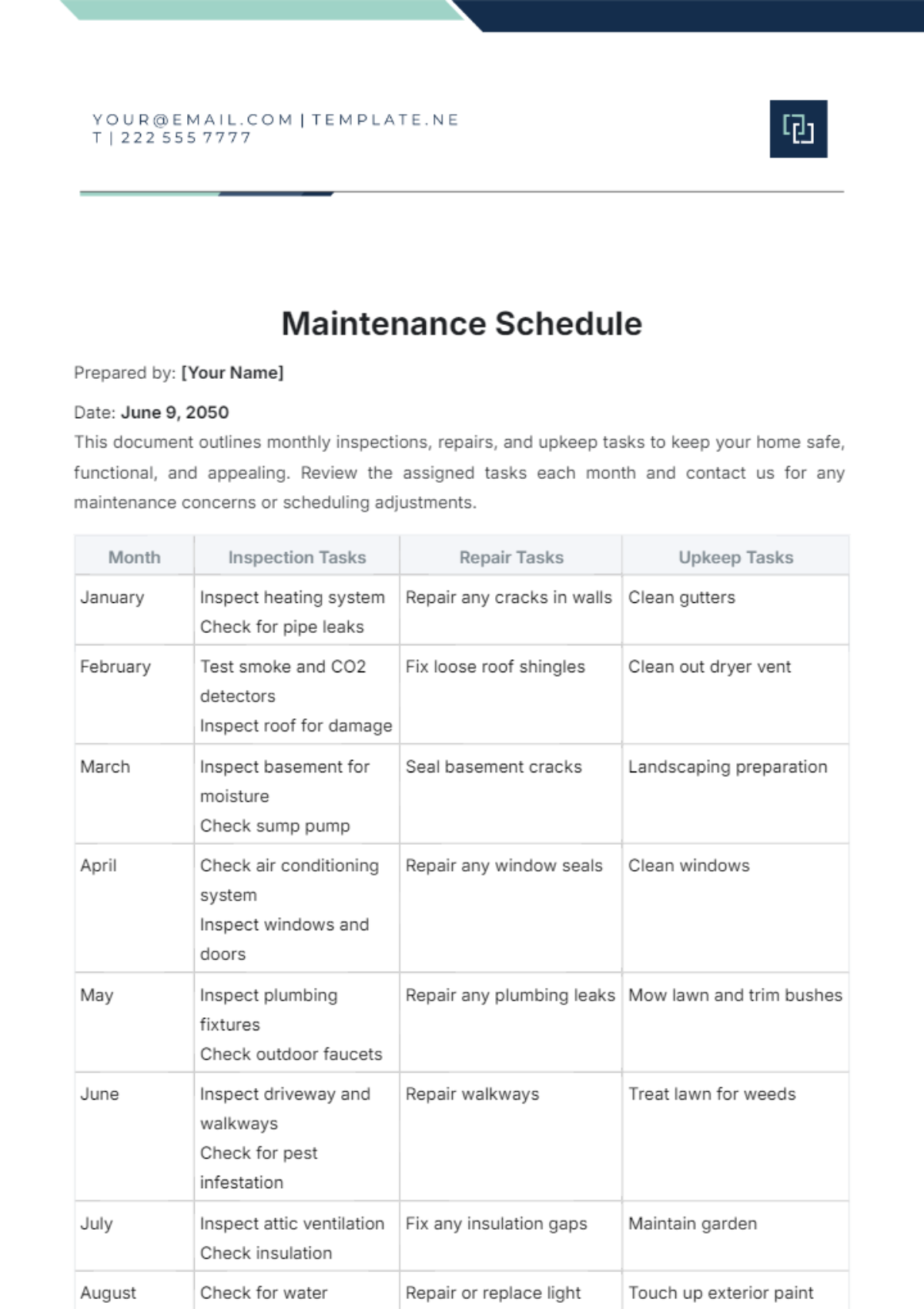

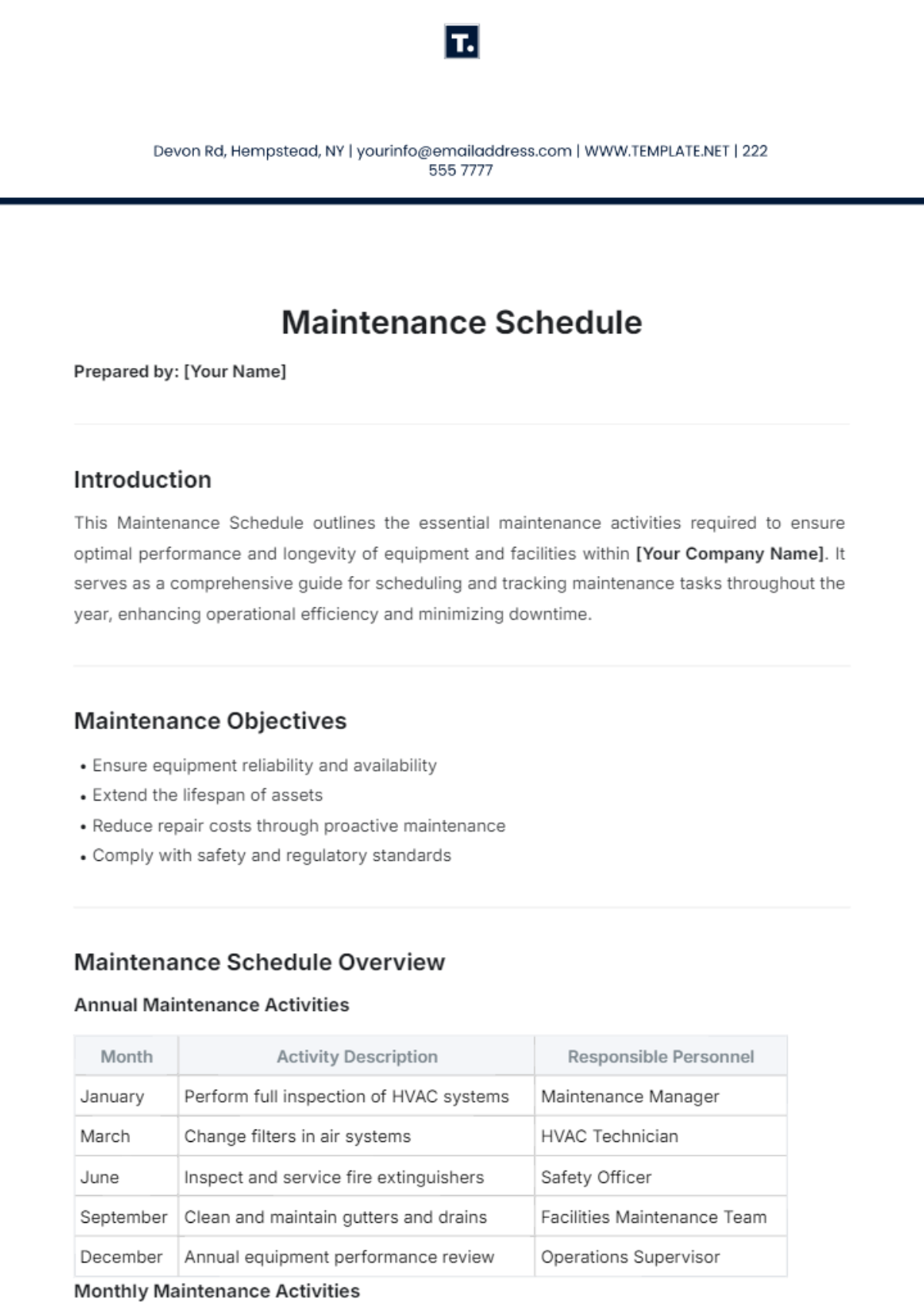

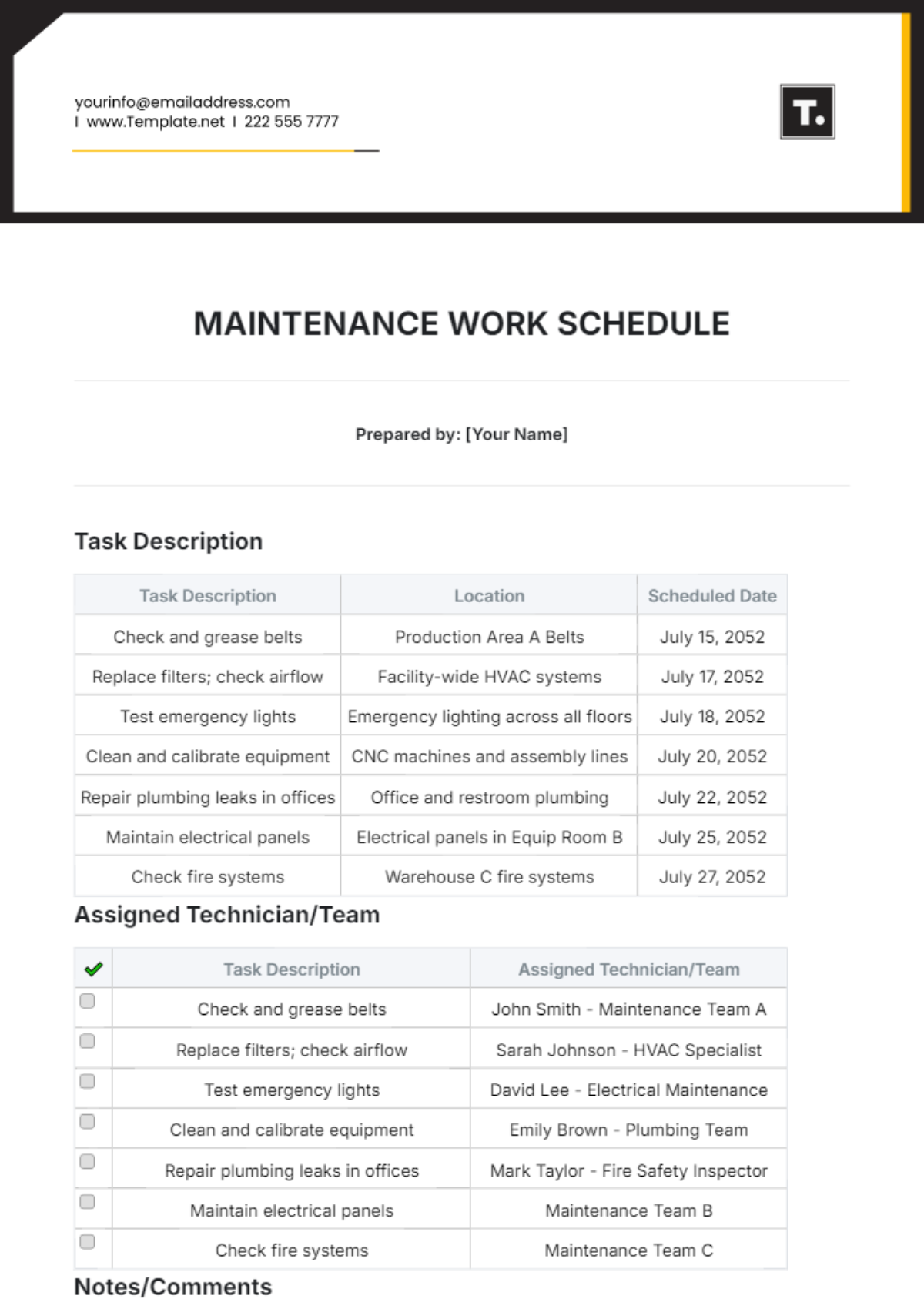

MAINTENANCE WORK SCHEDULE

Prepared by: [Your Name]

