Factory Expansion Project Specification

1. Introduction

The Factory Expansion Project at [Your Company Name] aims to increase manufacturing capacity, improve operational efficiency, and enhance overall workflow within the factory premises. This project specification document outlines the detailed requirements, objectives, and technical specifications necessary for the successful execution of the factory expansion. It encompasses various elements such as infrastructure development, machinery procurement, workforce augmentation, and compliance with industry standards.

2. Project Objectives

2.1 Primary Objectives

Increase production capacity by 50% within the next 12 months.

Optimize the factory layout to enhance workflow and reduce production time.

Ensure compliance with safety and environmental regulations.

Minimize disruption to ongoing operations during the expansion process.

2.2 Secondary Objectives

Integrate advanced technologies to improve production efficiency.

Enhance the working conditions for factory employees.

Improve energy efficiency and reduce overall operational costs.

3. Scope of Work

3.1 Infrastructure Development

The expansion project will involve the construction of additional factory floors, storage facilities, and administrative offices. The following tasks are included:

Constructing a new production wing with an area of 50,000 square feet.

Building a two-story administrative block with modern amenities.

Expanding existing storage facilities to accommodate additional raw materials and finished products.

Upgrading the factory's utility systems, including electricity, water, and waste management.

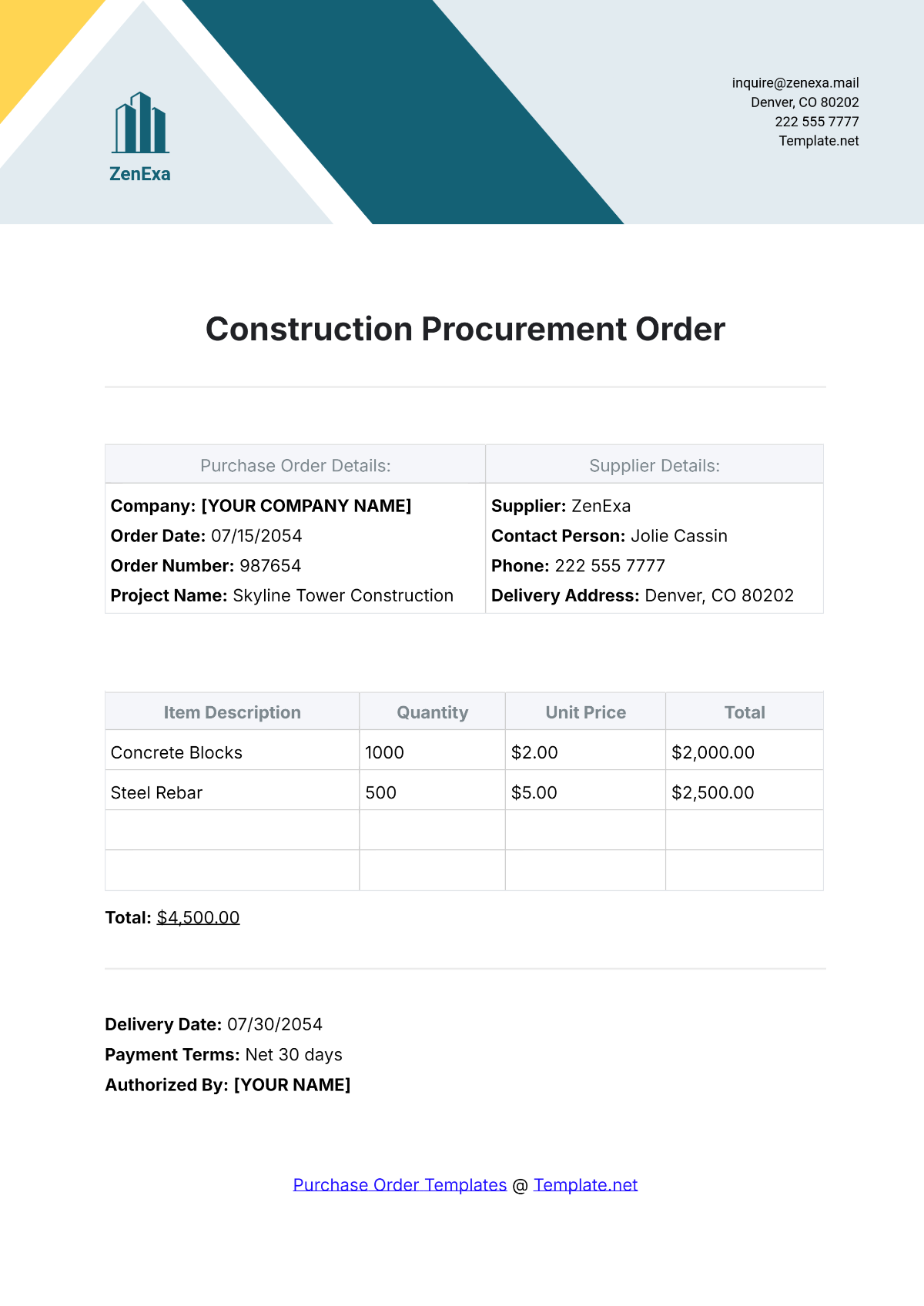

3.2 Machinery and Equipment

To support the increased production capacity, new machinery and equipment will be procured and installed. This includes but is not limited to:

Equipment | Quantity | Specifications |

|---|---|---|

Automated Assembly Lines | 3 | High-speed, multi-functional assembly lines with integrated quality control systems. |

Industrial Robots | 10 | Robotics for material handling, welding, and packaging. |

Advanced CNC Machines | 5 | Precision CNC machining centers for diverse manufacturing applications. |

Energy-efficient HVAC Systems | 8 | Modern, eco-friendly HVAC systems to maintain optimal working conditions. |

