Printable Work Instructions

Process Title: | Assembling Model Z200 Chair |

|---|---|

Department: | [Department Name] |

Contact Email: | [Your Company Email] |

Contact No.: | [Your Company Number] |

SOP I.D.: | |

Revision No.: | |

Effective Date: | [Date] |

I. Purpose

This document provides step-by-step instructions for the assembly of the Model Z200 Chair to ensure a consistent, high-quality product. All assembly steps must be followed to meet production standards and avoid defects.

II. Scope

This Work Instruction applies to all assembly line workers involved in the manufacturing process of the Model Z200 Chair at [Your Company Name].

III. Responsibilities

Assembler: Follow these instructions carefully to ensure proper assembly of the Model Z200 Chair.

Supervisor: Monitor the assembly process and verify that each worker follows the instructions.

IV. Materials & Tools

Component | Quantity | Notes |

|---|---|---|

Seat (Part 1) | 1 | Main base of the chair |

Backrest (Part 2) | 1 | Support for the back of the chair |

Legs | 4 | Supports for the chair |

Armrests | 2 | For arm support |

Screws | 12 | Used to fasten parts together |

Washers | 12 | To reinforce screw fastenings |

Nuts | 12 | To secure screws |

Tool | Purpose |

|---|---|

Screwdriver (Phillips head) | For tightening screws |

Wrench (10 mm) | For tightening nuts |

Allen key | For securing armrests |

Safety gloves | To protect hands during assembly |

V. Safety Precautions

Always wear safety gloves to avoid cuts from metal parts.

Ensure the work area is clean and free of clutter to prevent tripping hazards.

Use proper ergonomic lifting techniques when handling heavy parts such as the seat.

