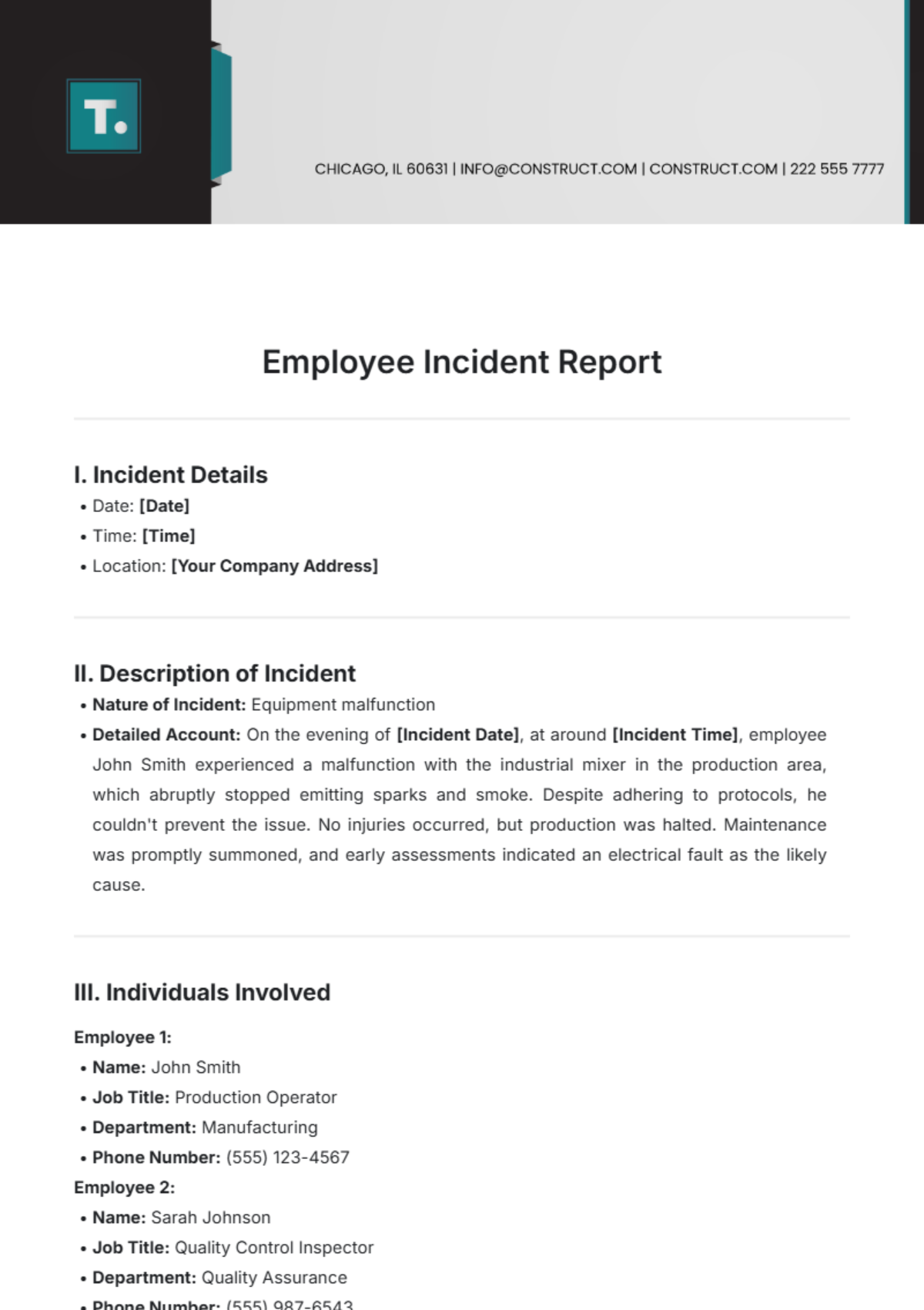

Free Employee Incident Report

I. Incident Details

Date: [Date]

Time: [Time]

Location: [Your Company Address]

II. Description of Incident

Nature of Incident: Equipment malfunction

Detailed Account: On the evening of [Incident Date], at around [Incident Time], employee John Smith experienced a malfunction with the industrial mixer in the production area, which abruptly stopped emitting sparks and smoke. Despite adhering to protocols, he couldn't prevent the issue. No injuries occurred, but production was halted. Maintenance was promptly summoned, and early assessments indicated an electrical fault as the likely cause.

III. Individuals Involved

Employee 1:

Name: John Smith

Job Title: Production Operator

Department: Manufacturing

Phone Number: (555) 123-4567

Employee 2:

Name: Sarah Johnson

Job Title: Quality Control Inspector

Department: Quality Assurance

Phone Number: (555) 987-6543

IV. Witnesses

Name: [YOUR NAME]

Email: [YOUR EMAIL]

Phone Number: [YOUR PHONE NUMBER]

Address: [YOUR ADDRESS]

V. Injuries or Damages

Injuries: The employee sustained injuries to their left arm and lower back due to the slip and fall accident. Consequently, they suffered from pain and swelling in these injured regions. Following the incident, they were promptly transported to the medical facility designated by the company, where they underwent evaluation and received treatment for their injuries.

Damages: No damages to property or equipment were reported as a result of this incident.

VI. Immediate Actions Taken

First Aid Provided: Upon witnessing the employee's fall, colleagues immediately provided first aid by stabilizing the employee and assessing their injuries. Basic first aid procedures, such as applying pressure to control bleeding and providing comfort measures, were administered until professional medical assistance arrived.

Emergency Services Contacted: Due to the severity of the injuries, emergency services were contacted immediately. An ambulance was dispatched to the scene to transport the injured employee to the nearest medical facility for further evaluation and treatment.

VII. Follow-up Actions

A. Investigation Plan

Conduct a thorough investigation into the circumstances of the incident, including reviewing CCTV footage, interviewing witnesses, and examining maintenance records of the equipment involved.

Identify any contributing factors, such as equipment malfunction, human error, or procedural deficiencies.

Compile a detailed report outlining findings and recommendations for corrective actions.

B. Corrective Actions

Repair or replace the faulty equipment identified in the incident investigation to prevent similar malfunctions in the future.

Implement enhanced training programs for employees operating machinery to ensure they are equipped with the necessary skills to identify and respond to equipment issues promptly.

Enhance safety protocols by implementing regular inspections of workplace environments to identify and address potential hazards, such as slippery floors or malfunctioning equipment.

C. Preventative Measures

Develop and implement a robust safety awareness program to educate employees on the importance of maintaining a safe work environment and adhering to safety protocols.

Install prominent warning signs in areas where potential hazards exist, such as wet floors, to alert employees and reduce the risk of accidents.

Establish a system for reporting and promptly addressing equipment malfunctions to prevent workflow disruptions and mitigate safety risks.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Streamline employee incident documentation with the Employee Incident Report Template from Template.net. Fully customizable and editable, this template helps you record workplace incidents effectively. Editable in our Ai Editor Tool, it provides a user-friendly experience, ensuring you capture all necessary details and maintain a safe, compliant work environment. Perfect for accurate and efficient incident reporting

You may also like

- Employee Letter

- Employee ID Card

- Employee Checklist

- Employee Certificate

- Employee Report

- Employee Training Checklist

- Employee Agreement

- Employee Contract

- Employee Training Plan

- Employee Incident Report

- Employee Survey

- Employee of the Month Certificate

- Employee Development Plan

- Employee Action Plan

- Employee Roadmap

- Employee Poster

- Employee Form

- Employee Engagement Survey