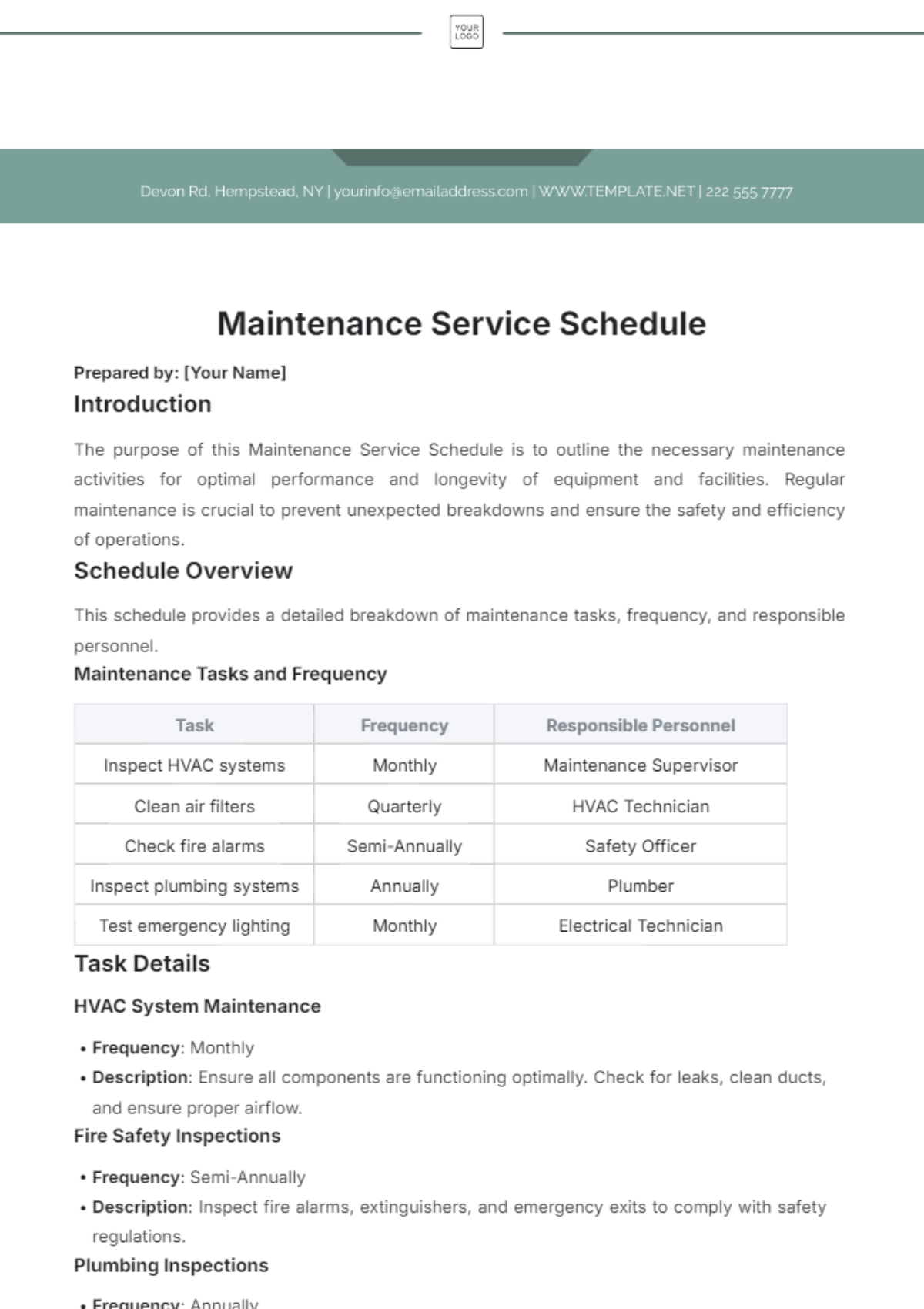

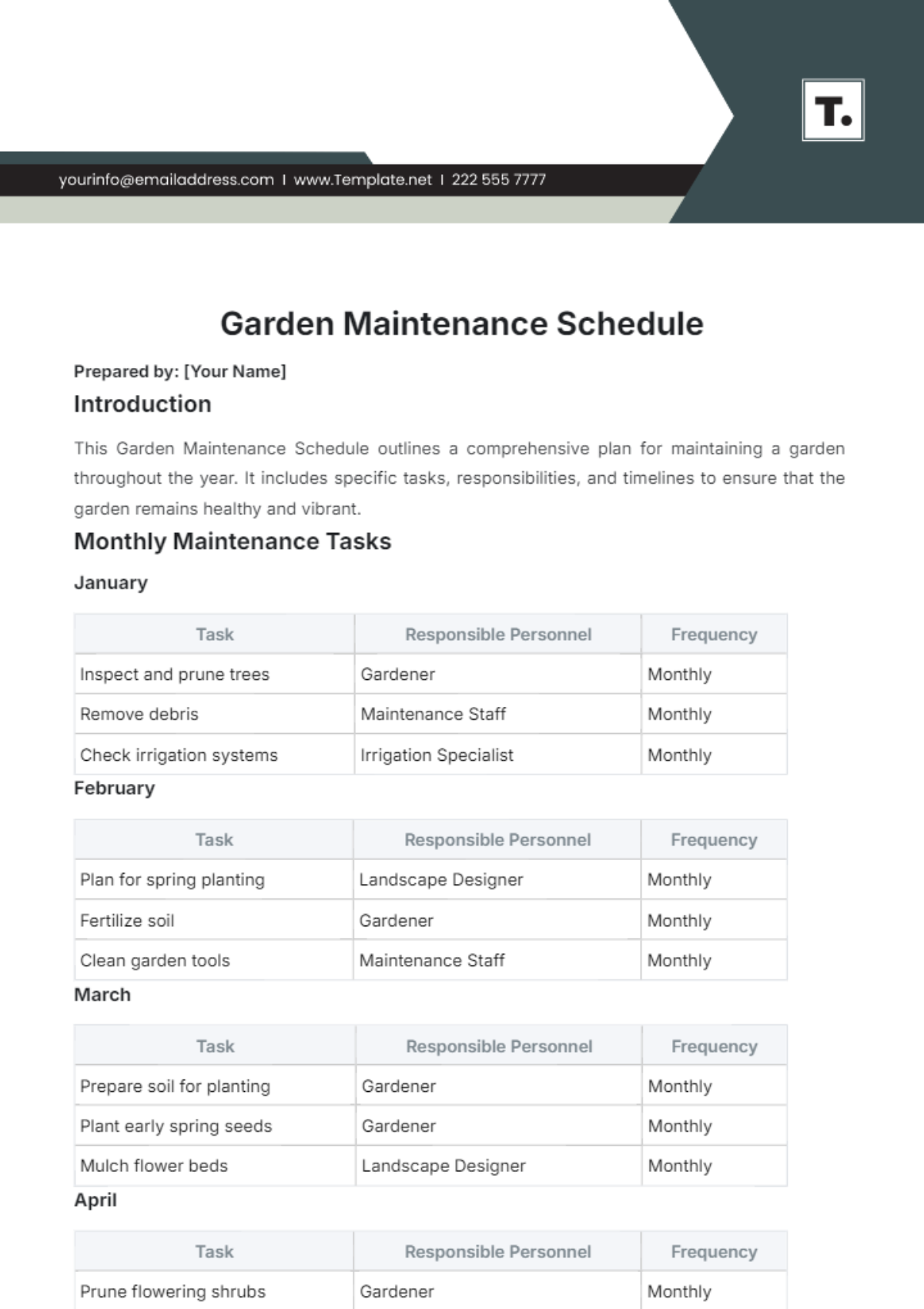

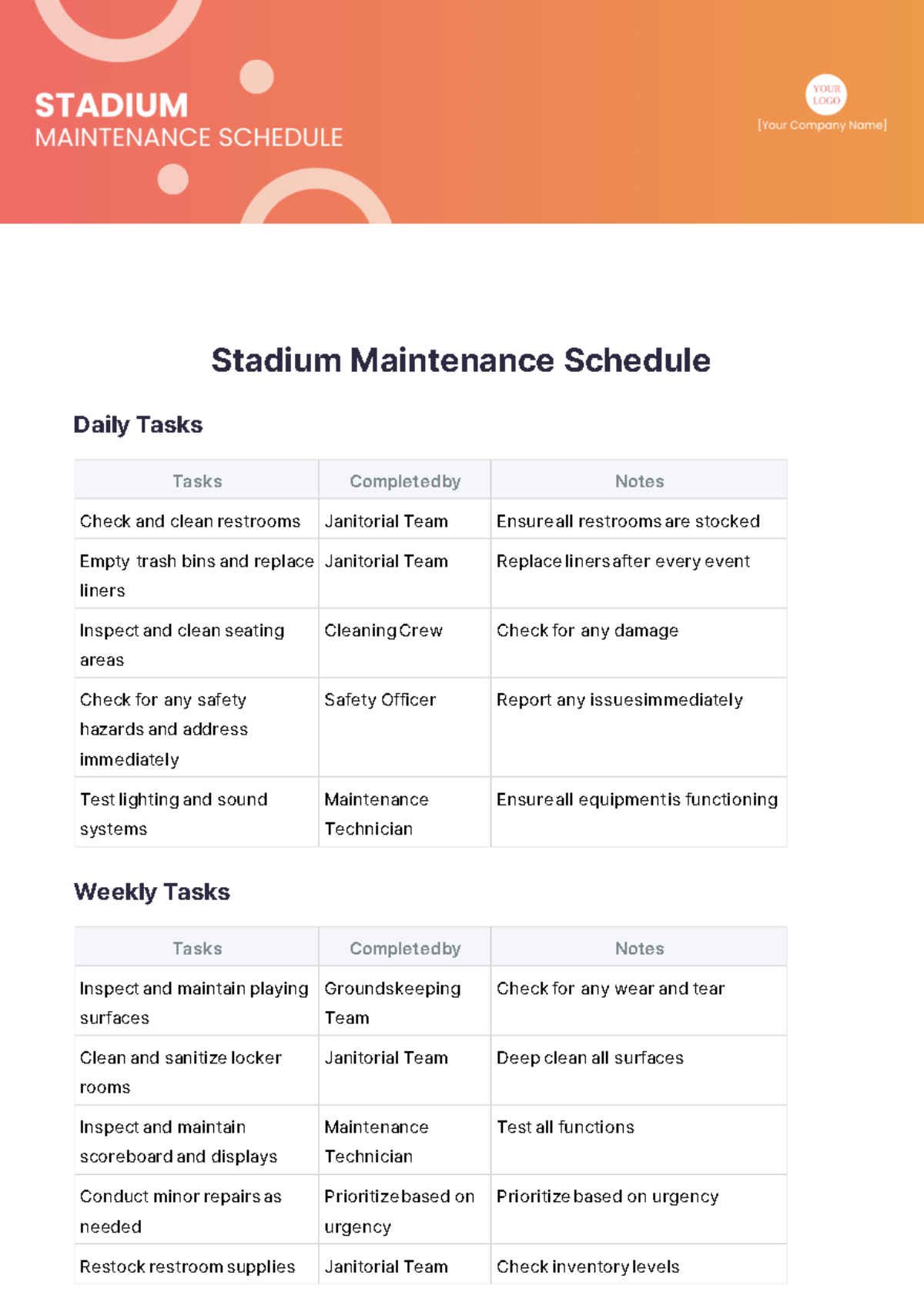

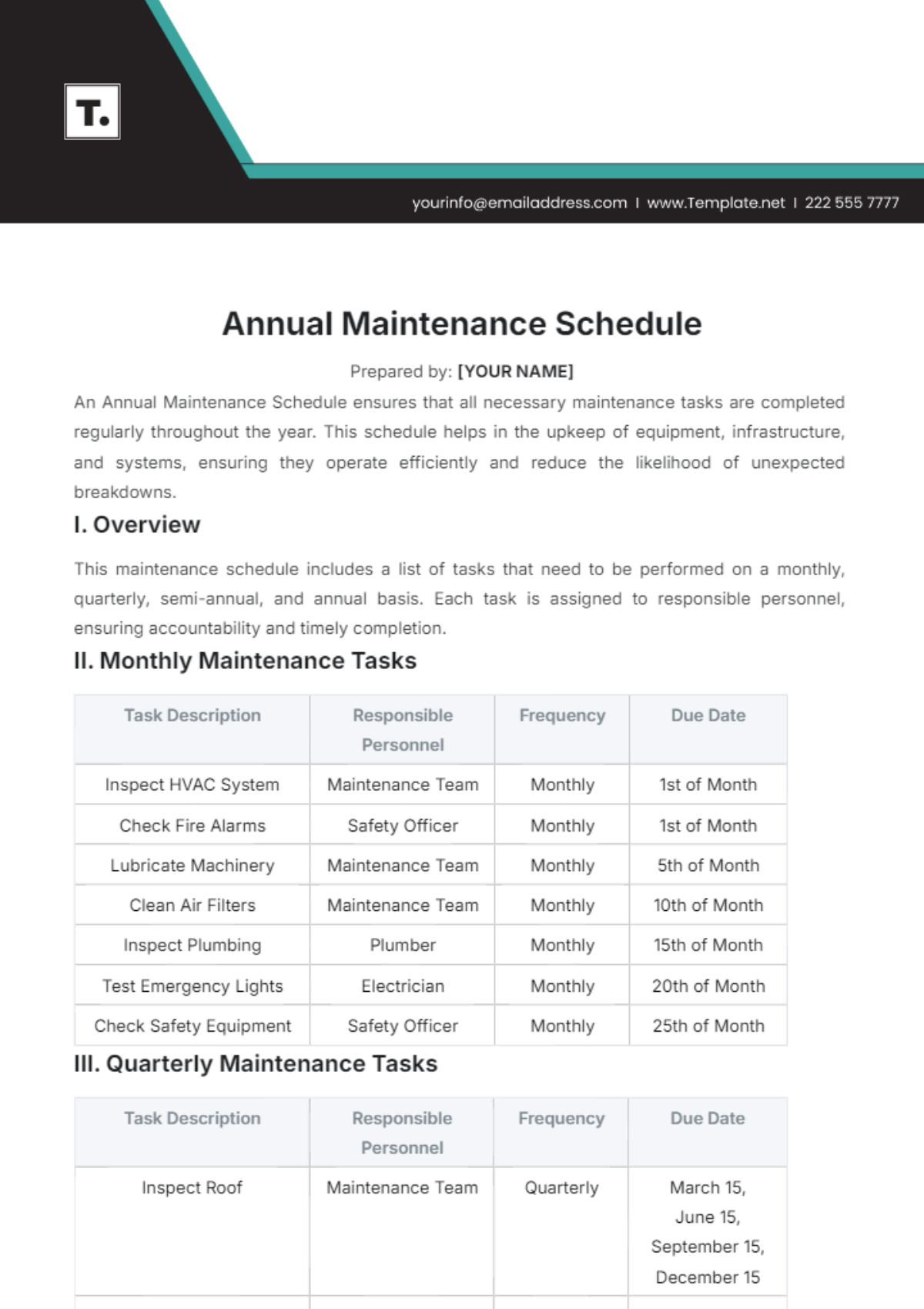

