Bakery Weekly Production Schedule Outline

1. Introduction

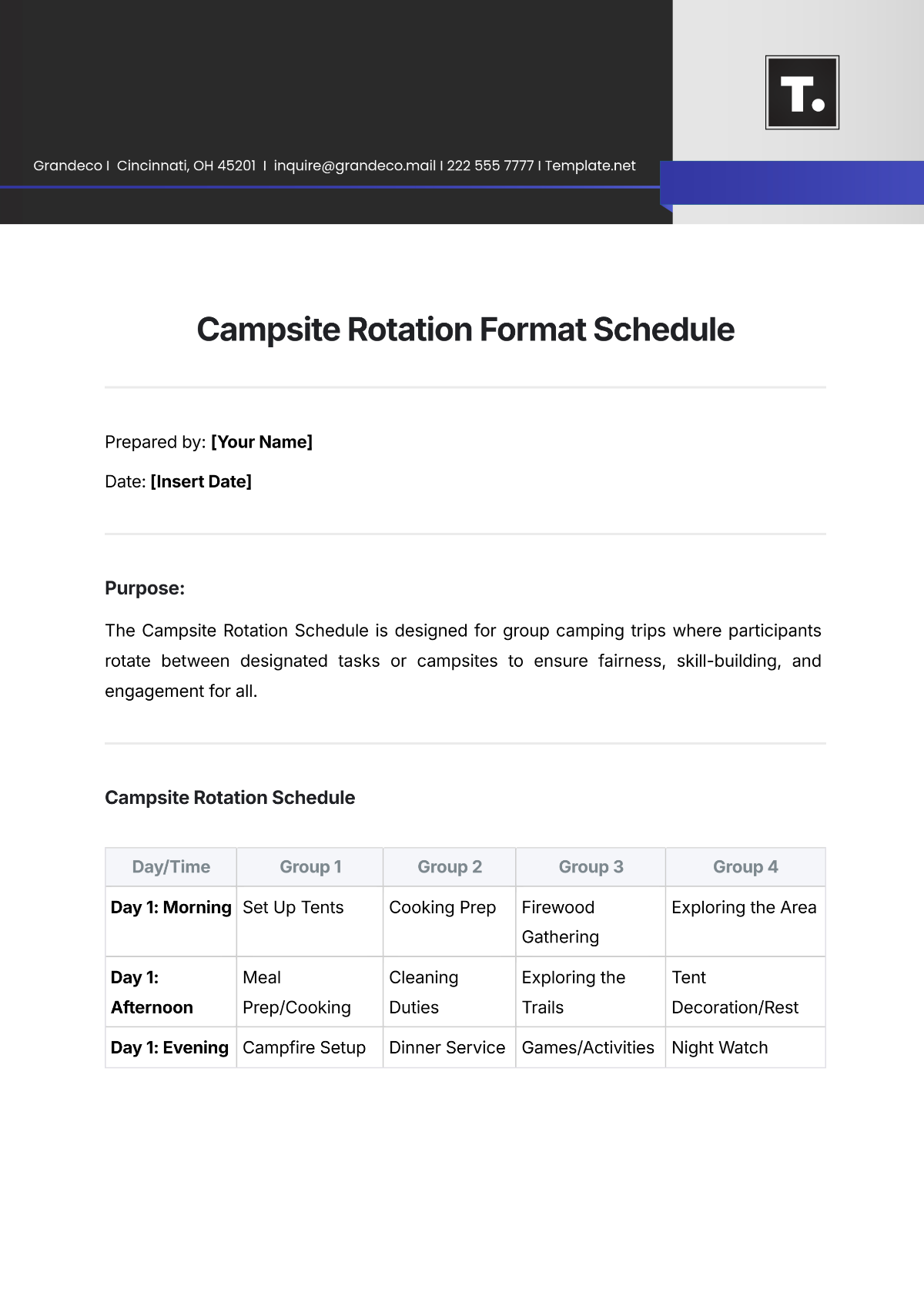

Purpose: (Explain the purpose of the weekly production schedule.)

Scope: (Outline the scope, including the types of products covered (bread, pastries, cakes, etc.).)

