Free Transport Inventory Management

1. Introduction

Transport inventory management is a comprehensive system designed to oversee the effective and efficient use of transportation resources. In the year 2050, the landscape of transport logistics will be vastly different, shaped by technological advancements, environmental regulations, and evolving customer expectations. This document provides an in-depth exploration of transport inventory management tailored for [Your Company Name], addressing key strategies, technologies, and practices essential for success in the future.

2. Objectives

The main objectives of transport inventory management are to:

Optimize Utilization of Assets: Maximize the use of transport assets to increase efficiency and reduce idle times.

Minimize Operational Costs: Reduce expenses related to fuel, maintenance, and labor through effective management and technology.

Enhance Visibility and Control: Provide real-time insights into inventory status and location to improve decision-making.

Improve Efficiency: Streamline operations to enhance the speed and accuracy of transport activities.

Ensure Compliance: Adhere to regulatory requirements and industry standards to avoid legal issues and maintain operational integrity.

Support Sustainability Goals: Implement practices that reduce environmental impact and promote green initiatives.

3. Key Components

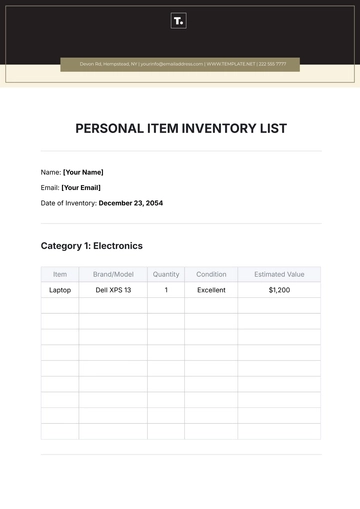

3.1 Transport Asset Management

Transport asset management encompasses the planning, acquisition, and maintenance of transportation resources. Effective management ensures that assets are used efficiently and are maintained in optimal condition.

3.1.1 Fleet Management

Fleet management involves overseeing the company’s vehicle fleet to ensure optimal performance and efficiency.

Table 1: Fleet Management Components

Component | Description | Technology Integration |

|---|---|---|

Vehicle Acquisition | Evaluating and selecting vehicles based on criteria such as fuel efficiency and technology. | Advanced analytics for vehicle selection |

Maintenance Scheduling | Planning regular maintenance to prevent breakdowns and ensure vehicle reliability. | Predictive maintenance tools |

Utilization Tracking | Monitoring vehicle usage to optimize routes and reduce idle times. | GPS and telematics systems |

Vehicle Acquisition: In 2050, the focus will shift towards electric, autonomous, and hybrid vehicles. Companies will need to assess vehicle capabilities related to energy efficiency, range, and integration with smart grid technologies.

Maintenance Scheduling: Predictive maintenance will use IoT sensors and data analytics to forecast when maintenance is needed, minimizing downtime and extending vehicle lifespan.

Utilization Tracking: GPS and telematics will provide real-time data on vehicle performance, location, and efficiency, helping to optimize routes and reduce operational costs.

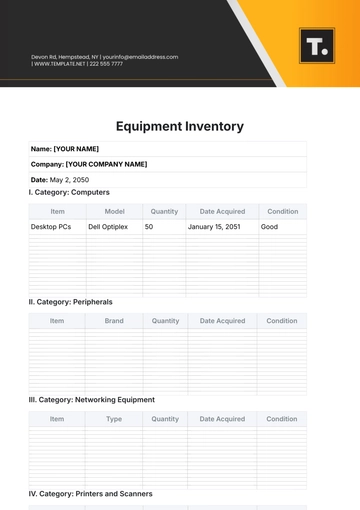

3.1.2 Container and Equipment Management

Managing containers and equipment involves ensuring that these resources are available and in good condition when needed.

Table 2: Container and Equipment Management

Component | Description | Technology Integration |

|---|---|---|

Inventory Tracking | Monitoring the location and condition of containers and equipment using advanced technologies. | RFID, IoT sensors |

Lifecycle Management | Managing the entire lifecycle from acquisition to disposal, including maintenance and upgrades. | Lifecycle management software |

Inventory Tracking: RFID tags and IoT sensors will provide detailed information on container locations, conditions, and usage patterns, improving inventory accuracy and reducing losses.

Lifecycle Management: Effective lifecycle management will involve tracking the usage, maintenance, and eventual disposal of containers and equipment, supported by software that provides insights into asset performance and needs.

3.2 Inventory Tracking and Control

Effective inventory tracking and control ensure that transport resources are managed efficiently to meet operational demands.

3.2.1 Real-Time Tracking

Real-time tracking provides visibility into the location and status of transport assets.