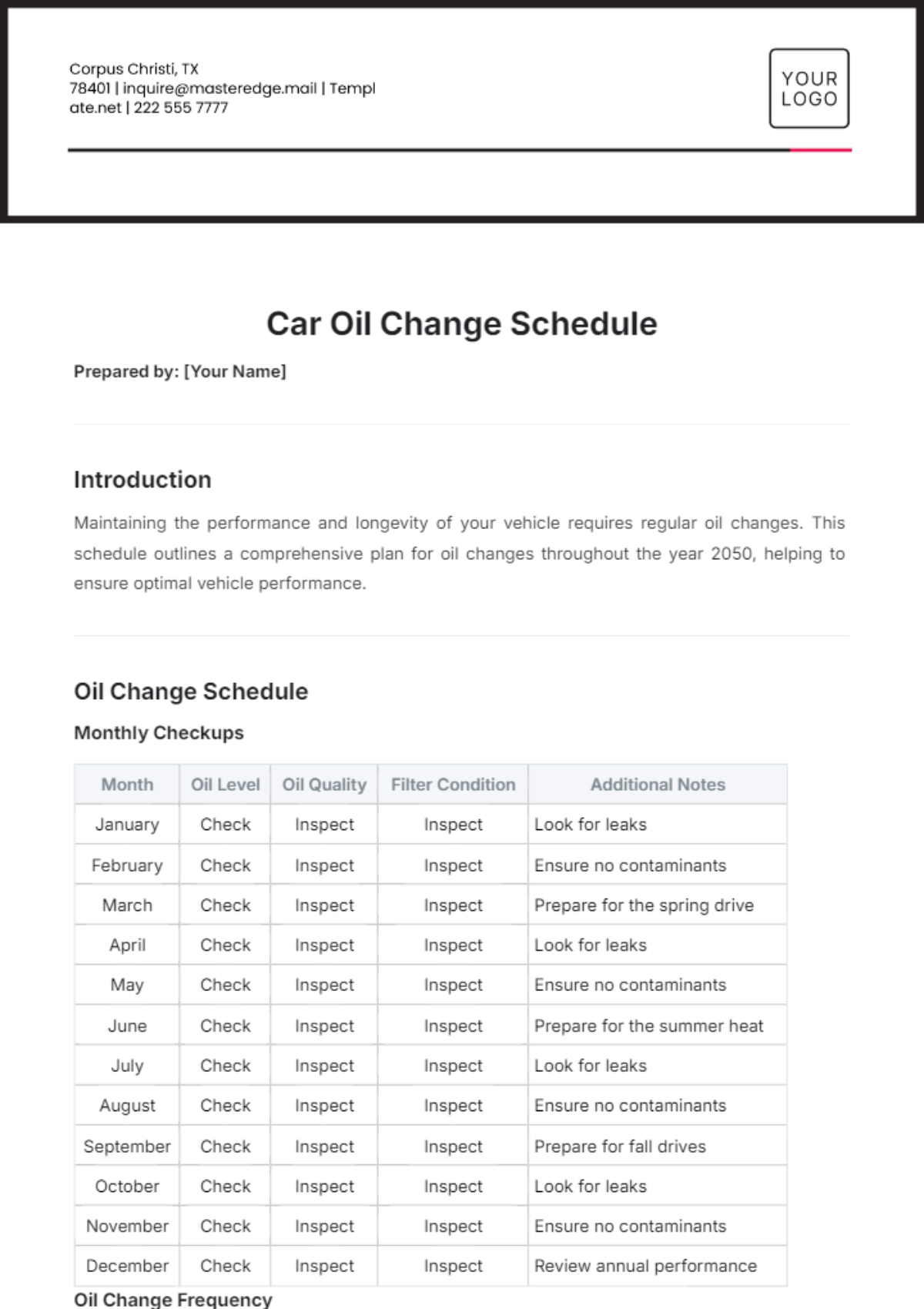

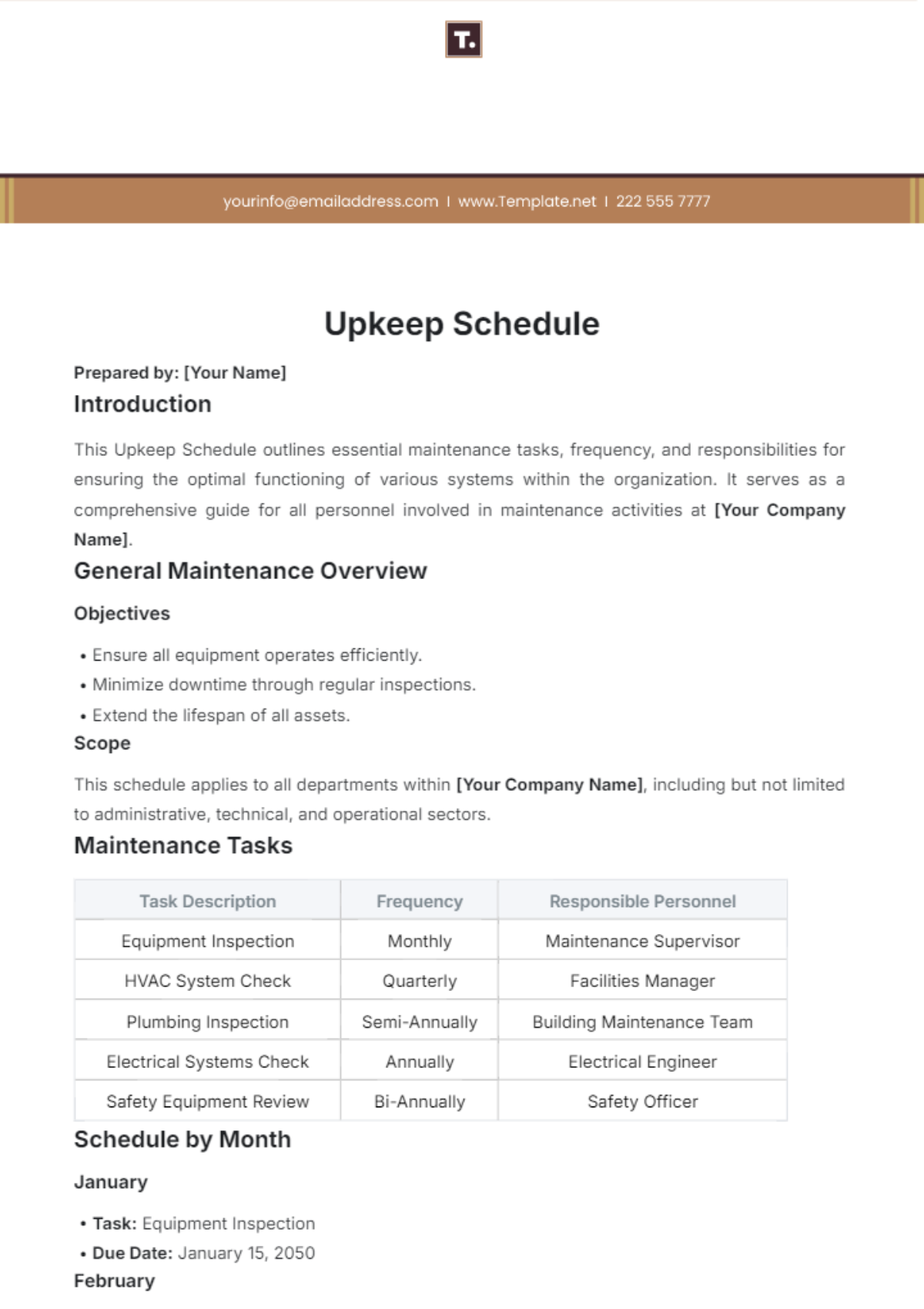

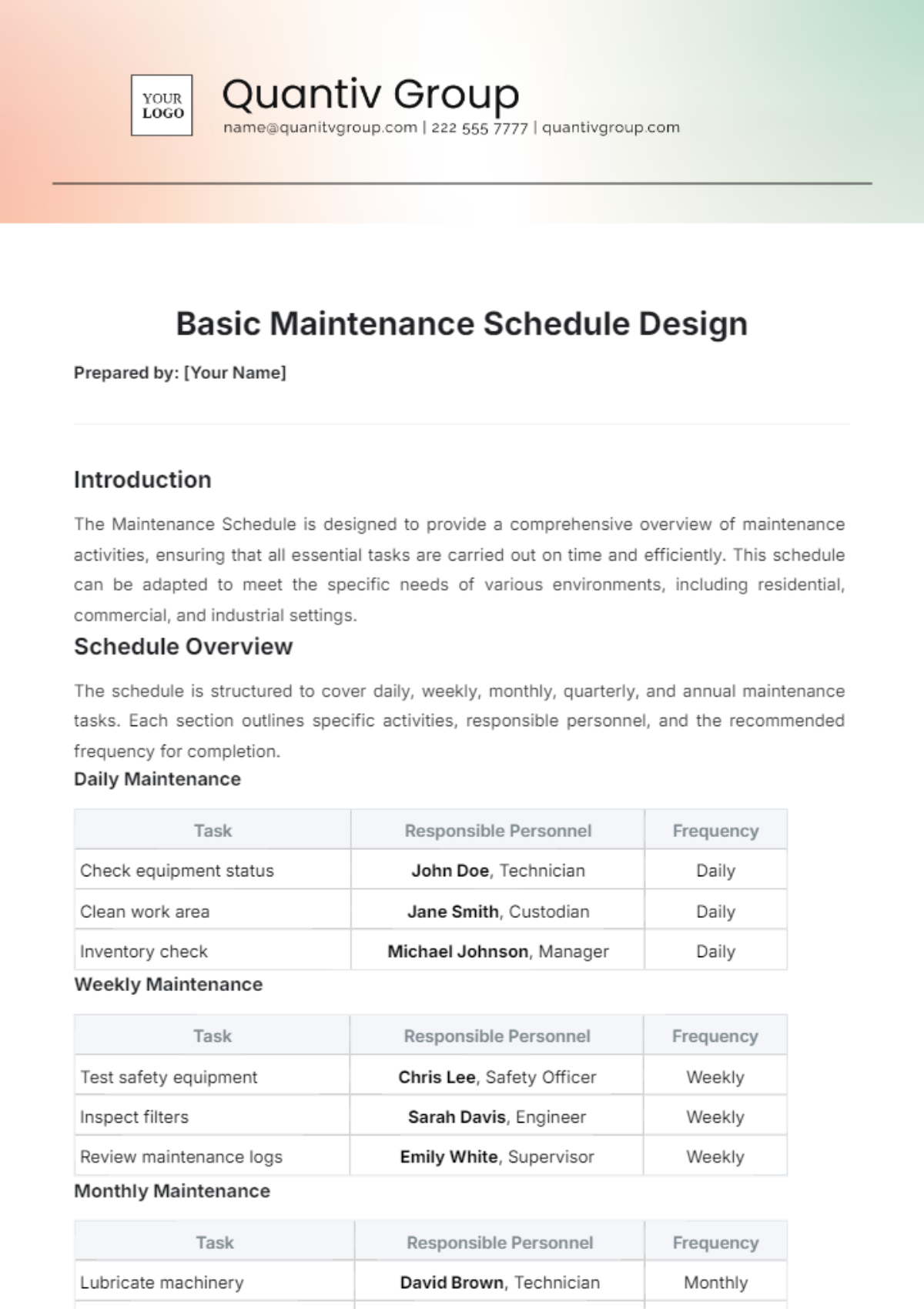

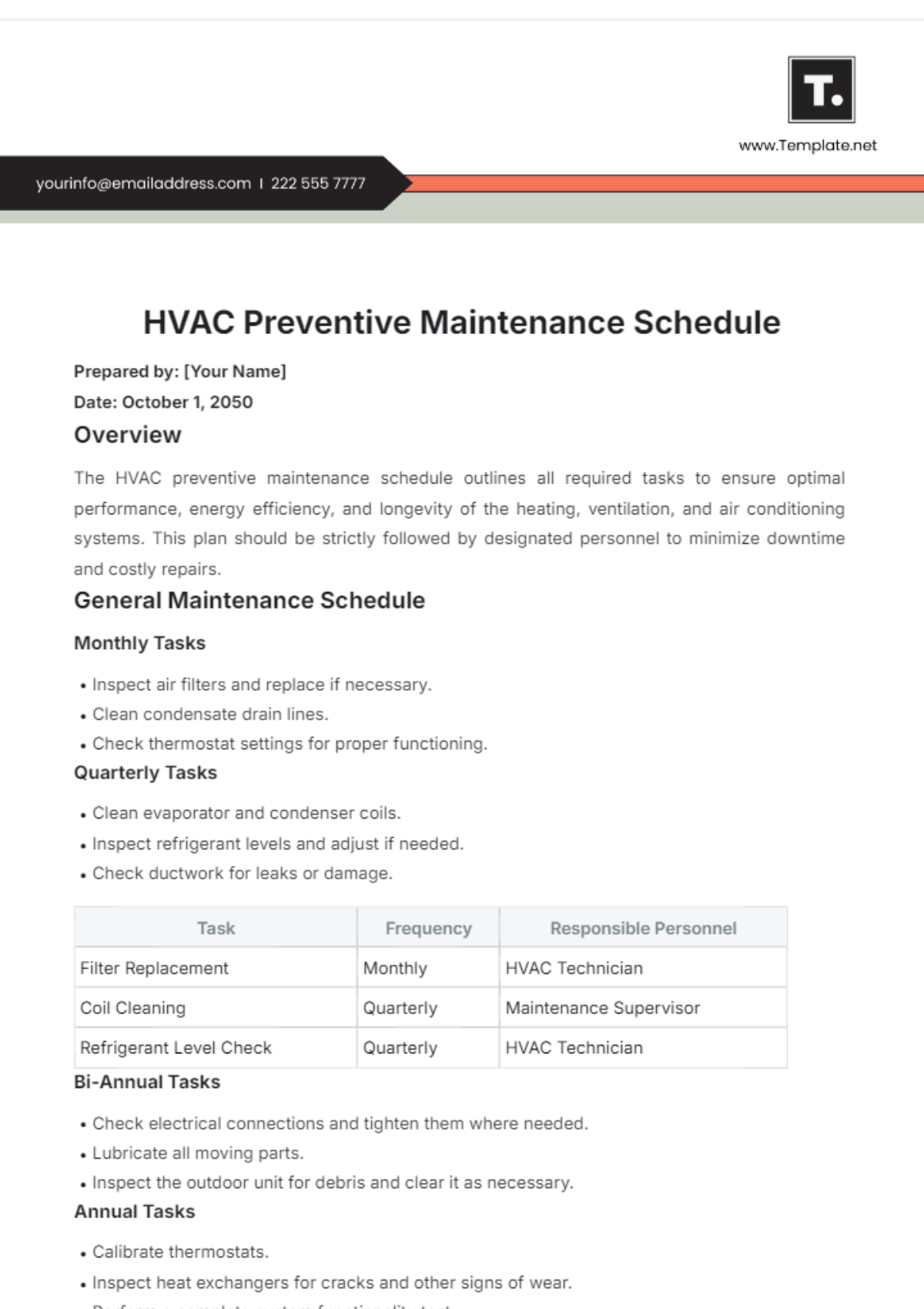

