Workplace Incident Report for Confluence

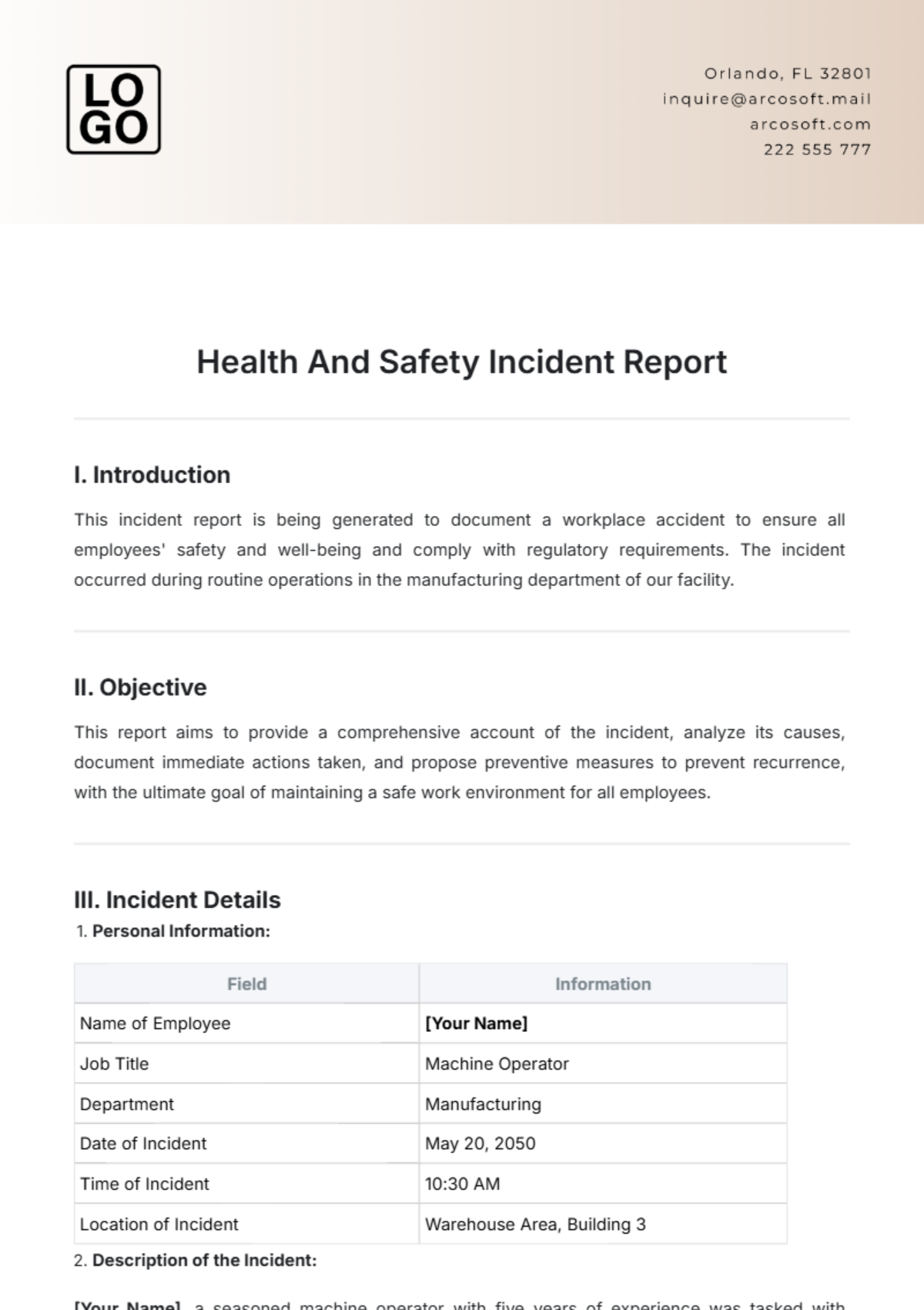

I. Incident Overview

Report Number: 2054-05-20-01

Reported By: [Your Name]

Email: [Your Company Email]

Company Name: [Your Company Name]

Date of Report: May 20, 2054

II. Incident Details

Date of Incident: May 18, 2054

Time of Incident: 2:30 PM

Location of Incident: Warehouse Loading Dock

Incident Type: Accident

Detailed Description: On May 18, 2054, at approximately 2:30 PM, an accident occurred at the warehouse loading dock involving a forklift and a pallet of goods. Michael Adams, a warehouse worker, was operating the forklift to move a heavy pallet. During the operation, the forklift's load shifted unexpectedly, causing the pallet to fall. The worker attempted to stabilize the load but was unable to prevent the fall. The incident resulted in the pallet falling onto the worker's foot, causing significant injury.