2. Weekly Overview

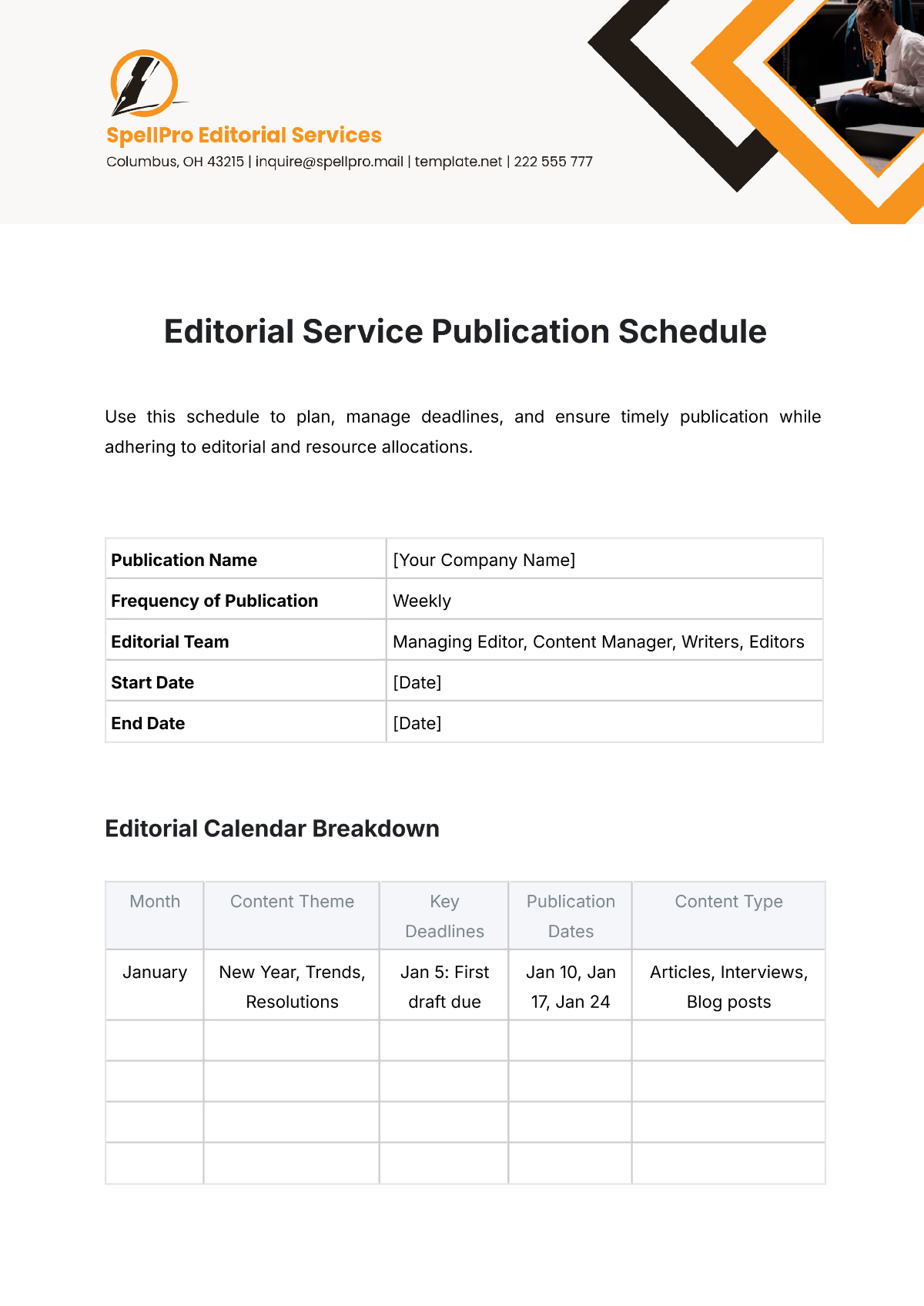

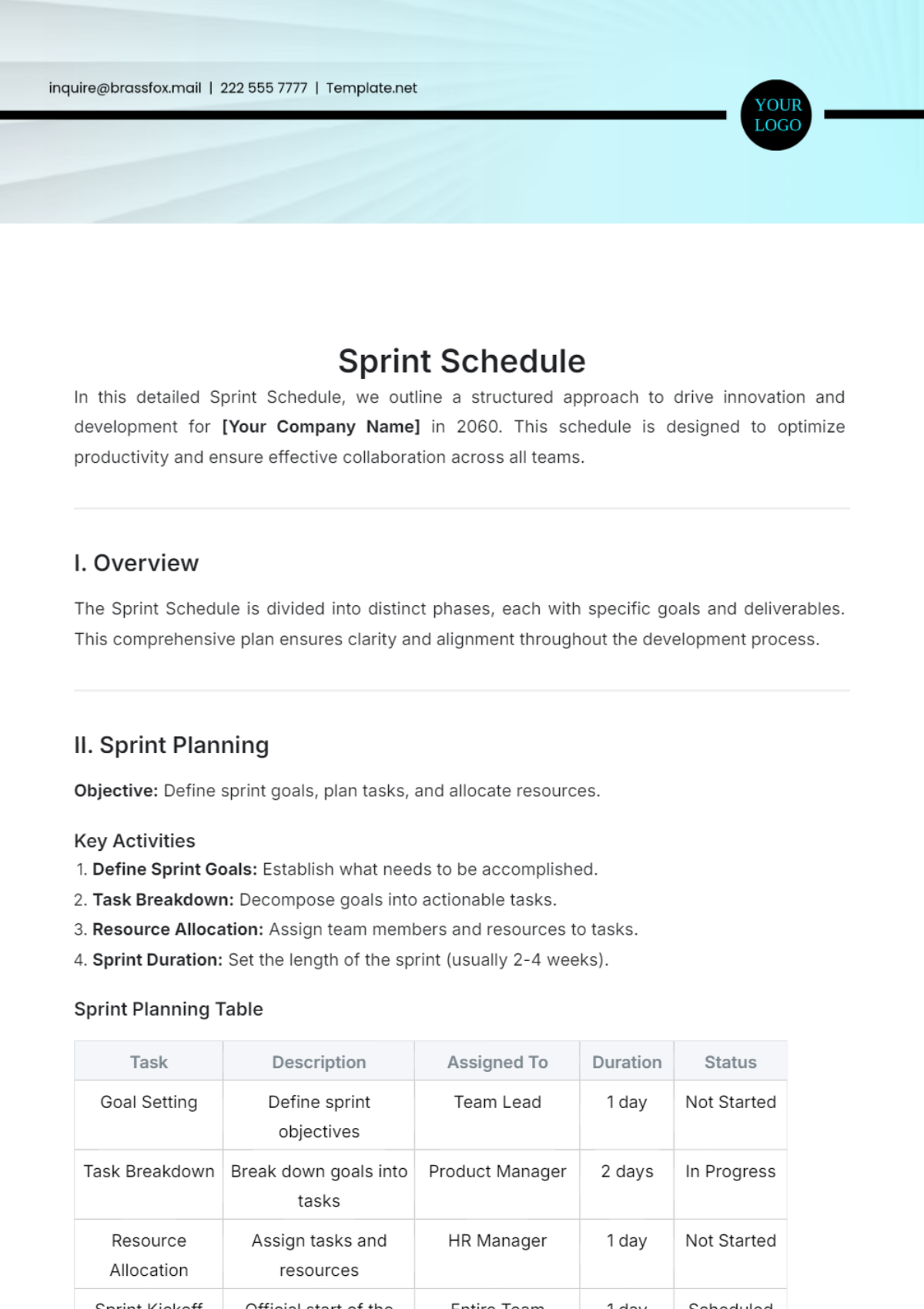

Production Goals: (Define the production goals for the week.)

Key Activities: (Highlight key activities such as ingredient preparation, baking, packaging, and delivery.)