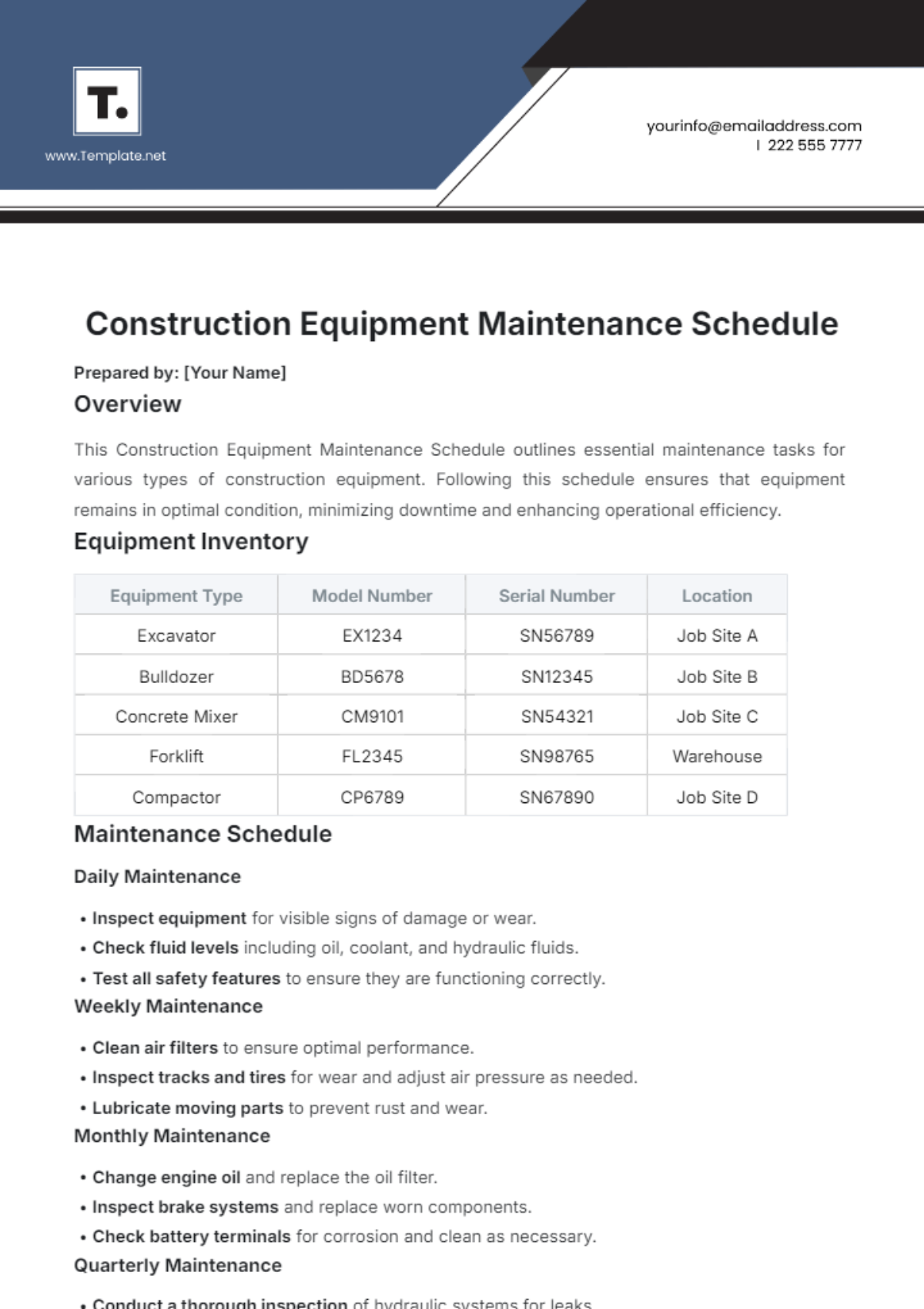

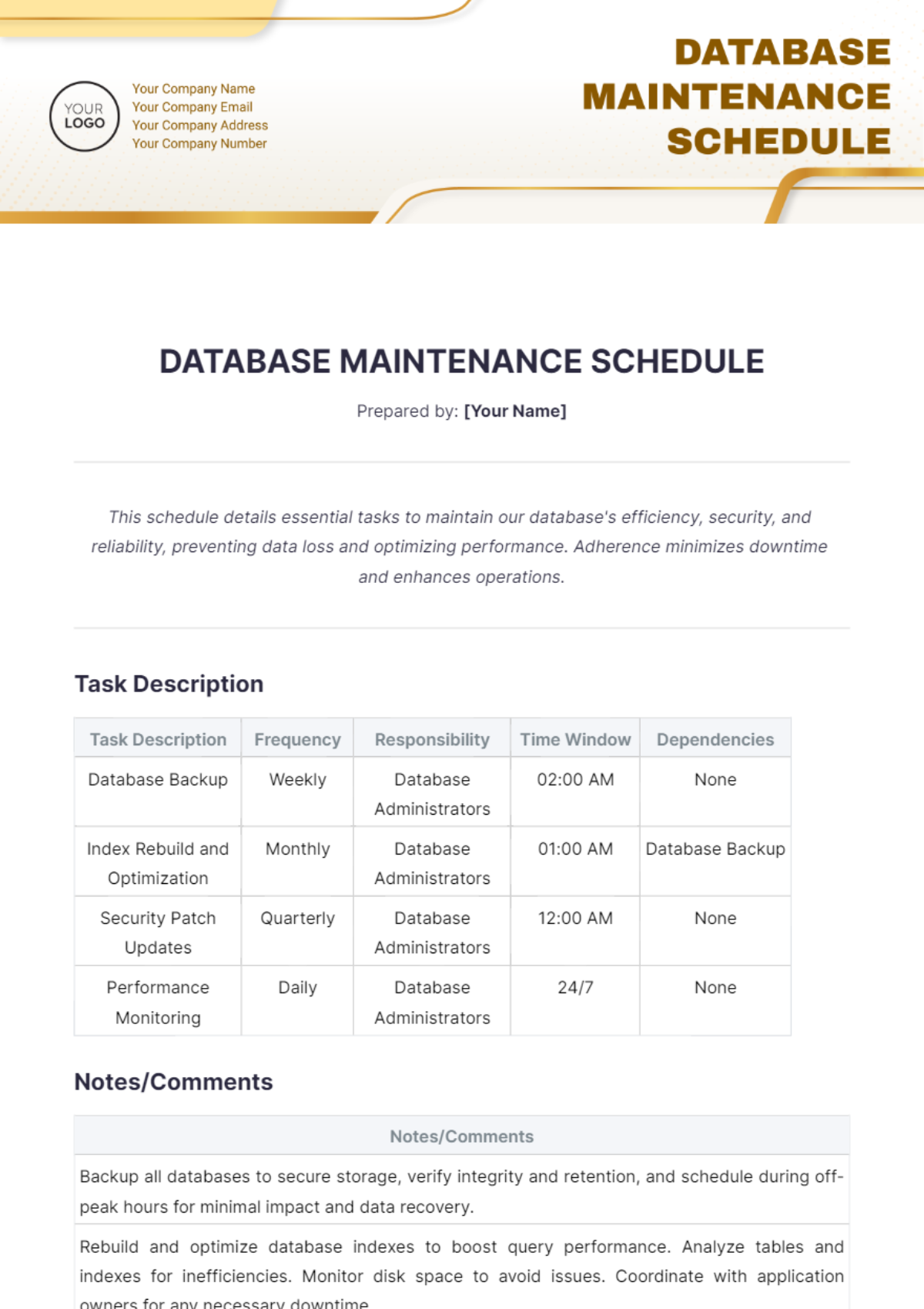

Task Description

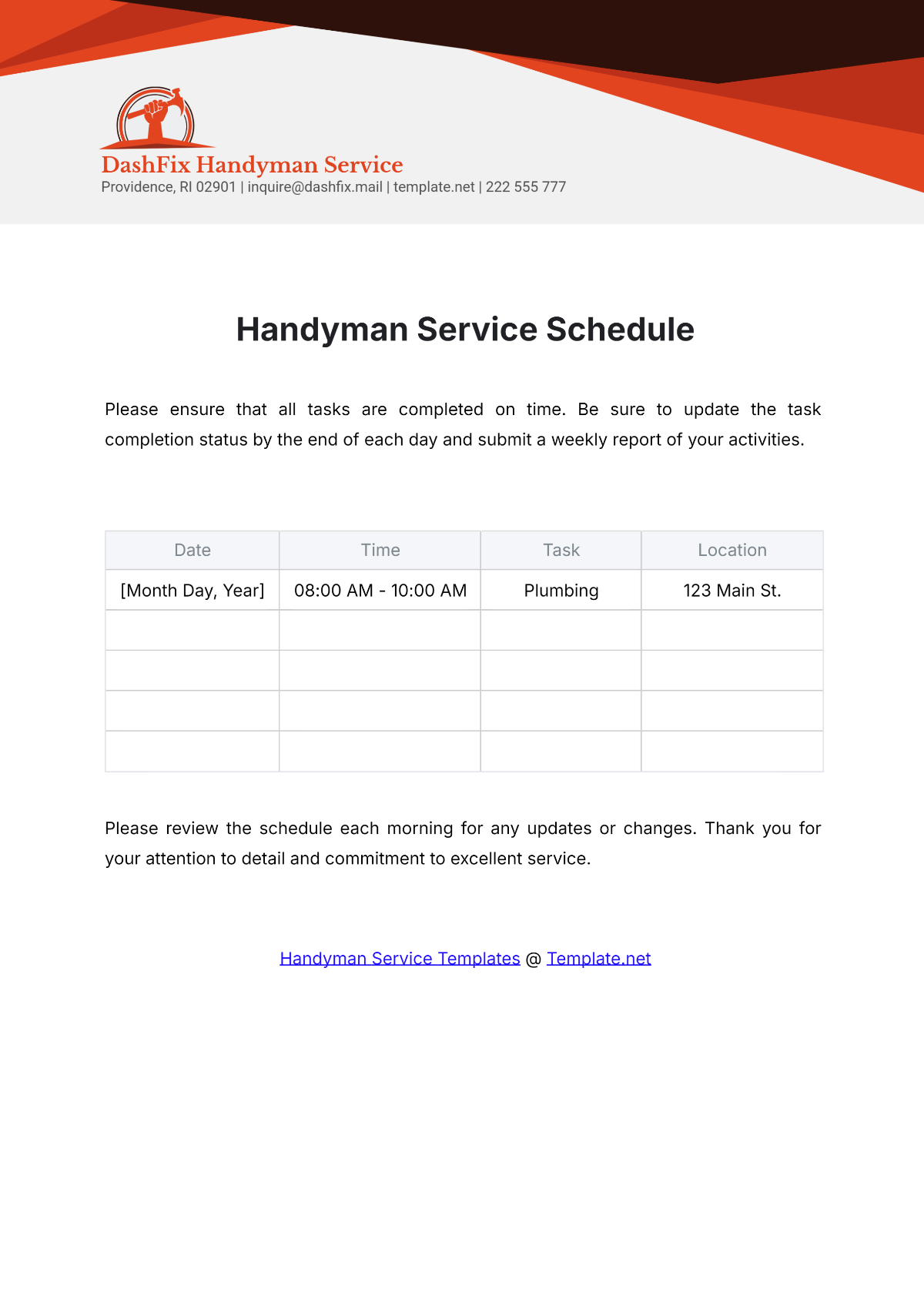

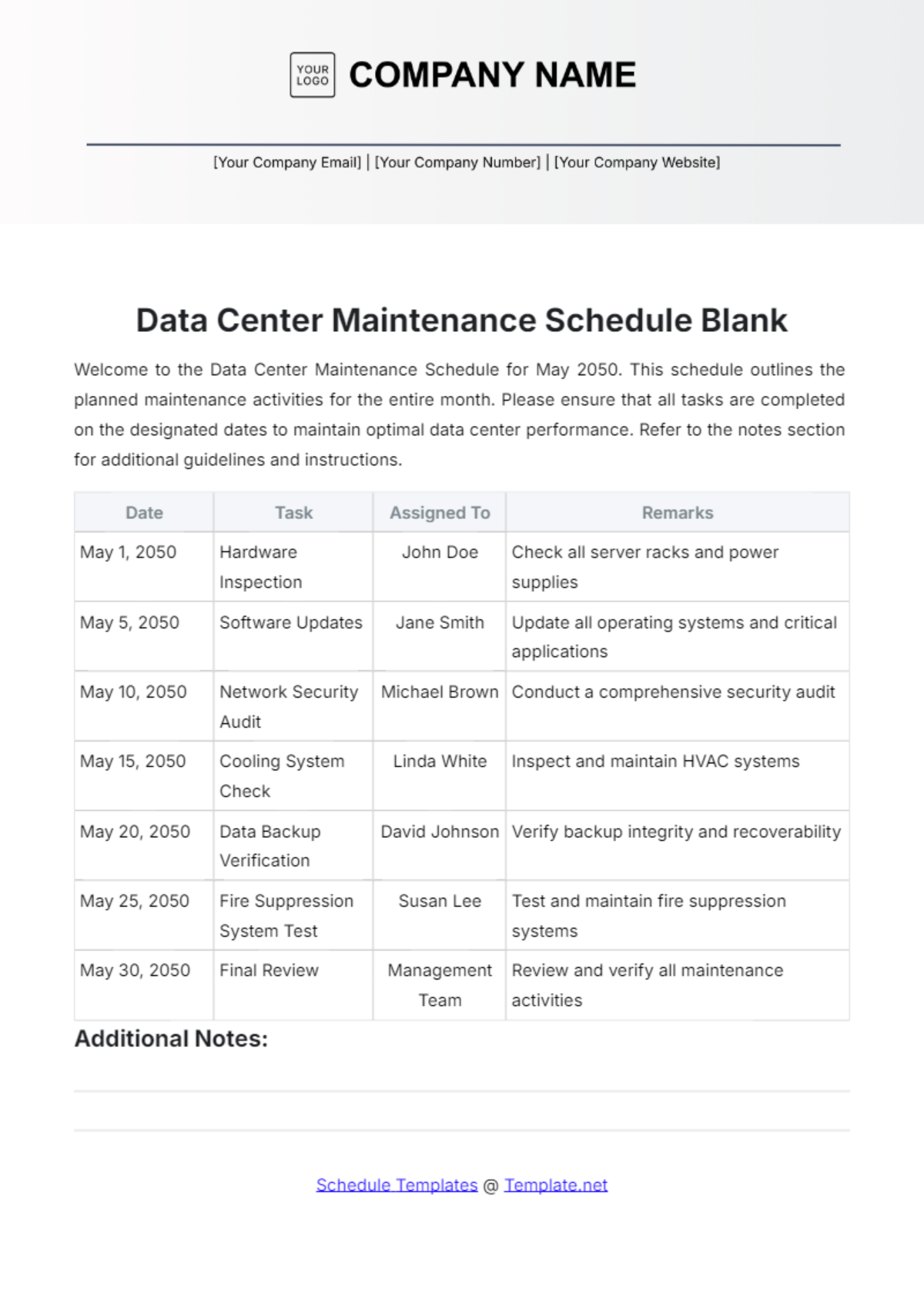

