Car Wash Employee Standard Operating Procedure

I. Overview

This Standard Operating Procedure (SOP) outlines the comprehensive guidelines and procedures for employees of [Your Company Name] Car Wash. The purpose of this SOP is to ensure a consistent and high-quality car wash experience for all customers while maintaining a safe and efficient work environment. By adhering to these procedures, employees will contribute to the overall success and reputation of [Your Company Name].

Maintaining high standards of service and cleanliness is paramount in our operations. This document provides detailed instructions for every aspect of the car wash process, from opening the facility to closing it at the end of the day, ensuring that each step is performed with precision and care.

II. Introduction

A. Purpose of the SOP

The purpose of this SOP is to provide clear and detailed instructions to [Your Company Name] Car Wash employees on how to perform their duties effectively and safely. This document serves as a guide to ensure consistency, quality, and compliance with all relevant regulations and standards.

B. Scope of the SOP

This SOP applies to all employees of [Your Company Name] Car Wash, including General Managers, Shift Supervisors, Car Wash Technicians, and Customer Service Representatives. It covers all aspects of the car wash operation, including employee conduct, safety procedures, daily operations, and customer service.

C. Applicability and Audience

The SOP is intended for use by all current and future employees of [Your Company Name] Car Wash. It is essential for new employees during their training period and serves as a reference for experienced employees to ensure ongoing compliance and performance excellence.

III. Roles and Responsibilities

A. General Manager

The General Manager is responsible for overseeing the entire car wash operation. This includes ensuring that all employees adhere to the SOP, managing resources, and addressing any operational issues that arise. The General Manager also conducts regular performance reviews and implements training programs to enhance employee skills.

B. Shift Supervisor

The Shift Supervisor oversees daily operations during their assigned shift. They are responsible for assigning tasks, ensuring adherence to safety protocols, and maintaining the quality of service. The Shift Supervisor also addresses any customer complaints or issues that arise during their shift.

C. Car Wash Technicians

Car Wash Technicians are responsible for performing the actual car wash services. This includes pre-wash procedures, washing, rinsing, and drying vehicles, as well as providing specialty services such as detailing and tire cleaning. Technicians must adhere to all safety and quality guidelines outlined in the SOP.

D. Customer Service Representatives

Customer Service Representatives (CSRs) are the first point of contact for customers. They greet customers, understand their preferences, handle complaints, and process payments. CSRs must ensure a positive customer experience and address any concerns promptly and professionally.

IV. Employee Conduct and Expectations

A. Dress Code and Appearance

Employees of [Your Company Name] Car Wash are expected to maintain a neat and professional appearance at all times. The dress code includes:

