Free Welder Continuity Log Template

Welder Continuity Log

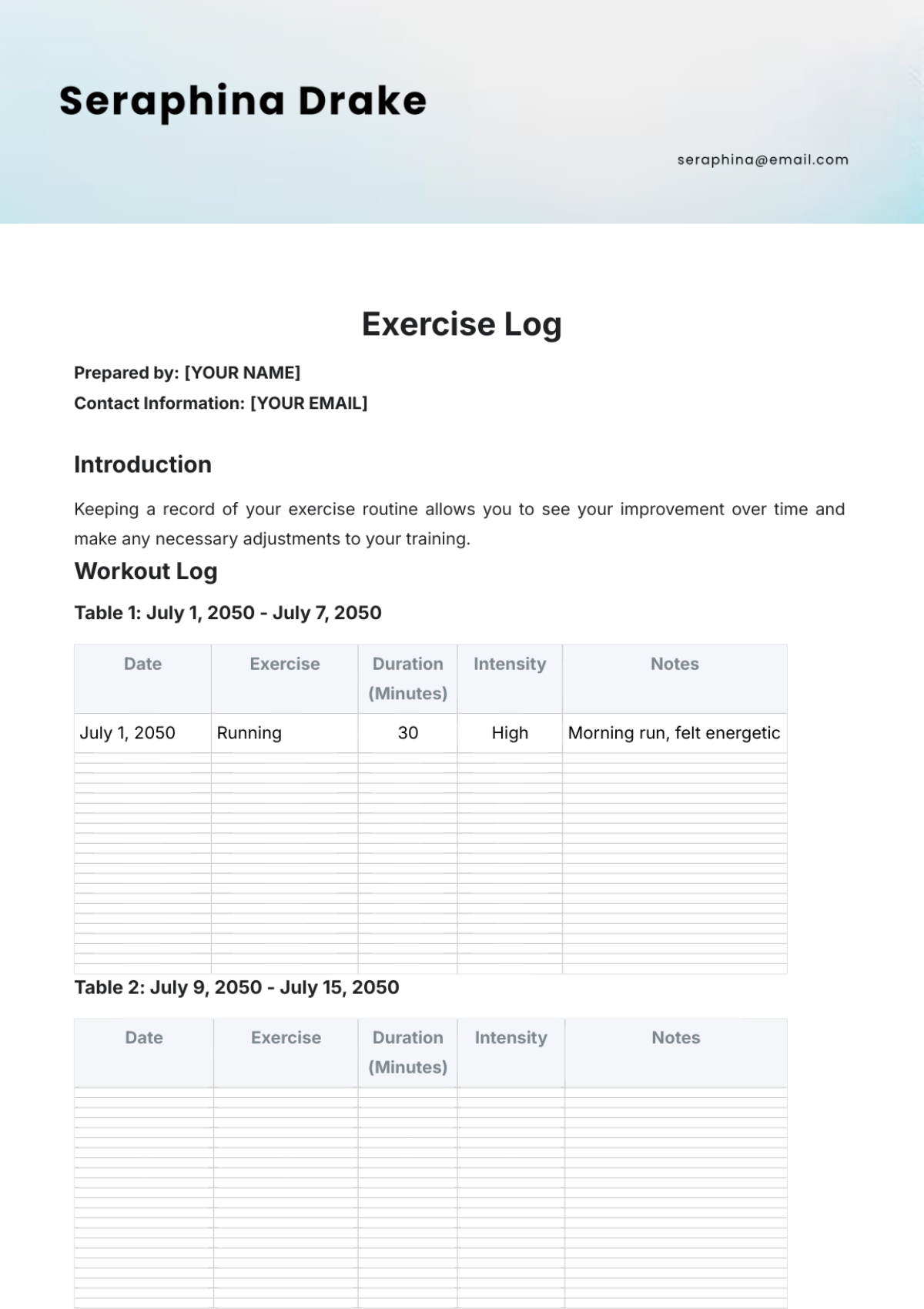

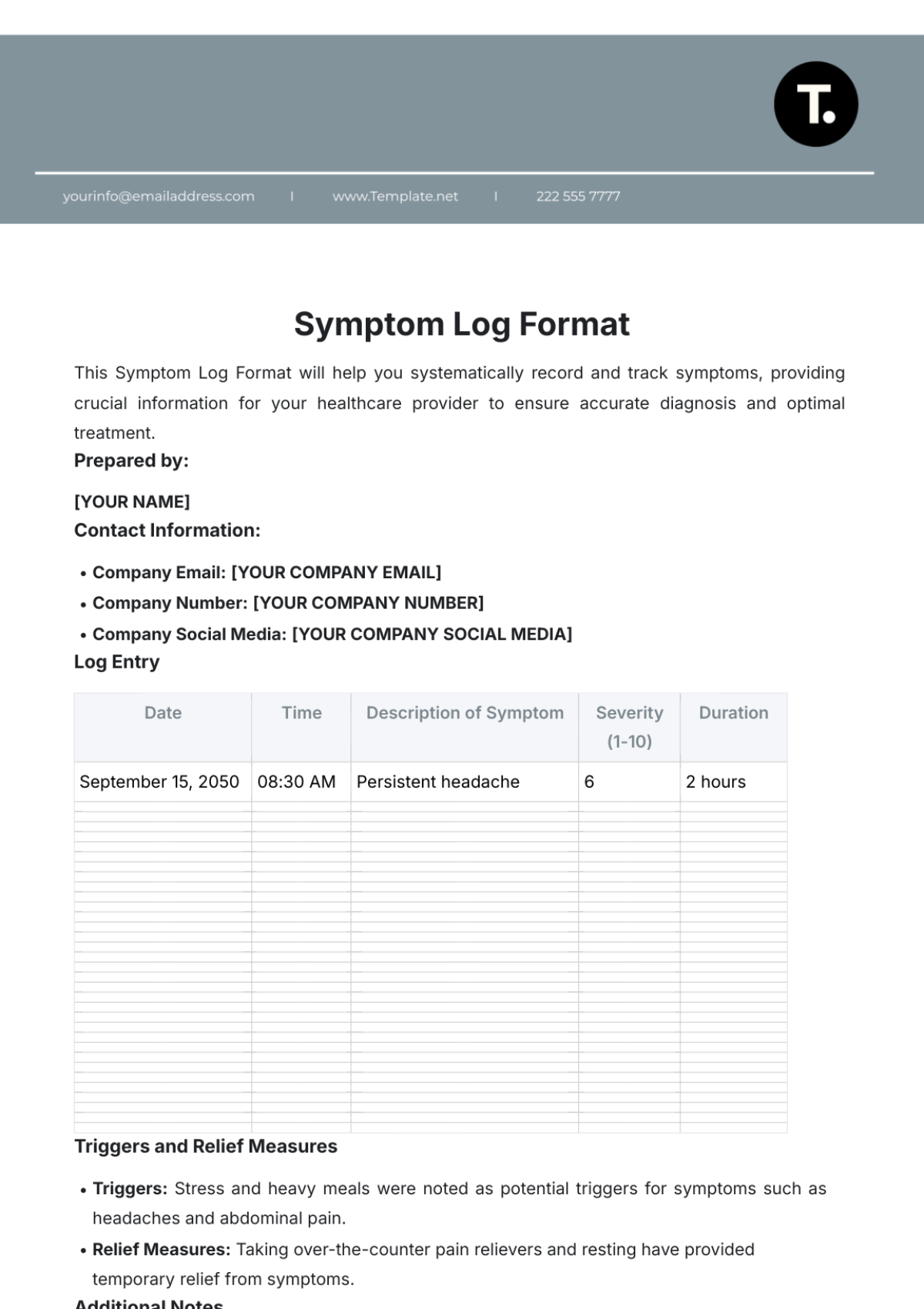

