Free Agriculture Safety Feasibility Study

A. Introduction

Agriculture, being one of the most critical sectors, significantly contributes to the economy by providing food and raw materials. However, it is also one of the most hazardous industries, with numerous safety risks and challenges. This Agriculture Safety Feasibility Study by [Your Company Name] aims to evaluate the existing safety practices, identify potential risks, and propose comprehensive measures to enhance the safety standards within our agricultural operations. The study will analyze the feasibility of implementing these safety measures in terms of technical, operational, financial, and environmental aspects.

B. Objectives

The primary objectives of this feasibility study are:

To identify and assess the safety hazards associated with agricultural activities at [Your Company Name].

To evaluate the effectiveness of current safety practices and identify gaps.

To propose actionable safety measures that can be implemented to mitigate identified risks.

To analyze the feasibility of the proposed measures from technical, operational, financial, and environmental perspectives.

To develop a comprehensive implementation plan for the proposed safety measures.

C. Methodology

The methodology for this feasibility study includes a combination of qualitative and quantitative approaches. Data collection methods comprise site visits, safety audits, interviews with employees, review of existing safety documentation, and analysis of historical incident data. Risk assessments will be conducted using standardized tools such as Hazard Identification (HAZID) and Risk Assessment Matrices. The study will also involve benchmarking against industry best practices and compliance requirements to ensure comprehensive analysis and recommendations.

II. Background and Context

A. Industry Overview

The agriculture industry is a vital sector that encompasses various activities such as crop production, livestock farming, and horticulture. It plays a crucial role in sustaining the global food supply and contributes significantly to the economy. Despite its importance, agriculture remains one of the most hazardous industries. According to the International Labour Organization (ILO), agriculture accounts for a significant percentage of occupational injuries and fatalities worldwide.

B. Safety Challenges in Agriculture

Agricultural activities expose workers to a wide range of safety hazards, including physical, chemical, biological, and ergonomic risks. Common hazards include machinery accidents, exposure to hazardous chemicals, animal-related injuries, and repetitive strain injuries. Historical data reveals a high incidence of accidents and fatalities in the agriculture sector, highlighting the need for robust safety measures. For instance, the U.S. Bureau of Labor Statistics reports that the fatality rate in agriculture is significantly higher than the national average for all industries.

C. Regulatory Framework

The regulatory framework for agricultural safety includes various national and international standards and guidelines. In the United States, the Occupational Safety and Health Administration (OSHA) sets and enforces safety standards for the agriculture industry. Similarly, the European Agency for Safety and Health at Work (EU-OSHA) provides regulations and guidelines to ensure the safety of agricultural workers. Compliance with these regulations is mandatory to protect workers and avoid legal penalties.

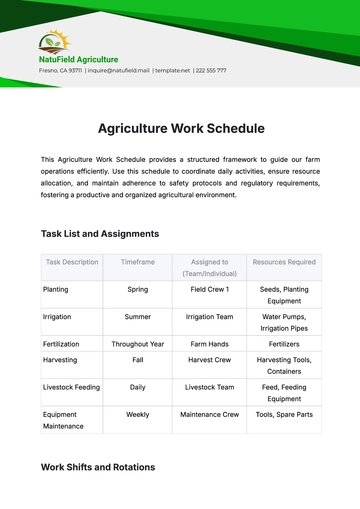

III. Safety Assessment

A. Risk Identification

Risk identification is a critical step in the safety assessment process. It involves identifying all potential hazards that could cause harm to workers during agricultural activities. This study utilizes various methods to identify risks, including site inspections, employee surveys, and review of incident reports. Common risks identified include:

Machinery and equipment-related accidents

Exposure to pesticides and fertilizers

Slips, trips, and falls

Livestock-related injuries

Heat stress and sun exposure

B. Risk Analysis

Once risks are identified, a detailed analysis is conducted to assess their likelihood and potential impact. This involves using a Risk Assessment Matrix to categorize risks based on their severity and probability. The table below illustrates an example of the risk analysis process:

Risk Type | Likelihood | Impact | Risk Level |

|---|---|---|---|

Machinery accidents | High | Severe | High |

Chemical exposure | Medium | Moderate | Medium |

Slips, trips, and falls | High | Moderate | High |

Livestock-related injuries | Medium | Severe | High |

Heat stress and sun exposure | High | Moderate | High |

C. Current Safety Measures

Evaluating existing safety measures is essential to identify gaps and areas for improvement. At [Your Company Name], current safety practices include the use of personal protective equipment (PPE), safety training programs, and regular maintenance of machinery. However, there are gaps in the comprehensive implementation and monitoring of these measures. For example, not all employees consistently use PPE, and there is a need for more frequent safety training sessions.

IV. Feasibility Analysis

A. Technical Feasibility

Technical feasibility assesses the practicality of implementing proposed safety measures from a technological perspective. This includes evaluating the availability, effectiveness, and suitability of safety technologies and equipment for agricultural operations at [Your Company Name]. Some potential safety technologies include:

Machinery safety guards and sensors

Advanced PPE such as heat-resistant clothing and respiratory protection

Chemical handling and storage systems

Ergonomic tools and equipment

B. Operational Feasibility

Operational feasibility examines the impact of proposed safety measures on daily agricultural operations. This involves assessing whether the new measures can be integrated into existing workflows without causing significant disruptions. For instance, implementing regular safety drills and inspections may require adjustments to work schedules but will ultimately enhance overall safety. Additionally, operational feasibility considers the capacity of the workforce to adapt to new safety protocols and training requirements.