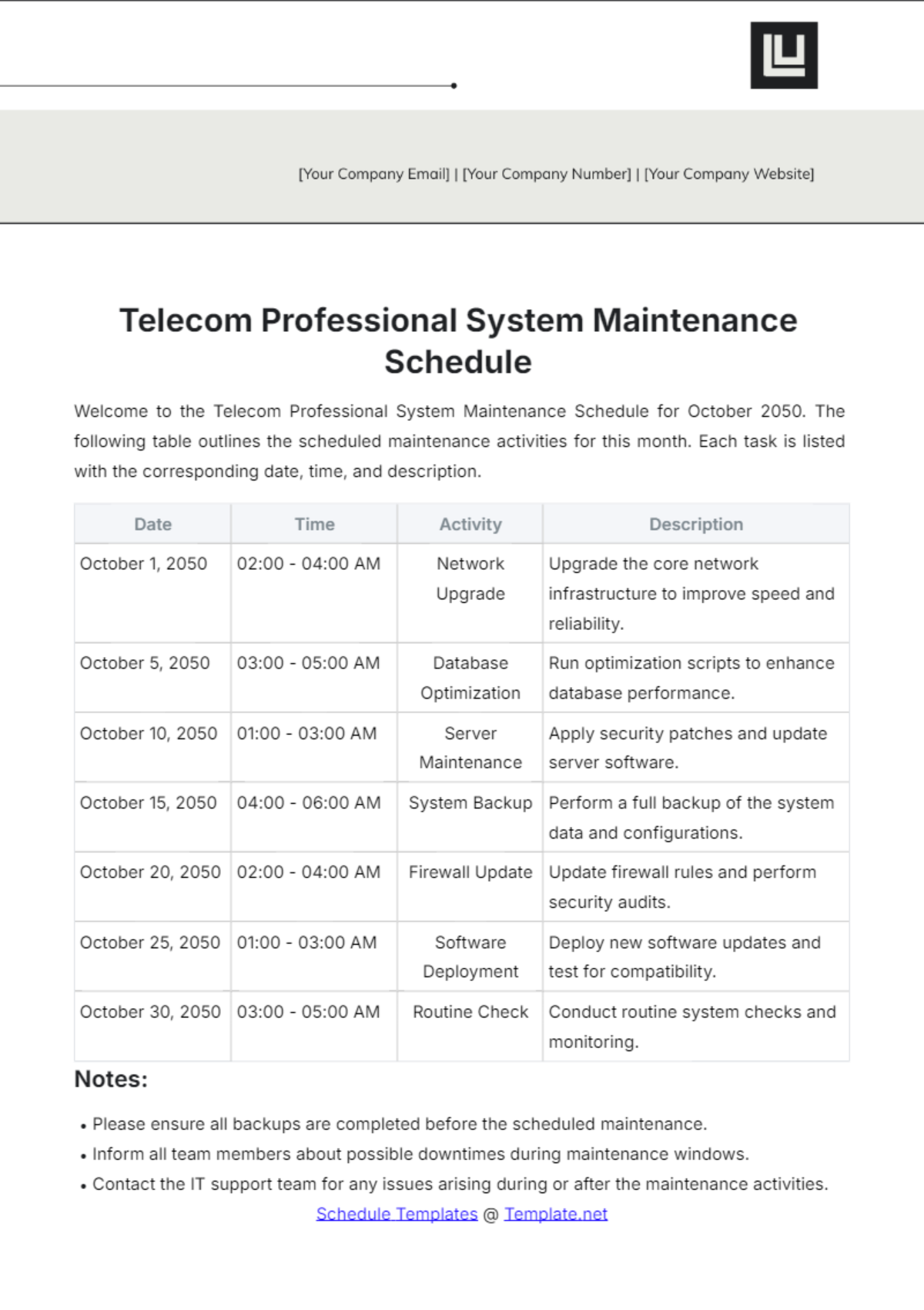

Task Description | Location | Scheduled Date |

|---|---|---|

Check and grease belts | Production Area A Belts | July 15, 2052 |

Replace filters; check airflow | Facility-wide HVAC systems | July 17, 2052 |

Test emergency lights | Emergency lighting across all floors | July 18, 2052 |

Clean and calibrate equipment | CNC machines and assembly lines | July 20, 2052 |

Repair plumbing leaks in offices | Office and restroom plumbing | July 22, 2052 |

