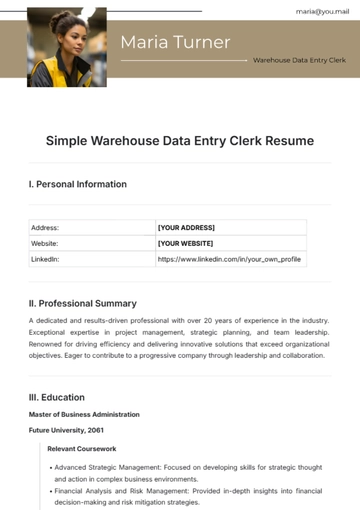

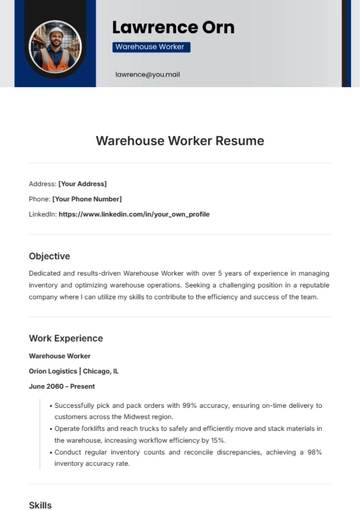

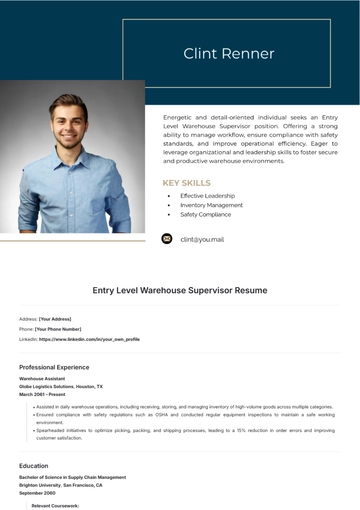

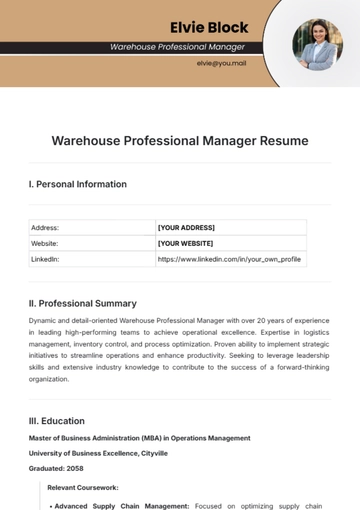

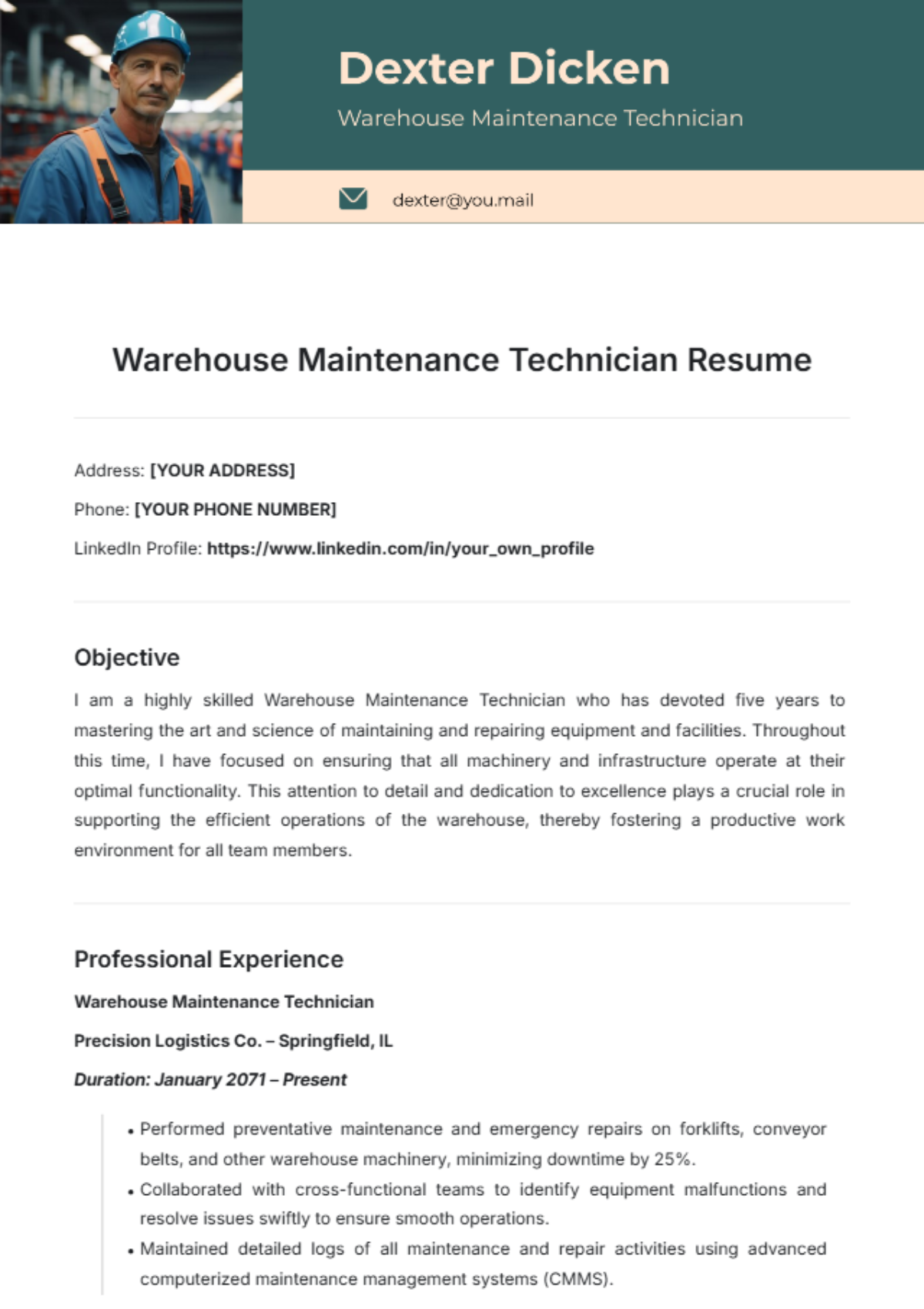

Free Warehouse Maintenance Technician Resume

Address: [YOUR ADDRESS]

Phone: [YOUR PHONE NUMBER]

LinkedIn Profile: https://www.linkedin.com/in/your_own_profile

Objective

I am a highly skilled Warehouse Maintenance Technician who has devoted five years to mastering the art and science of maintaining and repairing equipment and facilities. Throughout this time, I have focused on ensuring that all machinery and infrastructure operate at their optimal functionality. This attention to detail and dedication to excellence plays a crucial role in supporting the efficient operations of the warehouse, thereby fostering a productive work environment for all team members.

Professional Experience

Warehouse Maintenance Technician

Precision Logistics Co. – Springfield, IL

Duration: January 2071 – Present

Performed preventative maintenance and emergency repairs on forklifts, conveyor belts, and other warehouse machinery, minimizing downtime by 25%.

Collaborated with cross-functional teams to identify equipment malfunctions and resolve issues swiftly to ensure smooth operations.

Maintained detailed logs of all maintenance and repair activities using advanced computerized maintenance management systems (CMMS).

Maintenance Technician

Central Warehousing Corp. Chicago, IL