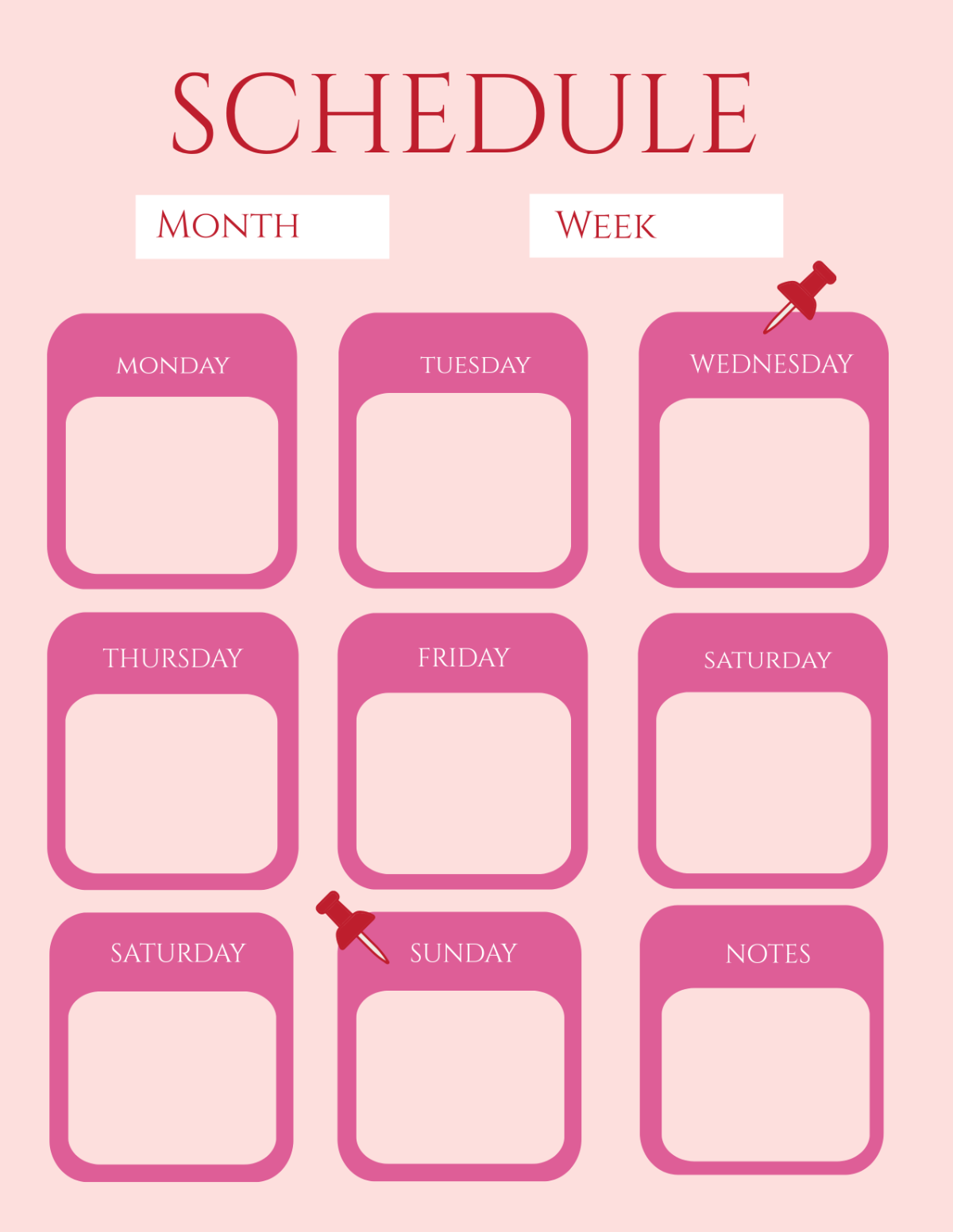

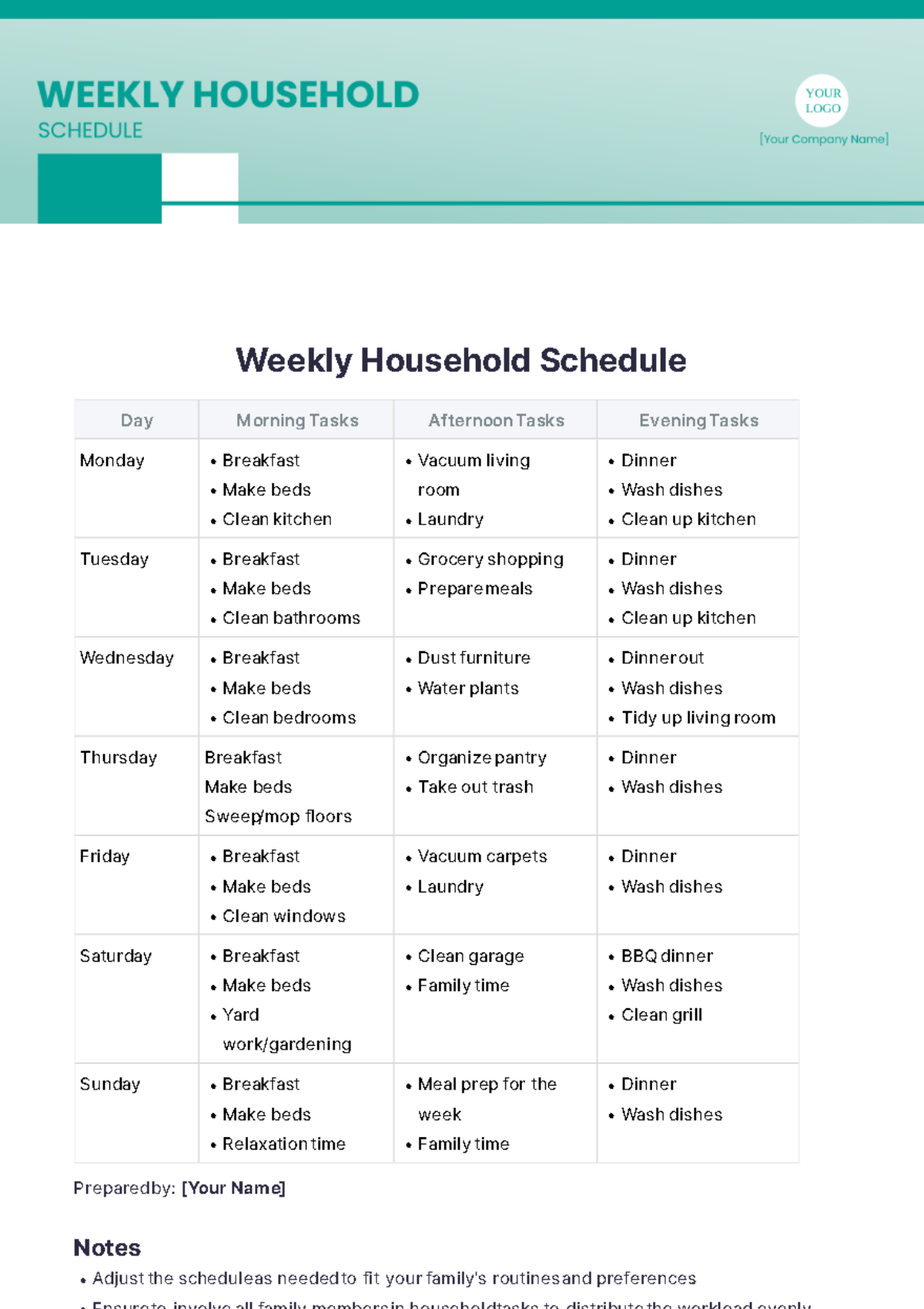

3. Daily Schedule Breakdown

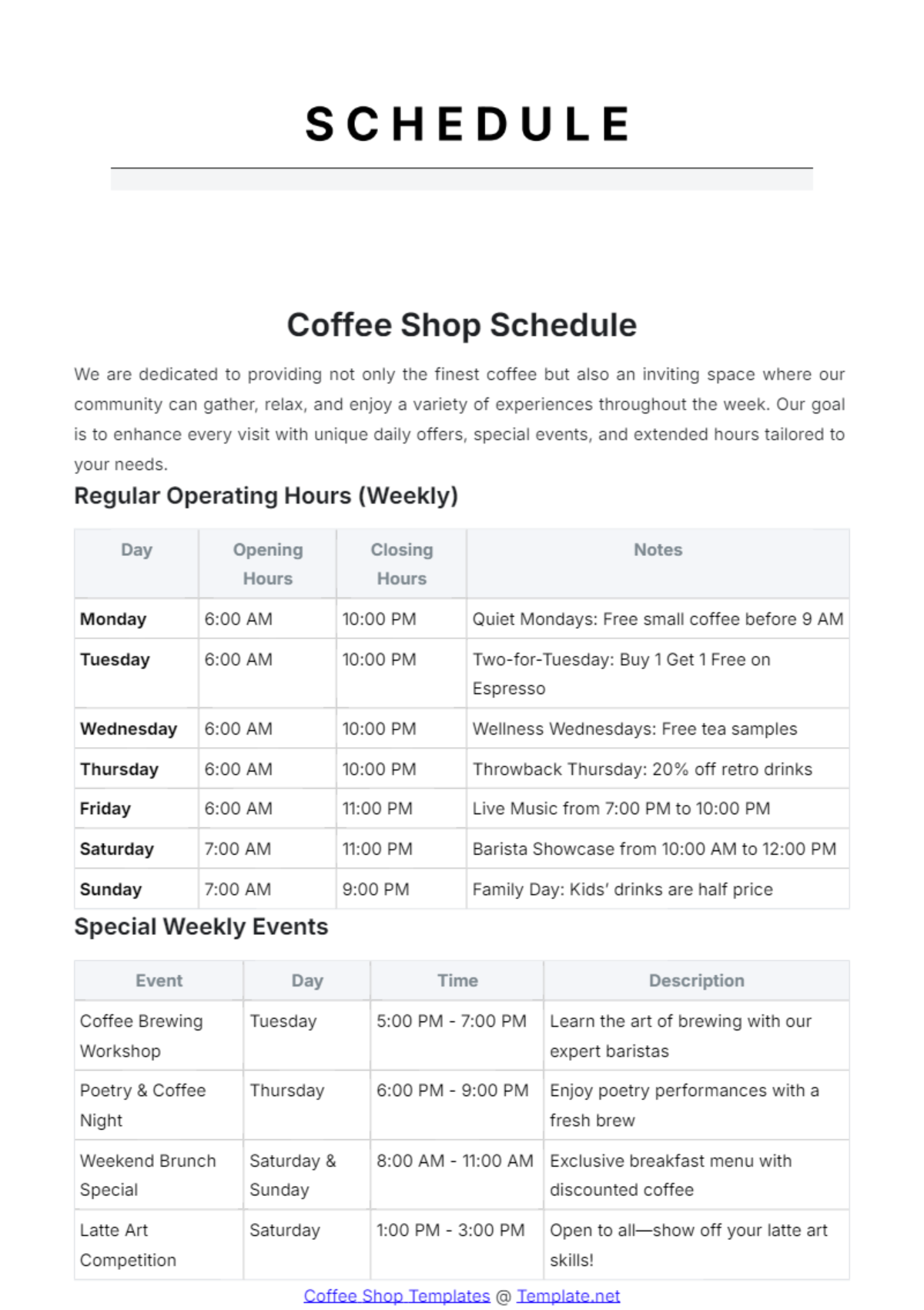

Monday:

Preparation Tasks: (Inventory check, ingredient prep, dough mixing.)

Production Tasks: (Baking breads, initial pastry preparation.)

Post-Production Tasks: (Cleaning, equipment maintenance.)

Tuesday:

Preparation Tasks: (Continuation of dough prep, pre-baking setup.)

Production Tasks: (Baking pastries, cake preparation.)

Post-Production Tasks: (Packaging, labeling.)

Wednesday:

Preparation Tasks: (Ingredient restocking, special orders prep.)

Production Tasks: (Specialty bread and pastry baking.)

Post-Production Tasks: (Delivery preparation, stock rotation.)

Thursday:

Preparation Tasks: (Dough prep, mise en place for cakes.)

Production Tasks: (Cake baking, icing, and decoration.)

Post-Production Tasks: (Quality checks, packaging.)

Friday:

Preparation Tasks: (Final ingredient prep for the weekend.)

Production Tasks: (Bulk baking for weekend demand.)

Post-Production Tasks: (Storage and delivery prep.)

Saturday:

Preparation Tasks: (Early morning setup.)

Production Tasks: (High-volume baking, fresh pastries.)

Post-Production Tasks: (Customer order fulfillment, stock checks.)

Sunday:

Preparation Tasks: (Light ingredient prep.)

Production Tasks: (Specialty items, small batch baking.)

Post-Production Tasks: (End-of-week cleaning, maintenance.)

