Retrofit Requirements

Prepared By: [YOUR NAME]

Date: [DATE]

I. Introduction

This document outlines the specifications and guidelines for the retrofit project, aimed at enhancing performance, efficiency, and compliance with current standards. The ultimate objective is to upgrade existing technologies and infrastructure to meet modern requirements and improve overall functionality.

II. Scope of Work

Assessment of Current System Conditions: Perform an in-depth assessment of current systems to pinpoint areas that need improvements, emphasizing performance issues and compliance deficiencies.

Replacement of Outdated Components: Replace outdated components with modern, high-performance ones methodically to enhance reliability and efficiency.

Integration of New Technologies: Utilize cutting-edge technologies like automation, energy-efficient systems, and smart innovations to improve system efficiency.

Modification of System Structures: Modify and update system structures to ensure full compliance with current safety, environmental, and operational standards.

Testing and Validation: Implement comprehensive testing and validation procedures to ensure that all retrofitted systems operate correctly and meet specified performance and compliance standards.

III. Technical Specifications

A. Materials

All materials intended for use must meet the highest standards of quality and durability, complying with industry specifications and regulations to ensure they satisfy or surpass established performance, reliability, and longevity requirements.

The specific materials that are incorporated include stainless steel, high-density plastic, and various components that are meticulously engineered to maximize energy efficiency.

B. Methods

It is imperative that every step of the installation process rigorously adheres to the specified guidelines provided by the manufacturer as well as aligns with the established best practices that are recognized and recommended within the industry.

In every instance where it is feasible, make use of methods and techniques that do not necessitate invasive procedures. This approach is taken to minimize any potential disruptions or interruptions to the ongoing operations and routines.

C. Standards

ISO 9001 (Quality Management): Implement quality management practices to ensure that all retrofit activities meet established quality criteria and customer expectations.

ISO 14001 (Environmental Management): Follow environmental management standards to minimize environmental impact and ensure sustainability throughout the retrofit process.

Relevant Industry-Specific Standards: Follow industry guidelines for safety, energy efficiency, and performance to ensure the retrofit complies with sector best practices and regulatory requirements.

IV. Compliance Requirements

Local Building and Safety Codes: Adhere to municipal and regional building codes and safety regulations to ensure structural integrity and safety of the retrofit.

Environmental Regulations: Follow regulations established by the Environmental Protection Agency (EPA) to manage environmental impact, including waste management and emissions control.

Industry-Specific Regulations and Guidelines: Adhere to industry standards regarding energy efficiency, health and safety, and operational procedures following regulatory or association guidelines.

