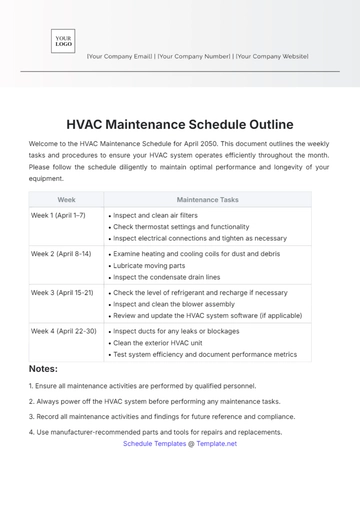

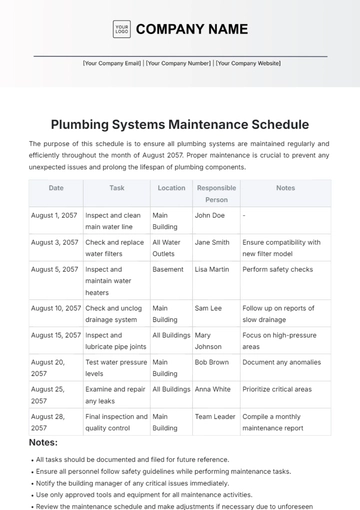

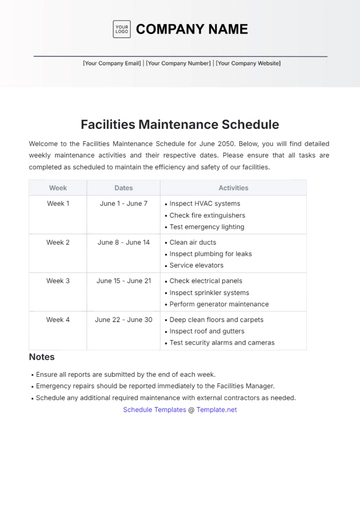

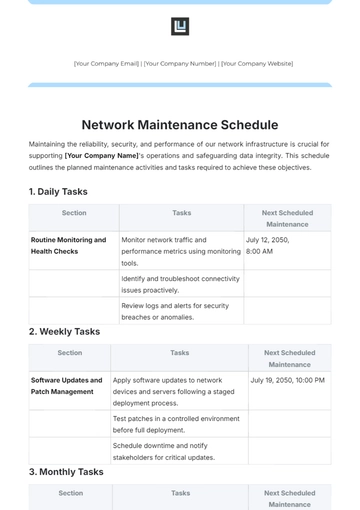

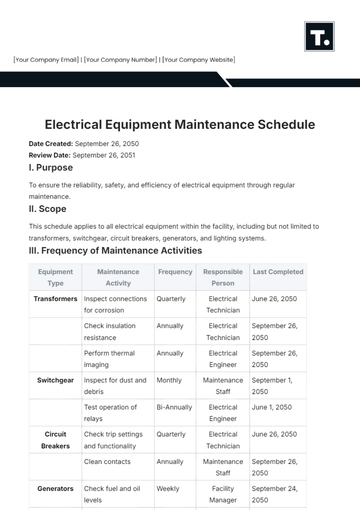

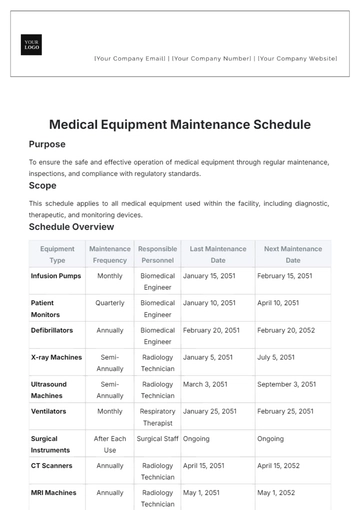

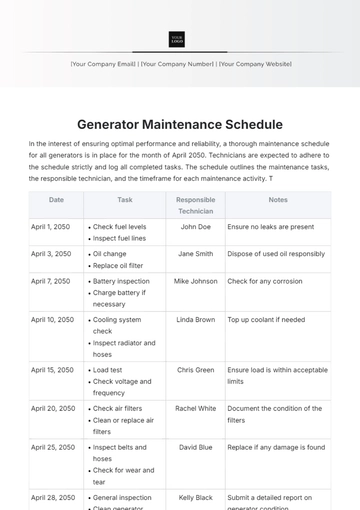

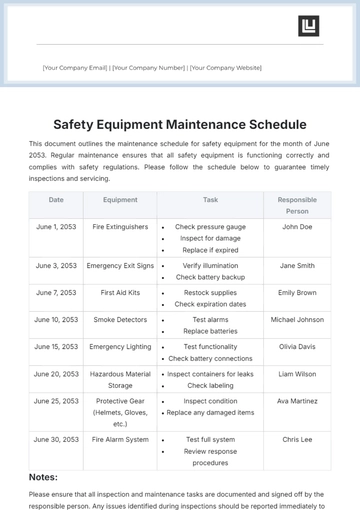

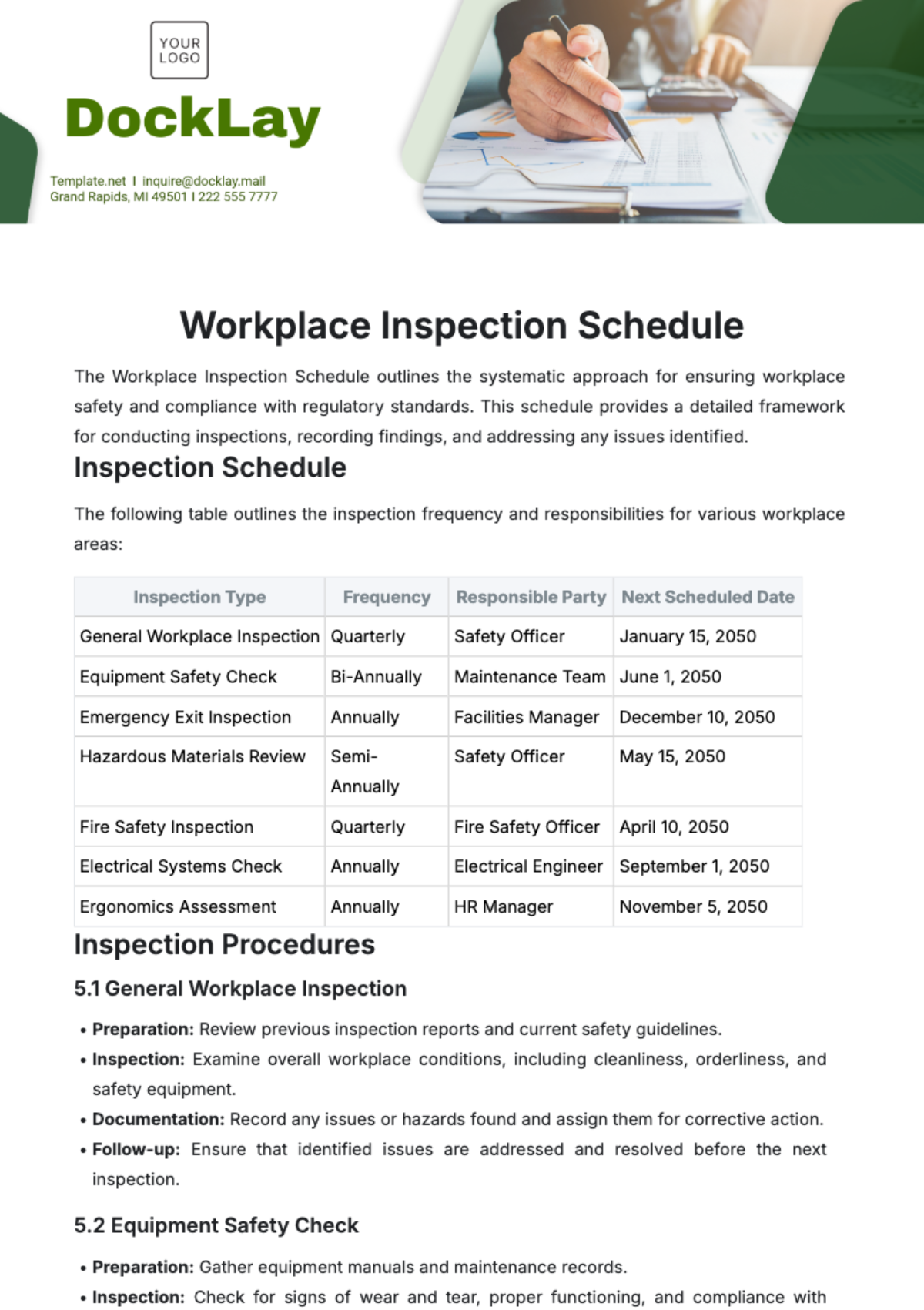

Free Workplace Inspection Schedule

Follow the Workplace Inspection Schedule to ensure safety, document findings, and address issues.

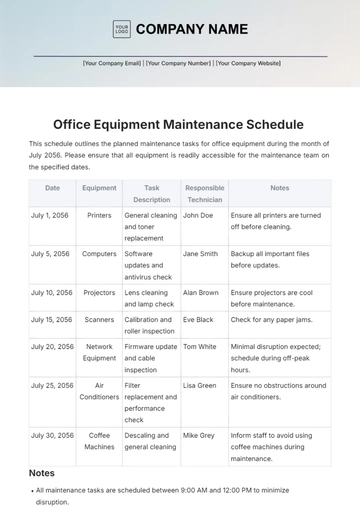

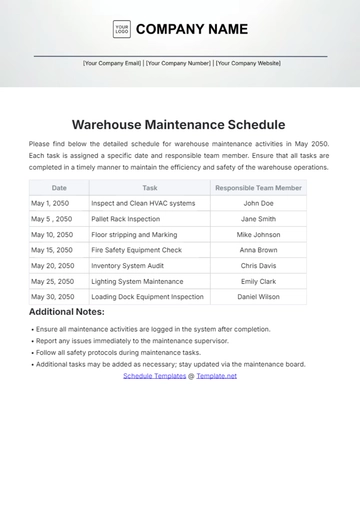

