Free Manufacturing Feasibility Study

Prepared by: [Your Name]

Date: October 26, 2050

1. Executive Summary

This feasibility study examines the potential for establishing a manufacturing facility to produce eco-friendly packaging materials. The study evaluates market demand, technical requirements, financial projections, and risks associated with the project. Based on the analysis, the project appears viable, given the increasing demand for sustainable packaging solutions. With an initial investment of $1.5 million, the facility could achieve profitability within three years.

2. Introduction

Objective: To determine the feasibility of producing biodegradable and compostable packaging materials aimed at reducing plastic waste.

Scope: The study covers market analysis, technical requirements, financial analysis, and risk assessment.

3. Market Analysis

Industry Overview: The global eco-friendly packaging market was valued at $4 billion in 2050 and is expected to grow at a CAGR of 12% over the next five years, driven by consumer demand for sustainable products.

Target Market: Small to medium-sized businesses in the food, cosmetics, and e-commerce sectors that are increasingly adopting sustainable practices.

Competitive Analysis: Key competitors include EcoPack Solutions and GreenWrap Inc., which dominate the market with established distribution networks and strong brand recognition.

Market Demand: The estimated market size of eco-friendly packaging materials is expected to reach $10 billion by 2053, with a projected demand for biodegradable products growing significantly.

4. Technical Feasibility

Location: The proposed facility is located in Springfield Industrial Park, benefiting from proximity to major transportation routes and utilities.

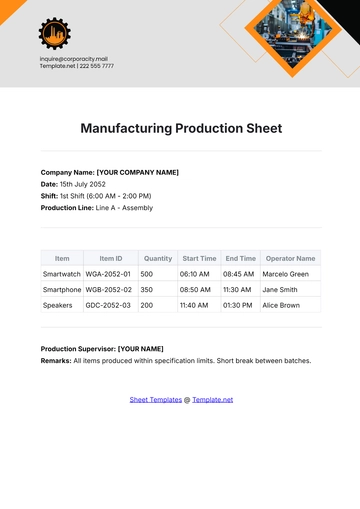

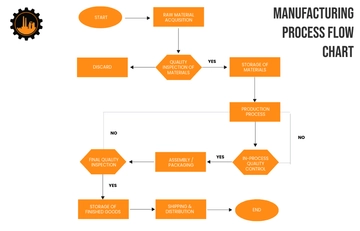

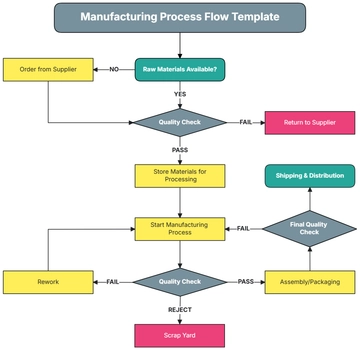

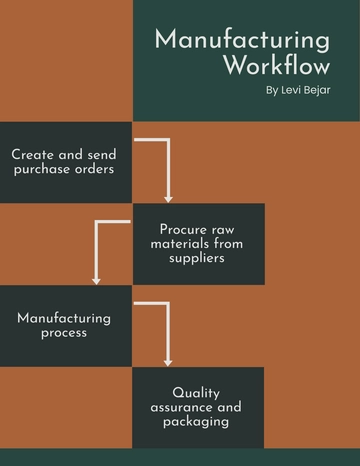

Manufacturing Process: The manufacturing process will consist of obtaining plant-derived raw materials like cornstarch and sugarcane, then shaping them into different packaging forms through extrusion and molding, such as bags and containers, with quality control steps including regular biodegradability testing.