III. Involved Parties

Employee Name: Michael Adams

Position: Warehouse Worker

Department: Logistics

Contact Information:(555) 987-6543

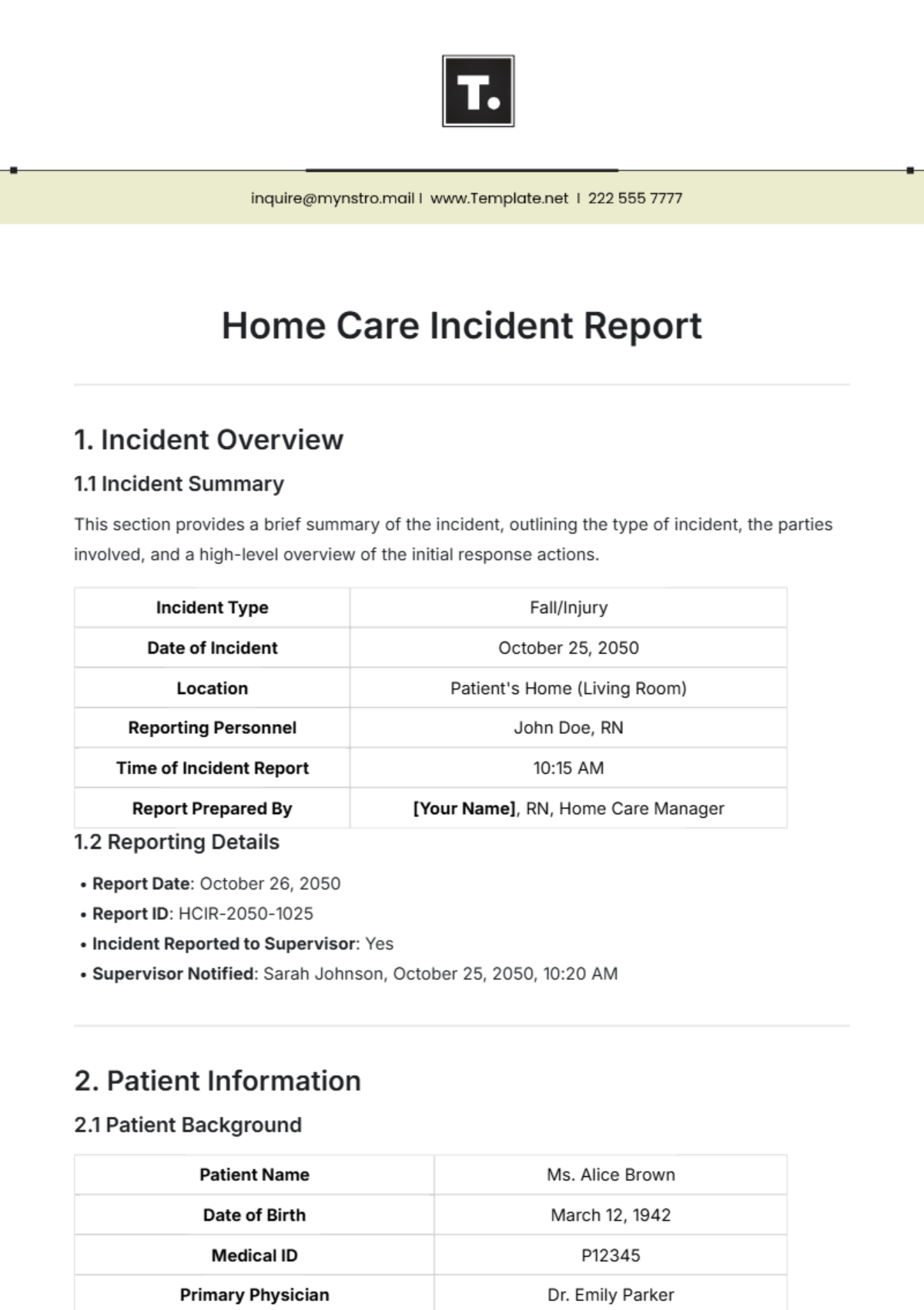

IV. Witness Information

Witness Name: Emily Thompson

Position: Warehouse Supervisor

Department: Logistics

Contact Information: (555) 123-4567

Witness Statement: The witness stated that they observed the incident from approximately 10 feet away. They noted that the employee was following standard operating procedures when the load shifted. The supervisor immediately called for medical assistance and initiated the emergency response protocol.

V. Injuries or Damages

A. Injuries:

The employee sustained a fractured foot due to a falling pallet. Immediate swelling and bruising were observed.

B. Medical Treatment Required:

The employee was taken to the nearest hospital for emergency medical treatment, including X-rays and a cast for the fractured foot.

C. Property Damage:

The pallet of goods, primarily consisting of electronic components, was damaged beyond salvage. The estimated loss of goods is valued at $5,000.