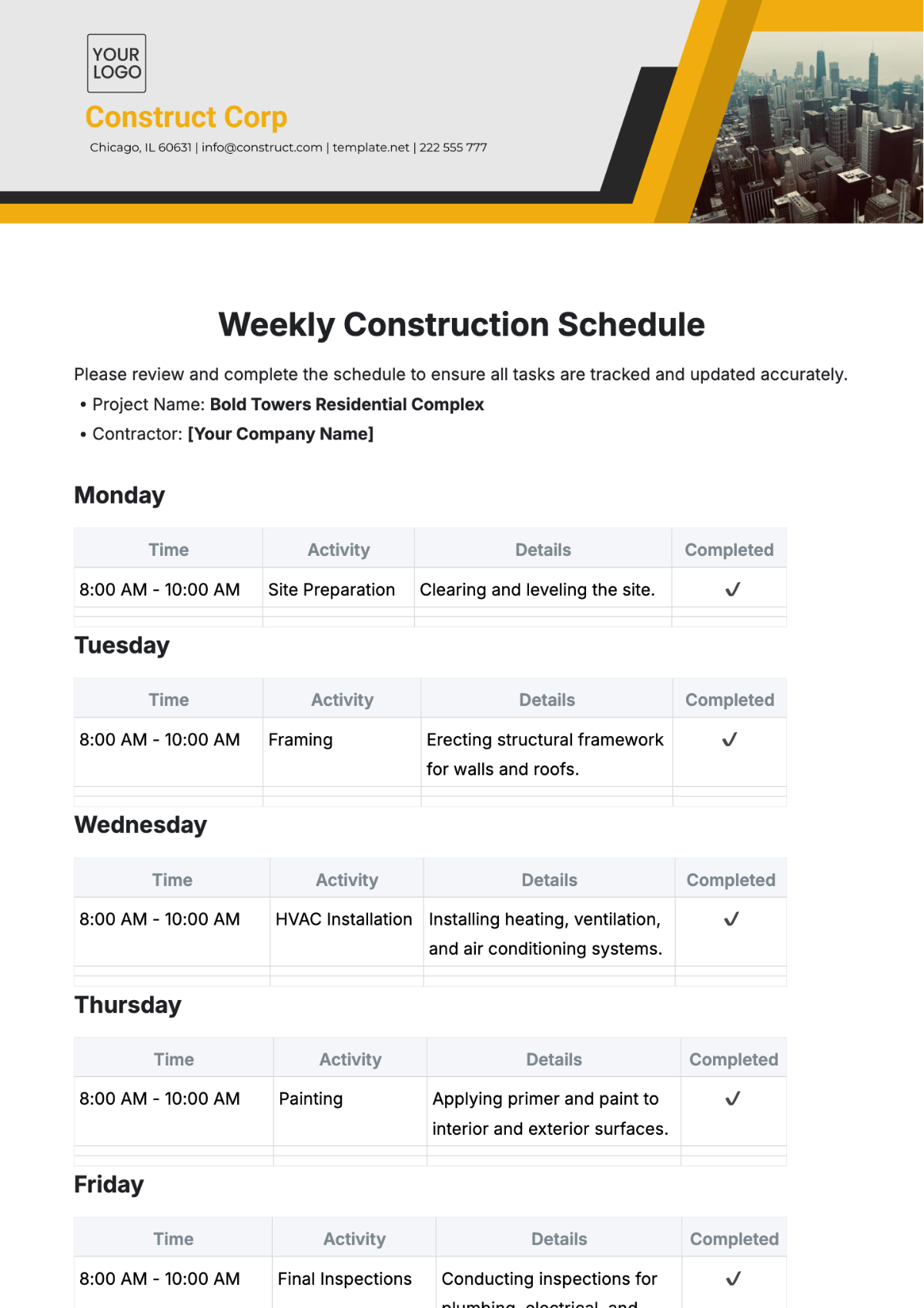

V. Project Schedule

Milestone | Description | Completion Date |

|---|---|---|

Assessment Phase | Evaluation of existing systems | March 31, 2050 |

Design Phase | Design specification and planning | June 30, 2050 |

Implementation Phase | Installation and integration of new components | December 31, 2050 |

Testing and Validation | System testing and performance validation | March 31, 2051 |

