Free Bakery Maintenance Guideline

I. Introduction

This Bakery Maintenance Guideline of [Your Company Name] is designed to provide comprehensive instructions for maintaining our bakery in optimal condition. This guideline ensures that all equipment, facilities, and processes are kept in top-notch shape to guarantee quality and safety in our operations.

A. Purpose

Ensure Optimal Operation: The primary purpose of this guideline is to ensure that all bakery equipment and facilities operate optimally. Proper maintenance minimizes breakdowns and ensures smooth operation.

Enhance Safety: Regular maintenance enhances the safety of both our staff and customers. Well-maintained equipment reduces the risk of accidents.

Maintain Quality: Consistent maintenance helps in maintaining the quality of our baked goods. It ensures that all machinery works as intended, producing high-quality products.

Extend Equipment Life: By following this guideline, we can extend the life of our bakery equipment. Prolonging equipment life reduces long-term costs.

B. Scope

Equipment Maintenance: This guideline covers the maintenance of all bakery equipment, including ovens, mixers, and refrigeration units. Ensuring each piece of equipment is serviced regularly.

Facility Maintenance: It also includes the upkeep of the bakery facility itself. This encompasses cleaning schedules, building repairs, and pest control.

Process Adherence: Emphasizes adherence to maintenance schedules and processes. Regular inspections and adherence to schedules are critical.

Record Keeping: Maintenance activities must be meticulously documented. Proper documentation ensures compliance and traceability.

C. Target Audience

Maintenance Staff: Primarily intended for the maintenance team responsible for carrying out the procedures. The guideline provides detailed instructions for them.

Bakery Managers: Also relevant to bakery managers who oversee the maintenance activities. Managers ensure that the guidelines are followed correctly.

Staff Training: Useful for training new staff on maintenance procedures. Proper training ensures all staff understand and follow the guidelines.

Quality Control Personnel: Quality control personnel will find this guideline helpful in ensuring that maintenance activities align with quality standards.

II. Equipment Maintenance

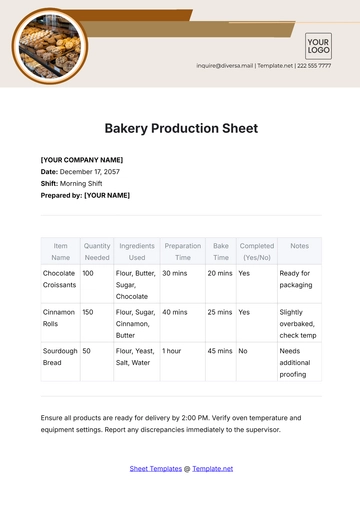

Proper equipment maintenance is essential for ensuring efficient bakery operations. The following table outlines the key maintenance activities for our bakery equipment:

No. | Equipment | Maintenance Activity | Frequency |

|---|---|---|---|

1 | Ovens | Clean and inspect heating elements | Weekly |

2 | Mixers | Lubricate moving parts and check belts | Monthly |

3 | Refrigerators | Defrost and clean coils | Quarterly |

4 | Proofing Cabinets | Sanitize interiors and check seals | Monthly |

5 | Dough Sheeters | Inspect rollers and adjust tension | Bi-monthly |

A. Ovens

Cleaning Heating Elements: Remove and clean heating elements to prevent buildup of food residue. This ensures consistent baking temperatures.

Inspecting for Wear: Regularly inspect the heating elements for any signs of wear or damage. Early detection of issues prevents major breakdowns.

Checking Thermostats: Ensure thermostats are calibrated correctly. Accurate thermostats are crucial for maintaining precise baking conditions.

Ventilation Maintenance: Clean and inspect ventilation systems to ensure proper airflow. Proper ventilation prevents overheating and ensures safety.

B. Mixers

Lubricating Moving Parts: Apply appropriate lubricants to all moving parts to reduce friction and wear. This extends the life of the mixers.

Checking Belts: Inspect belts for signs of wear and proper tension. Worn or loose belts can cause the mixer to malfunction.

Cleaning After Use: Clean mixers thoroughly after each use to prevent dough buildup. Clean equipment operates more efficiently.