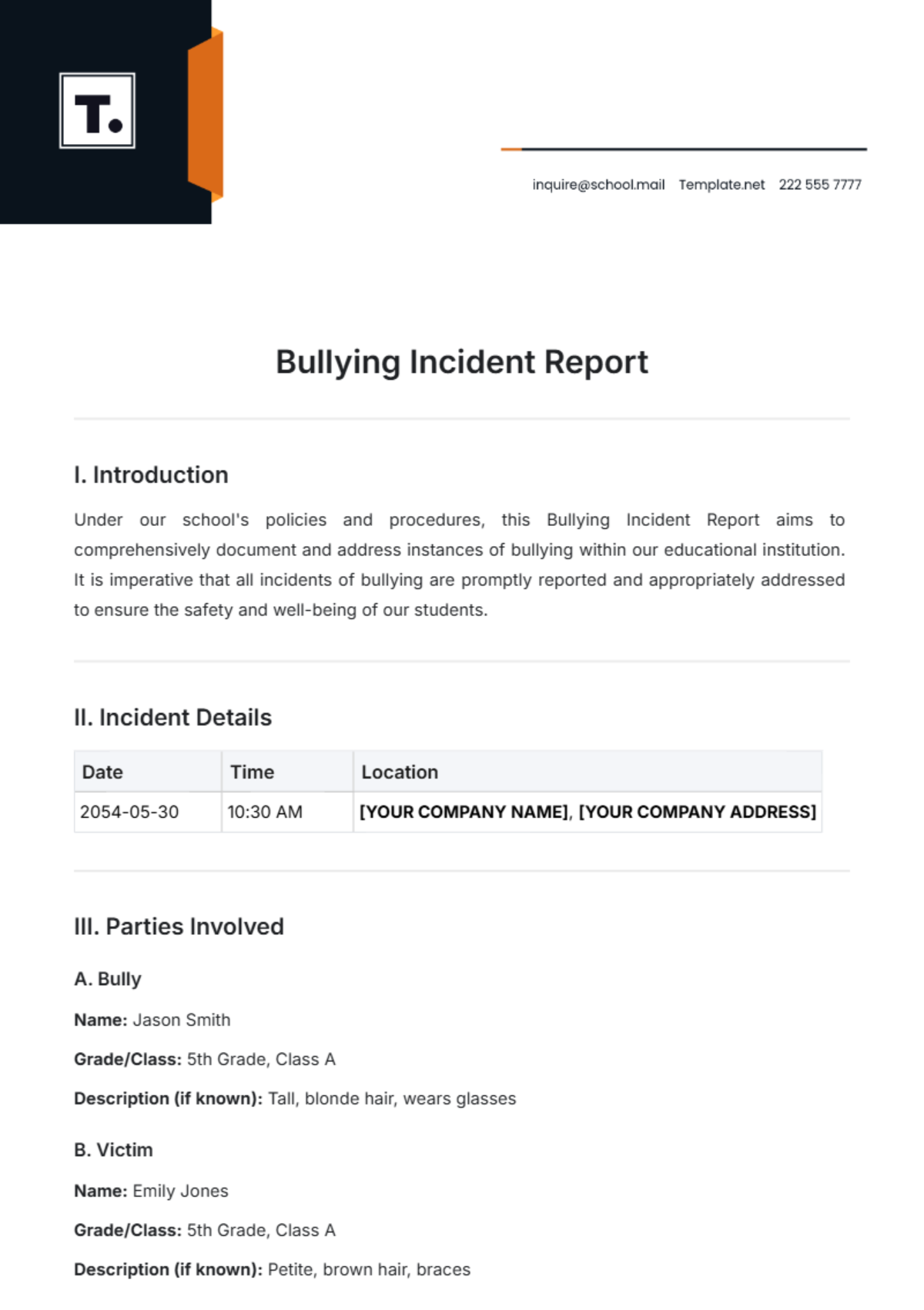

VI. Corrective Actions

A. Immediate Actions Taken:

The injured employee was provided first aid by on-site medical staff.

An ambulance was called, and the injured employee was transported to the hospital.

The area was secured to prevent further incidents, and operations at the loading dock were temporarily halted.

B. Future Preventive Measures:

Review and reinforcement of forklift operation training for all warehouse personnel.

Implementation of additional safety checks before moving heavy or unstable loads.

Installation of load stabilizers on all forklifts to prevent similar incidents.

Scheduled safety drills focusing on emergency response to accidents involving heavy machinery.

VII. Additional Notes

The employee's family was notified of the incident and provided with regular updates regarding their condition.

An internal review meeting is scheduled to discuss the incident and evaluate current safety protocols.

Counseling services were offered to the employee to help cope with the trauma of the accident.

