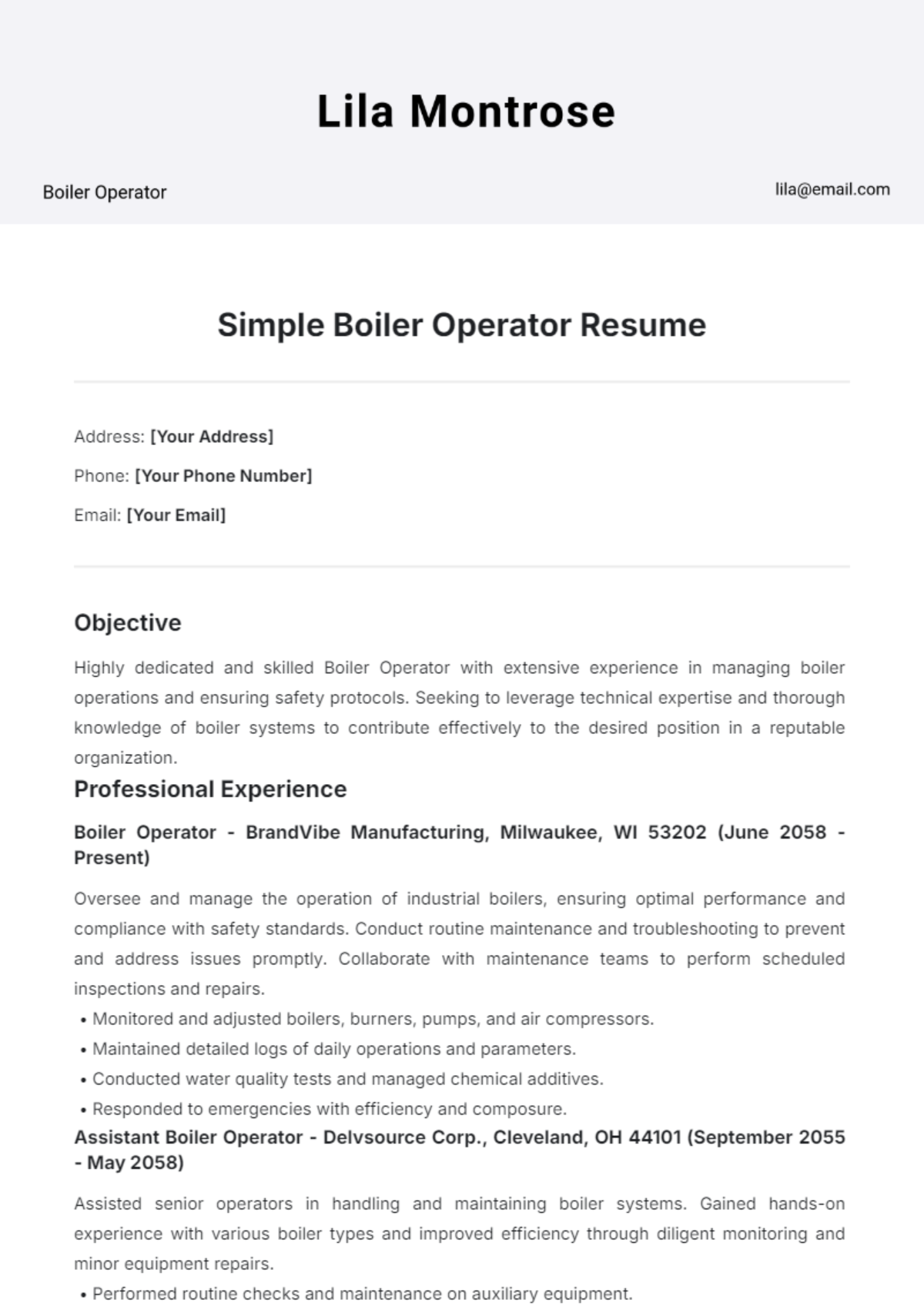

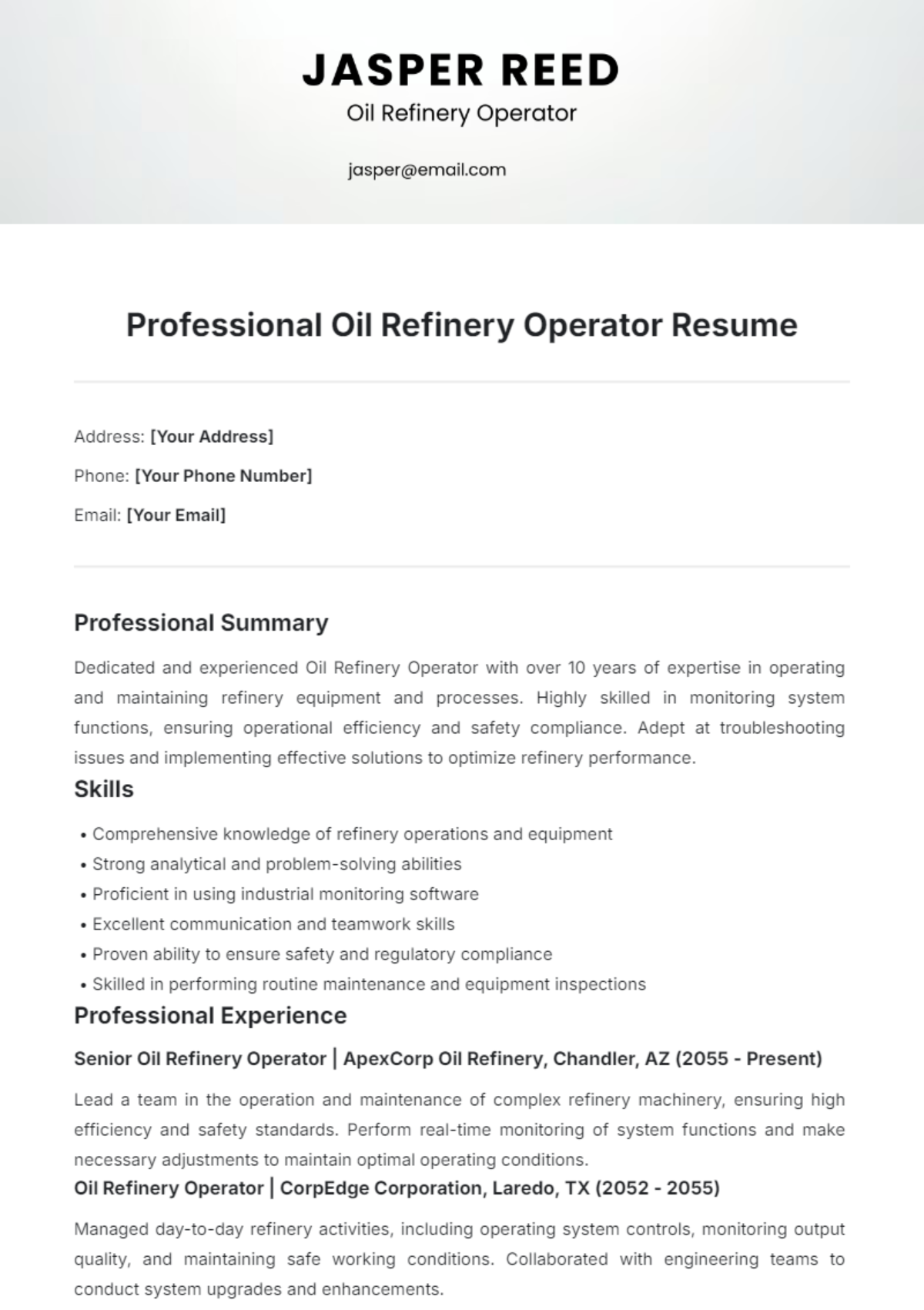

Free Drilling Machine Operator Resume Template

Drilling Machine Operator Resume

Address: [Your Address]

Phone: [Your Phone Number]

Email: [Your Email]

Professional Summary

Highly skilled Drilling Machine Operator with over 10 years of experience in the construction and manufacturing industries. Proficient in operating a diverse range of drilling machinery, including CNC, conventional, and rotary drills, with a strong emphasis on precision and safety. Adept at performing machine maintenance, troubleshooting issues, and implementing efficient operational procedures. Committed to upholding the highest standards of quality, meeting project deadlines consistently, and contributing to team success. Recognized for innovative problem-solving abilities and a proactive approach to machine management.

Skills

Proficient in operating and maintaining a variety of drilling machines, including CNC, conventional, and rotary drills, ensuring optimal functionality.

Strong understanding of safety protocols and procedures in drilling operations, adhering to OSHA regulations and industry standards.

Ability to read and interpret complex blueprints and technical drawings, facilitating accurate machine setup and operation.

Excellent problem-solving skills, with a proven track record in troubleshooting machine malfunctions swiftly and effectively.

Strong attention to detail, ensuring precision and accuracy in all drilling processes, thereby minimizing errors and maximizing output.

Experience in team collaboration, demonstrating effective communication skills and a commitment to fostering a safe and productive work environment.

Professional Experience

Senior Drilling Machine Operator | NeoEdge Drilling Services, Houston, TX | June 2056 - Present

Manage and operate a diverse range of drilling machinery on large-scale construction projects, overseeing all operational aspects to ensure efficiency and compliance with safety standards.