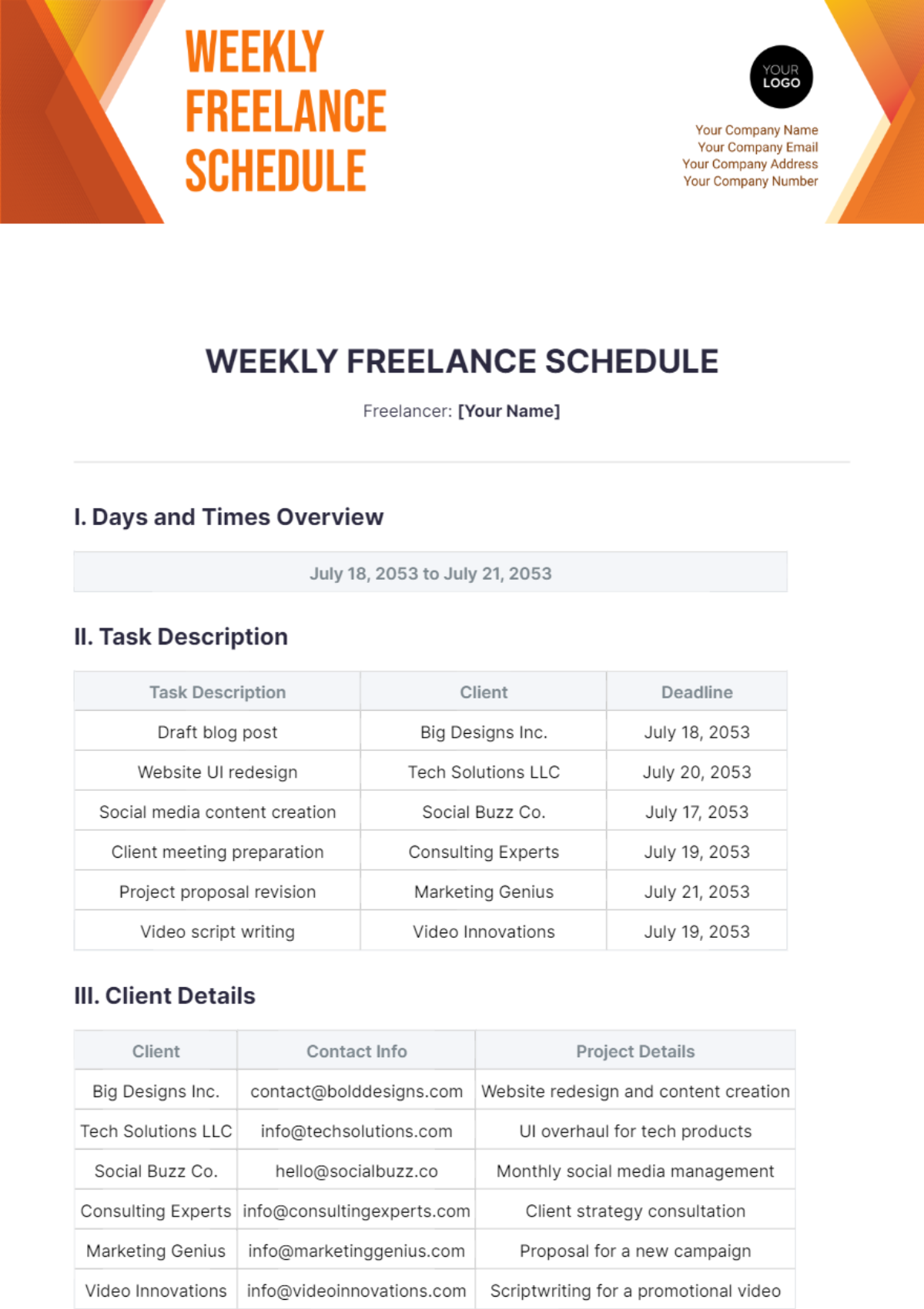

4. Resource Allocation

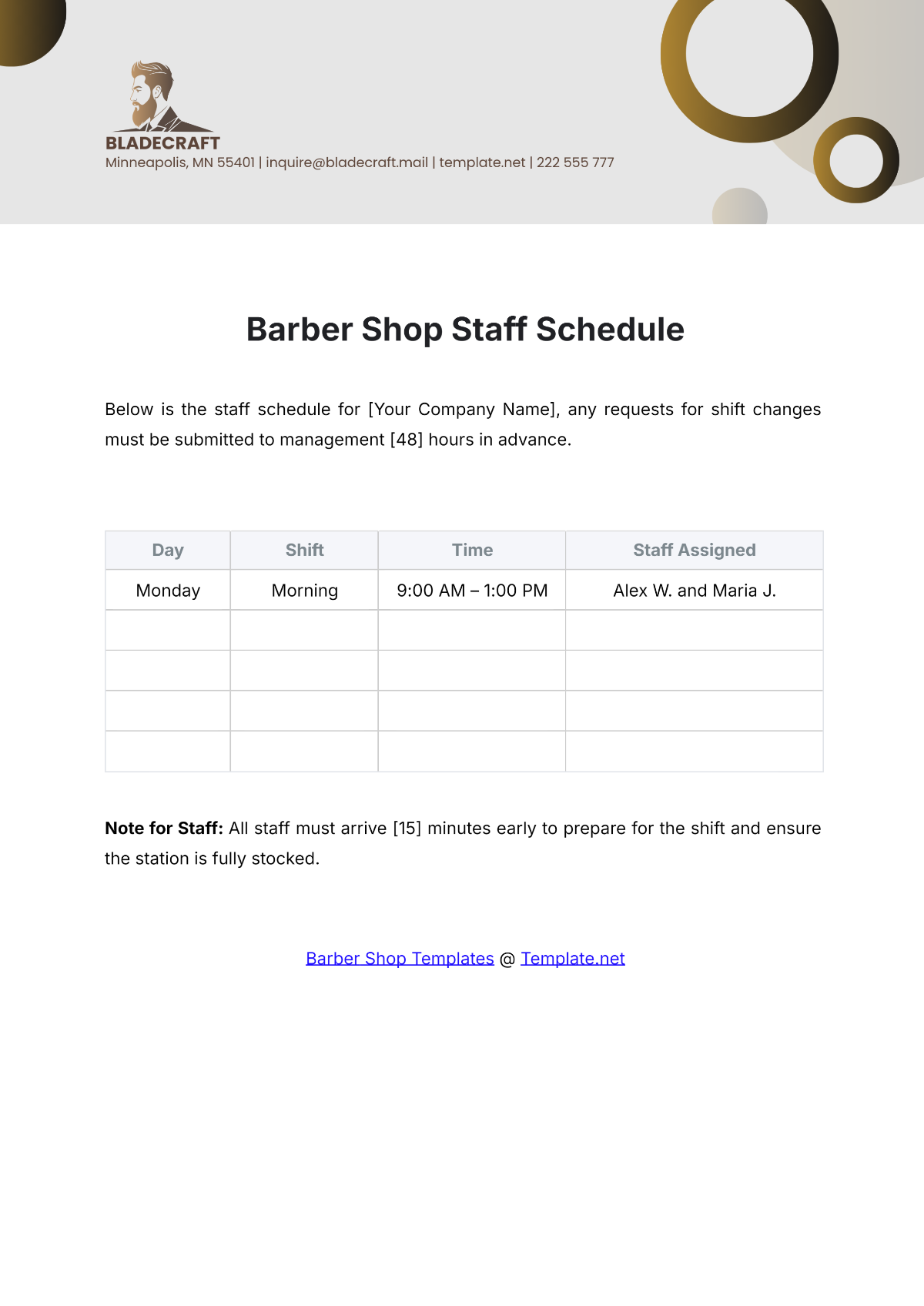

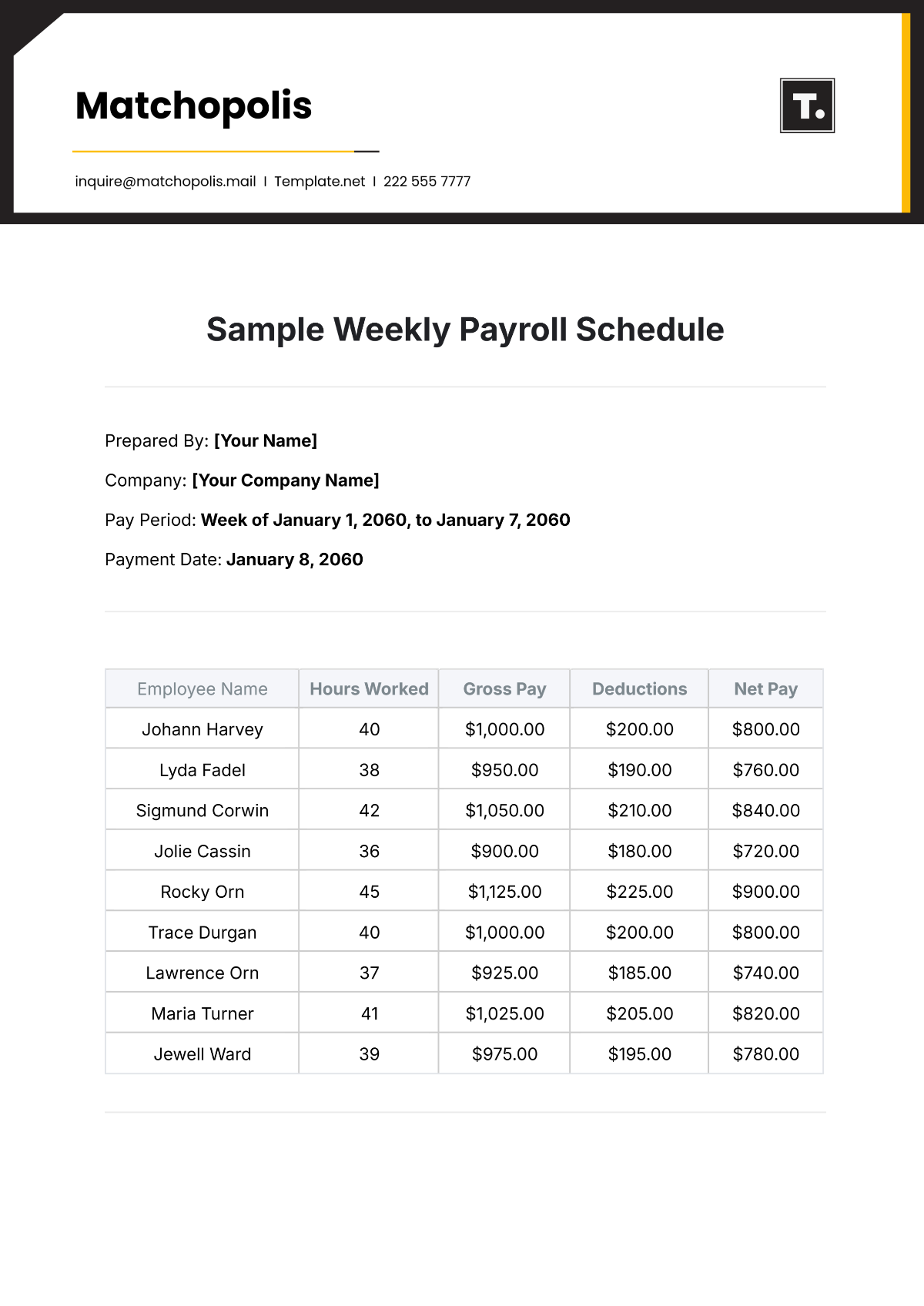

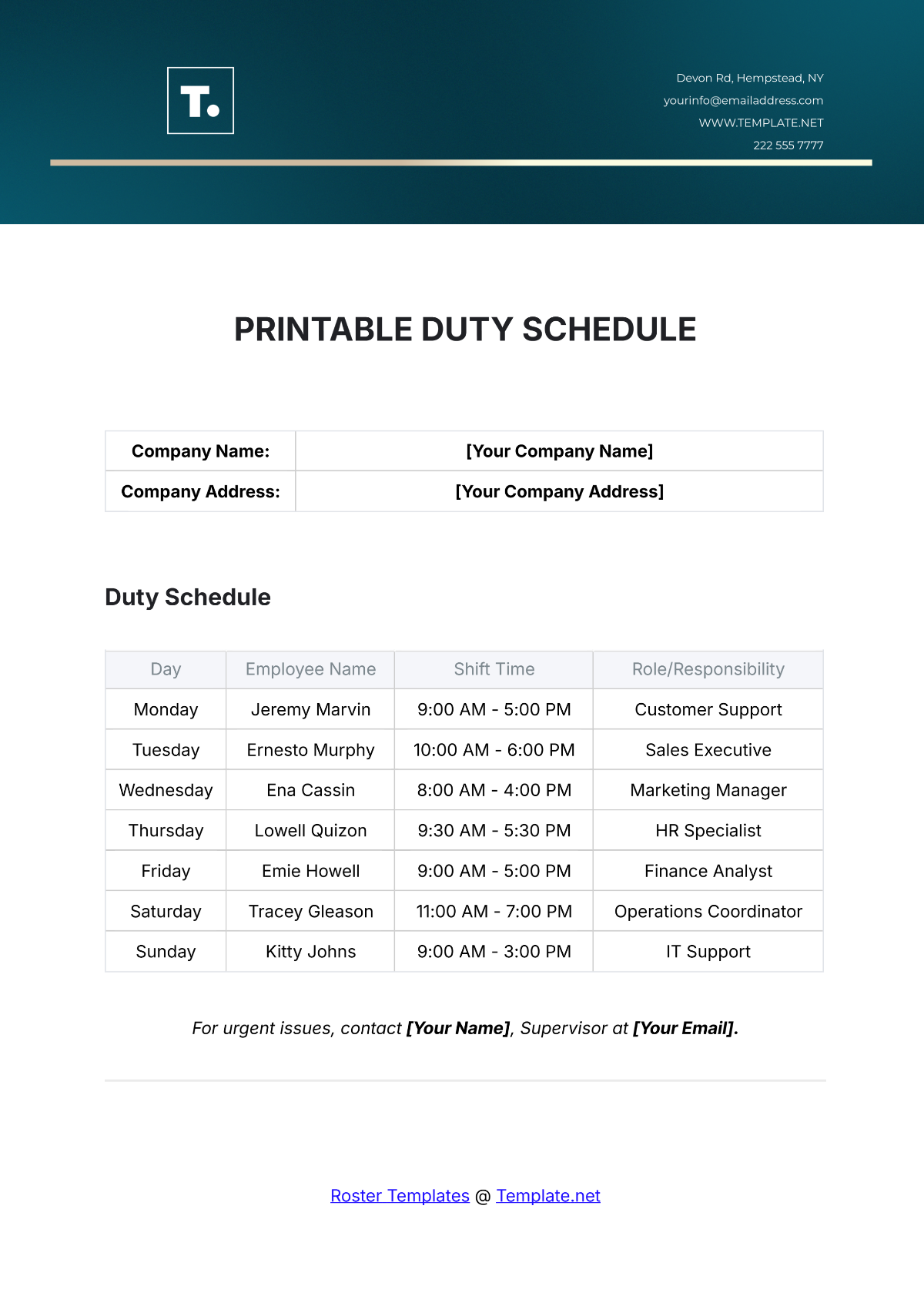