Electrical Checks: Regularly inspect electrical connections and controls. Safe and secure electrical connections prevent hazards.

C. Refrigerators

Defrosting Coils: Regularly defrost coils to maintain efficient cooling. Ice buildup can reduce the refrigerator's efficiency.

Cleaning Interiors: Clean the interior surfaces to maintain hygiene. A clean refrigerator prevents contamination of ingredients.

Inspecting Seals: Check door seals for any signs of wear or damage. Good seals ensure proper insulation and energy efficiency.

Temperature Monitoring: Regularly monitor and log temperatures. Consistent temperatures are critical for food safety.

D. Proofing Cabinets

Sanitizing Interiors: Regularly sanitize the interiors to prevent mold and bacteria growth. Clean cabinets ensure a hygienic proofing environment.

Checking Seals: Inspect door seals to ensure proper insulation. Good seals maintain the necessary humidity and temperature levels.

Adjusting Controls: Ensure that temperature and humidity controls are working correctly. Accurate controls ensure consistent proofing results.

Cleaning Trays: Clean and sanitize trays regularly. Clean trays prevent contamination and maintain product quality.

E. Dough Sheeters

Inspecting Rollers: Regularly inspect rollers for signs of wear or damage. Smooth rollers ensure consistent dough thickness.

Adjusting Tension: Adjust the tension of the rollers to ensure proper dough sheeting. Correct tension prevents dough tearing.

Cleaning After Use: Clean dough sheeters thoroughly after each use. Clean equipment operates more efficiently and prevents contamination.

Lubrication: Apply lubricants to moving parts as needed. Proper lubrication reduces wear and extends equipment life.

III. Facility Maintenance

Facility maintenance is crucial for maintaining a clean, safe, and efficient bakery environment. The following table outlines key facility maintenance activities:

No. | Area | Maintenance Activity | Frequency |

|---|---|---|---|

1 | Floors | Sweep and mop | Daily |

2 | Walls | Clean and inspect for damage | Monthly |

3 | Restrooms | Clean and sanitize | Daily |

4 | Storage Areas | Organize and inspect for pests | Weekly |

5 | Lighting | Inspect and replace bulbs | Monthly |

A. Floors

Sweeping: Sweep floors daily to remove debris and prevent slips. Clean floors contribute to a safe working environment.

Mopping: Mop floors with appropriate cleaning solutions. Mopping removes dirt and prevents buildup of residues.

Inspection: Regularly inspect floors for signs of damage. Prompt repairs prevent accidents and maintain facility aesthetics.

Non-Slip Surfaces: Ensure that non-slip surfaces are maintained. Non-slip surfaces reduce the risk of falls and injuries.

B. Walls

Cleaning: Clean walls regularly to remove stains and dust. Clean walls contribute to a hygienic environment.

Inspection for Damage: Inspect walls for cracks or other damage. Early detection and repair of damage prevent larger issues.

Painting: Repaint walls as needed to maintain a fresh appearance. Fresh paint enhances the overall look of the bakery.

Pest Control: Inspect walls for signs of pests. Prompt pest control measures maintain hygiene and prevent infestations.

C. Restrooms

Sanitizing: Clean and sanitize restrooms daily. Sanitized restrooms prevent the spread of germs and maintain hygiene.

Stocking Supplies: Ensure that restrooms are stocked with necessary supplies. Well-stocked restrooms enhance convenience for staff.

Inspection for Damage: Regularly inspect restrooms for any signs of damage. Prompt repairs ensure that restrooms are functional and safe.

Ventilation: Ensure proper ventilation in restrooms. Good ventilation prevents odors and maintains air quality.

D. Storage Areas

Organization: Keep storage areas well-organized to prevent clutter. Organized storage areas improve efficiency and accessibility.

Pest Inspection: Regularly inspect storage areas for signs of pests. Early detection and control of pests maintain hygiene.

Cleaning: Clean storage areas to remove dust and debris. Clean storage areas prevent contamination of ingredients.