VI. Instructions

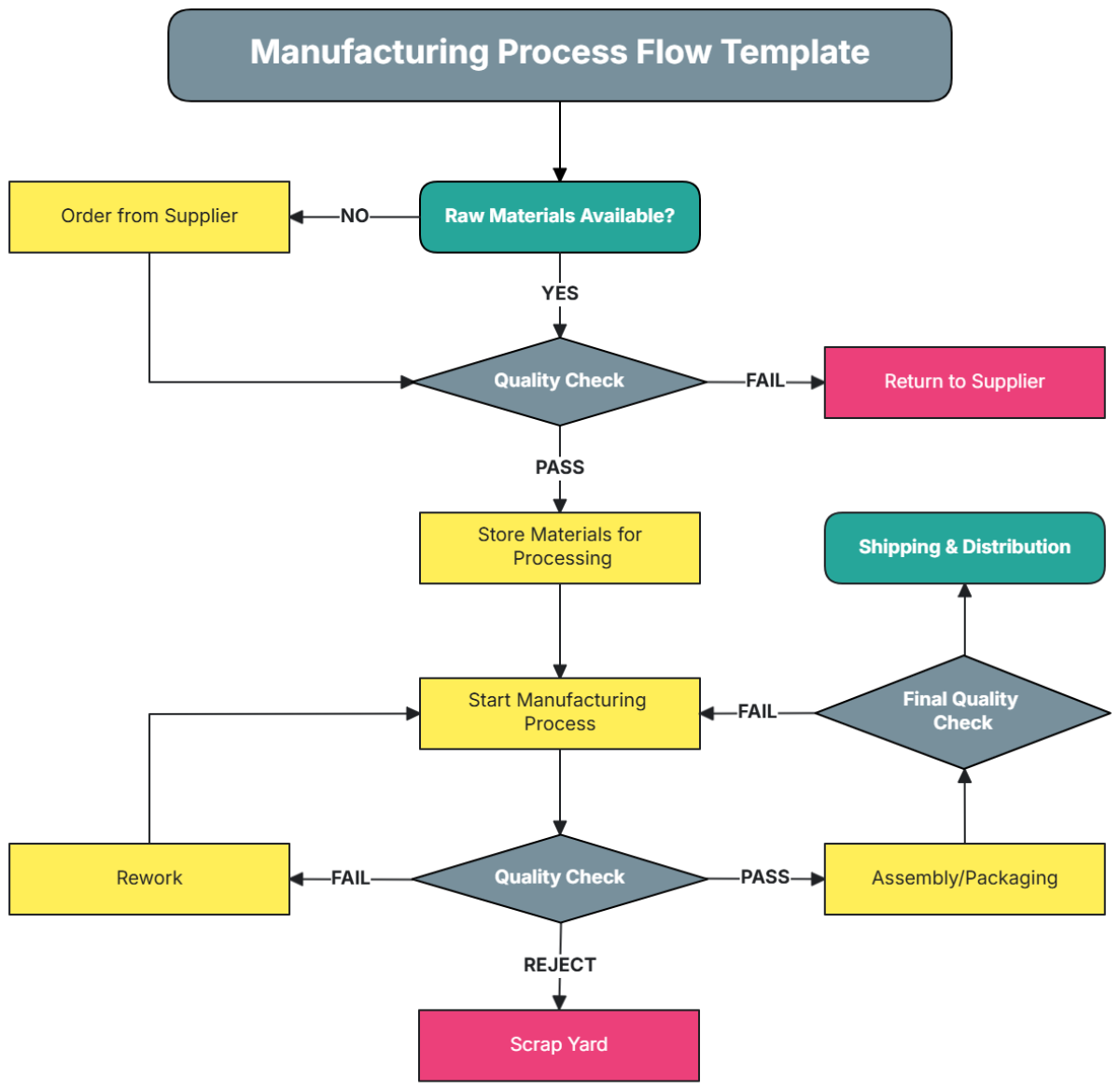

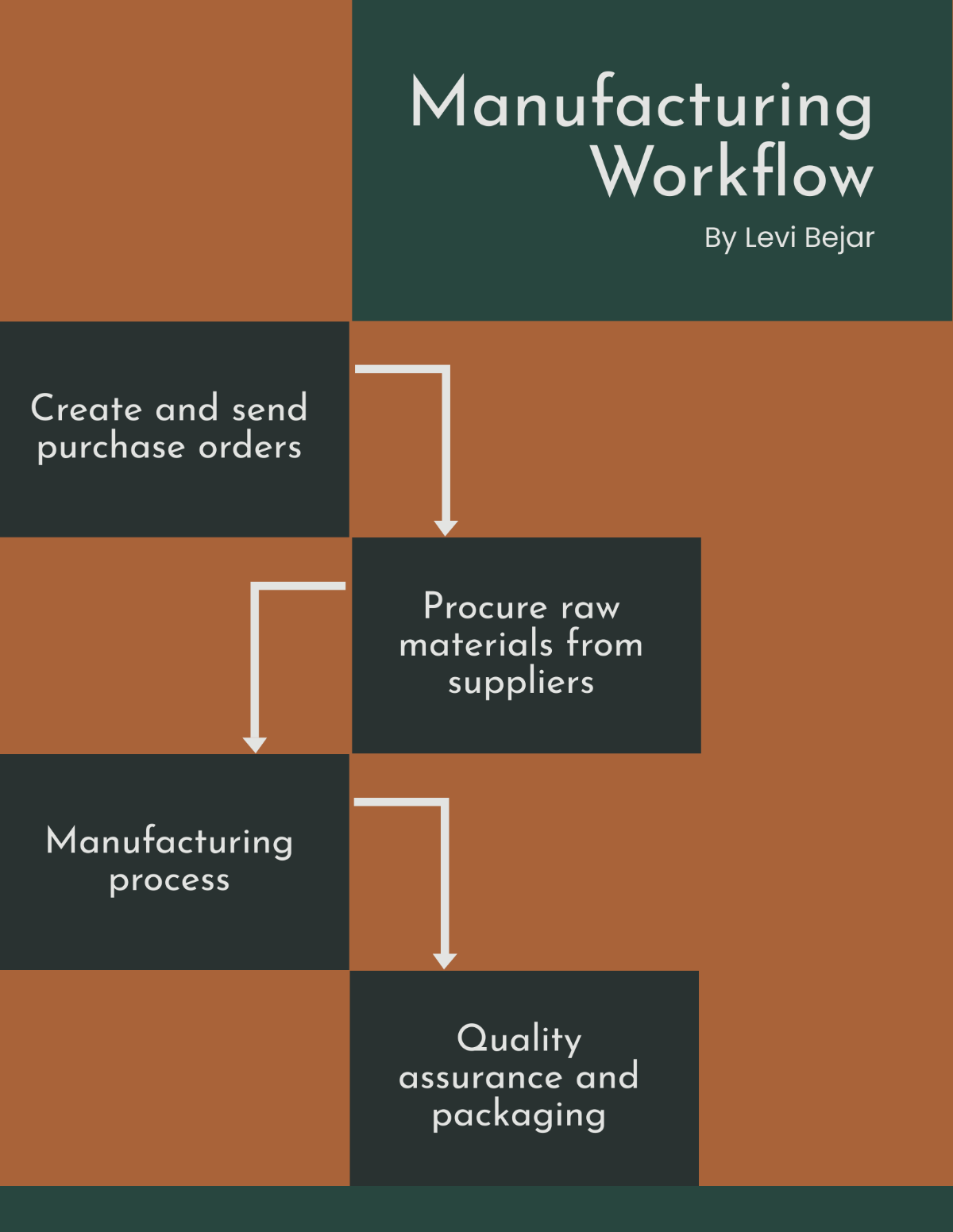

1. Preparation

Ensure all components for the Model Z200 Chair are available and undamaged.