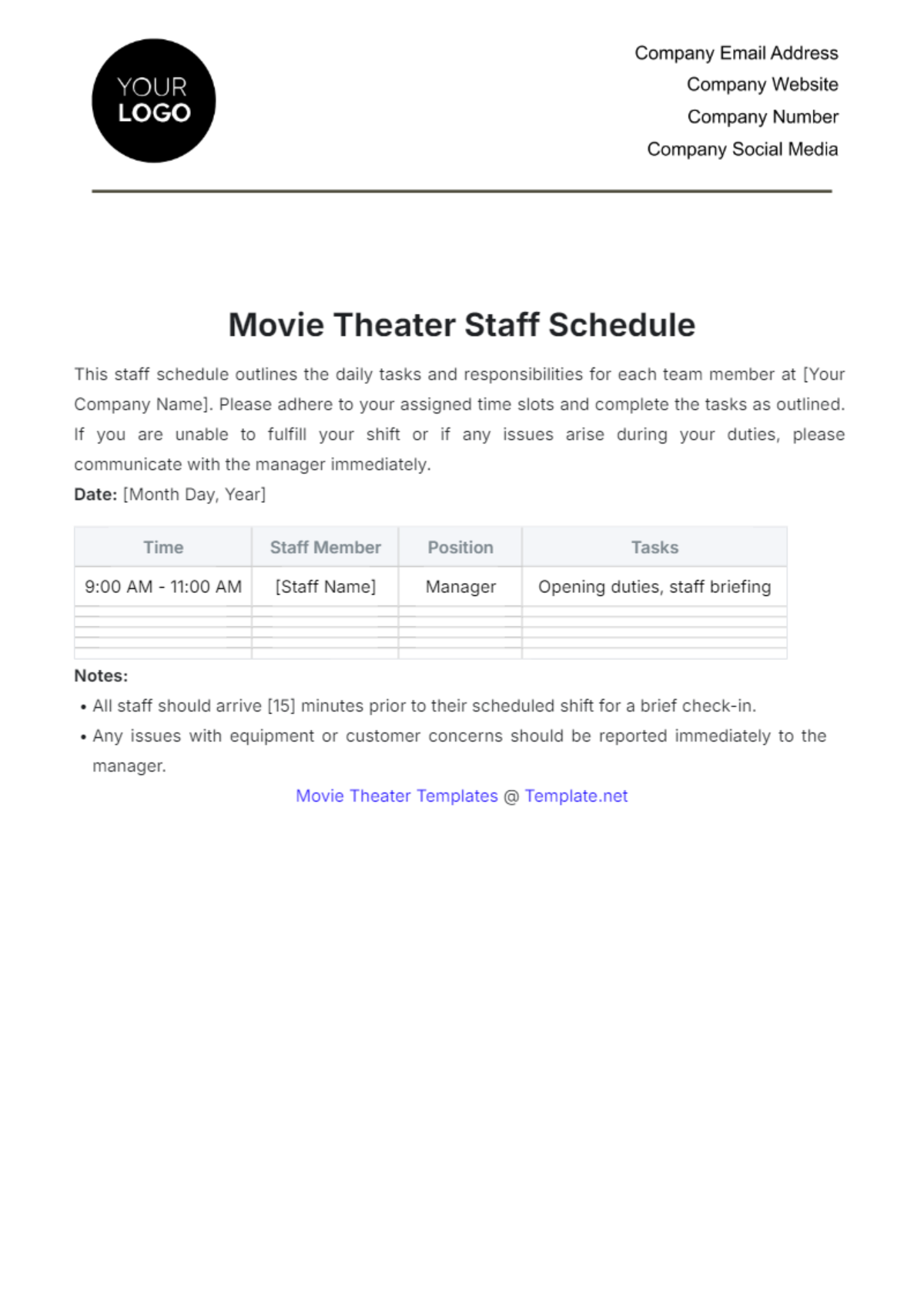

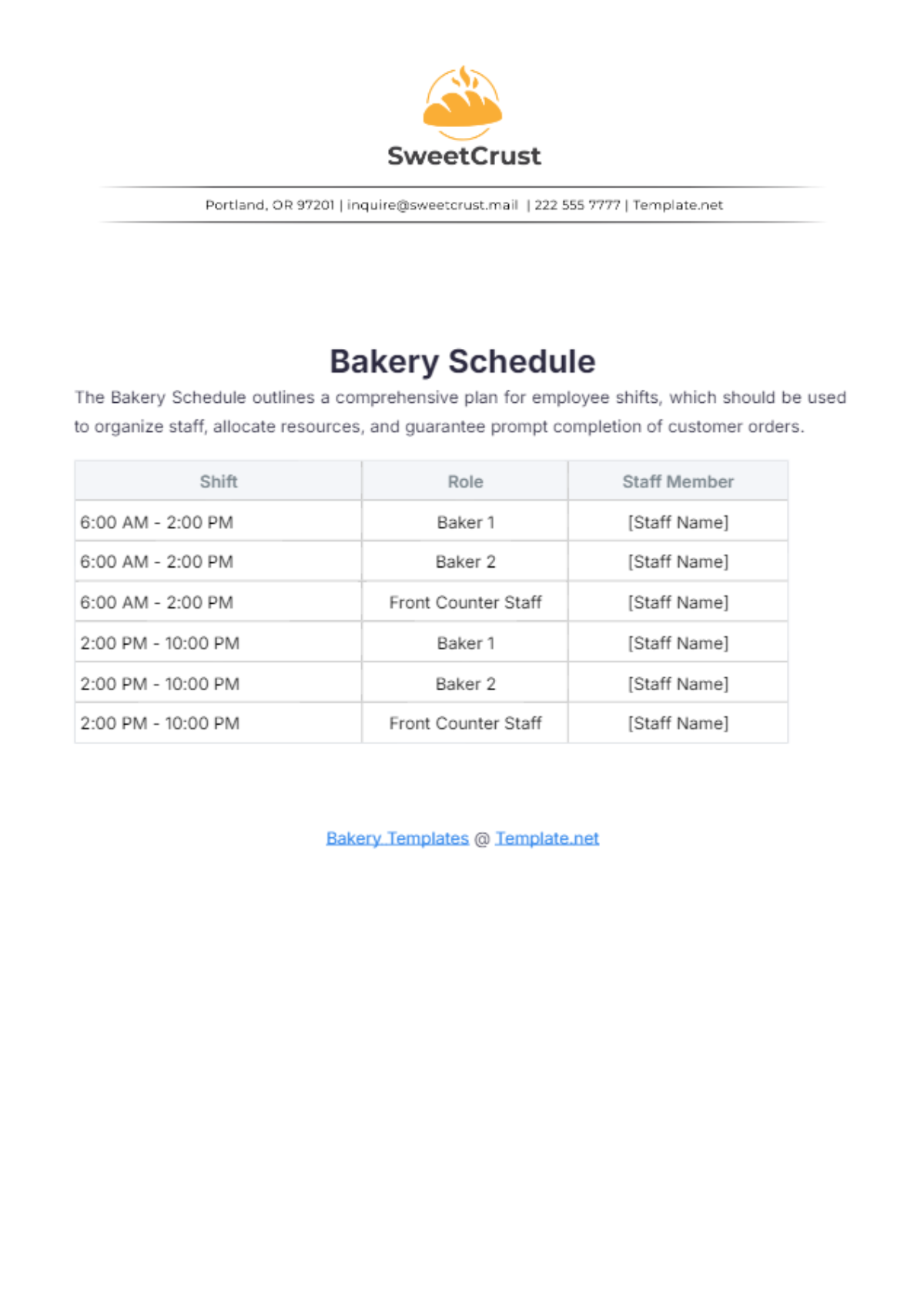

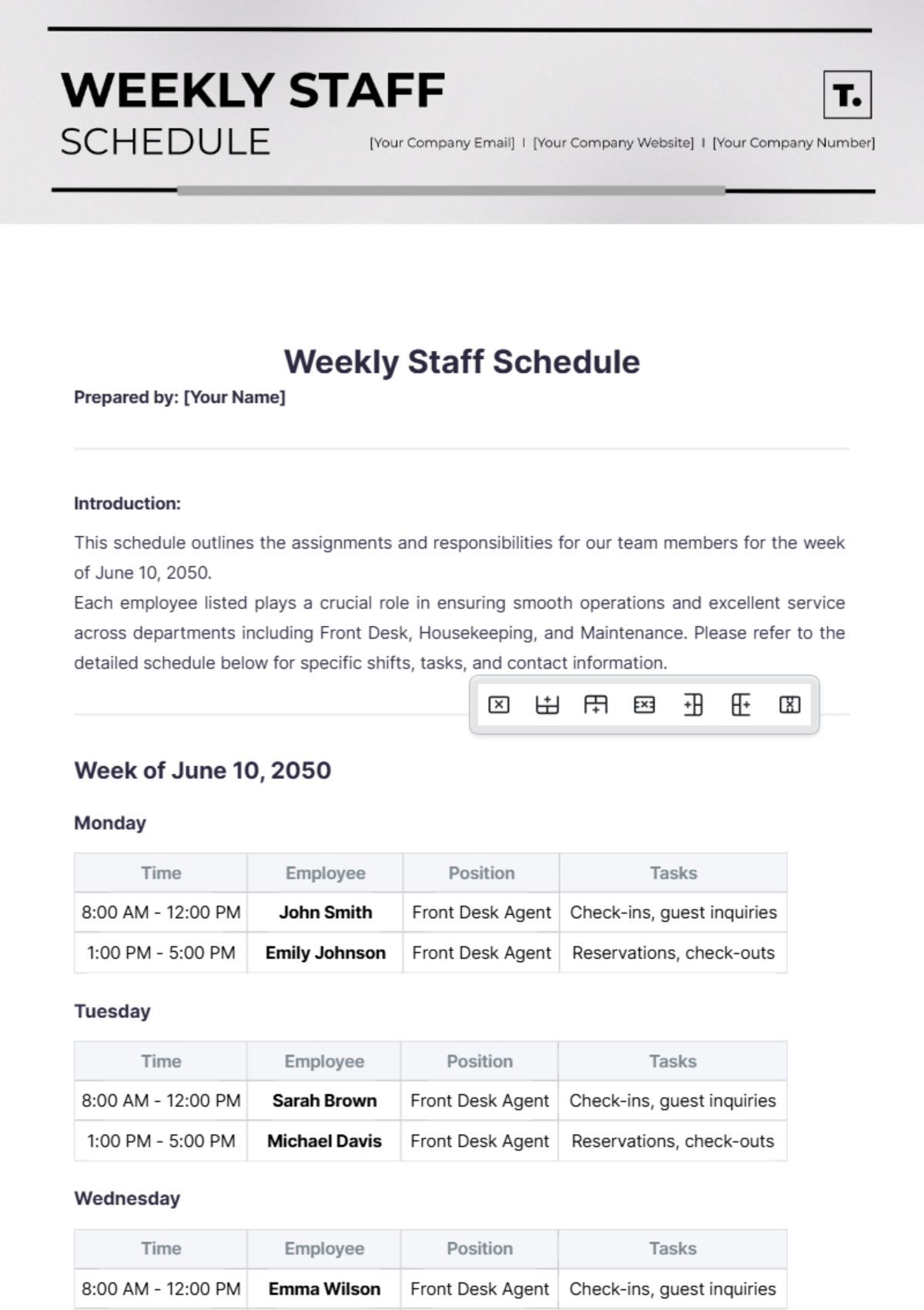

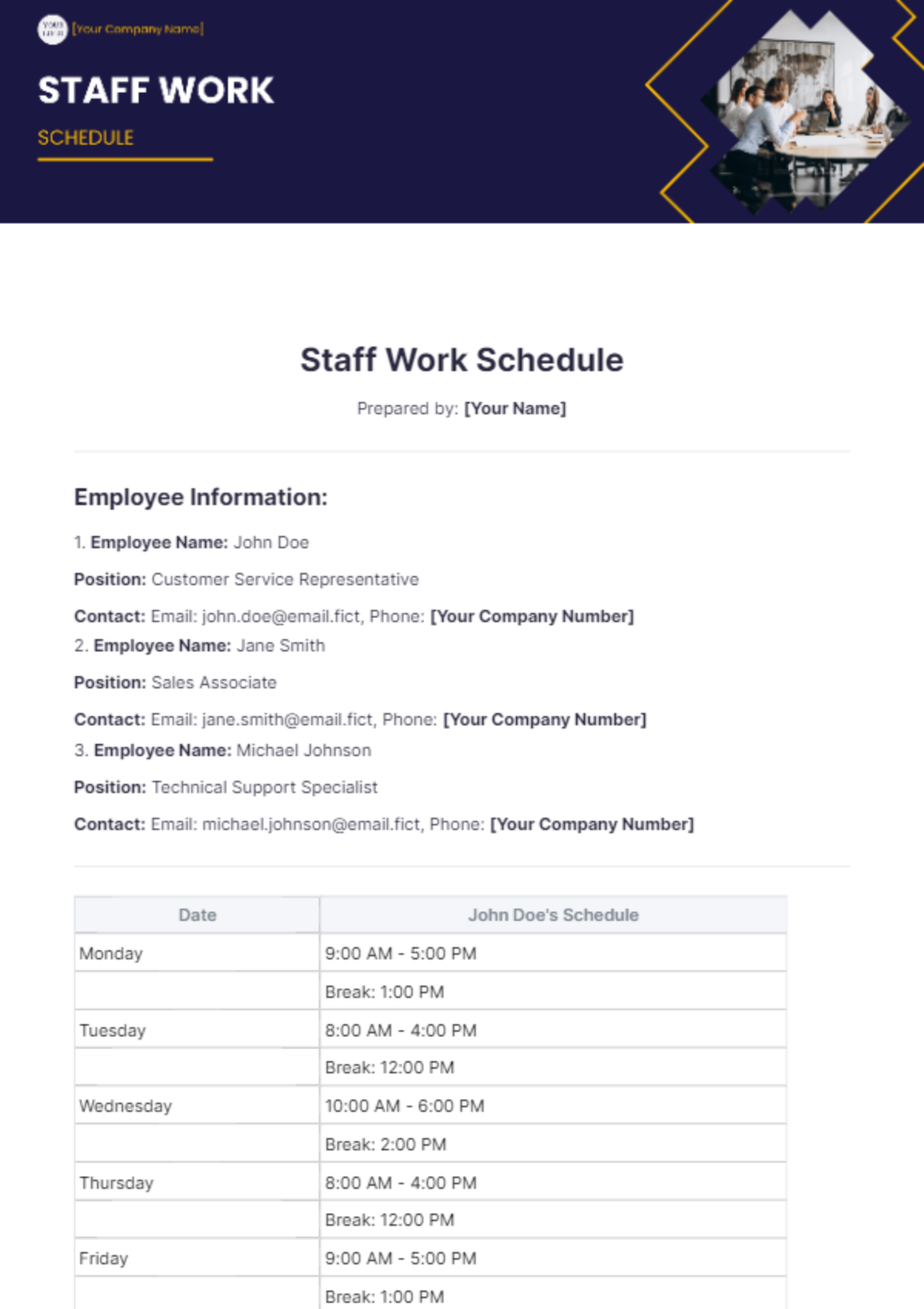

Staff Assignments: (Assign staff to specific tasks and shifts.)