Company-issued uniform

Clean and presentable attire

Closed-toe shoes with non-slip soles

B. Punctuality and Attendance

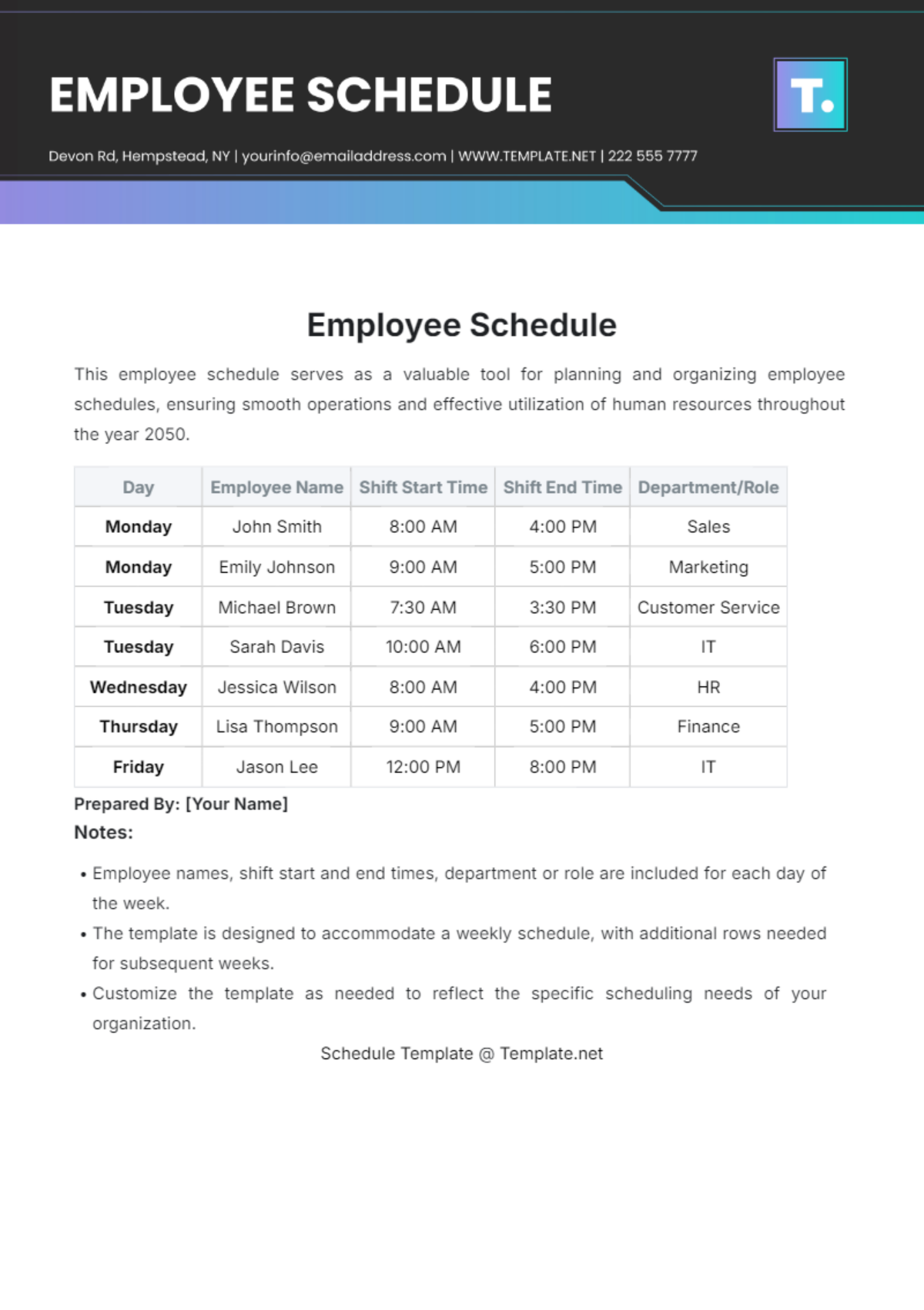

Employees must adhere to their assigned work schedules and arrive on time. Attendance is critical to maintaining smooth operations and providing excellent customer service. Employees must notify their supervisor in advance if they are unable to attend their shift.

C. Professional Behavior and Attitude

Employees are expected to conduct themselves in a professional manner at all times. This includes treating customers and colleagues with respect, maintaining a positive attitude, and adhering to company policies and procedures. Unprofessional behavior, such as using inappropriate language or engaging in conflicts, will not be tolerated.

D. Communication Protocols

Effective communication is essential for smooth operations. Employees must use clear and respectful communication when interacting with customers and colleagues. Any issues or concerns should be promptly reported to the Shift Supervisor or General Manager.

V. Safety Procedures

A. Personal Protective Equipment (PPE)

Employees must wear appropriate Personal Protective Equipment (PPE) at all times while on duty. This includes gloves, safety glasses, and any other protective gear required for specific tasks. PPE must be inspected regularly and replaced as needed.