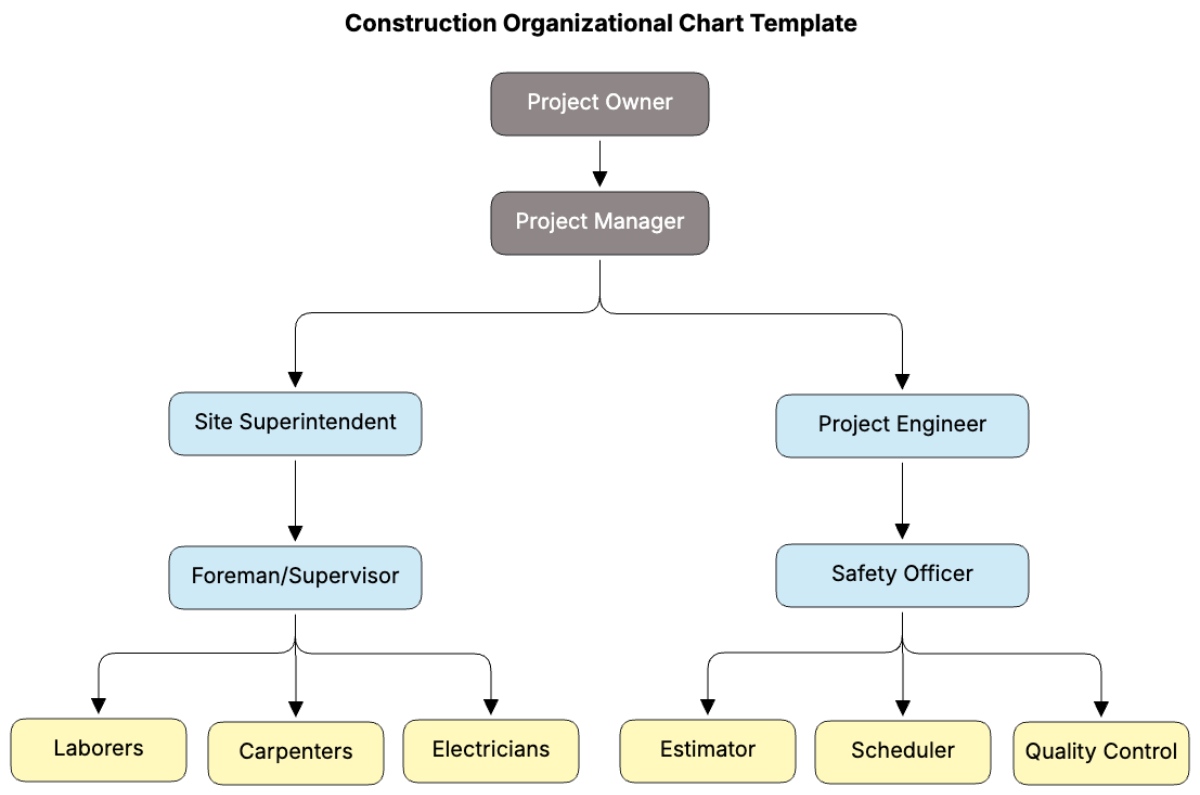

3.3 Workforce Augmentation

The project will necessitate hiring additional staff to operate the new machinery and manage the expanded operations. The workforce augmentation plan includes:

Recruiting 50 new production line operators and technicians.

Hiring 10 additional quality control inspectors.

Onboarding 5 new administrative staff members for the expanded office.

Providing training programs for existing and new employees on the use of advanced machinery and safety protocols.