Table 3: Real-Time Tracking Technologies

Technology | Description | Benefits |

|---|---|---|

GPS | Global Positioning System for tracking vehicle location in real-time. | Accurate location data |

Telematics | Systems that monitor vehicle performance and provide diagnostics. | Enhanced maintenance and performance |

RFID and IoT | Radio-frequency identification and Internet of Things for tracking containers and equipment. | Detailed asset tracking and monitoring |

GPS and Telematics: These technologies will enable real-time tracking of vehicles, providing information on location, speed, and performance, leading to better route planning and maintenance management.

RFID and IoT: RFID and IoT technologies will offer comprehensive tracking of containers and equipment, ensuring accurate inventory levels and reducing the risk of loss or misplacement.

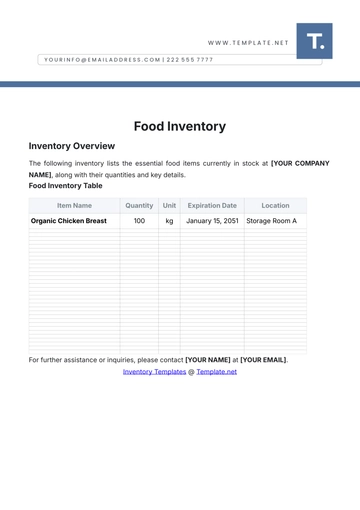

3.2.2 Inventory Replenishment

Inventory replenishment ensures that transport resources are available when needed, preventing shortages and disruptions.

Table 4: Inventory Replenishment Strategies

Strategy | Description | Benefits |

|---|---|---|

Automated Replenishment | Using AI and data analytics to automate inventory orders based on predicted needs. | Reduced manual intervention and errors |

Safety Stock Levels | Setting safety stock levels to buffer against demand fluctuations and supply chain disruptions. | Ensures availability during peak times |

Automated Replenishment: AI-driven systems will analyze historical data and predict future needs, automating the replenishment process and reducing the risk of stockouts or overstocking.

Safety Stock Levels: Establishing appropriate safety stock levels will help mitigate the impact of demand spikes and supply chain disruptions, ensuring that transport resources are always available.

3.3 Demand Forecasting

Accurate demand forecasting is essential for planning and managing transport inventory effectively.

3.3.1 Predictive Analytics

Predictive analytics uses historical data and advanced algorithms to forecast future demand.

Table 5: Predictive Analytics Tools

Tool | Description | Benefits |

|---|---|---|

Data Analysis | Analyzing historical data to identify patterns and trends. | Improved forecasting accuracy |

Machine Learning | Employing machine learning algorithms to refine predictions and adapt to changing conditions. | Enhanced predictive capabilities |

Data Analysis: Historical data analysis will help identify trends and patterns, allowing for more accurate demand forecasts and better inventory management.

Machine Learning: Machine learning algorithms will continually improve predictions by learning from new data, adapting to changes in demand and supply conditions.

3.3.2 Scenario Planning

Scenario planning involves preparing for various demand conditions and their impact on inventory needs.

Table 6: Scenario Planning Techniques

Technique | Description | Benefits |

|---|---|---|

What-If Analysis | Analyzing different scenarios to understand their impact on inventory and transport needs. | Better preparedness for uncertainties |

Contingency Planning | Developing plans to address potential demand fluctuations and disruptions. | Enhanced resilience and flexibility |

What-If Analysis: By simulating different scenarios, companies can better understand how changes in demand or supply conditions will affect their transport inventory needs.

Contingency Planning: Creating contingency plans will help companies respond effectively to unexpected demand fluctuations or disruptions, maintaining operational continuity.

3.4 Technology Integration

Integrating advanced technologies into transport inventory management enhances efficiency and accuracy.

3.4.1 Advanced Software Solutions

Advanced software solutions streamline transport inventory management processes.

Table 7: Advanced Software Solutions

Software Type | Description | Features |

|---|---|---|

Transport Management Systems (TMS) | Systems for planning, executing, and optimizing transportation activities. | Route optimization, load planning, real-time tracking |

Enterprise Resource Planning (ERP) | Integrated systems for coordinating transport inventory with other business processes. | Centralized data management, cross-functional integration |

Transport Management Systems (TMS): TMS will facilitate planning, execution, and optimization of transport activities, including route planning, load optimization, and real-time tracking.

Enterprise Resource Planning (ERP): ERP systems will integrate transport inventory management with other business processes, providing a comprehensive view of operations and improving coordination.

3.4.2 Automation and Robotics

Automation and robotics streamline operations and reduce manual labor.

Table 8: Automation and Robotics Applications

Application | Description | Benefits |

|---|---|---|

Automated Warehousing | Robotics and automation for sorting, packing, and managing inventory in warehouses. | Increased efficiency and accuracy |

Autonomous Vehicles | Vehicles that operate without human intervention, using advanced sensors and control systems. | Reduced labor costs and improved safety |

Automated Warehousing: Robotics and automated systems will handle sorting, packing, and inventory management tasks in warehouses, improving efficiency and accuracy.