VIII. Incident Investigation

Investigating Officer: John Smith, Safety Officer

A. Investigation Findings:

The investigation concluded that the primary cause of the incident was the unexpected shift of the load due to improper securing. While the employee followed procedures, additional measures to secure the load could have prevented the accident.

B. Corrective Action Plan:

Immediate refresher training for all forklift operators.

Introduction of mandatory load securing protocols.

Regular maintenance and safety checks on all forklifts.

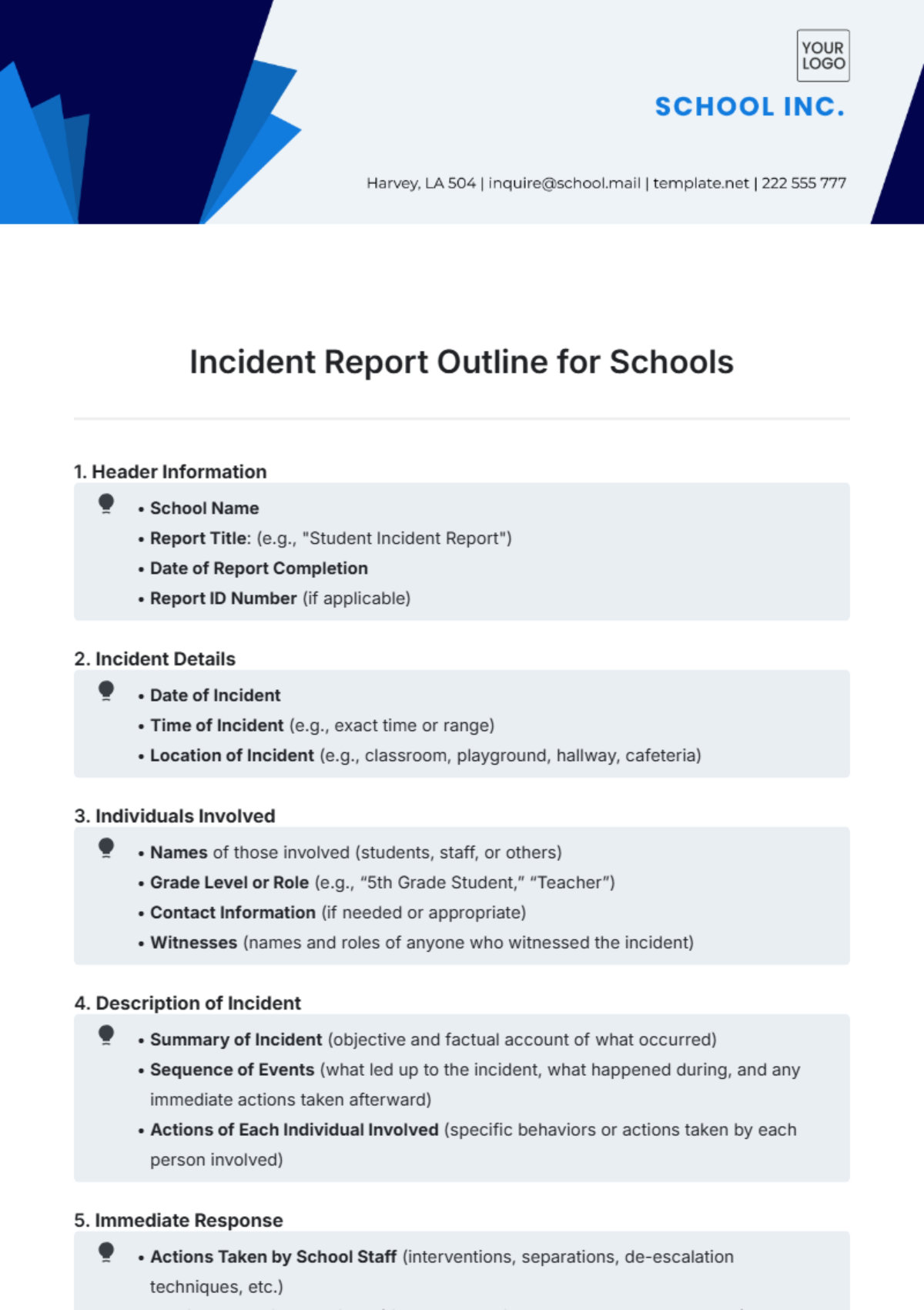

IX. Report Status

Status: Open

Follow-Up Actions:

Continuous monitoring of the employee's recovery progress.

Implementation of recommended safety measures.

Ongoing review and updates of warehouse safety protocols.

X. Conclusion

The incident report identifies a major safety oversight causing employee injury and property damage, promptly addressed with medical assistance and containment measures. Root cause analysis revealed inadequate load-securing procedures, prompting updated training and improved safety policies to lower future risks and promote a safer workplace. Ongoing commitment to the corrective action plan is vital to avoid similar incidents, underscoring the company's dedication to safety.