Duration: June 2065 – May 2070

Diagnosed and repaired complex mechanical and electrical failures on industrial equipment, reducing service callouts by 20%.

Developed and implemented a maintenance schedule that reduced equipment downtime by 30%, improving overall warehouse efficiency.

Conducted routine inspections of heating, ventilation, and air conditioning (HVAC) systems, ensuring optimal warehouse climate control.

Education

Associate of Applied Science in Industrial Maintenance Technology

Springfield Technical College – Springfield, IL

Graduated: May 2059

Relevant Coursework:

Industrial Safety and Regulations: Comprehensive study of OSHA regulations and workplace safety standards, focusing on risk management and incident prevention in industrial environments.

Electrical Systems for Industrial Maintenance: In-depth exploration of electrical systems and circuits commonly used in industrial settings, including diagnostic methods and repair procedures.

Mechanical Systems and Equipment Maintenance: Practical training in troubleshooting, repairing, and maintaining various mechanical systems, such as conveyor belts, pumps, and motors, ensuring optimal functionality.

Skills

Expertise in Warehouse Machinery: Proficient in the maintenance and repair of forklifts, conveyor systems, pallet jacks, and other warehouse equipment.

Strong Troubleshooting Abilities: Skilled in identifying root causes of equipment failures and implementing swift and effective solutions.