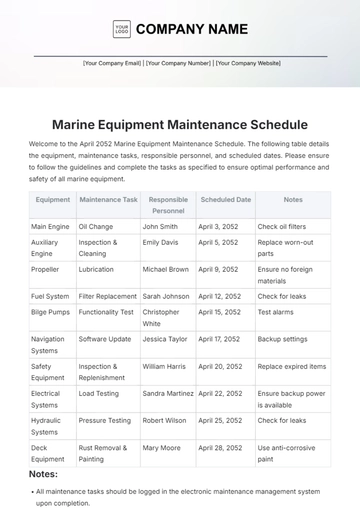

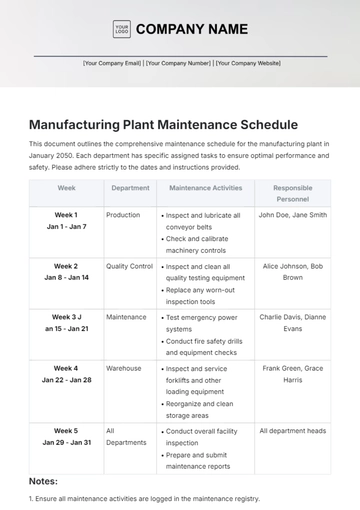

Inspection Type | Frequency | Responsible Party | Next Scheduled Date |

|---|---|---|---|

General Workplace Inspection | Quarterly | Safety Officer | January 15, 2050 |

Equipment Safety Check | Bi-Annually | Maintenance Team | June 1, 2050 |

Emergency Exit Inspection | Annually | Facilities Manager | December 10, 2050 |

Hazardous Materials Review | Semi-Annually | Safety Officer | May 15, 2050 |

Fire Safety Inspection | Quarterly | Fire Safety Officer | April 10, 2050 |

Electrical Systems Check | Annually | Electrical Engineer | September 1, 2050 |

Ergonomics Assessment | Annually | HR Manager | November 5, 2050 |

Notes

Ensure that identified issues are addressed and resolved before the next inspection.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Keep track of your workplace inspections with the Workplace Inspection Schedule Template available on Template.net. This editable template helps you plan and document regular safety inspections. Editable in our AI Editor Tool, it ensures your workplace remains compliant with safety standards. Download now to maintain a safe work environment!