Inventory Management: Regularly check inventory levels and conditions. Proper inventory management ensures that supplies are fresh and available.

E. Lighting

Inspection: Inspect lighting fixtures regularly to ensure proper functioning. Good lighting enhances visibility and safety.

Replacing Bulbs: Replace burnt-out bulbs promptly. Functional lighting fixtures ensure adequate illumination.

Energy Efficiency: Use energy-efficient lighting options where possible. Energy-efficient lighting reduces costs and environmental impact.

Emergency Lighting: Ensure that emergency lighting is functional. Emergency lighting is crucial for safety during power outages.

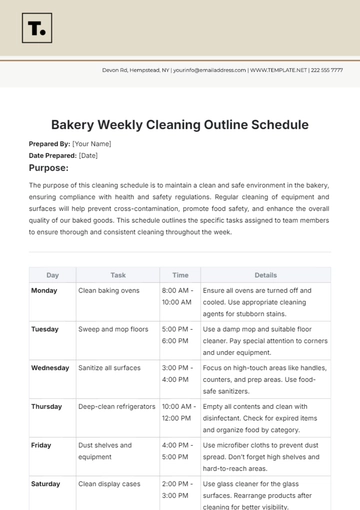

IV. Cleaning and Sanitation

Cleaning and sanitation are vital for maintaining hygiene and preventing contamination in the bakery. The following table outlines key cleaning and sanitation activities:

No. | Area/Equipment | Cleaning Activity | Frequency |

|---|---|---|---|

1 | Baking Equipment | Clean and sanitize after each use | After each use |

2 | Work Surfaces | Wipe and sanitize | Hourly |

3 | Utensils | Wash and sanitize | After each use |

4 | Storage Containers | Clean and sanitize | Weekly |

5 | Hand Washing Stations | Clean and restock | Daily |

A. Baking Equipment

Cleaning After Use: Clean all baking equipment thoroughly after each use. This prevents the buildup of residues that can affect product quality.

Sanitizing: Sanitize baking equipment to eliminate any harmful bacteria. Sanitized equipment ensures food safety.

Disassembly and Cleaning: Disassemble equipment where necessary for thorough cleaning. Proper cleaning prevents contamination.

Drying: Ensure that equipment is completely dry before reassembly. Dry equipment prevents the growth of mold and bacteria.

B. Work Surfaces

Wiping: Wipe work surfaces regularly to remove debris and spills. Clean surfaces prevent cross-contamination.

Sanitizing: Sanitize work surfaces to maintain hygiene. Sanitized surfaces ensure food safety.

Inspection: Regularly inspect work surfaces for damage. Damaged surfaces should be repaired or replaced promptly.

Documentation: Keep records of cleaning activities. Proper documentation ensures compliance with hygiene standards.

C. Utensils

Washing: Wash utensils thoroughly after each use. Clean utensils prevent contamination.

Sanitizing: Sanitize utensils to ensure they are free of harmful bacteria. Sanitized utensils ensure food safety.

Drying: Ensure that utensils are completely dry before storage. Dry utensils prevent the growth of mold and bacteria.

Storage: Store utensils in a clean, dry place. Proper storage maintains utensil hygiene.

D. Storage Containers

Cleaning: Clean storage containers regularly to prevent contamination. Clean containers ensure that stored ingredients remain safe.

Sanitizing: Sanitize storage containers to eliminate any harmful bacteria. Sanitized containers ensure food safety.

Inspection: Inspect containers for damage and wear. Replace damaged containers promptly to maintain hygiene.

Labeling: Label containers clearly with contents and dates. Proper labeling ensures proper inventory management.

E. Hand Washing Stations

Cleaning: Clean hand washing stations daily to maintain hygiene. Clean stations encourage proper hand washing practices.

Restocking Supplies: Ensure that hand washing stations are stocked with soap and paper towels. Well-stocked stations promote hygiene.

Inspection: Regularly inspect hand washing stations for functionality. Functional stations ensure that staff can wash their hands effectively.

Signage: Display signage to remind staff of proper hand washing techniques. Signage reinforces good hygiene practices.