Team Collaboration: Experienced in working with maintenance teams, warehouse staff, and management to ensure smooth operations and timely issue resolution.

Professional Affiliations

National Association of Warehouse Maintenance Professionals (NAWMP)

Position: Active Member

Participating in annual workshops on emerging technologies in warehouse automation and equipment maintenance.

Engaging in networking events to collaborate with industry experts and stay current on best practices for warehouse maintenance and safety.

References

Available upon request

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

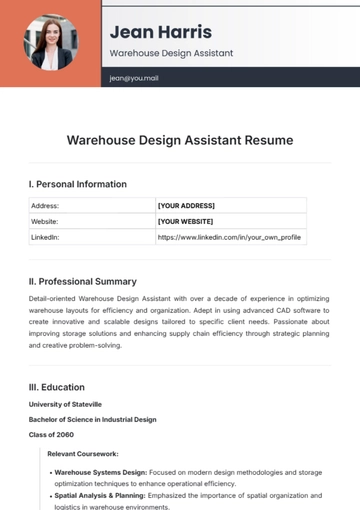

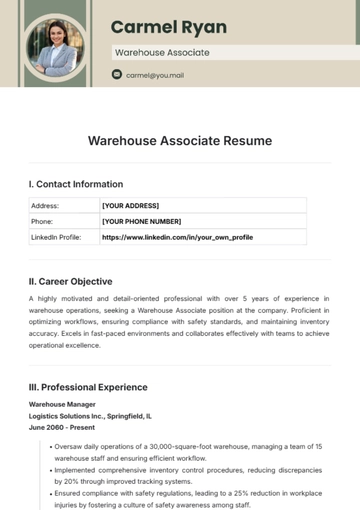

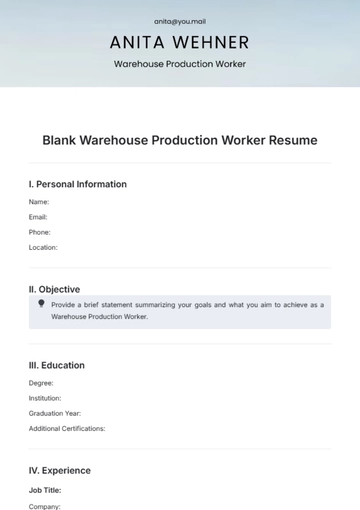

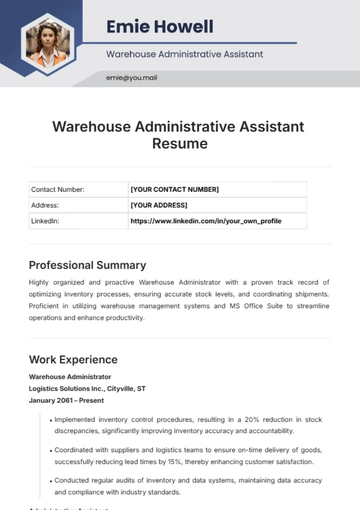

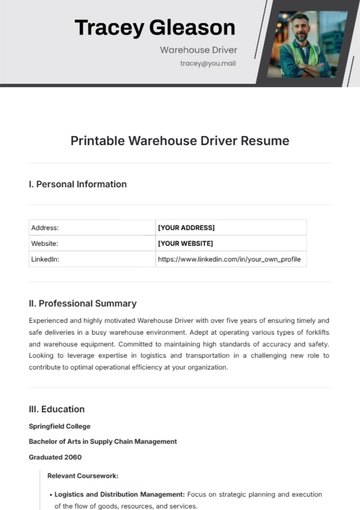

Warehouse Maintenance Technician Resume, meticulously crafted and offered by Template.net. This customizable, downloadable, and printable template empowers you to showcase your expertise seamlessly. Crafted to perfection, it's editable in our AI Editor Tool, ensuring you tailor it to your specific needs effortlessly. Elevate your resume game and land your dream job in warehouse maintenance with this premium offering.