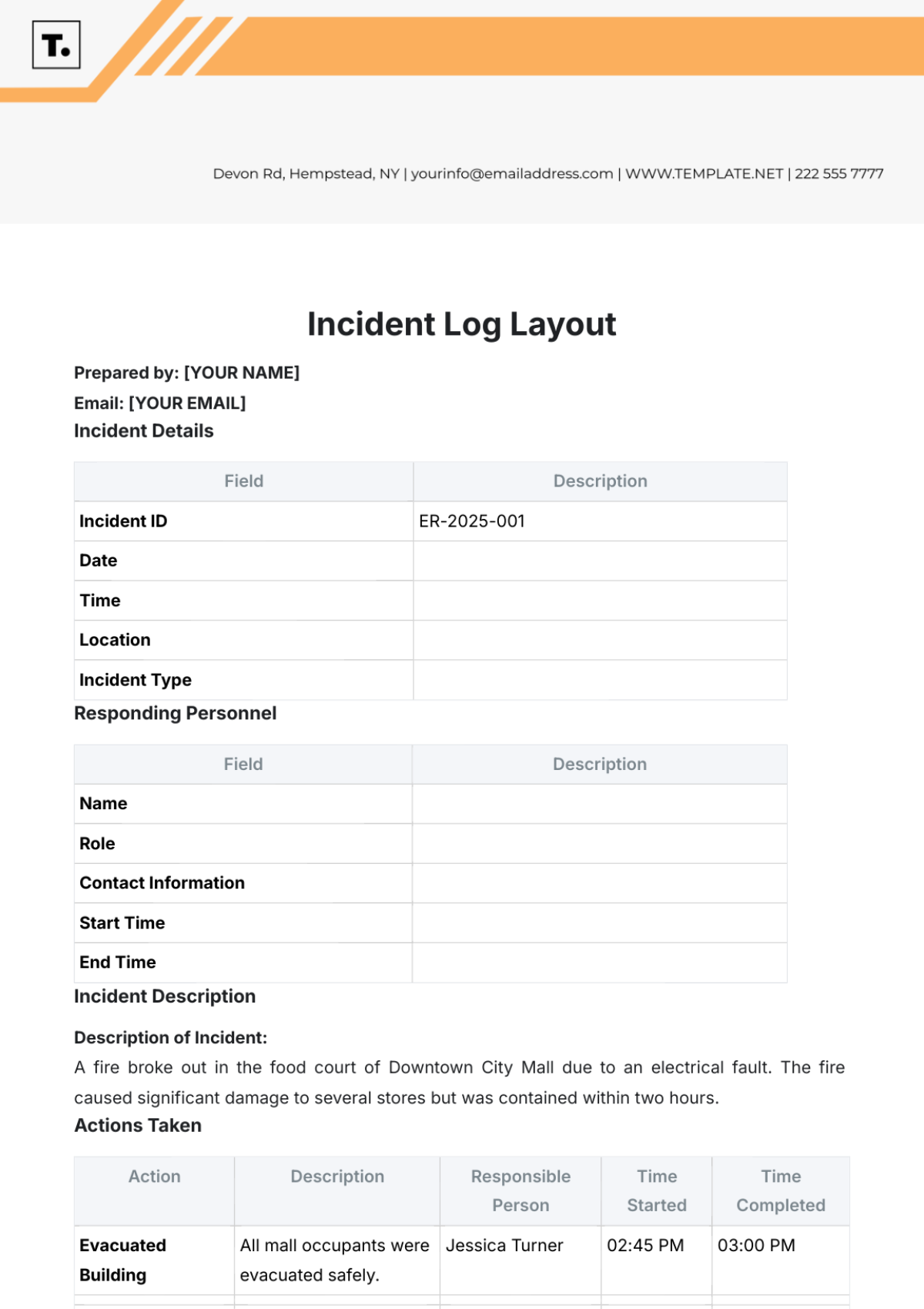

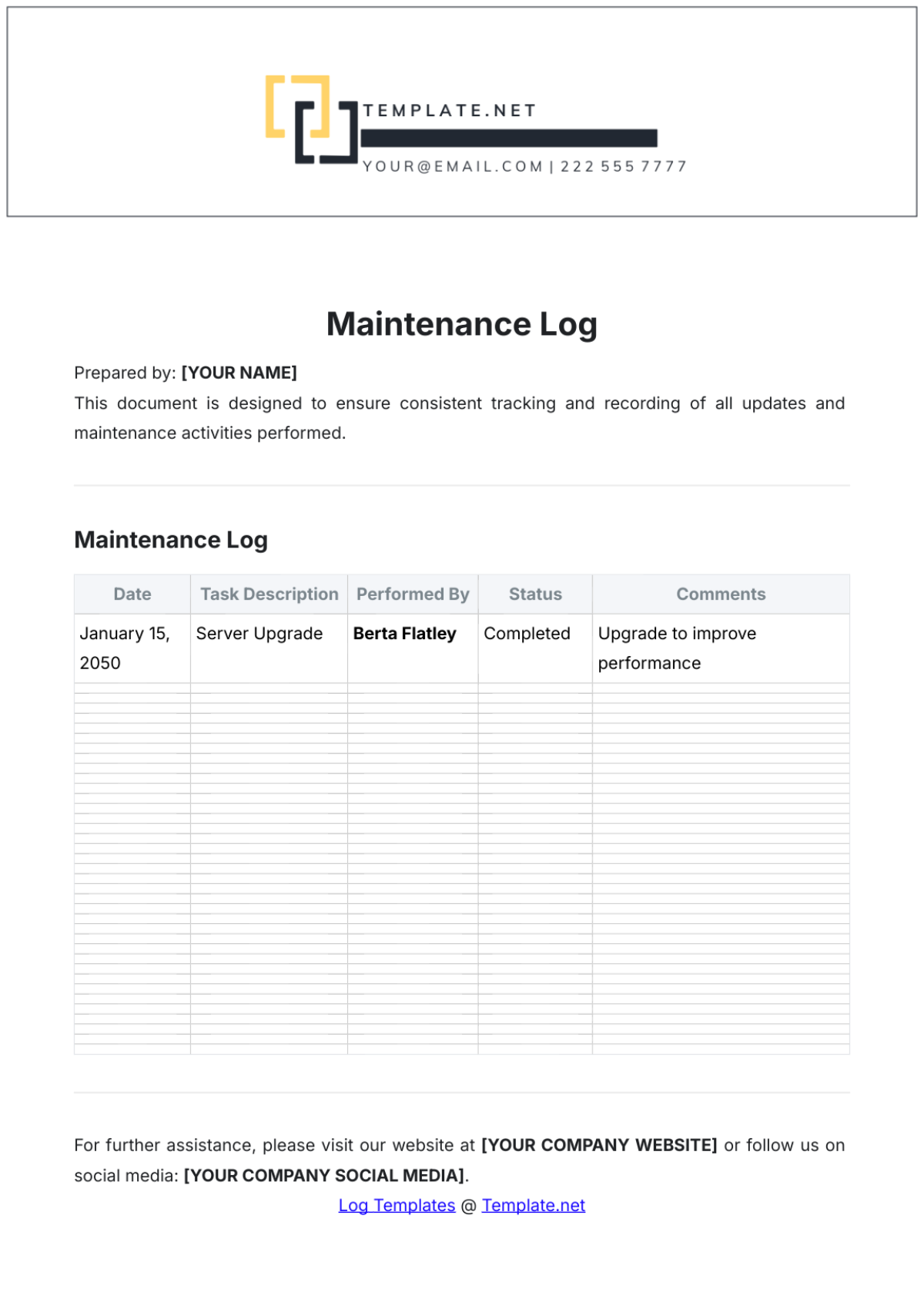

The Welder Continuity Log is a vital document designed to record welding activities and ensure adherence to welding procedures. It serves as a comprehensive record of welder qualifications, work performed, and compliance with industry standards.