V. Safety Procedures

Safety procedures are essential for protecting our staff and maintaining a safe working environment. The following table outlines key safety procedures for the bakery:

No. | Procedure | Description | Frequency |

|---|---|---|---|

1 | Fire Safety | Inspect and maintain fire extinguishers | Monthly |

2 | Electrical Safety | Check electrical equipment and wiring | Quarterly |

3 | Personal Protective Equipment (PPE) | Ensure availability and usage | Daily |

4 | First Aid | Maintain first aid kits and train staff | Annually |

5 | Emergency Drills | Conduct emergency evacuation drills | Bi-annually |

A. Fire Safety

Inspecting Fire Extinguishers: Inspect fire extinguishers monthly to ensure they are functional. Functional fire extinguishers are crucial for responding to fires.

Maintaining Fire Exits: Ensure that fire exits are clear and accessible at all times. Clear exits are essential for safe evacuation.

Fire Safety Training: Conduct regular fire safety training for all staff. Training ensures that staff know how to respond in case of a fire.

Fire Alarms: Test fire alarms regularly to ensure they are operational. Working fire alarms provide early warning of fire hazards.

B. Electrical Safety

Checking Electrical Equipment: Regularly check electrical equipment for signs of wear or damage. Early detection of issues prevents electrical hazards.

Inspecting Wiring: Inspect wiring for any signs of fraying or damage. Proper wiring ensures electrical safety.

Using Proper Outlets: Ensure that electrical equipment is plugged into appropriate outlets. Proper usage prevents overload and reduces the risk of fire.

Training Staff: Train staff on proper electrical safety practices. Training helps prevent accidents and ensures safe operations.

C. Personal Protective Equipment (PPE)

Ensuring Availability: Ensure that PPE is available and accessible to all staff. Availability of PPE is crucial for safety.

Proper Usage: Train staff on the proper use of PPE. Proper usage ensures maximum protection.

Regular Inspection: Regularly inspect PPE for signs of wear or damage. Damaged PPE should be replaced promptly.

Compliance: Ensure that staff comply with PPE usage guidelines. Compliance with guidelines ensures safety for everyone.

D. First Aid

Maintaining First Aid Kits: Maintain well-stocked first aid kits. Well-stocked kits ensure that necessary supplies are available in case of injury.

Training Staff: Provide first aid training to staff. Trained staff can respond effectively to injuries and emergencies.

Regular Inspections: Inspect first aid kits regularly to ensure they are complete and up to date. Regular inspections ensure readiness.

Emergency Contact Information: Display emergency contact information clearly. Clear information ensures quick access in case of emergencies.

E. Emergency Drills

Conducting Drills: Conduct emergency evacuation drills bi-annually. Drills prepare staff for real emergencies.

Reviewing Procedures: Review emergency procedures regularly. Regular reviews ensure procedures are up to date and effective.

Staff Participation: Ensure that all staff participate in emergency drills. Participation ensures that everyone knows their role.

Feedback and Improvement: Collect feedback after drills to identify areas for improvement. Feedback helps enhance emergency preparedness.

VI. Preventive Maintenance

Preventive maintenance is essential for ensuring the longevity and reliability of bakery equipment. The following table outlines key preventive maintenance activities:

No. | Equipment | Preventive Maintenance Activity | Frequency |

|---|---|---|---|

1 | Ovens | Calibrate thermostats | Quarterly |

2 | Mixers | Replace worn belts | Bi-annually |

3 | Refrigerators | Clean condenser coils | Monthly |

4 | Proofing Cabinets | Check and replace door seals | Annually |

5 | Dough Sheeters | Inspect and adjust tension | Bi-monthly |

A. Ovens

Calibrating Thermostats: Calibrate oven thermostats quarterly to ensure accurate temperatures. Accurate temperatures are crucial for consistent baking.

Inspecting Burners: Inspect burners for signs of wear or damage. Well-maintained burners ensure efficient operation.

Cleaning Filters: Clean or replace filters to ensure proper airflow. Clean filters prevent overheating and improve efficiency.