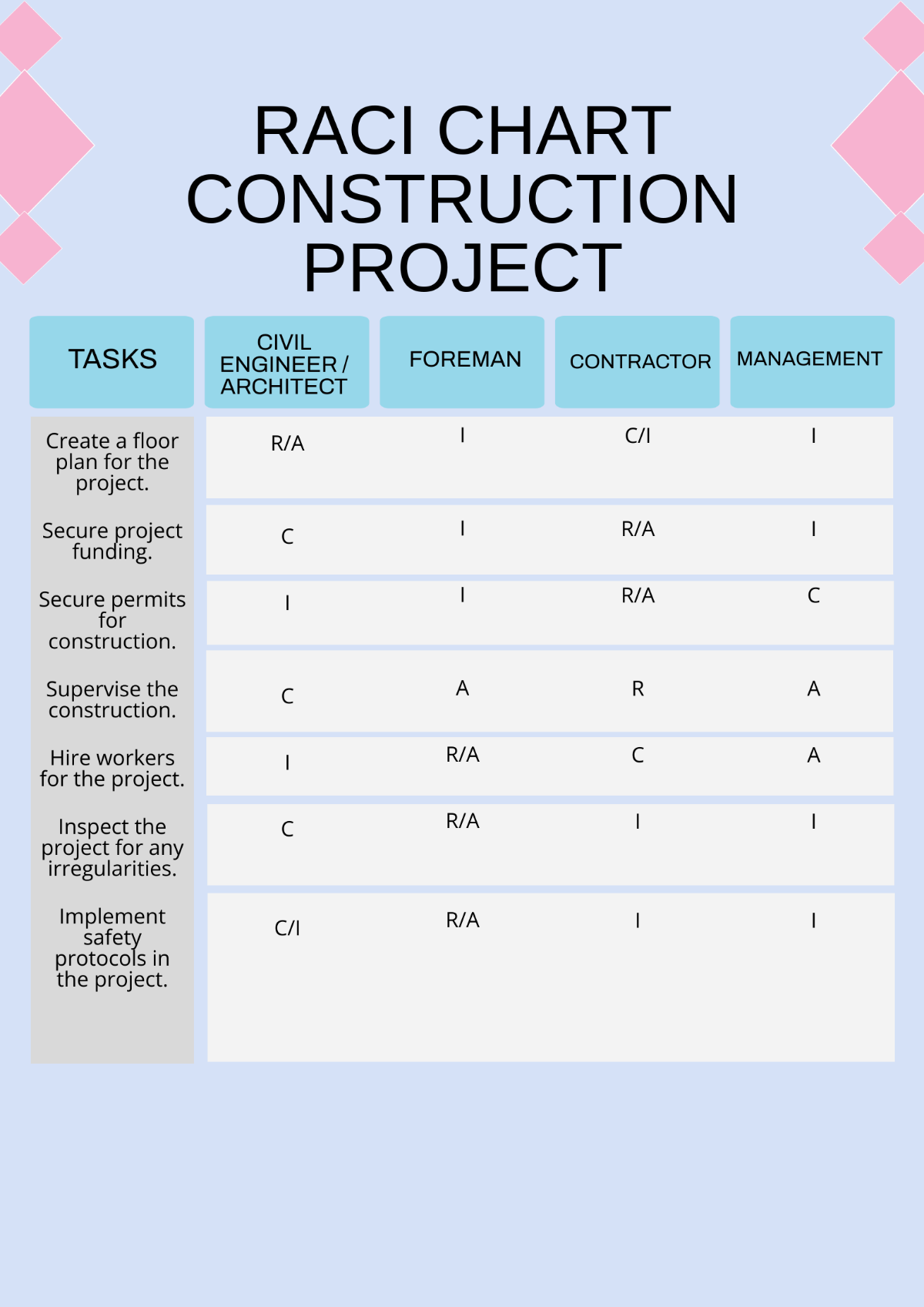

3.4 Compliance and Safety

Ensuring compliance with industry regulations and safety standards is a crucial aspect of the project. Key focus areas include:

Adhering to local building codes and safety regulations during construction.

Implementing rigorous workplace safety measures and employee training programs.

Conducting regular safety audits and risk assessments.

Ensuring proper disposal of industrial waste and compliance with environmental regulations.

4. Technical Specifications

4.1 Infrastructure Specifications

The new production floors and administrative blocks will be constructed to the following specifications:

Construction Materials: Reinforced concrete, steel, and eco-friendly insulation materials.

Floor Load Capacity: Designed to support heavy industrial machinery with a load capacity of 500 kg/m².

Electrical Systems: High-capacity industrial electrical systems with backup generators.

Plumbing: Modern plumbing systems with water-saving fixtures.

4.2 Machinery Specifications

The machinery and equipment to be installed will meet the following technical criteria:

Automation Level: Fully automated with AI-driven process optimization.

Energy Efficiency: Machines will conform to the highest energy efficiency standards.

Maintenance: Designed for easy maintenance and minimal downtime.

Safety Features: Equipped with emergency shutoff systems and real-time monitoring.

4.3 Environmental Impact

Efforts will be made to minimize the environmental impact of the factory expansion. Environmental considerations include:

Using sustainable construction materials wherever possible.

Installing solar panels to supplement the factory's energy needs.

Implementing a comprehensive waste management system.

Conducting an Environmental Impact Assessment (EIA) before the commencement of construction.