You may also like

- Schedule Appointment

- Work Schedule

- Weekly Schedule

- Cleaning Schedule

- Payment Schedule

- School Schedule

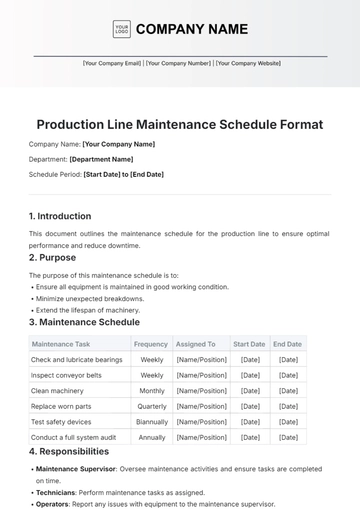

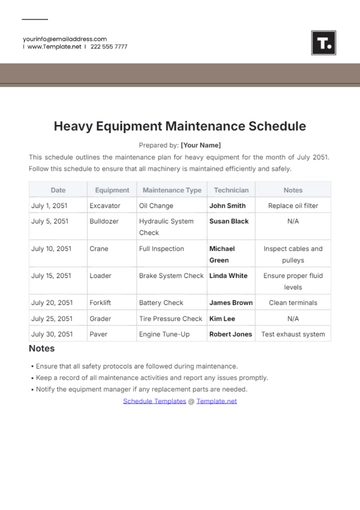

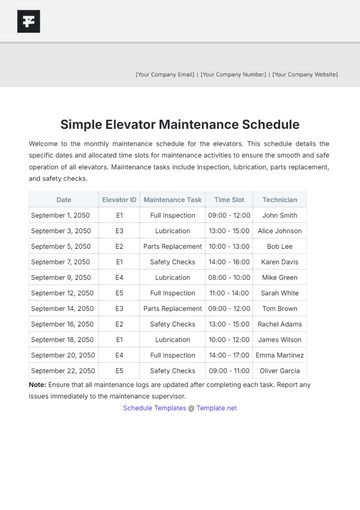

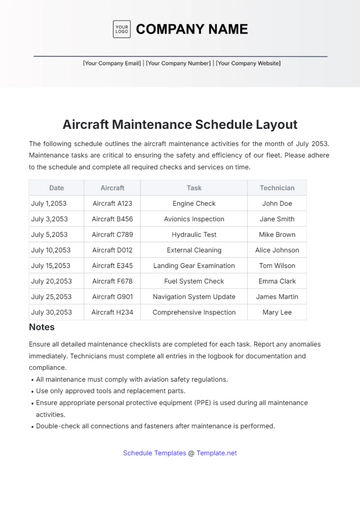

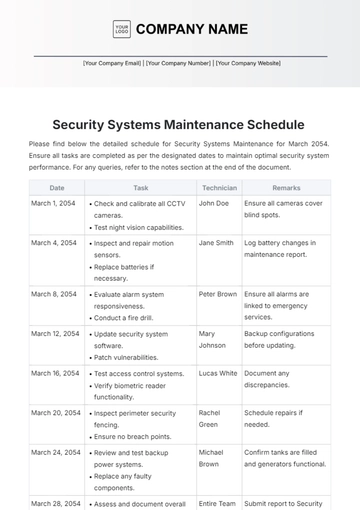

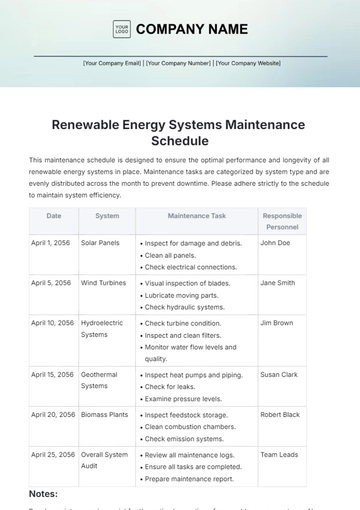

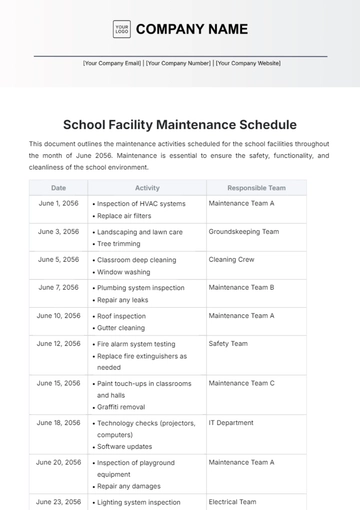

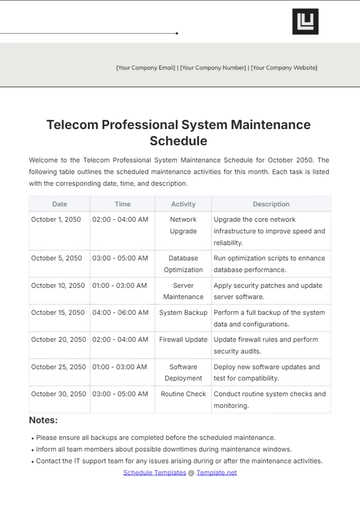

- Maintenance Schedule

- Daily Schedule

- Class Schedule

- Workout Schedule