Regular Maintenance Schedule: Adhere to a regular maintenance schedule to prevent unexpected breakdowns. Scheduled maintenance ensures reliability.

B. Mixers

Replacing Belts: Replace worn belts bi-annually to ensure efficient operation. New belts prevent slippage and maintain performance.

Lubricating Bearings: Lubricate bearings to reduce friction and wear. Proper lubrication extends the life of the mixer.

Inspecting Motors: Inspect mixer motors for signs of wear or overheating. Early detection of issues prevents major breakdowns.

Cleaning Vents: Clean vents to ensure proper cooling. Clean vents prevent overheating and improve performance.

C. Refrigerators

Cleaning Condenser Coils: Clean condenser coils monthly to ensure efficient cooling. Clean coils improve refrigerator efficiency.

Checking Refrigerant Levels: Regularly check refrigerant levels and refill if necessary. Proper refrigerant levels ensure optimal cooling.

Inspecting Doors: Inspect refrigerator doors and seals for damage. Good seals maintain proper insulation and efficiency.

Defrosting: Regularly defrost refrigerators to prevent ice buildup. Defrosting ensures consistent cooling performance.

D. Proofing Cabinets

Checking Door Seals: Check and replace door seals annually to maintain proper insulation. Good seals ensure optimal proofing conditions.

Calibrating Controls: Calibrate temperature and humidity controls for accurate settings. Accurate controls ensure consistent proofing results.

Inspecting Heating Elements: Inspect heating elements for signs of wear. Well-maintained elements ensure consistent performance.

Cleaning Interiors: Clean and sanitize the interior of proofing cabinets regularly. Clean interiors prevent contamination.

E. Dough Sheeters

Inspecting Rollers: Inspect rollers for signs of wear and adjust tension bi-monthly. Proper tension ensures consistent dough thickness.

Lubricating Bearings: Lubricate bearings to reduce friction and wear. Proper lubrication extends the life of the dough sheeter.

Checking Electrical Components: Inspect electrical components for signs of wear or damage. Safe electrical components ensure reliable operation.

Cleaning Surfaces: Clean dough sheeter surfaces to remove dough residue. Clean surfaces prevent contamination and ensure smooth operation.

VII. Documentation and Record Keeping

Proper documentation and record-keeping are essential for maintaining compliance and traceability. The following table outlines key documentation and record-keeping activities:

No. | Activity | Description | Frequency |

|---|---|---|---|

1 | Maintenance Logs | Record all maintenance activities | Daily |

2 | Cleaning Schedules | Document cleaning activities | Daily |

3 | Safety Inspections | Record safety inspection findings | Monthly |

4 | Quality Checks | Document quality control activities | Daily |

5 | Inventory Management | Record inventory levels and conditions | Weekly |

A. Maintenance Logs

Daily Logging: Record all maintenance activities daily. Detailed logs provide a record of maintenance history.

Activity Details: Include details of the maintenance activities performed. Detailed records ensure traceability and compliance.

Personnel Information: Record the names of personnel performing the maintenance. Proper documentation ensures accountability.

Equipment Condition: Note the condition of the equipment after maintenance. Recording equipment condition ensures accurate tracking.

B. Cleaning Schedules

Daily Documentation: Document all cleaning activities daily. Detailed records ensure compliance with hygiene standards.

Activity Details: Include details of the cleaning activities performed. Detailed records provide a comprehensive cleaning history.

Personnel Information: Record the names of personnel performing the cleaning. Proper documentation ensures accountability.

Inspection Findings: Note any findings from cleaning inspections. Recording inspection findings ensures accurate tracking.

C. Safety Inspections

Monthly Recording: Record safety inspection findings monthly. Detailed records provide a history of safety compliance.

Inspection Details: Include details of the safety inspections performed. Detailed records ensure compliance with safety standards.

Personnel Information: Record the names of personnel performing the inspections. Proper documentation ensures accountability.

Corrective Actions: Note any corrective actions taken. Recording corrective actions ensures accurate tracking.

D. Quality Checks

Daily Documentation: Document all quality control activities daily. Detailed records ensure compliance with quality standards.