B. Handling of Chemicals and Cleaning Agents

Employees must follow strict guidelines when handling chemicals and cleaning agents. This includes:

Reading and understanding Safety Data Sheets (SDS) for all chemicals used

Storing chemicals in designated areas

Using appropriate PPE when handling chemicals

Following proper disposal procedures for used chemicals

C. Emergency Procedures

Fire Safety

In the event of a fire, employees must follow these steps:

Activate the nearest fire alarm

Evacuate the building immediately using the closest exit

Assemble at the designated meeting point

Do not attempt to fight the fire unless trained and it is safe to do so

First Aid

First aid kits are available at designated locations throughout the facility. Employees must report any injuries immediately to the Shift Supervisor, who will provide first aid or seek medical assistance as needed. All injuries, no matter how minor, must be documented in an incident report.

Incident Reporting

All incidents, including accidents, injuries, and near misses, must be reported to the Shift Supervisor immediately. An incident report form must be completed and submitted to the General Manager for review and follow-up.

VI. Opening Procedures

A. Preparing the Work Area

Checking Equipment

Before starting operations, employees must inspect all equipment to ensure it is in proper working condition. This includes:

Inspecting hoses, brushes, and nozzles for damage

Checking water pressure and temperature settings

Ensuring all cleaning agents are stocked and properly diluted

Stocking Supplies

Employees must ensure that all necessary supplies are stocked and readily available. This includes:

Cleaning agents and chemicals

Towels and drying cloths

PPE and safety equipment

B. Daily Briefing and Task Assignment

At the beginning of each shift, the Shift Supervisor will conduct a daily briefing to review the day's schedule, assign tasks, and address any issues or concerns. This briefing ensures that all employees are aware of their responsibilities and any special instructions for the day.

VII. Car Wash Process

A. Initial Inspection

Upon arrival, each vehicle must undergo an initial inspection to identify any pre-existing damage and to determine the appropriate cleaning method. This inspection involves:

Checking for scratches, dents, and other damage

Assessing the level of dirt and debris

Noting any special customer requests

B. Pre-Wash Procedures

Removing Debris

Before the washing process begins, employees must remove any large debris from the vehicle's exterior. This includes leaves, mud, and other contaminants that could damage the vehicle or interfere with the washing process.

Applying Pre-Wash Solutions

A pre-wash solution is applied to the vehicle to loosen dirt and grime. This solution is allowed to sit for a specified period to ensure maximum effectiveness. Employees must ensure even coverage and avoid over-saturation.

C. Washing Procedures

Hand Wash vs. Automatic Wash

Depending on customer preference and the condition of the vehicle, employees will choose between a hand wash and an automatic wash.

Hand Wash: For hand washing, employees use soft brushes and microfiber cloths to gently scrub the vehicle.

Automatic Wash: For automatic washes, vehicles are guided through the car wash tunnel where automated brushes and high-pressure nozzles clean the vehicle. Steps include:

D. Rinse Procedures

Water Pressure Guidelines

Water pressure must be adjusted to ensure thorough rinsing without damaging the vehicle’s surface. Employees are trained to use the correct pressure settings for different parts of the vehicle, such as windows, body panels, and wheels.

Ensuring All Soap is Removed

To prevent streaking and soap residue, employees must ensure that all soap is thoroughly rinsed from the vehicle. This involves multiple passes with the rinse hose, paying close attention to hard-to-reach areas.

E. Drying Procedures

Towels vs. Air Drying

Employees use clean, dry microfiber towels to hand dry the vehicle, ensuring a streak-free finish. Alternatively, air blowers can be used to remove excess water from hard-to-reach areas such as mirrors and door handles.

Ensuring a Streak-Free Finish

To achieve a streak-free finish, employees must:

Use clean towels for each vehicle

Dry the vehicle in a systematic manner, starting from the top and working down

Pay special attention to windows and mirrors

VIII. Specialty Services

A. Detailing Services

Interior Cleaning

Employees thoroughly vacuum the vehicle's carpets, seats, and floor mats. Surfaces, including the dashboard, console, and door panels, are wiped down with appropriate cleaners. Specialized products are used for upholstery and leather to ensure they are treated correctly.