Autonomous Vehicles: Autonomous vehicles will operate with minimal human intervention, using advanced sensors and control systems to enhance safety and reduce labor costs.

3.5 Compliance and Regulations

Ensuring compliance with regulations and standards is crucial for legal and operational reasons.

3.5.1 Regulatory Requirements

Adhering to local and international regulations helps avoid legal issues and maintain operational standards.

Table 9: Regulatory Requirements

Regulation Type | Description | Compliance Measures |

|---|---|---|

Transportation Safety Standards | Regulations governing the safety of transportation activities and equipment. | Safety audits, regular inspections |

Environmental Regulations | Rules related to emissions, waste management, and environmental impact of transportation activities. | Adoption of green technologies, reporting |

Transportation Safety Standards: Compliance with safety standards will involve regular audits and inspections to ensure that transportation activities and equipment meet required safety criteria.

Environmental Regulations: Meeting environmental regulations will require the adoption of green technologies and practices, as well as regular reporting on emissions and waste management.

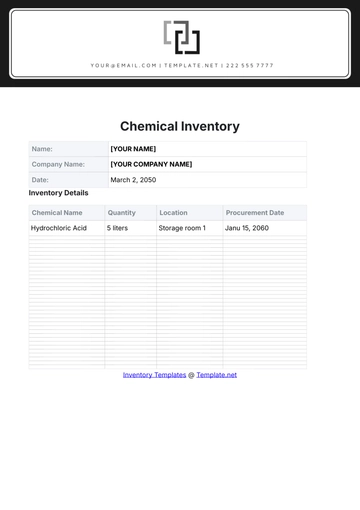

3.5.2 Documentation and Reporting

Accurate documentation and reporting are essential for compliance and transparency.

Table 10: Documentation and Reporting

Document Type | Description | Purpose |

|---|---|---|

Inventory Records | Detailed records of inventory levels, usage, and conditions. | Tracking and management |

Audit Trails | Records of transactions and activities for transparency and accountability. | Compliance and inspection |

Inventory Records: Maintaining detailed inventory records will provide insights into inventory levels, usage patterns, and conditions, aiding in effective management and decision-making.

Audit Trails: Implementing audit trails will ensure transparency and accountability by providing records of transactions and activities, facilitating compliance and inspections.

3.6 Sustainability and Environmental Impact

Integrating sustainability practices into transport inventory management reduces environmental impact and supports green initiatives.

3.6.1 Green Technologies

Adopting green technologies minimizes the carbon footprint and promotes environmental responsibility.

Table 11: Green Technologies

Technology | Description | Benefits |

|---|---|---|

Electric Vehicles | Vehicles powered by electricity, reducing reliance on fossil fuels. | Lower emissions, reduced fuel costs |

Alternative Fuels | Use of fuels such as hydrogen or biofuels to reduce environmental impact. | Reduced carbon footprint |

Electric Vehicles: Transitioning to electric vehicles will help reduce emissions and reliance on fossil fuels, contributing to sustainability goals.

Alternative Fuels: Exploring and adopting alternative fuels such as hydrogen and biofuels will further reduce the environmental impact of transportation activities.

3.6.2 Sustainable Practices

Implementing sustainable practices in transport operations reduces waste and enhances efficiency.

Table 12: Sustainable Practices

Practice | Description | Benefits |

|---|---|---|

Energy Efficiency | Improving energy efficiency in transportation and warehousing through the use of efficient equipment and practices. | Reduced energy consumption and costs |

Waste Reduction | Implementing recycling programs and efficient resource utilization to minimize waste. | Lower environmental impact |

Energy Efficiency: Enhancing energy efficiency through the use of energy-efficient equipment and practices will reduce energy consumption and costs in transportation and warehousing.

Waste Reduction: Implementing recycling programs and efficient resource utilization will minimize waste and lower the environmental impact of transport operations.

3.7 Risk Management

Effective risk management involves identifying, assessing, and mitigating risks associated with transport inventory.

3.7.1 Risk Assessment

Conducting risk assessments helps identify potential issues and prepare for them.

Table 13: Risk Assessment

Risk Type | Description | Assessment Methods |

|---|---|---|

Operational Risks | Risks related to vehicle breakdowns, delays, and supply chain disruptions. | Risk analysis, scenario planning |

Financial Risks | Risks related to fluctuations in fuel prices, maintenance costs, and other financial factors. | Financial analysis, budgeting |

Operational Risks: Assessing operational risks involves analyzing potential issues such as vehicle breakdowns and supply chain disruptions, and preparing contingency plans to address them.

