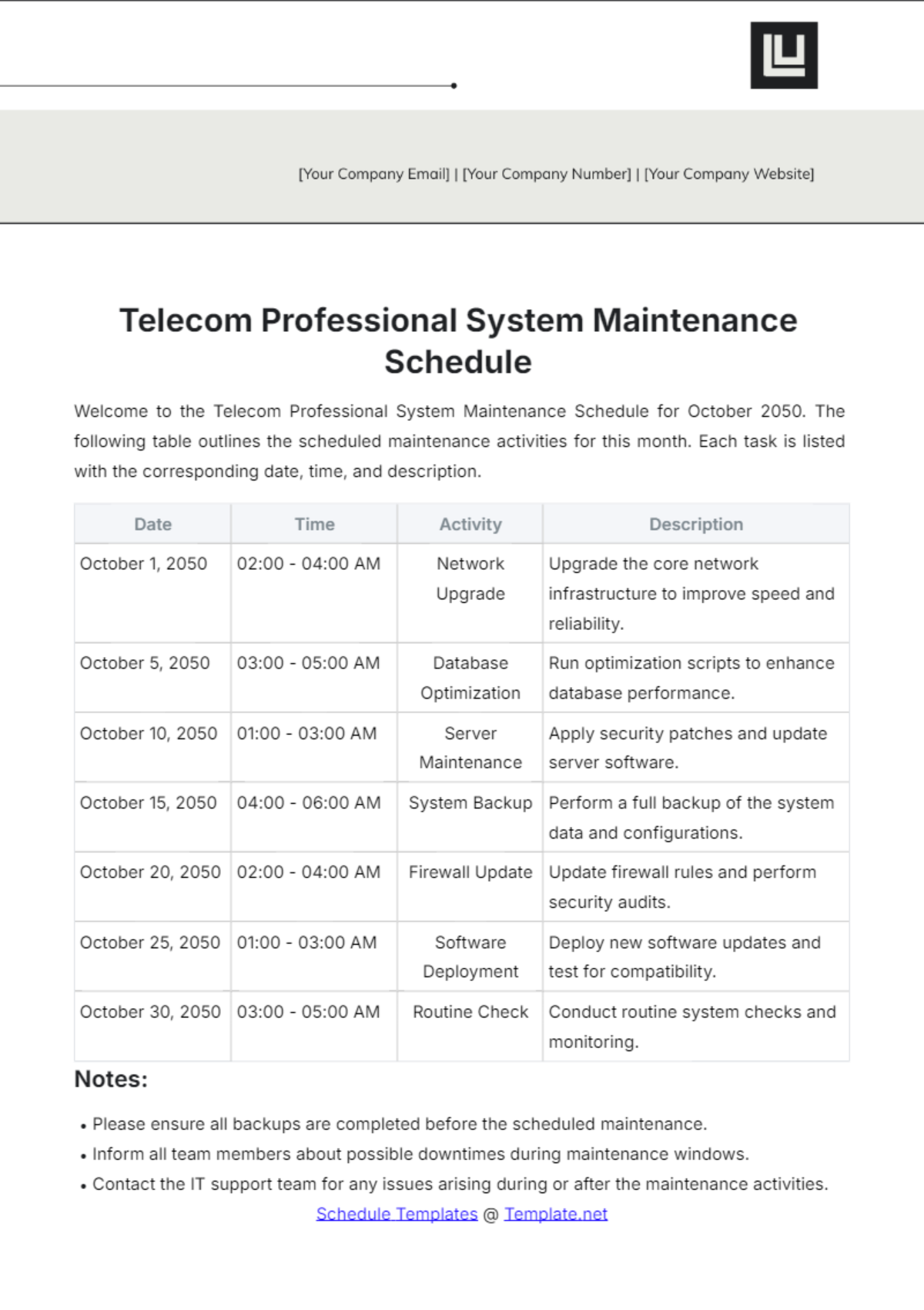

Discover the many Preventive Maintenance Schedule Templates we have on hand that cater to a wide array of maintenance scenarios. Selecting a template is a breeze; simply swap in your specific assets, tailor the colors and fonts to align with your branding, and make your schedule stand out with unique customizations. Elevate your templates by dragging and dropping icons or adding animated effects for a dynamic presentation, while our AI-powered text tools assist you in crafting clear and concise instructions effortlessly. Enjoy the endless possibilities our easy-to-use platform offers, ensuring you'll have fun while creating schedules that meet your precise needs. With regularly updated templates, you'll never run out of fresh designs and ideas. When you're finished, download or share your tailored schedule via link, print, email, or any other preferred export method, making it ideal for sharing across multiple channels or collaborating in real time.