Implement routine maintenance schedules and conduct machine inspections to guarantee optimal operational performance, reducing unexpected breakdowns.

Train and mentor junior operators, instilling best practices in safety and operational efficiency to foster a culture of excellence.

Achievements:

Successfully reduced machine downtime by 15% through proactive maintenance and troubleshooting initiatives, leading to significant cost savings for the company.

Enhanced project efficiency by implementing innovative drilling techniques, resulting in time savings and improved accuracy.

Spearheaded a team initiative that improved operational safety protocols, contributing to a 25% reduction in workplace incidents.

Drilling Machine Operator | AireMix Manufacturing, Denver, CO | April 2052 - May 2056

Operated CNC drilling machines to produce high-precision components for various manufacturing projects, ensuring compliance with stringent quality standards.

Collaborated closely with engineering teams to verify that all specifications and quality requirements were met throughout the production process.

Achievements:

Played a key role in a major project that improved production efficiency by 20%, exceeding client expectations and enhancing the company's reputation.

Recognized for maintaining a perfect safety record over four years, demonstrating a commitment to workplace safety and adherence to protocols.

Developed a best practices manual for new operators, streamlining the onboarding process and enhancing team productivity.

Education

Associate of Applied Science in Machine Technology | Community College of Denver, Denver, CO | Graduated: May 2052

Completed comprehensive coursework in machining technologies, blueprint reading, and safety procedures, preparing for a successful career in the field.

Certifications

Certified Machine Operator (CMO) - National Institute for Metalworking Skills (NIMS)

OSHA Safety Certification for Construction and General Industry

Forklift Operation Certification

Advanced Drilling Techniques Certification

References

Available upon request.