Activity Details: Include details of the quality checks performed. Detailed records provide a comprehensive quality history.

Personnel Information: Record the names of personnel performing the quality checks. Proper documentation ensures accountability.

Inspection Findings: Note any findings from quality inspections. Recording inspection findings ensures accurate tracking.

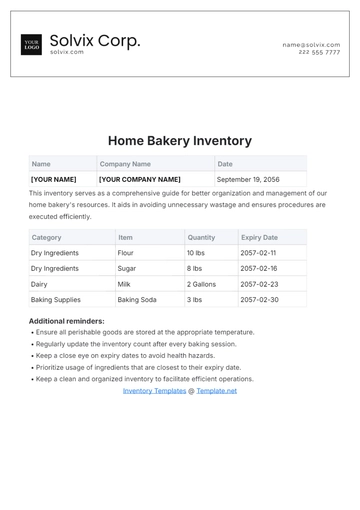

E. Inventory Management

Weekly Recording: Record inventory levels and conditions weekly. Detailed records provide a history of inventory management.

Inventory Details: Include details of the inventory levels and conditions. Detailed records ensure accurate tracking.

Personnel Information: Record the names of personnel performing the inventory checks. Proper documentation ensures accountability.

Condition Findings: Note any findings from inventory inspections. Recording condition findings ensures accurate tracking.

VIII. Continuous Improvement

A. Staff Training

Quarterly Sessions: Conduct regular training sessions for all staff. Training ensures that staff are up-to-date with the latest practices.

Skill Development: Focus on developing both technical and soft skills. Well-rounded training improves overall performance.

Compliance Training: Include training on compliance with safety and hygiene standards. Compliance training ensures adherence to regulations.

Feedback Integration: Integrate feedback from previous training sessions. Feedback helps tailor training to staff needs.

B. Process Review

Bi-annual Reviews: Review and optimize processes bi-annually. Regular reviews ensure that processes remain efficient and effective.

Stakeholder Involvement: Involve stakeholders in the review process. Involvement ensures that all perspectives are considered.

Data Analysis: Use data to identify areas for improvement. Data-driven analysis ensures objective decision-making.

Implementation: Implement changes based on review findings. Implementation ensures continuous improvement.

C. Feedback Collection

Monthly Collection: Collect feedback from staff and customers monthly. Regular feedback provides insights for improvement.

Surveys and Interviews: Use surveys and interviews to gather feedback. Multiple methods ensure comprehensive data collection.

Analysis: Analyze feedback to identify trends and issues. Analysis helps prioritize areas for improvement.

Action Plans: Develop action plans based on feedback. Action plans ensure that feedback leads to tangible improvements.

D. Innovation Implementation

Annual Implementation: Implement new technologies and methods annually. Regular innovation keeps the bakery competitive.

Research and Development: Invest in research and development to identify new opportunities. R&D ensures that the bakery stays ahead of trends.

Pilot Testing: Test new technologies and methods on a small scale. Pilot testing ensures that innovations are viable before full implementation.

Evaluation: Evaluate the impact of implemented innovations. Evaluation ensures that innovations achieve desired results.

E. Performance Evaluation

Annual Evaluations: Evaluate performance and set new goals annually. Regular evaluations ensure continuous progress.

Key Performance Indicators (KPIs): Use KPIs to measure performance. KPIs provide objective metrics for evaluation.

Goal Setting: Set new goals based on evaluation findings. Goal setting ensures continuous improvement.

Reward and Recognition: Recognize and reward high performance. Recognition motivates staff and reinforces desired behaviors.

Continuous improvement ensures that the bakery maintains and enhances the quality and efficiency of its operations. Regular training, process reviews, feedback collection, innovation implementation, and performance evaluation support ongoing progress.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Optimize your bakery's upkeep with the Bakery Maintenance Guideline Template! Offered by Template.net, this editable and customizable template provides a comprehensive framework for maintaining your equipment and facilities. The AI Editor Tool enables you to adapt the guidelines to your bakery's specific needs, ensuring efficient maintenance practices that minimize downtime!