Equipment Utilization: (Plan the use of ovens, mixers, and other equipment.)

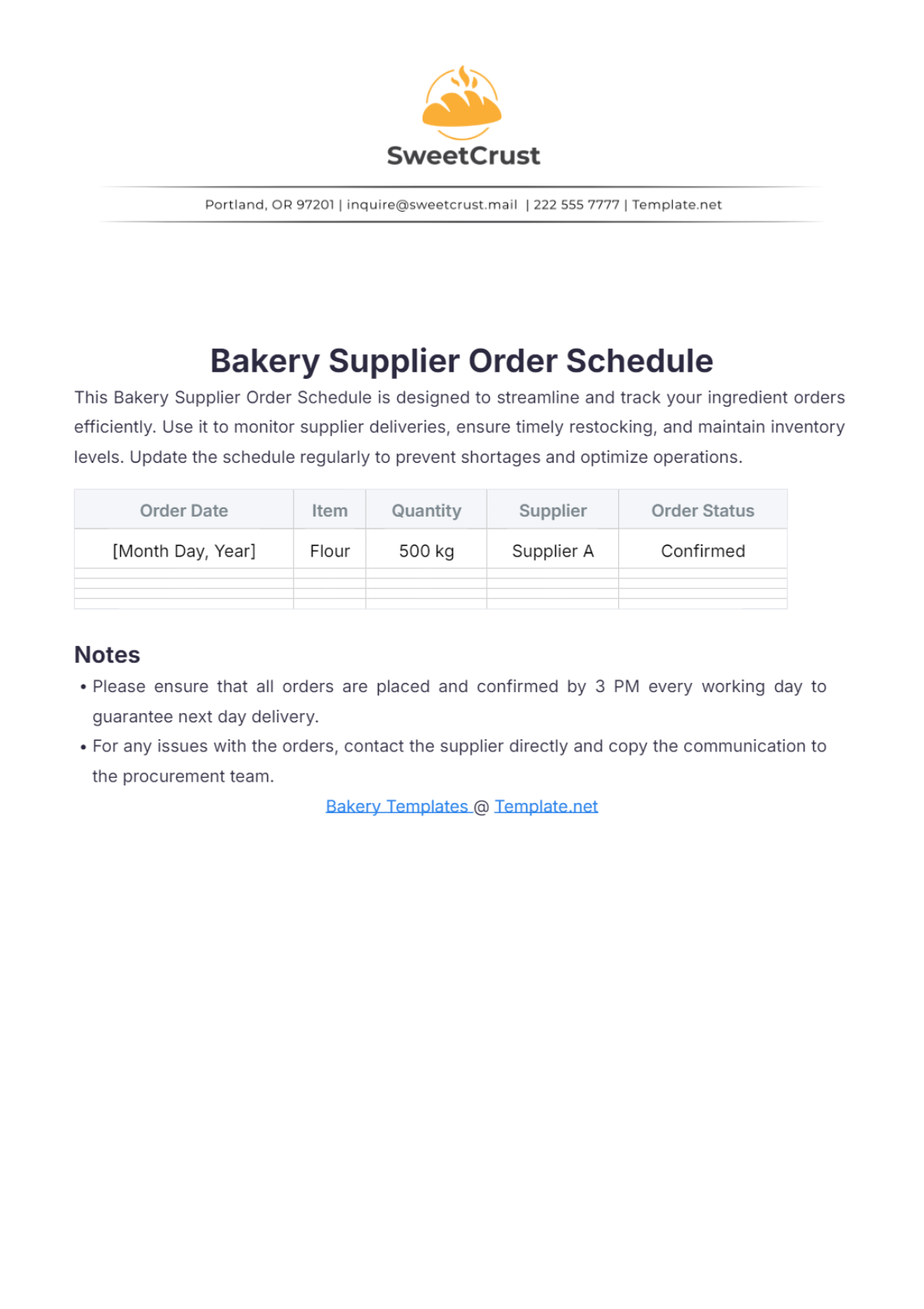

5. Inventory Management

Ingredient Stock Levels: (Monitor and maintain stock levels of key ingredients.)

Supply Orders: (Schedule orders for fresh ingredients and supplies.)

6. Special Orders and Custom Requests

Tracking: (Keep track of special orders and custom requests.)

