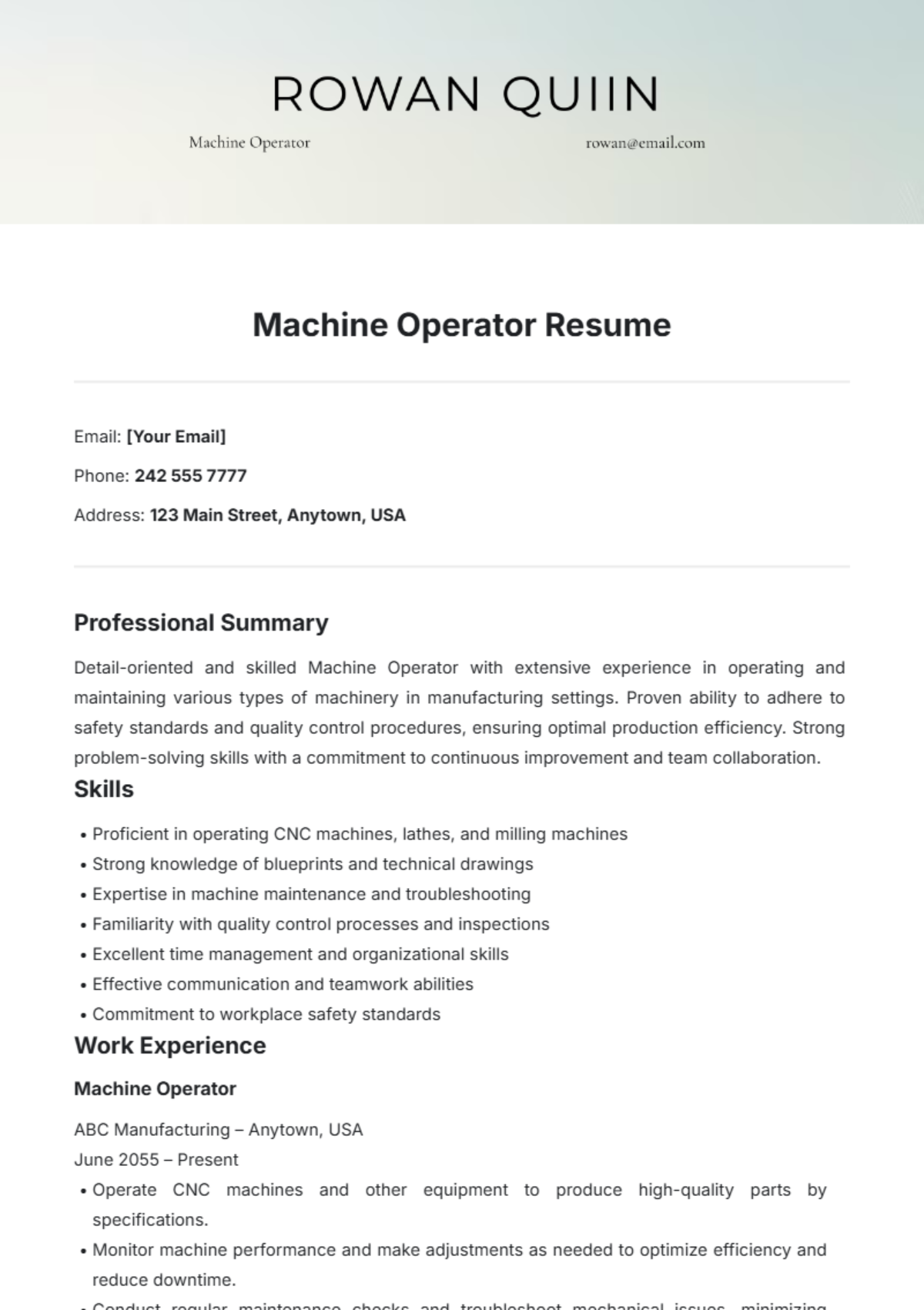

Lathe Machine Operator Resume Format

Address: [Your Address]

Phone: [Your Phone Number]

Email: [Your Email]

Objective

To obtain a challenging position as a Lathe Machine Operator at a forward-thinking manufacturing company, where I can apply my extensive skills in precision machining and contribute to the production of high-quality components while driving efficiency and innovation in manufacturing processes.

Qualifications

10+ years of experience operating CNC and conventional lathes, consistently delivering quality products on time and within budget.

Proficient in reading engineering drawings and blueprints for accurate setup and production.

Strong mechanical skills, producing high-precision components within tolerance limits.

Excellent safety record and commitment to maintaining a zero-incident work environment.

Skilled with measuring tools (calipers, micrometers, gauges) for precise machining.

Effective in troubleshooting and resolving issues to reduce downtime and boost productivity.

Professional Experience

Senior Lathe Machine Operator

SmithBrand Industries, San Diego, CA 92101 (2055 - Present)

Operate and set up CNC lathe machines to create precision parts according to detailed specifications, ensuring adherence to production schedules.

Collaborate with engineers and quality control personnel to improve manufacturing processes and enhance product quality, contributing to a 15% increase in production efficiency over the last year.

Led a team of junior operators to ensure production goals were met and quality standards were maintained, providing training and mentorship to improve their skills.

Conduct routine machine maintenance to ensure operational efficiency and reduce downtime, implementing a preventive maintenance schedule that decreased unexpected breakdowns by 20%.

Analyze production data and machine performance metrics to identify areas for improvement, contributing to continuous process enhancements and waste reduction initiatives.

Lathe Machine Operator

CastleBrand Manufacturing, Charlotte, NC 28202 (2052 - 2055)

Operated manual and CNC lathe machines for the production of mechanical parts, completing over 5,000 components with minimal errors.

Worked closely with the quality control team to inspect finished parts for accuracy and compliance, achieving a 98% first-pass yield rate.

Adjusted machine settings to optimize performance and ensure product precision, routinely suggesting modifications that improved cycle times by up to 10%.

Maintained a clean and organized workspace to promote safety and efficiency, receiving recognition for maintaining high workplace standards during quarterly audits.

Assisted in the development of Standard Operating Procedures (SOPs) to streamline operations and enhance team performance.

Education

Associate Degree in Mechanical Engineering Technology

Future Technological Institute, Charlotte, NC 28202 (2052)

Relevant coursework: Advanced Manufacturing Processes, CNC Machining, Mechanical Design, and Materials Science.

Participated in hands-on projects focusing on machine operation and maintenance, enhancing practical skills in a real-world setting.

Certifications

Certified CNC Machine Operator - Advanced Level (2050)

OSHA Safety Certification (2050)

Lean Manufacturing Certification (2051) - completed training focused on waste reduction and efficiency improvement.

Six Sigma Green Belt Certification (2053) - developed skills in process improvement and quality management methodologies.

Skills

Precision Machining: Expertise in producing components to exact specifications, ensuring high levels of accuracy and repeatability.

CNC Programming: Proficient in programming CNC machines using G-code and M-code, enhancing automation and efficiency.

Blueprint Reading: Ability to read and interpret complex blueprints and technical drawings, facilitating precise manufacturing.

Quality Control: Strong experience in quality assurance processes, including inspections, testing, and compliance with industry standards.

Machine Maintenance: Knowledgeable in routine maintenance, troubleshooting, and repairs, ensuring machines operate at peak performance.

References

Available upon request.