Equipment Required:

Extruder: $300,000

Injection Molding Machine: $450,000

Quality Testing Equipment: $150,000

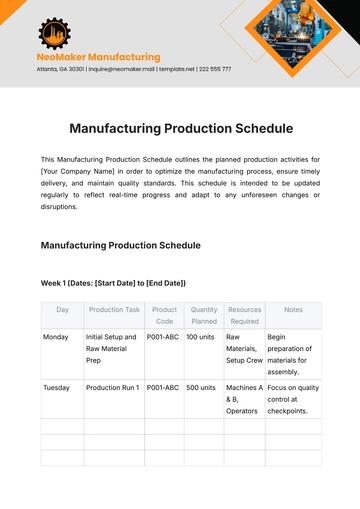

Production Capacity: Initial production capacity is estimated at 500,000 units per year, with the potential to expand to 1 million units as demand increases.

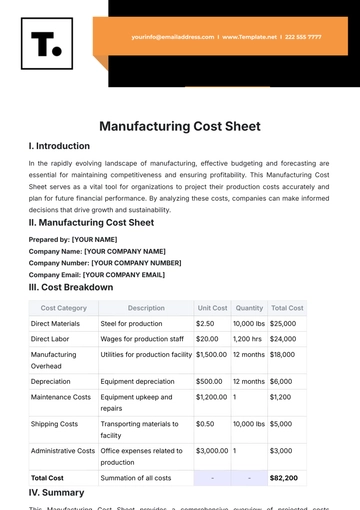

5. Financial Analysis

Startup Costs

Cost Item | Amount ($) |

|---|---|

Land and Building | 500,000 |

Machinery | 900,000 |

Initial Working Capital | 100,000 |

Total Startup Costs | 1,500,000 |

Operational Costs (Monthly)

Cost Item | Amount ($) |

|---|---|

Labor | 50,000 |

Utilities | 10,000 |

Raw Materials | 30,000 |

Maintenance | 5,000 |

Total Monthly Costs | 95,000 |

Revenue Projections

Estimated unit sale price: $4

Year 1 projected sales: 500,000 units

Year 1 revenue: $2 million

Profitability Analysis: Projected net profit margin of 20% after reaching full capacity by Year 3, leading to net profits of approximately $400,000 by Year 3.

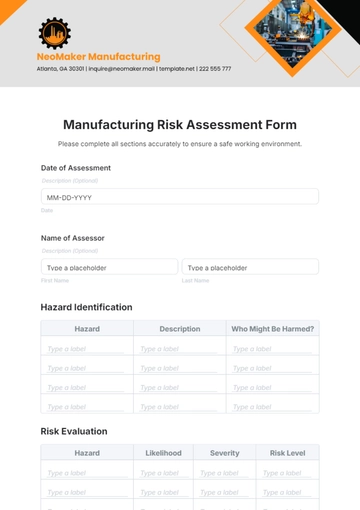

6. Risk Assessment

Market Risks: Fluctuations in demand due to economic downturns and competition from cheaper plastic alternatives.

Operational Risks: Challenges in sourcing high-quality, eco-friendly raw materials may impact production.

Financial Risks: Risks associated with the initial capital investment could affect cash flow, especially in the early stages.

Mitigation Strategies: Establish long-term contracts with suppliers for raw materials and develop a diversified product line to mitigate market fluctuations.

7. Conclusion

The feasibility study concludes that the manufacturing of eco-friendly packaging materials is a viable project due to increasing market demand, manageable operational requirements, and positive financial projections. It is recommended to proceed with detailed planning and securing funding for project implementation.

8. Recommendations

Develop a detailed business plan, including a marketing strategy targeting eco-conscious businesses.

Conduct further research on potential suppliers for raw materials, focusing on those with sustainable practices.

Initiate discussions with potential clients to gauge interest and secure early orders, possibly through pilot projects.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Unlock efficient planning with the Manufacturing Feasibility Study Template from Template.net. This fully editable and customizable resource streamlines your project assessment, allowing you to tailor every aspect to your unique needs. Effortlessly edit in our AI Editor Tool for a seamless experience, ensuring your feasibility study is both professional and precisely aligned with your objectives.