C. Financial Feasibility

Financial feasibility involves a cost-benefit analysis of the proposed safety measures. This includes estimating the initial investment required for purchasing safety equipment, training programs, and other resources. The table below provides a sample cost-benefit analysis for proposed safety measures:

Safety Measure | Initial Cost | Annual Maintenance Cost | Expected Benefits |

|---|---|---|---|

Machinery safety guards | $50,000 | $5,000 | Reduced machinery-related accidents |

Advanced PPE | $20,000 | $2,000 | Enhanced protection from chemical exposure |

Chemical handling systems | $30,000 | $3,000 | Improved chemical safety |

Ergonomic tools | $10,000 | $1,000 | Reduced ergonomic injuries |

Safety training programs | $15,000 | $1,500 | Increased safety awareness and compliance |

D. Environmental Feasibility

Environmental feasibility assesses the impact of proposed safety measures on the environment. This includes evaluating the sustainability of the measures and their potential to reduce environmental hazards associated with agricultural activities. For example, the adoption of advanced chemical handling systems can minimize the risk of soil and water contamination. Additionally, implementing sustainable practices such as organic farming and integrated pest management can enhance both worker safety and environmental protection.

V. Proposed Safety Measures

A. Safety Training Programs

Developing comprehensive safety training programs is essential to ensure that all employees are aware of potential hazards and the necessary precautions to take. These programs should cover various topics, including machinery operation, chemical handling, ergonomics, and emergency response. Regular training sessions, both theoretical and practical, will help reinforce safety protocols and improve the overall safety culture at [Your Company Name].

B. Equipment and Technology

Investing in advanced safety equipment and technology is crucial to mitigate risks and enhance worker protection. Recommendations include installing machinery safety guards, providing employees with high-quality PPE, and adopting ergonomic tools to reduce physical strain. Additionally, implementing safety sensors and alarms can help detect and prevent potential accidents in real-time.

C. Policy and Procedures

Establishing clear and comprehensive safety policies and procedures is fundamental to creating a safe working environment. These policies should outline the roles and responsibilities of employees, supervisors, and management in maintaining safety standards. Procedures should include detailed guidelines for operating machinery, handling chemicals, responding to emergencies, and reporting incidents. Regular reviews and updates of these policies and procedures are necessary to ensure they remain effective and relevant.

D. Emergency Response Plans

Creating robust emergency response plans is essential to effectively manage and mitigate the impact of accidents and disasters. These plans should include protocols for various scenarios, such as machinery accidents, chemical spills, fires, and natural disasters. Regular emergency drills and simulations will help ensure that employees are well-prepared and know how to respond swiftly and effectively in case of an emergency.

VI. Implementation Plan

A. Timeline

Developing a timeline for implementing the proposed safety measures is critical to ensure a systematic and organized approach. The timeline should include key milestones, deadlines, and a sequence of activities. An example timeline is provided below:

Activity | Start Date | End Date |

|---|---|---|

Risk assessment and analysis | Month 1 | Month 2 |

Procurement of safety equipment | Month 2 | Month 3 |

Development of training programs | Month 2 | Month 4 |

Implementation of safety measures | Month 4 | Month 6 |

Monitoring and evaluation | Month 6 | Ongoing |

B. Resources Required

Identifying the resources required for implementing the proposed safety measures is essential for successful execution. This includes financial resources, human resources, and technological resources. For example, financial resources will be needed to purchase safety equipment, while human resources will be required to conduct training sessions and monitor compliance. Technological resources such as safety sensors and monitoring systems will also be necessary.

C. Roles and Responsibilities

Assigning clear roles and responsibilities to employees, supervisors, and management is crucial for the effective implementation of safety measures. A safety committee can be established to oversee the implementation process and ensure compliance with safety standards. The roles and responsibilities should be clearly outlined in the safety policies and procedures.

D. Monitoring and Evaluation

Establishing a robust monitoring and evaluation framework is essential to assess the effectiveness of the implemented safety measures. This involves regular safety audits, inspections, and incident reporting. Key performance indicators (KPIs) such as the number of accidents, near-misses, and compliance rates should be tracked and analyzed to identify areas for improvement. Continuous feedback from employees and stakeholders will also help refine and enhance safety practices.

VII. Conclusion

A. Summary of Findings

This Agriculture Safety Feasibility Study for [Your Company Name] has identified significant safety risks associated with agricultural activities and assessed the effectiveness of current safety practices. The study has highlighted the need for comprehensive safety measures to mitigate these risks and enhance worker protection.

B. Recommendations

Based on the findings, the following recommendations are proposed:

Develop and implement comprehensive safety training programs for all employees.

Invest in advanced safety equipment and technology to mitigate risks.

Establish clear safety policies and procedures to guide safe practices.

Create robust emergency response plans to manage accidents and disasters effectively.

Implement a systematic and organized approach to monitor and evaluate safety measures.

C. Future Considerations

To ensure continuous improvement in safety practices, it is essential to regularly review and update safety measures based on feedback, incident data, and industry advancements. Future research should focus on exploring innovative safety technologies and practices that can further enhance safety standards in agriculture. Collaboration with industry stakeholders and regulatory bodies will also help stay updated with evolving safety regulations and best practices.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Conduct detailed feasibility studies with Template.net's customizable and editable Agriculture Safety Feasibility Study Template. Use the AI Editor Tool for comprehensive analysis. This user-friendly template ensures thorough safety assessments, enhancing decision-making and operational safety in your agricultural business.