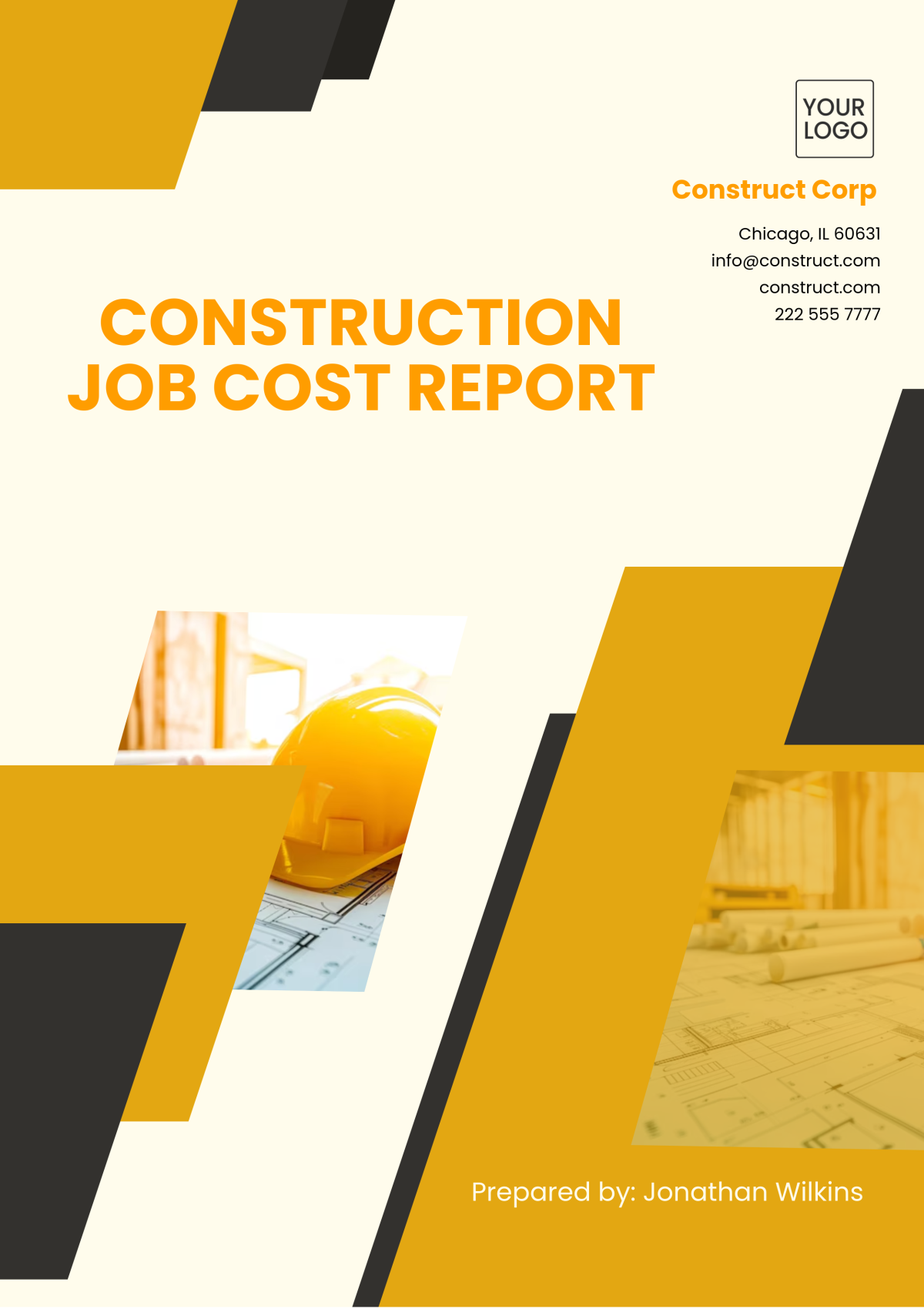

VI. Budget and Cost Estimates

Total budget allocation: $2,000,000

VII. Quality Assurance

To ensure the retrofit meets the required standards and performance criteria, the following quality assurance measures will be implemented:

Regular Inspections and Quality Audits: Perform regular inspections and quality assessments at each phase of the project to ensure compliance, identify issues early, and maintain consistent quality.

Adherence to Quality Management Plan: Follow an ISO 9001 quality management plan with documented processes for quality control, corrective actions, and continuous improvement during the retrofit.

Performance Testing and Validation: Perform detailed pre- and post-retrofit tests to ensure system efficiency, functionality, and compliance.

VIII. Safety Considerations

To ensure a safe working environment during the retrofit process, the following safety protocols and measures will be implemented:

Compliance with OSHA Safety Standards: Adhering to OSHA regulations ensures a safe workplace by maintaining appropriate site conditions, identifying hazards, and implementing safe work practices.

Mandatory Safety Training: Ensure that all employees receive training in recognizing hazards, adhering to emergency procedures, and properly using equipment and safety gear.

Use of Personal Protective Equipment (PPE): Require the use of PPE, such as helmets, gloves, eye protection, and hearing protection, at all times on-site.

Implementation of Emergency Response Plans: Establish and execute emergency response plans for medical emergencies, fire safety, and evacuation procedures.