Production Integration: (Integrate special orders into the daily schedule.)

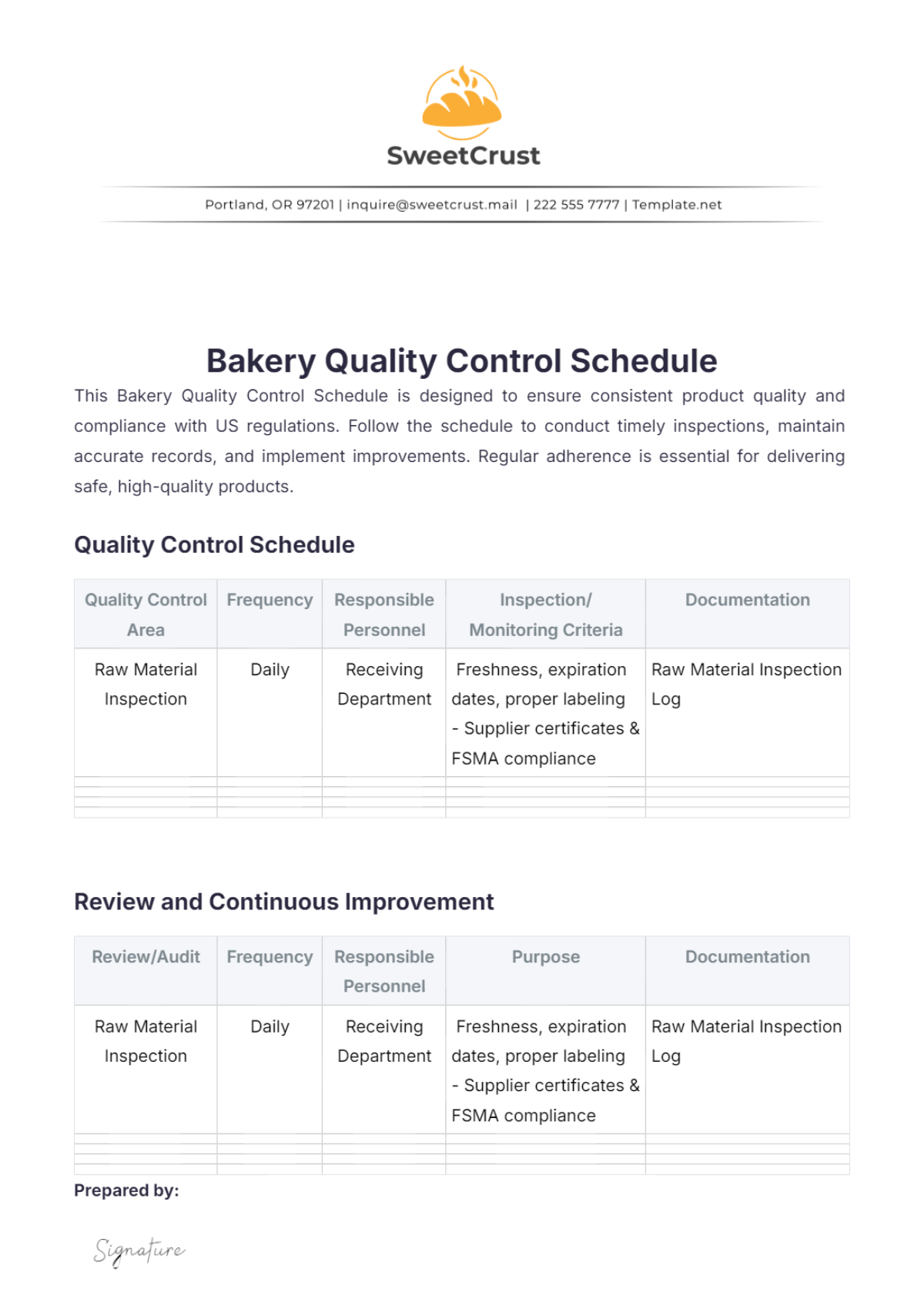

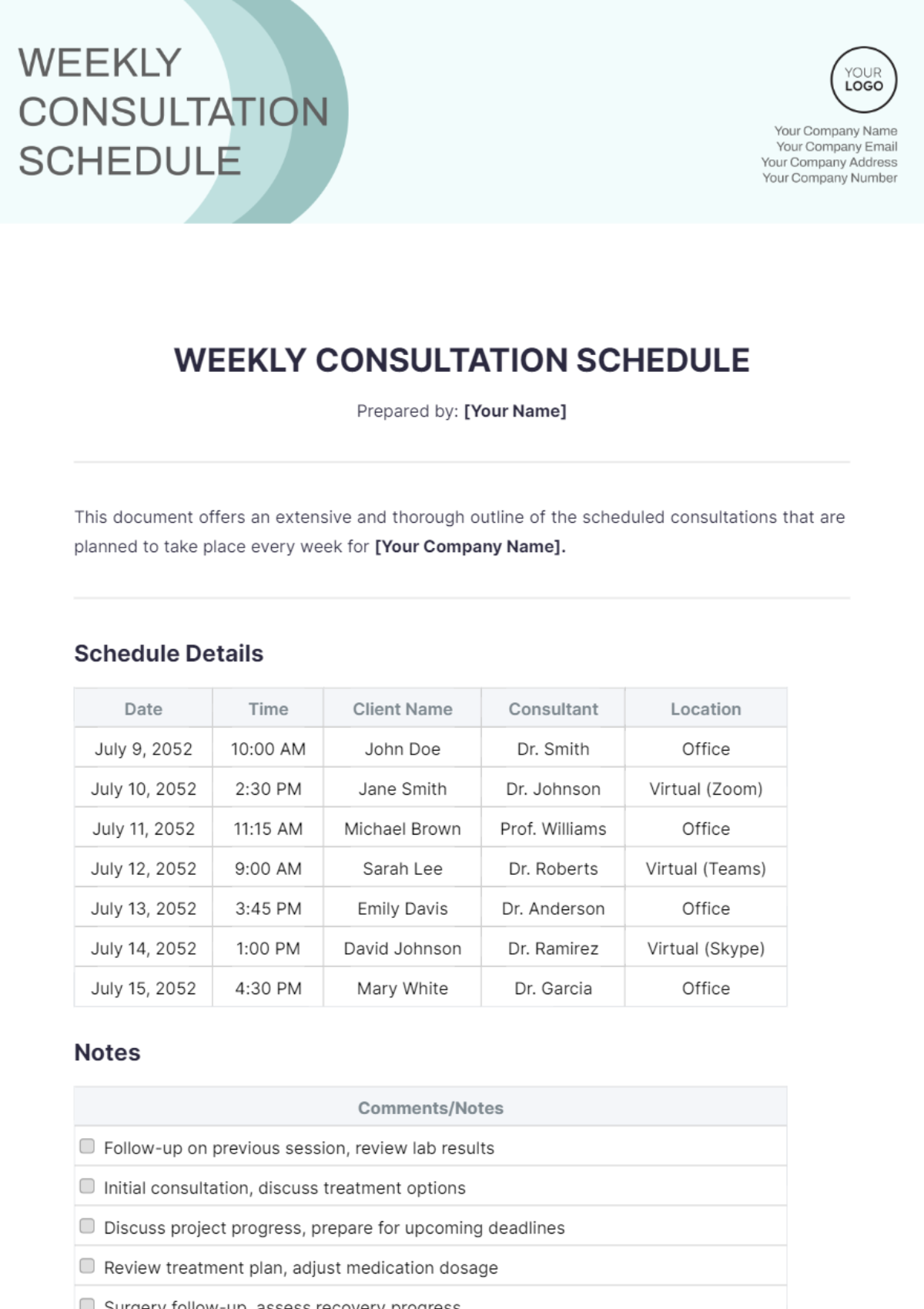

7. Quality Control

Standards: (Establish quality standards for each product.)

Inspections: (Schedule regular quality inspections during production.)

8. Health and Safety

Compliance: (Ensure all health and safety regulations are followed.)

Sanitation: (Schedule regular cleaning and sanitizing of work areas and equipment.)

9. Contingency Plans

Backup Plans: (Develop backup plans for equipment failure, staff shortages, or ingredient shortages.)

Adjustment Strategies: (Strategies for adjusting production in case of unexpected demand changes.)

10. Review and Feedback

Weekly Review: (Conduct a review of the week’s production to identify areas for improvement.)

Feedback Mechanism: (Implement a system for staff to provide feedback on the production process.)

Conclusion

Summarize the importance of the production schedule in ensuring a smooth and efficient bakery operation, and highlight the role of each team member in adhering to the schedule.