Waxing and Polishing

Employees apply high-quality waxes and polishes to the vehicle's exterior, ensuring an even application and buffing to a high shine for added protection and a glossy finish.

Tire and Wheel Cleaning

Special attention is given to tires and wheels, using brushes and cleaners designed to remove brake dust, grime, and road dirt, ensuring a clean and polished appearance.

IX. Customer Service

A. Greeting and Interacting with Customers

Initial Greeting

When a customer arrives at [Your Company Name] Car Wash, they should be greeted warmly by the Customer Service Representative (CSR). The CSR should approach the customer with a smile, introduce themselves, and ask how they can assist.

Understanding Customer Preferences

The CSR should listen attentively to the customer's preferences and needs. This involves asking questions about the type of wash or detailing service they prefer and any specific concerns or requests they might have.

B. Handling Complaints and Feedback

Addressing Complaints

If a customer has a complaint, the CSR should handle it promptly and professionally. This involves listening to the customer's concern, apologizing for any inconvenience, and offering a solution to resolve the issue.

Collecting Feedback

CSRs should encourage customers to provide feedback about their experience. This feedback can be collected through surveys, comment cards, or online reviews. Positive feedback is acknowledged and appreciated, while constructive criticism is used to improve services.

C. Processing Payments

Payment Methods

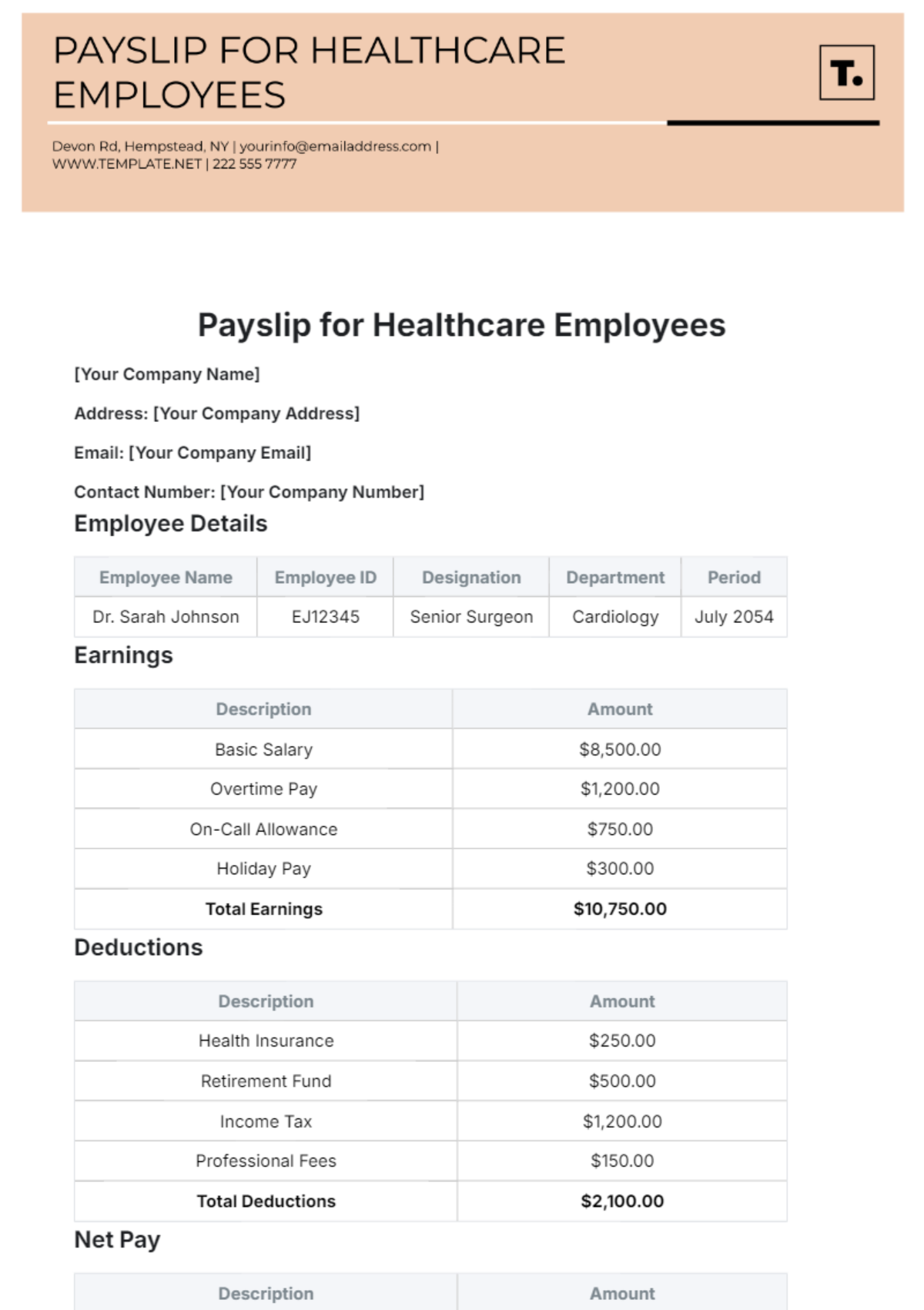

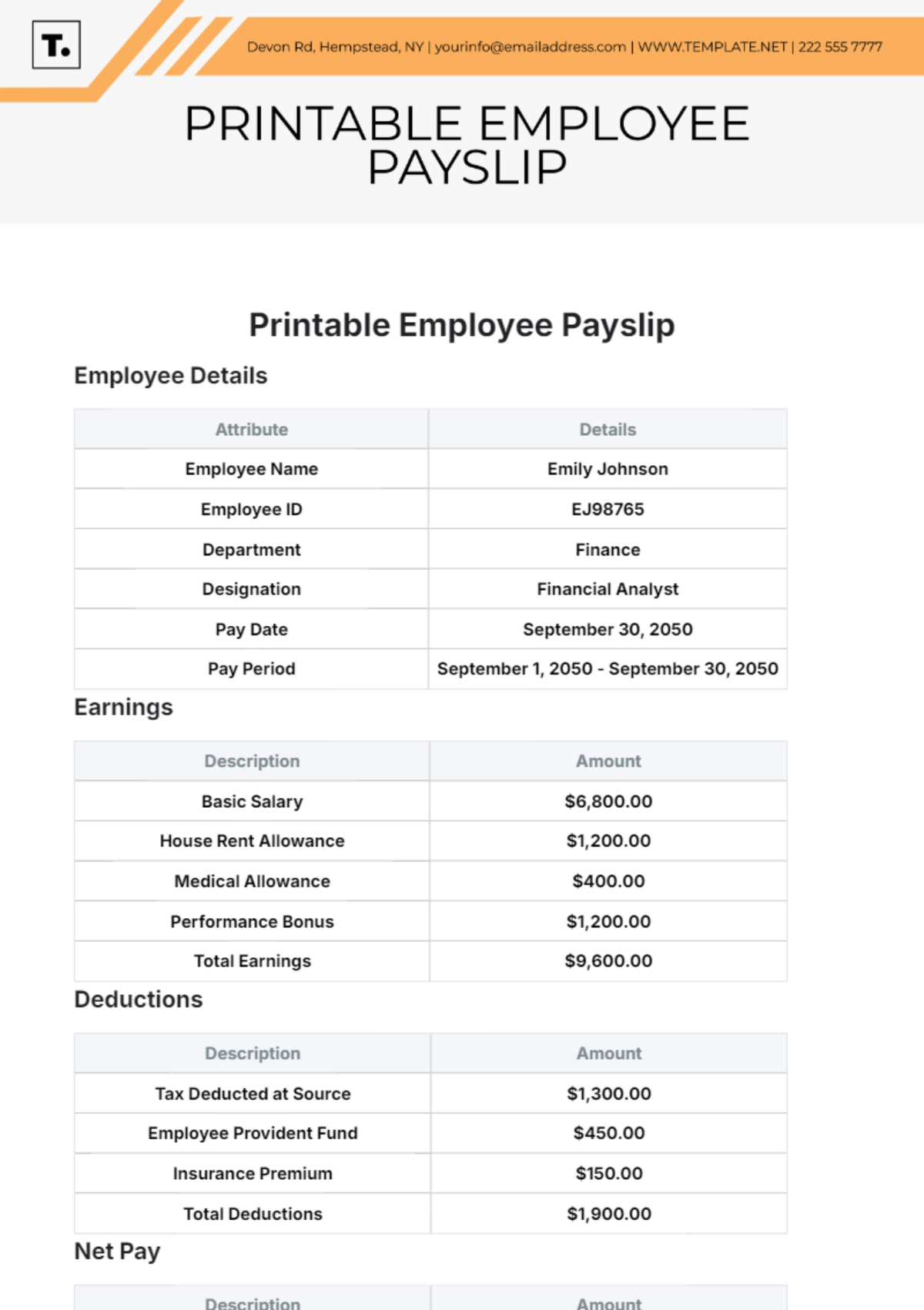

Customers can pay for services using various methods, including cash, credit/debit cards, and mobile payment options. The CSR should be knowledgeable about the payment process and able to assist customers with any payment-related questions.

Issuing Receipts

After processing the payment, the CSR should provide the customer with a receipt. The receipt should include a detailed breakdown of the services provided and the total cost.

X. Closing Procedures

A. Cleaning and Securing the Facility

Cleaning the Work Area

At the end of each shift, employees are responsible for cleaning their work areas. This includes:

Collecting and disposing of any trash

Cleaning and storing equipment

Ensuring all supplies are properly stocked

Securing the Facility

The Shift Supervisor is responsible for ensuring that the facility is secure at the end of the day. This includes locking all doors and windows, setting the alarm system, and ensuring that all equipment is turned off.

B. End-of-Day Reporting

Sales and Inventory Reports

The Shift Supervisor must complete end-of-day sales and inventory reports. These reports include:

Total sales for the day

Inventory levels of cleaning supplies and chemicals

Any equipment issues or maintenance needs

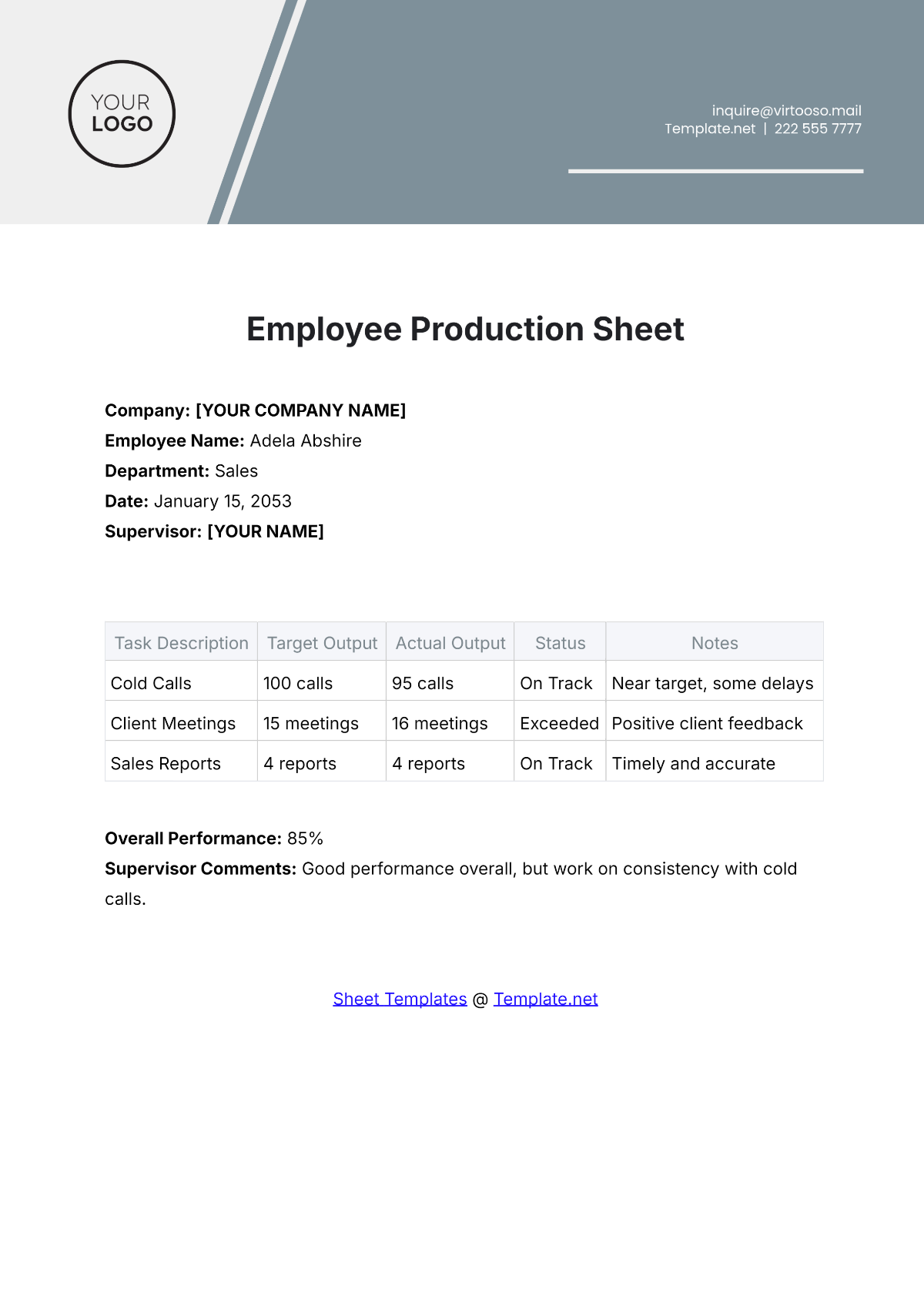

Employee Performance Review

The Shift Supervisor conducts a brief review of employee performance for the day, noting any exceptional work or areas needing improvement. This information is used to provide feedback and plan future training sessions.

XI. Training and Development

A. New Employee Orientation

New employees undergo an orientation program that introduces them to the company's policies, procedures, and culture. This includes a detailed review of the SOP, hands-on training, and a probationary period during which their performance is closely monitored.

B. Ongoing Training Programs

Employees participate in regular training programs to keep their skills up-to-date and learn new techniques. This includes safety training, customer service workshops, and technical skills development.

C. Performance Evaluation

Employees receive regular performance evaluations to assess their progress and identify areas for improvement. These evaluations include feedback from supervisors, peer reviews, and self-assessments.

XII. Compliance and Quality Assurance

A. Adherence to Regulations

[Your Company Name] Car Wash complies with all relevant local, state, and federal regulations. This includes environmental regulations, health and safety standards, and labor laws.

B. Quality Control Measures

Quality control measures are implemented to ensure that all services meet the company's high standards. This includes regular inspections, customer feedback, and adherence to the SOP.

C. Continuous Improvement

The company is committed to continuous improvement. Employees are encouraged to provide suggestions for improving processes and services, and management regularly reviews and updates the SOP to reflect best practices.