Place the seat (Part 1) on a flat, clean surface for ease of assembly.

Double-check that the tools are in good working condition.

2. Assembly Process

Step 1: Attach the Legs

Align the four legs with the pre-drilled holes on the underside of the seat (Part 1).

Insert a screw with a washer through each hole, securing the leg to the seat.

Use the screwdriver to tighten the screws until snug but not overly tight.

Step 2: Attach the Backrest

Position the backrest (Part 2) behind the seat and align the connecting holes.

Insert the screws through the backrest and secure them using the washers and nuts on the other side.

Use the wrench to tighten the nuts while holding the screw steady with the screwdriver.

Step 3: Attach the Armrests

Align the armrests on either side of the chair.

Insert screws through the armrest holes and into the side of the seat.

Tighten all screws using the Allen key until they are securely fastened.

3. Final Inspection

Ensure that all screws and nuts are securely tightened and that the chair is stable when placed upright.

Check for any loose parts, wobbly legs, or misalignment.

Test the chair’s structural integrity by applying light pressure to various parts.

VII. Quality Control

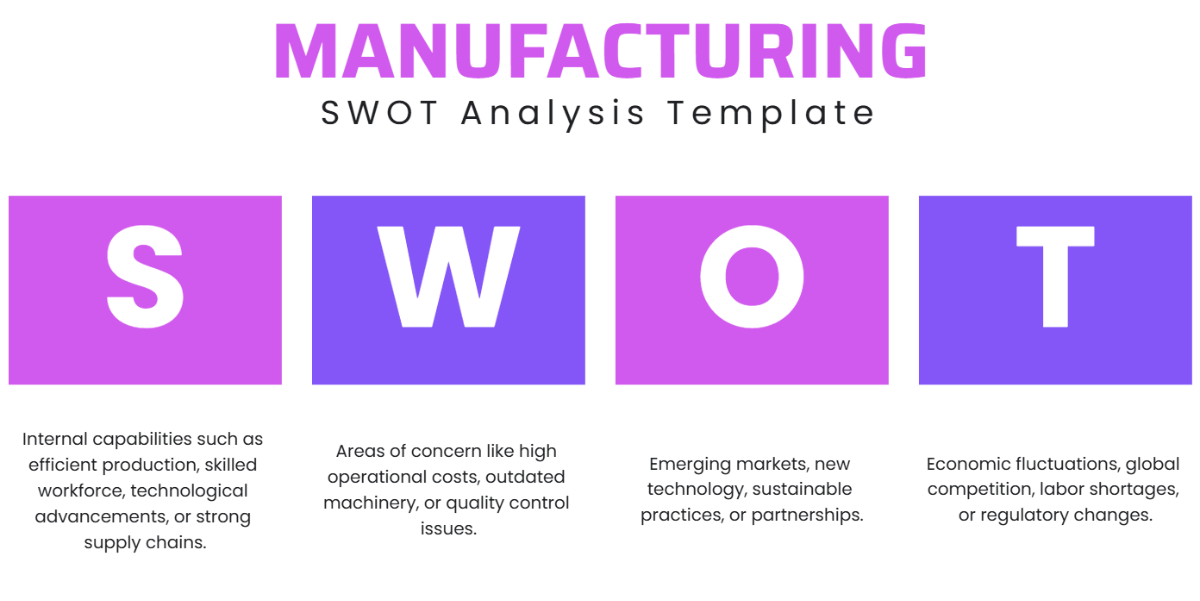

Inspect the assembled Model Z200 Chair for any visible defects, including scratches, misaligned parts, or loose fittings.

Record inspection results on the Model Z200 Chair Quality Control Checklist.

Place a quality control sticker on the chair once it passes inspection.

VIII. Troubleshooting

Loose Armrest: Re-check the alignment of the armrest and ensure all screws are fully tightened.

Unstable Chair: Verify that all legs are evenly attached, and screws are secure. Reposition the legs if necessary.

IX. References

Model Z200 Chair Assembly Guide (Edition 2050)

[Your Company Name] Safety Manual (Section 4: Ergonomics)