Maintain electrical panels | Electrical panels in Equip Room B | July 25, 2052 |

Check fire systems | Warehouse C fire systems | July 27, 2052 |

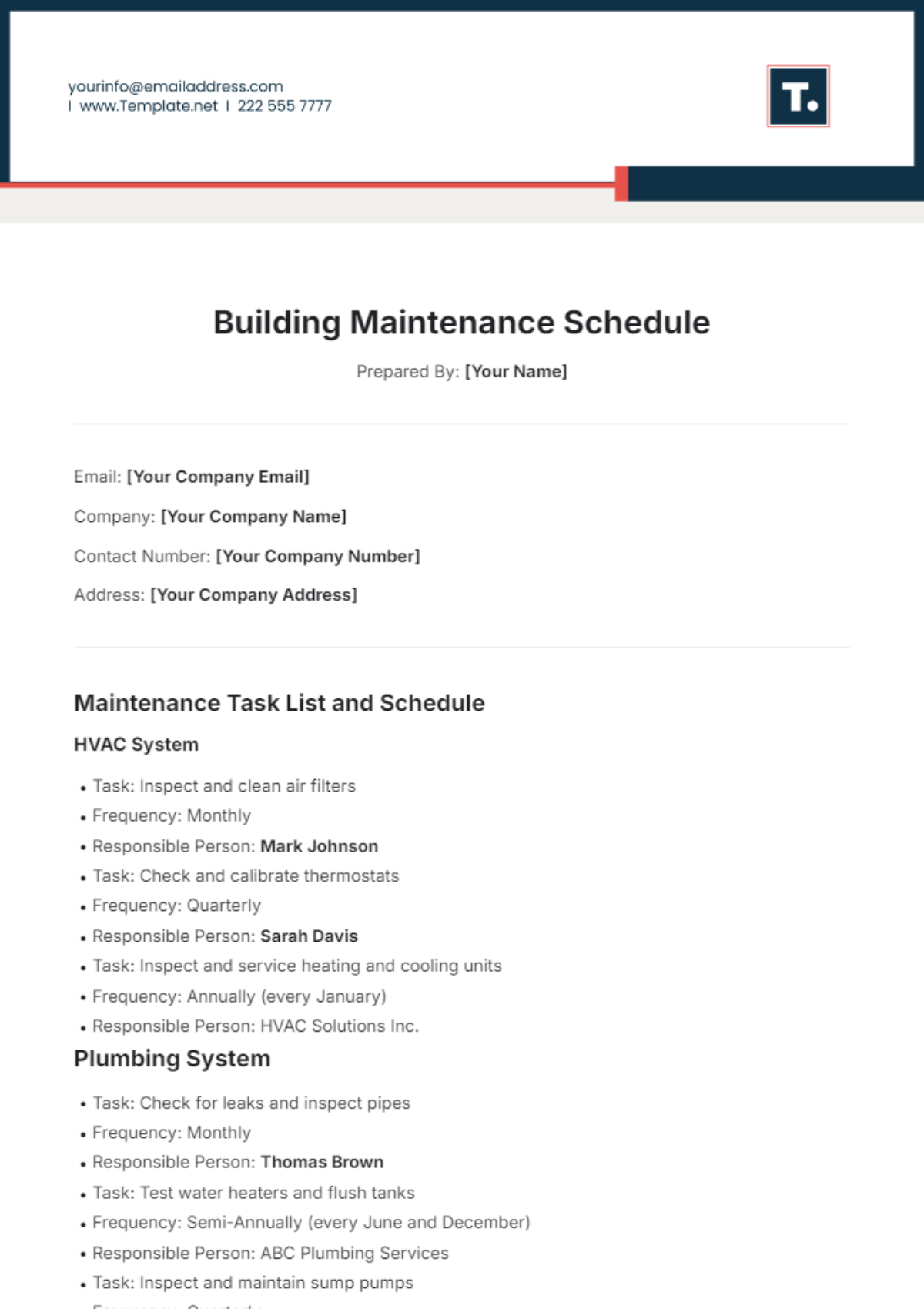

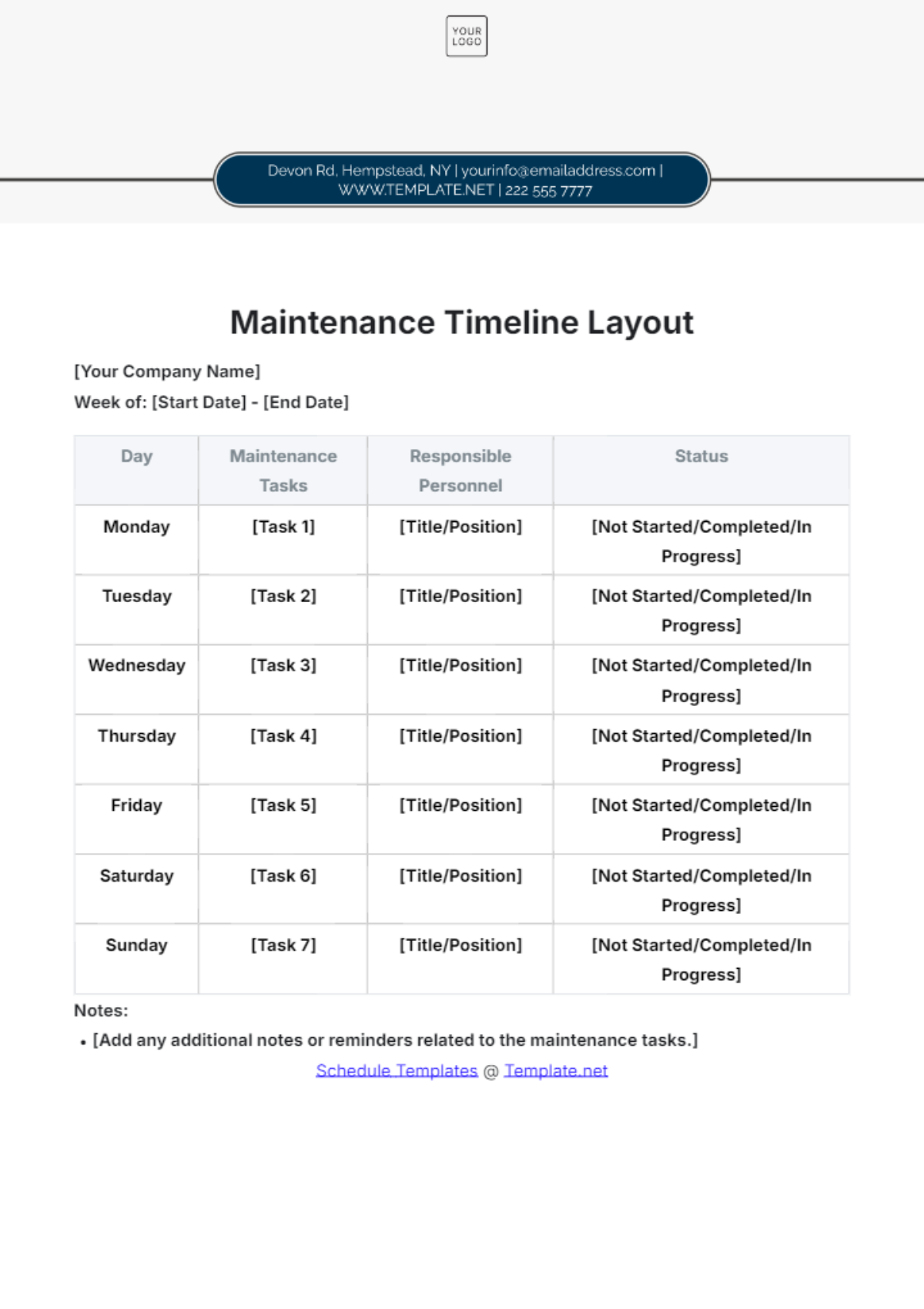

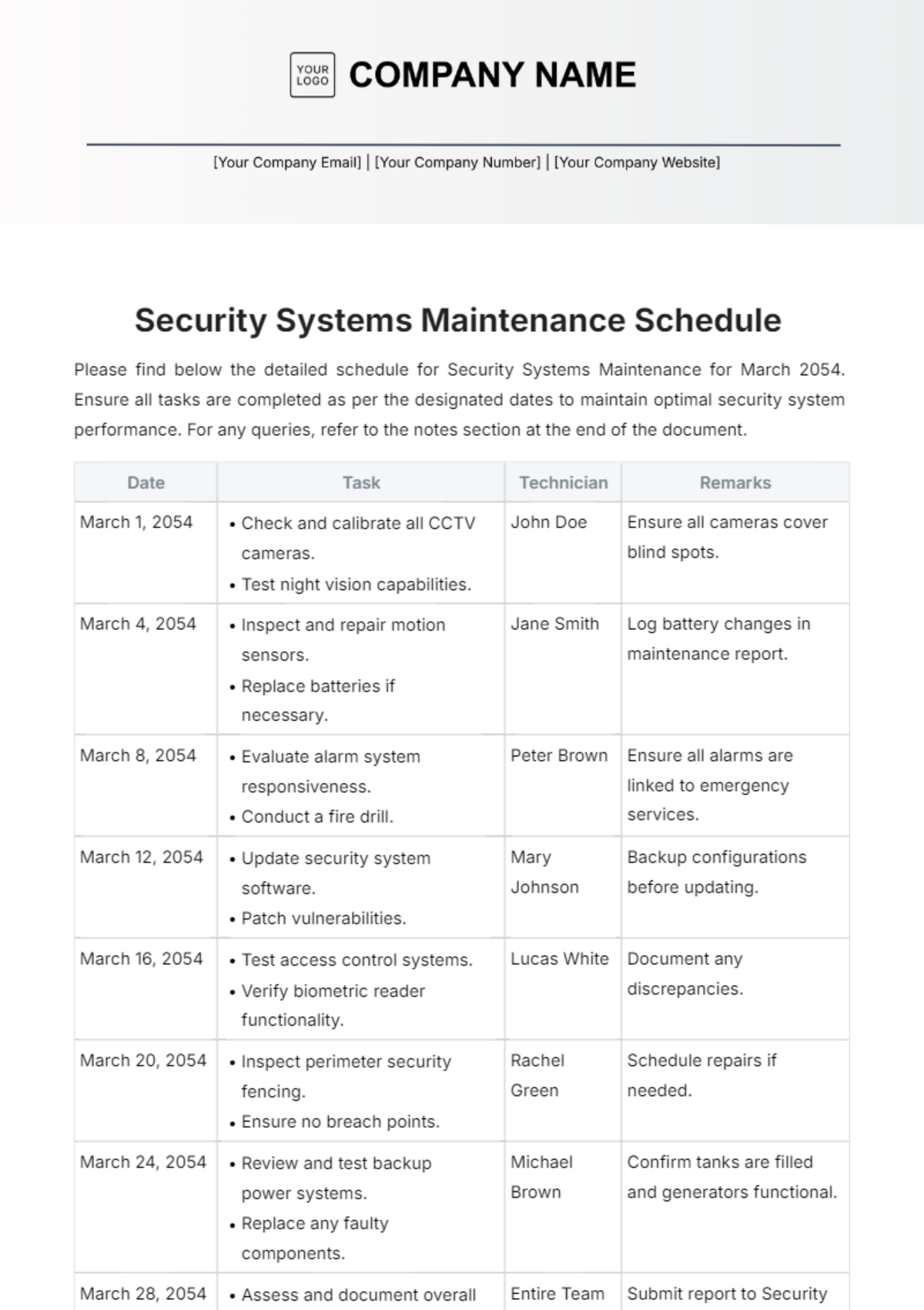

Assigned Technician/Team

✔️ | Task Description | Assigned Technician/Team |

|---|---|---|

Check and grease belts | John Smith - Maintenance Team A | |

Replace filters; check airflow | Sarah Johnson - HVAC Specialist | |

Test emergency lights | David Lee - Electrical Maintenance | |

Clean and calibrate equipment | Emily Brown - Plumbing Team | |

Repair plumbing leaks in offices | Mark Taylor - Fire Safety Inspector | |

Maintain electrical panels | Maintenance Team B | |

Check fire systems | Maintenance Team C |