5. Implementation Timeline

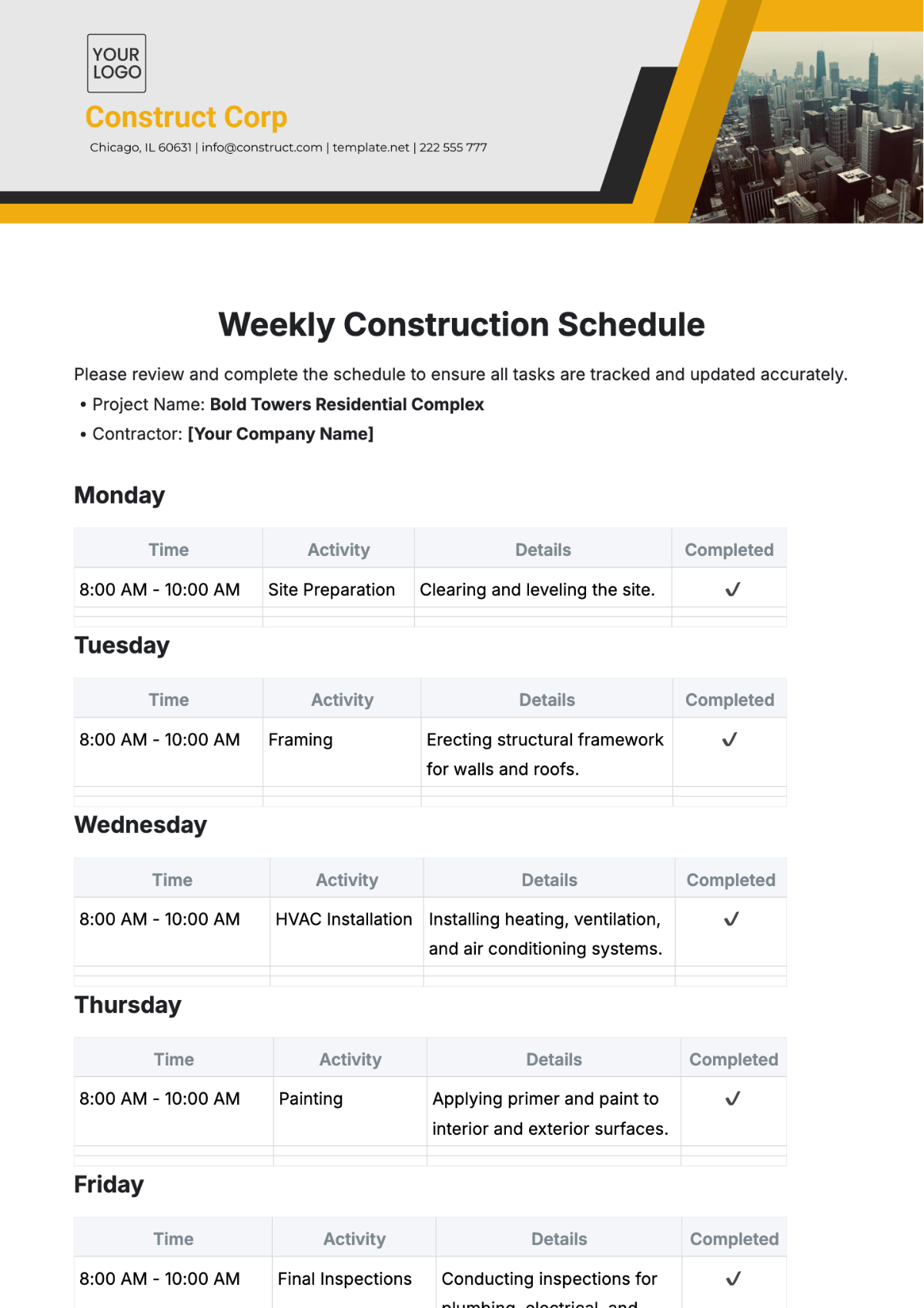

The project will be executed in three phases over 18 months. The timeline is as follows:

Phase | Duration | Description |

|---|---|---|

Phase 1 - Planning and Design | 3 months | Develop detailed architectural plans, obtain necessary permits, and finalize machinery specifications. |

Phase 2 - Construction and Installation | 10 months | Execute building construction, install machinery, and upgrade utility systems. |

Phase 3 - Testing and Commissioning | 5 months | Conduct comprehensive testing of all systems, train staff, and commence full-scale production. |

6. Budget and Cost Estimates

A preliminary budget has been outlined for the factory expansion project, including all major components:

Item | Estimated Cost (USD) |

|---|---|

Construction | 5,000,000 |

Machinery and Equipment | 3,500,000 |

Workforce Augmentation | 1,200,000 |

Compliance and Safety Measures | 300,000 |

Contingency Fund | 500,000 |

Total Estimated Cost | 10,500,000 |

7. Risk Management

7.1 Potential Risks

Several potential risks have been identified, which could impact the project timeline and budget:

Construction delays due to unforeseen site conditions or weather.

Supply chain disruptions affecting machinery and material procurement.

Regulatory approval delays.

Labor strikes or workforce availability issues.

Budget overruns due to unforeseen expenses.

7.2 Mitigation Strategies

Mitigation strategies will be implemented to address these risks proactively:

Developing a detailed project schedule with buffer periods for unexpected delays.

Establishing agreements with multiple suppliers to mitigate supply chain risks.

Engaging with regulatory bodies early in the planning phase.

Maintaining open communication channels with workforce representatives.

Setting aside a contingency fund to address budget overruns and unexpected costs.

8. Conclusion

The Factory Expansion Project is a significant undertaking aimed at enhancing the manufacturing capabilities and operational efficiency of the factory. This detailed project specification document serves as a comprehensive guide outlining the requirements, objectives, and technical specifications essential for the successful execution of the expansion. Careful planning, diligent execution, and stringent adherence to safety and regulatory standards will ensure the project's success, ultimately leading to increased production capacity and improved overall efficiency.

9. Approval and Sign-off

Role | Name | Signature | Date |

|---|---|---|---|

Project Sponsor | [Name] |

| March 3, 2050 |

Project Manager | [Name] |

| March 3, 2050 |

Design Lead | [Name] |

| March 3, 2050 |

Compliance Officer | [Name] |

| March 3, 2050 |