Free Quality Incident Report

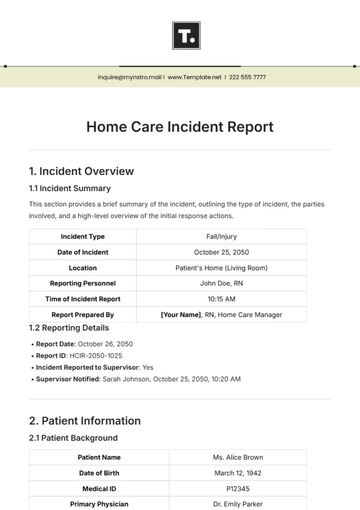

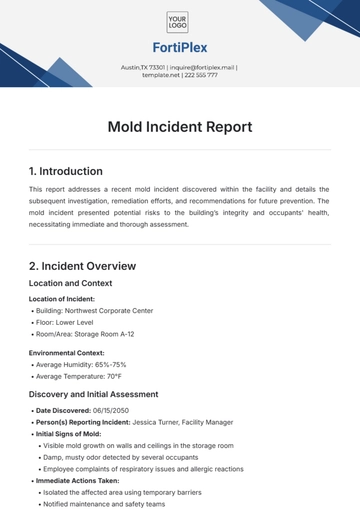

I. Reporting Personnel

Reported By: | [Your Name] |

Report Date: | May 16, 2050 |

Company Name: | [Your Company Name] |

Company Address: | [Your Company Address] |

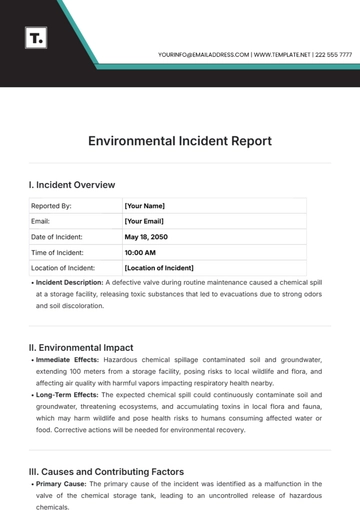

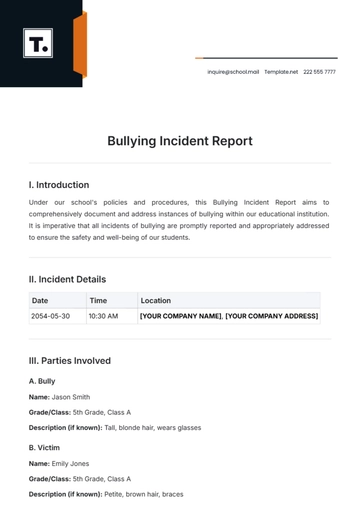

II. Incident Details

Incident Date: | May 15, 2050 |

Time of Incident | 10:30 AM |

Location: | Main Production Facility |

Product/Service Affected: | Widget X |

Description of Incident: | On May 15, 2050, during routine quality checks, anomalies were detected in the manufacturing process of Widget X. Upon investigation, it was found that a malfunction in the assembly line led to a deviation from the standard production protocol, resulting in a batch of defective widgets being produced. |

III. Individuals Involved

Names | Roles |

|---|---|

[Employee 1 Name] | Production Supervisor |

[Employee 2 Name] | Quality Control Manager |

[Employee 3 Name] | Assembly Line Operator |

IV. Immediate Actions Taken

Production was halted immediately upon detection of anomalies.

The defective batch was quarantined to prevent further distribution.

Quality control teams were dispatched to assess the extent of the issue and identify affected products.

V. Root Cause Analysis

A thorough investigation revealed that a software glitch in the assembly line's control system caused a deviation from the programmed parameters, leading to improper assembly of components.

VI. Corrective and Preventive Actions

A software patch was applied to rectify the control system glitch.

Intensive retraining sessions were conducted for assembly line operators to ensure adherence to production protocols.

VII. Preventive Actions

Implementation of regular maintenance checks on assembly line machinery to detect and address any potential software or hardware issues proactively.

Review of production protocols to identify areas for improvement and enhance system redundancies.

VIII. Impact Assessment

The incident resulted in a temporary halt in production, causing a delay in delivery schedules and potential financial losses due to the disposal of defective products. Additionally, customer confidence may be affected if timely corrective measures are not implemented.

IX. Recommendations and Follow-Up

A. Recommendations

Regular audits of production processes and equipment to identify and mitigate potential risks.

Continuous monitoring of software systems to ensure optimal performance and prevent similar incidents.

Establishing a cross-functional task force to oversee the implementation of preventive measures and monitor their effectiveness.

B. Follow-Up

Ongoing monitoring and review of production processes and quality control measures to evaluate the effectiveness of corrective actions and prevent the recurrence of similar incidents. Regular updates and training sessions for employees to reinforce adherence to standard operating procedures and promote a culture of quality and safety.

X. Conclusion

The swift response to the incident, coupled with comprehensive root cause analysis, enabled [Your Company Name] to identify and address the underlying issues in the production process. By implementing immediate corrective actions and establishing preventive measures, the company aims to mitigate the impact on operations and prevent similar incidents in the future. Continuous monitoring and follow-up will be crucial to ensuring the effectiveness of these measures and maintaining the highest standards of quality and reliability in product delivery.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Introducing the Quality Incident Report Template by Template.net, your comprehensive solution for meticulous incident documentation. Fully editable and customizable, this template enables precise detailing of quality incidents. Tailor it to your exact needs, ensuring thorough and clear reporting. Simplify your quality management process and uphold impeccable standards with this versatile and user-friendly template.

You may also like

- Sales Report

- Daily Report

- Project Report

- Business Report

- Weekly Report

- Incident Report

- Annual Report

- Report Layout

- Report Design

- Progress Report

- Marketing Report

- Company Report

- Monthly Report

- Audit Report

- Status Report

- School Report

- Reports Hr

- Management Report

- Project Status Report

- Handover Report

- Health And Safety Report

- Restaurant Report

- Construction Report

- Research Report

- Evaluation Report

- Investigation Report

- Employee Report

- Advertising Report

- Weekly Status Report

- Project Management Report

- Finance Report

- Service Report

- Technical Report

- Meeting Report

- Quarterly Report

- Inspection Report

- Medical Report

- Test Report

- Summary Report

- Inventory Report

- Valuation Report

- Operations Report

- Payroll Report

- Training Report

- Job Report

- Case Report

- Performance Report

- Board Report

- Internal Audit Report

- Student Report

- Monthly Management Report

- Small Business Report

- Accident Report

- Call Center Report

- Activity Report

- IT and Software Report

- Internship Report

- Visit Report

- Product Report

- Book Report

- Property Report

- Recruitment Report

- University Report

- Event Report

- SEO Report

- Conference Report

- Narrative Report

- Nursing Home Report

- Preschool Report

- Call Report

- Customer Report

- Employee Incident Report

- Accomplishment Report

- Social Media Report

- Work From Home Report

- Security Report

- Damage Report

- Quality Report

- Internal Report

- Nurse Report

- Real Estate Report

- Hotel Report

- Equipment Report

- Credit Report

- Field Report

- Non Profit Report

- Maintenance Report

- News Report

- Survey Report

- Executive Report

- Law Firm Report

- Advertising Agency Report

- Interior Design Report

- Travel Agency Report

- Stock Report

- Salon Report

- Bug Report

- Workplace Report

- Action Report

- Investor Report

- Cleaning Services Report

- Consulting Report

- Freelancer Report

- Site Visit Report

- Trip Report

- Classroom Observation Report

- Vehicle Report

- Final Report

- Software Report