Financial Risks: Evaluating financial risks involves analyzing factors such as fluctuations in fuel prices and maintenance costs, and implementing strategies to manage these risks.

3.7.2 Mitigation Strategies

Developing and implementing strategies to mitigate identified risks is essential for maintaining operational stability.

Table 14: Mitigation Strategies

Strategy | Description | Benefits |

|---|---|---|

Contingency Planning | Developing plans to address potential disruptions and ensure business continuity. | Enhanced resilience and preparedness |

Insurance Coverage | Securing insurance to protect against financial losses from accidents, theft, or damage. | Financial protection and risk management |

Contingency Planning: Developing contingency plans will help companies respond effectively to potential disruptions, ensuring business continuity and minimizing operational impact.

Insurance Coverage: Securing adequate insurance coverage will provide financial protection against losses from accidents, theft, or damage, helping to manage risks and safeguard assets.

4. Implementation Plan

Implementing a transport inventory management system requires a structured approach, involving assessment, planning, technology selection, training, and monitoring.

4.1 Assessment and Planning

The initial phase involves assessing current processes and developing a strategic plan for implementation.

Table 15: Assessment and Planning Steps

Step | Description | Deliverables |

|---|---|---|

Current State Analysis | Evaluating existing transport inventory management practices and identifying areas for improvement. | Analysis report, improvement plan |

Strategic Planning | Developing a strategic plan outlining goals, objectives, and required resources for implementation. | Strategic plan document |

Current State Analysis: Assessing current practices will help identify strengths, weaknesses, and areas for improvement, providing a foundation for developing an effective implementation plan.

Strategic Planning: Creating a strategic plan will outline the goals, objectives, and resources needed for successful implementation, guiding the overall process.

4.2 Technology Selection and Integration

Selecting and integrating appropriate technologies is crucial for enhancing transport inventory management.

Table 16: Technology Selection and Integration

Step | Description | Deliverables |

|---|---|---|

Technology Evaluation | Assessing and selecting technologies that align with operational needs and strategic goals. | Technology selection report |

Integration | Integrating selected technologies with existing systems and ensuring seamless operation. | Integration plan, implementation report |

Technology Evaluation: Evaluating and selecting technologies will ensure that the chosen solutions align with operational needs and strategic goals, providing the necessary tools for effective management.

Integration: Integrating selected technologies with existing systems will ensure seamless operation and enhance overall efficiency, supported by a detailed integration plan and implementation report.

4.3 Training and Development

Providing training and development for staff ensures that they are proficient in new systems and processes.

Table 17: Training and Development

Step | Description | Deliverables |

|---|---|---|

Training Programs | Developing and delivering training programs to ensure staff proficiency in new systems and processes. | Training materials, training sessions |

Ongoing Development | Implementing ongoing development programs to keep staff updated on technological advancements and best practices. | Development programs, progress reports |

Training Programs: Developing and delivering training programs will ensure that staff are proficient in new systems and processes, enhancing their ability to manage transport inventory effectively.

Ongoing Development: Implementing ongoing development programs will keep staff updated on technological advancements and best practices, supporting continuous improvement.

4.4 Monitoring and Evaluation

Monitoring and evaluating the effectiveness of the transport inventory management system is essential for identifying areas for improvement and ensuring optimal performance.

Table 18: Monitoring and Evaluation

Step | Description | Deliverables |

|---|---|---|

Performance Metrics | Defining and tracking performance metrics to assess the effectiveness of the system. | Metrics report, performance analysis |

Continuous Improvement | Implementing a continuous improvement process to address issues and optimize performance. | Improvement plan, progress reports |

Performance Metrics: Defining and tracking performance metrics will provide insights into the effectiveness of the transport inventory management system, allowing for data-driven decision-making and optimization.

Continuous Improvement: Implementing a continuous improvement process will address issues and optimize performance, ensuring that the system remains effective and aligned with operational goals.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

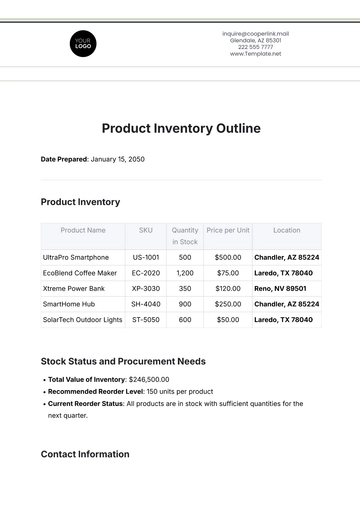

Manage transport assets with the Transport Inventory Management Template from Template.net. This editable and customizable template helps track vehicles, equipment, and supplies. Adjust it in our Ai Editor Tool to fit your inventory management needs.