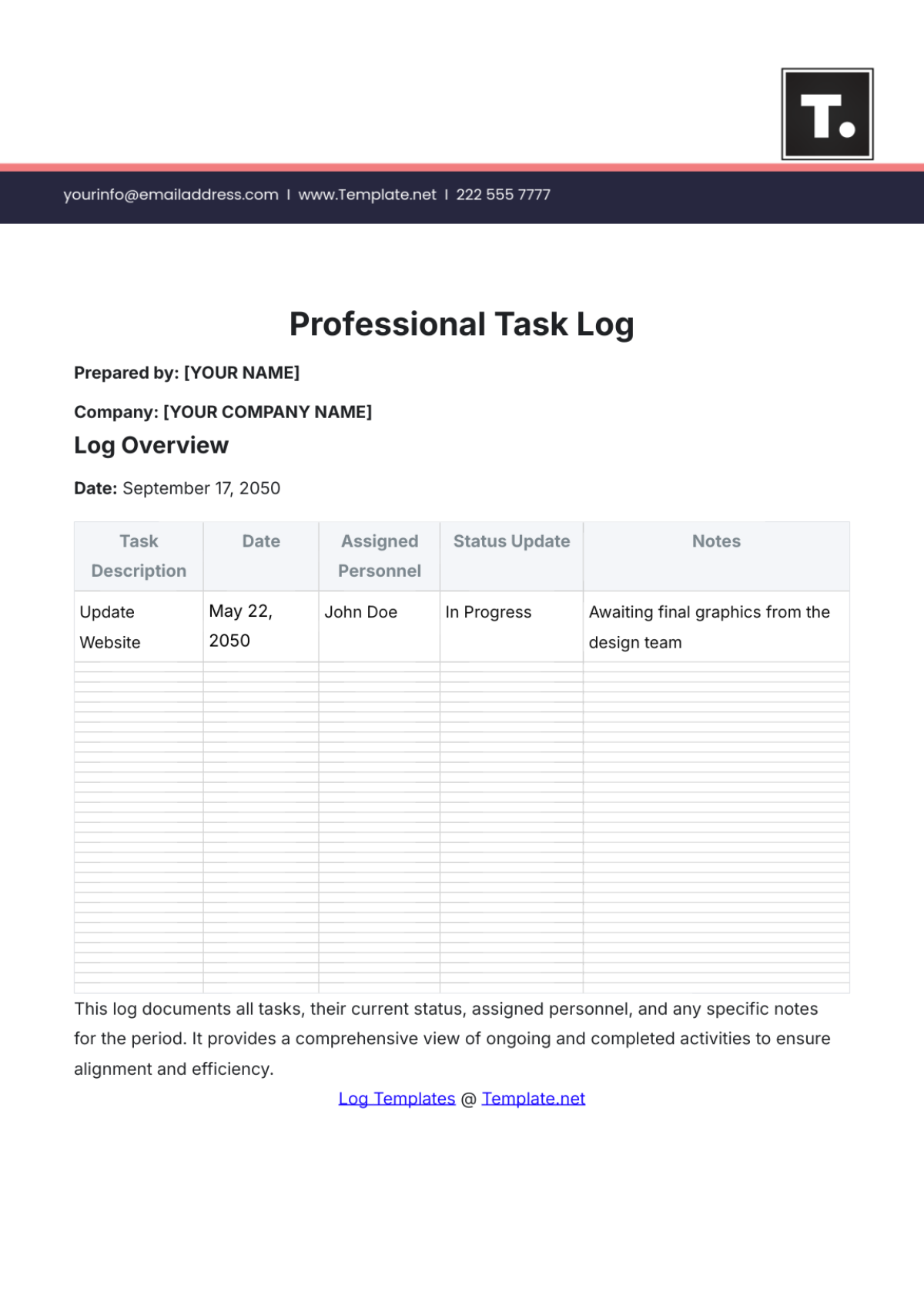

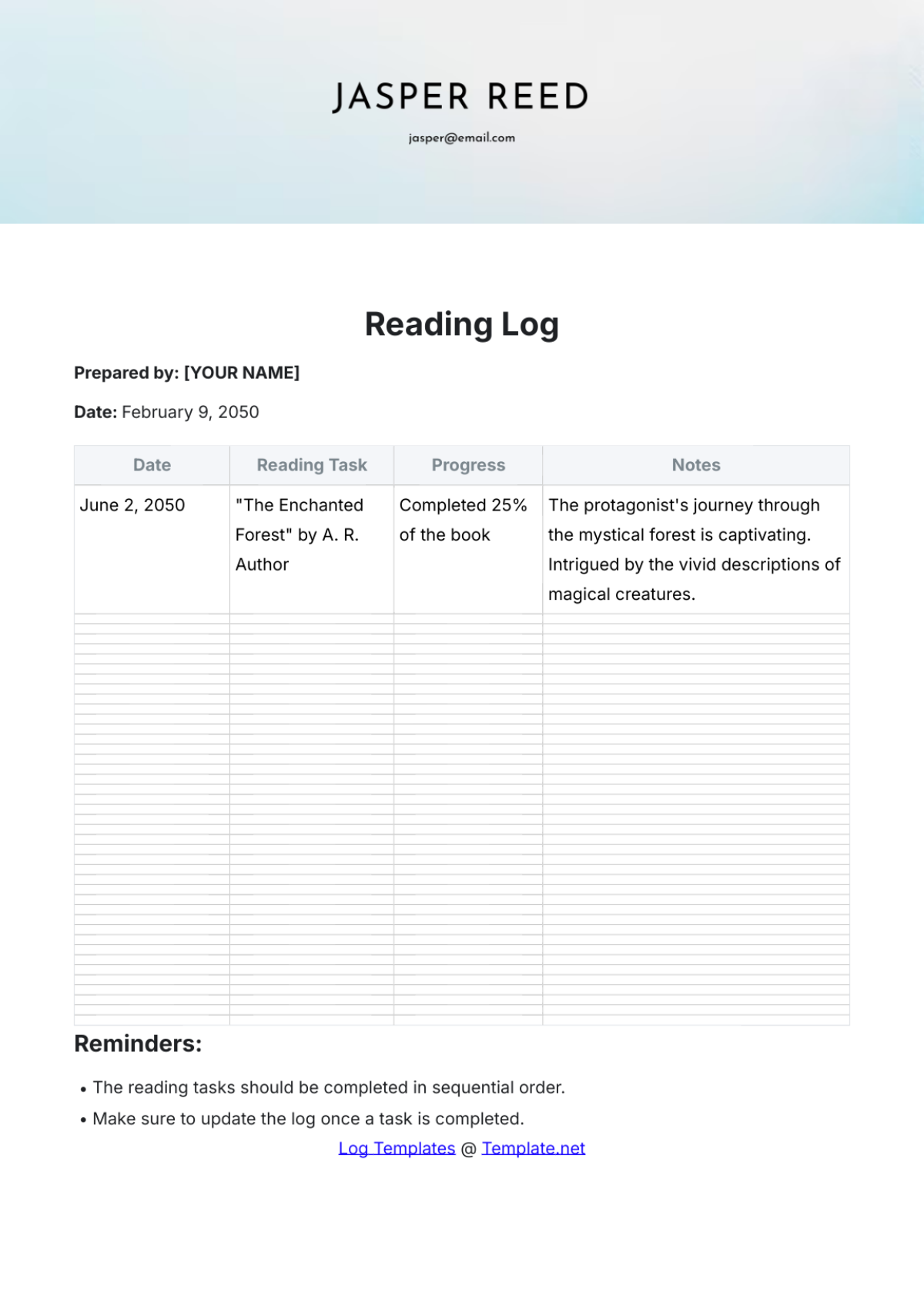

Prepared by: [YOUR NAME]

Date: March 5, 2050

Company: [YOUR COMPANY NAME]