You may also like

- Simple Resume

- High School Resume

- Actor Resume

- Accountant Resume

- Academic Resume

- Corporate Resume

- Infographic Resume

- Sale Resume

- Business Analyst Resume

- Skills Based Resume

- Professional Resume

- ATS Resume

- Summary Resume

- Customer Service Resume

- Software Engineer Resume

- Data Analyst Resume

- Functional Resume

- Project Manager Resume

- Nurse Resume

- Federal Resume

- Server Resume

- Administrative Assistant Resume

- Sales Associate Resume

- CNA Resume

- Bartender Resume

- Graduate Resume

- Engineer Resume

- Data Science Resume

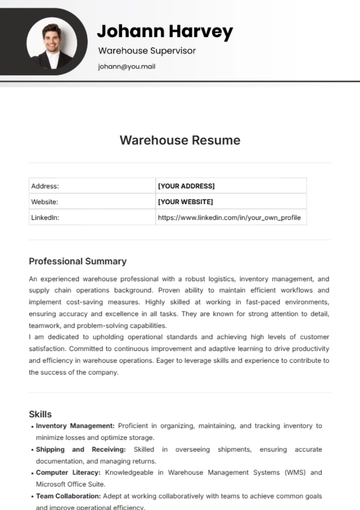

- Warehouse Resume

- Volunteer Resume

- No Experience Resume

- Chronological Resume

- Marketing Resume

- Executive Resume

- Truck Driver Resume

- Cashier Resume

- Resume Format

- Two Page Resume

- Basic Resume

- Manager Resume

- Supervisor Resume

- Director Resume

- Blank Resume

- One Page Resume

- Developer Resume

- Caregiver Resume

- Personal Resume

- Consultant Resume

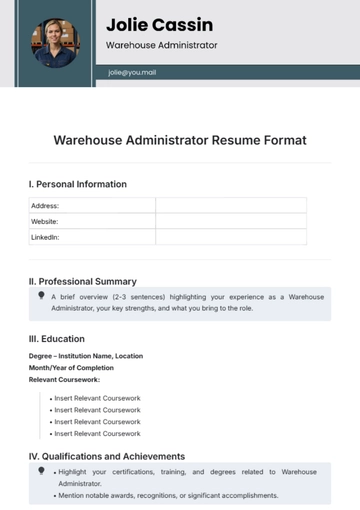

- Administrator Resume

- Officer Resume

- Medical Resume

- Job Resume

- Technician Resume

- Clerk Resume

- Driver Resume

- Data Entry Resume

- Freelancer Resume

- Operator Resume

- Printable Resume

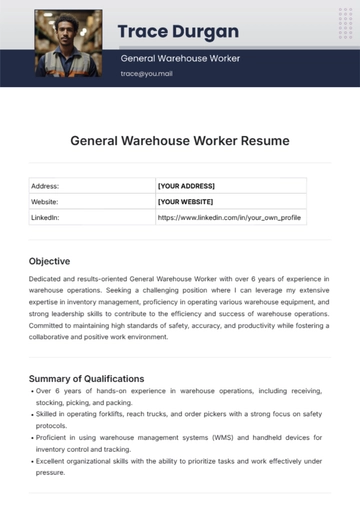

- Worker Resume

- Student Resume

- Doctor Resume

- Merchandiser Resume

- Architecture Resume

- Photographer Resume

- Chef Resume

- Lawyer Resume

- Secretary Resume

- Customer Support Resume

- Computer Operator Resume

- Programmer Resume

- Pharmacist Resume

- Electrician Resume

- Librarian Resume

- Computer Resume

- IT Resume

- Experience Resume

- Instructor Resume

- Fashion Designer Resume

- Mechanic Resume

- Attendant Resume

- Principal Resume

- Professor Resume

- Safety Resume

- Waitress Resume

- MBA Resume

- Security Guard Resume

- Editor Resume

- Tester Resume

- Auditor Resume

- Writer Resume

- Trainer Resume

- Advertising Resume

- Harvard Resume

- Receptionist Resume

- Buyer Resume

- Physician Resume

- Scientist Resume

- 2 Page Resume

- Therapist Resume

- CEO resume

- General Manager Resume

- Attorney Resume

- Project Coordinator Resume

- Bus Driver Resume

- Cook Resume

- Artist Resume

- Pastor Resume

- Recruiter Resume

- Team Leader Resume

- Apprentice Resume

- Police Resume

- Military Resume

- Personal Trainer Resume

- Contractor Resume

- Dietician Resume

- First Job Resume

- HVAC Resume

- Psychologist Resume

- Public Relations Resume

- Support Specialist Resume

- Computer Technician Resume

- Drafter Resume

- Foreman Resume

- Underwriter Resume

- Photo Resume

- Teacher Resume

- Modern Resume

- Fresher Resume

- Creative Resume

- Internship Resume

- Graphic Designer Resume

- College Resume