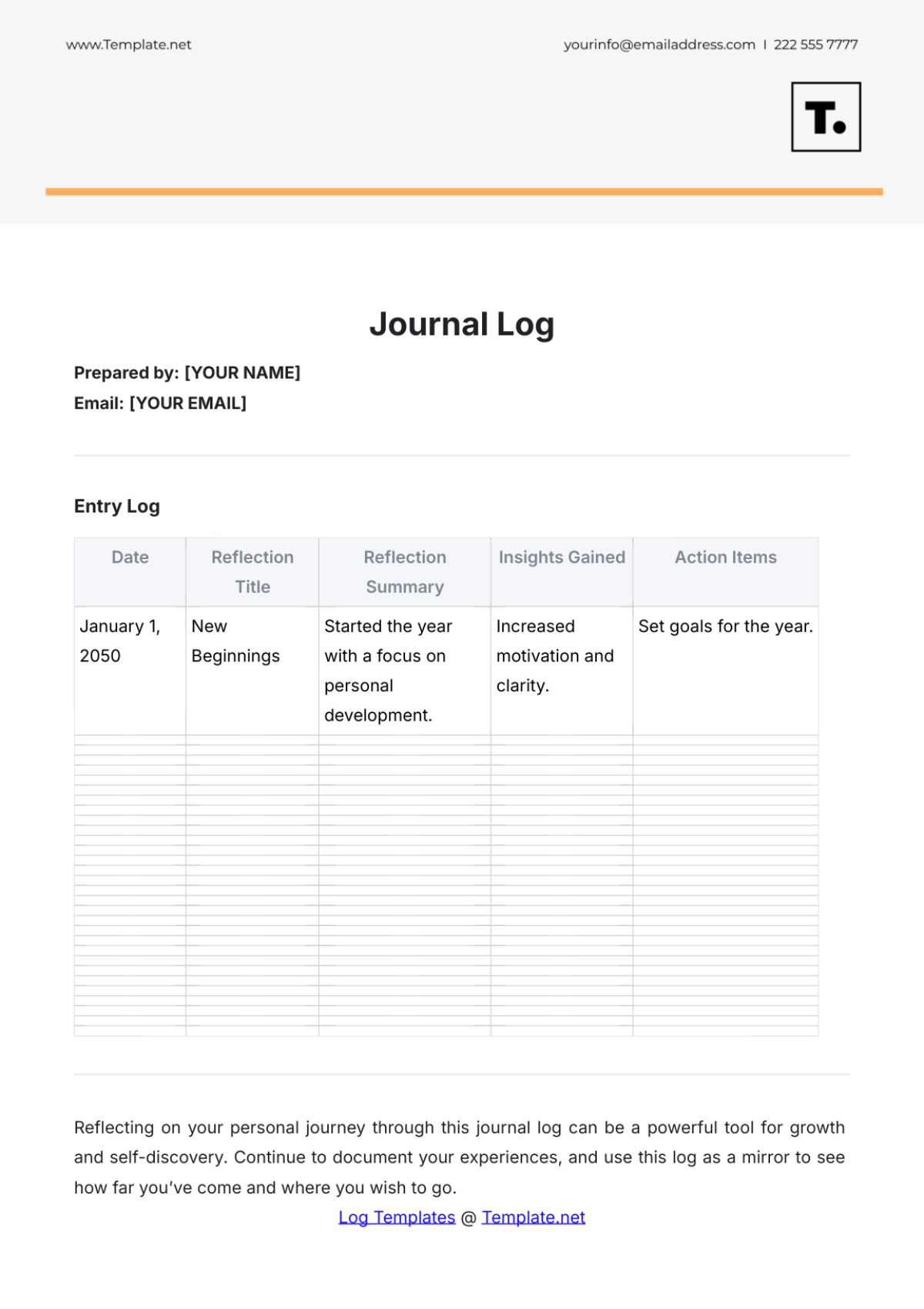

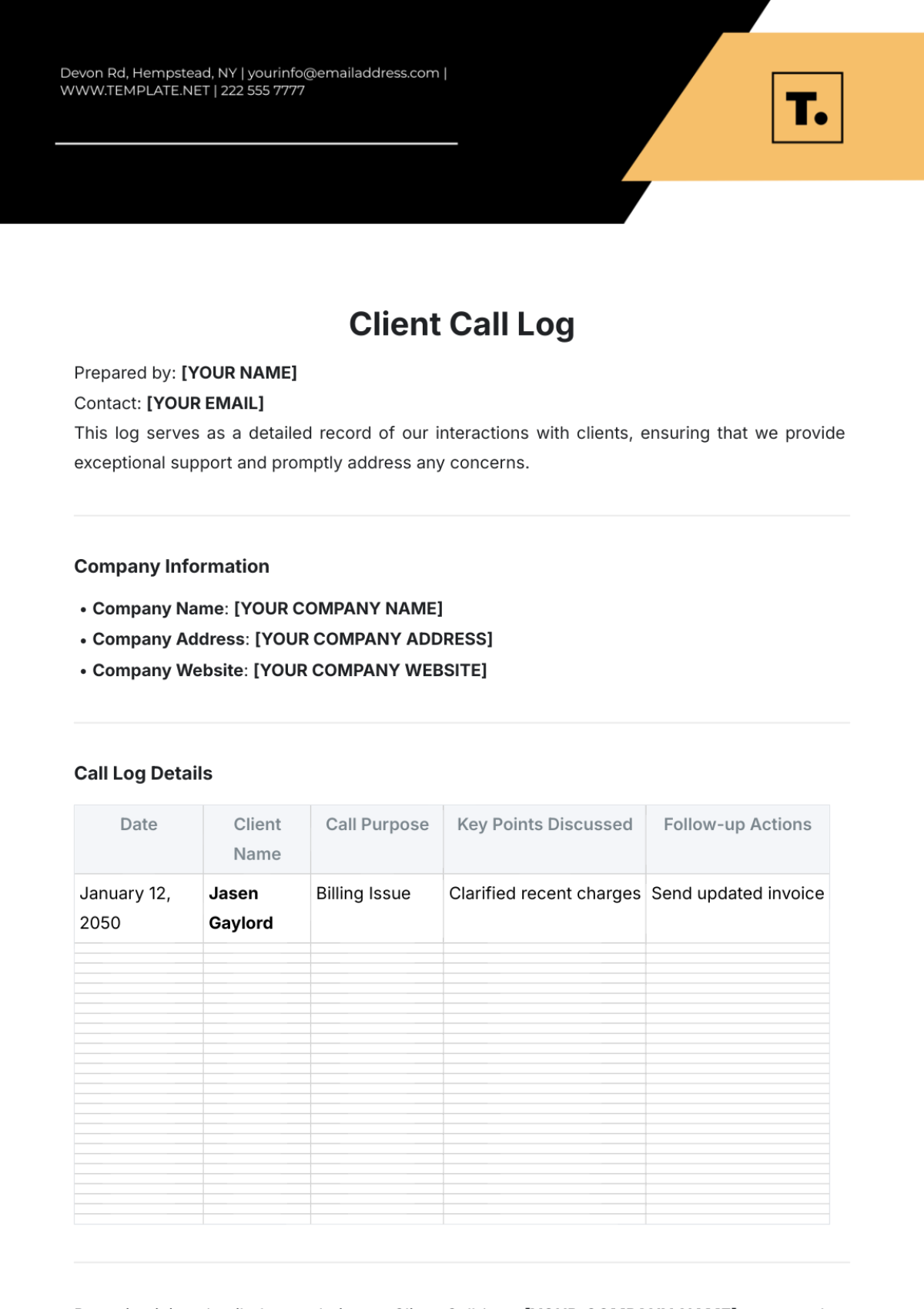

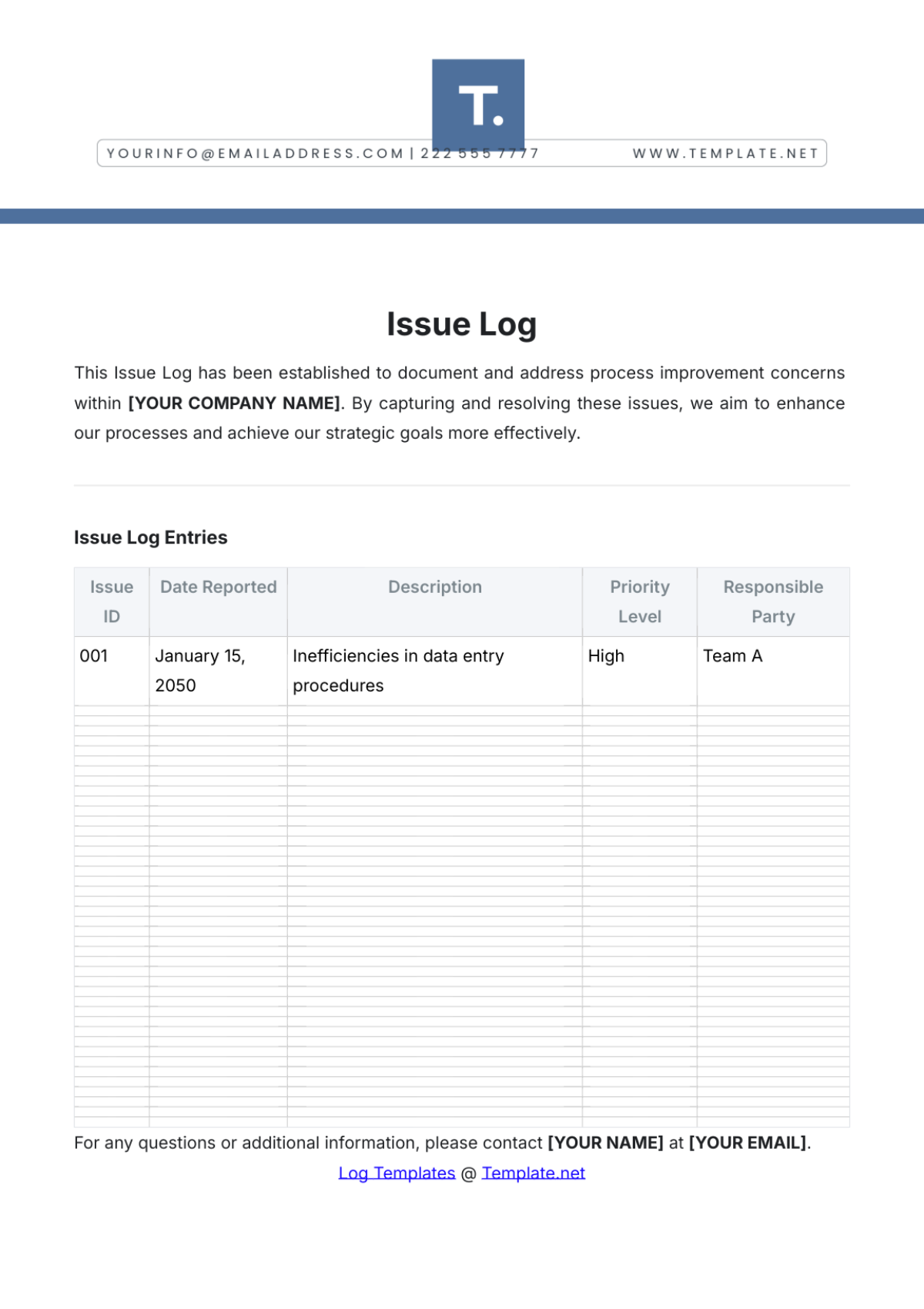

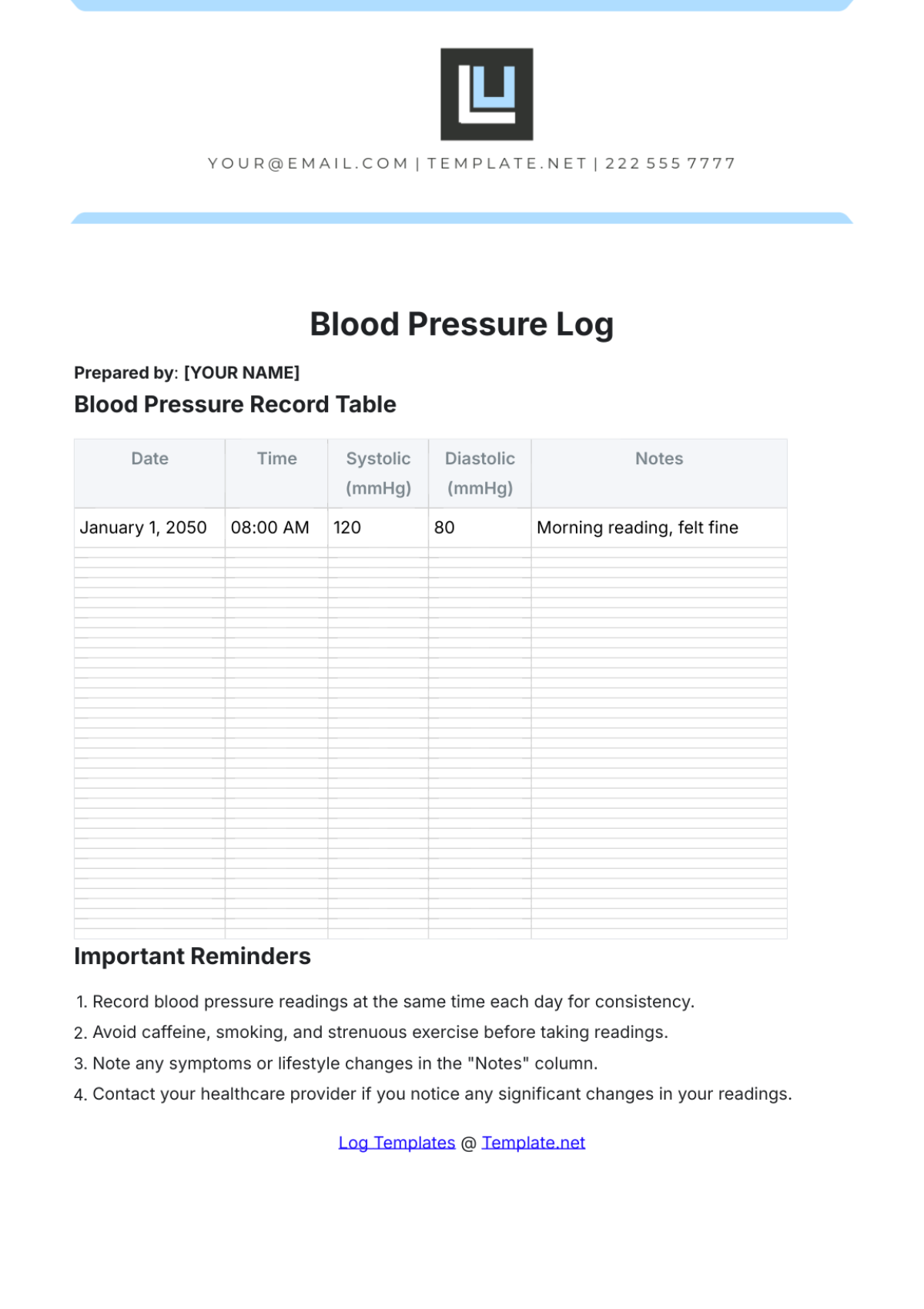

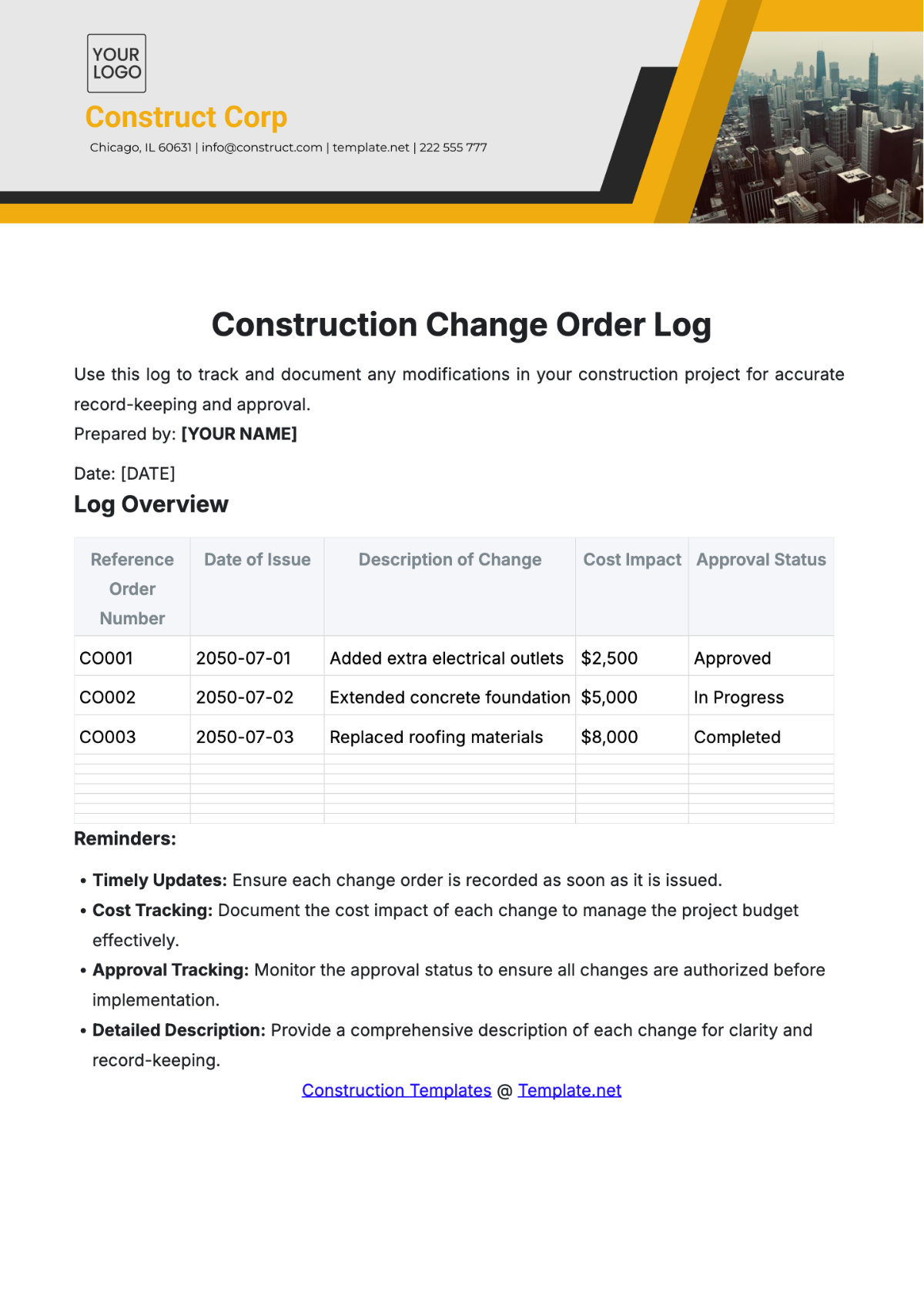

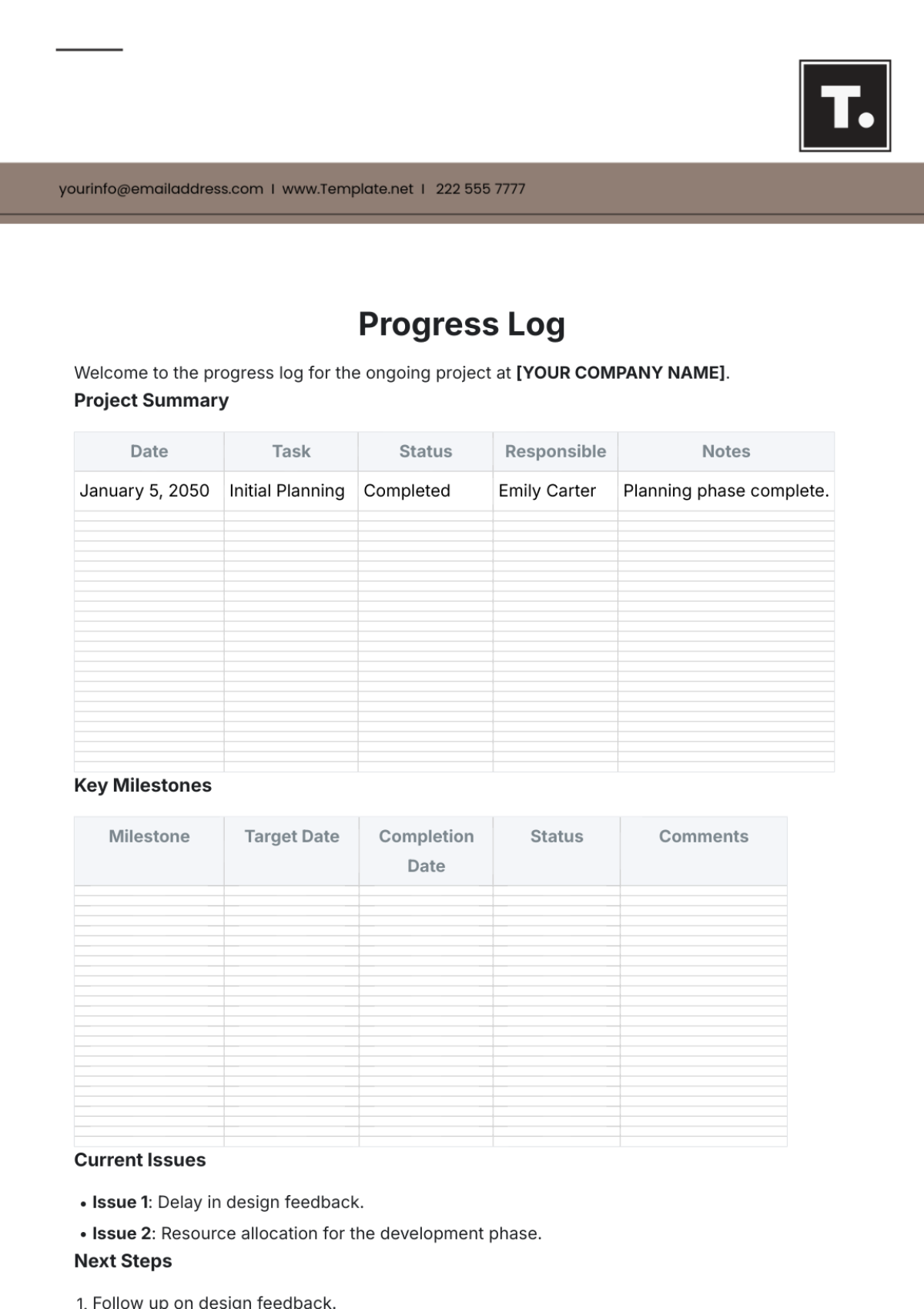

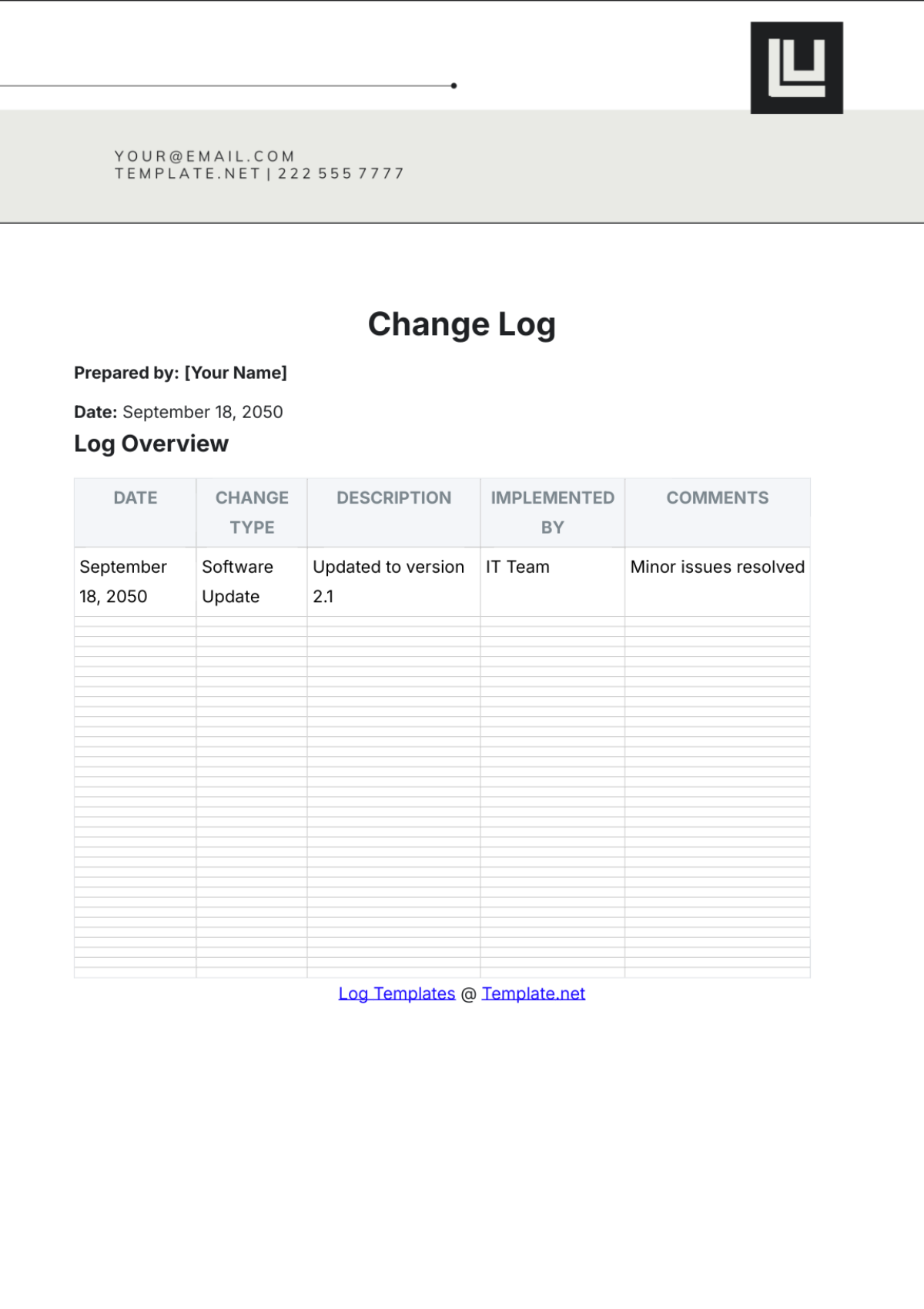

Log Overview

Date: [DATE]

Summary: Record ensuring adherence to welding procedures by documenting welding activities, parameters, and remarks.

Date | Welder Name | Welding Process | Welding Procedure (WPS) | Remarks |

|---|---|---|---|---|

2024-03-05 | John Smith | GMAW | WPS-GMAW-001 | Successful weld, no issues observed. |

2024-03-06 | Emily Johnson | SMAW | WPS-SMAW-002 | Weld completed without any discrepancies. |

2024-03-07 | Michael Brown | GTAW | WPS-GTAW-003 | Weld quality meets specifications, ready for next inspection. |

Reminders:

Regular Updates: Ensure the Welder Continuity Log is updated promptly after each welding activity.

Accuracy: Double-check all entries for accuracy in welder names, dates, and welding details.

Procedure Adherence: Verify that welding procedures specified in the log align with approved welding procedure specifications (WPS).

Remarks: Include relevant remarks or observations for each weld, noting any deviations from standard procedures or unexpected issues.