- Event Schedule

- Marketing Schedule

- Weekly Cleaning Schedule

- Work From Home Schedule

- Payroll Schedule

- Restaurant Schedule

- Kitchen Cleaning Schedule

- Schedule of Values

- Hourly Schedule

- Study Schedule

- University Schedule

- Construction Schedule

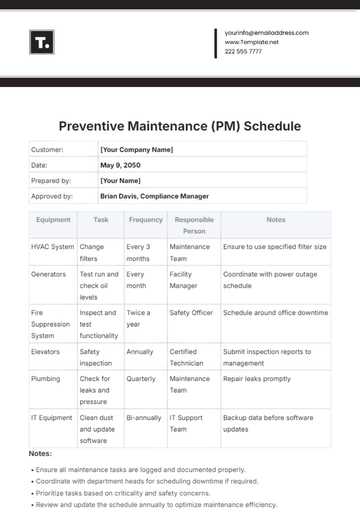

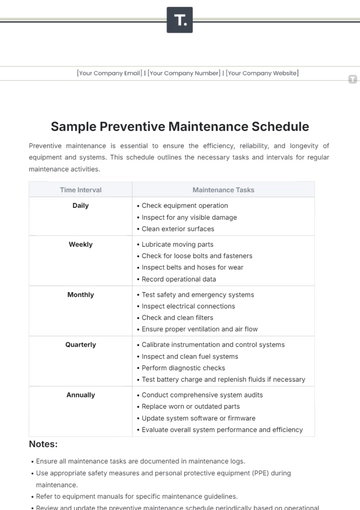

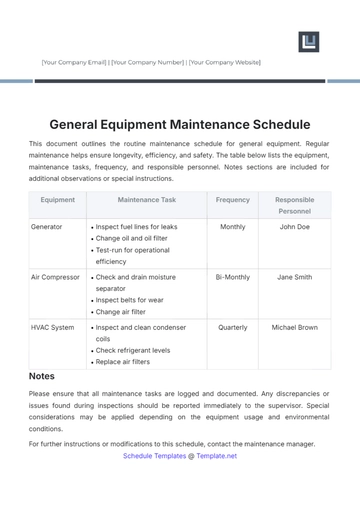

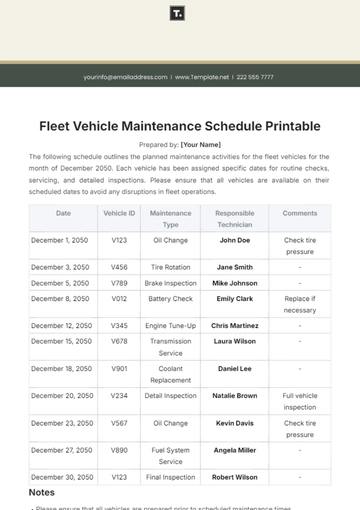

- Preventive Maintenance Schedule

- Fitness Schedule

- Education Schedule

- Training Schedule

- Agency Schedule

- Panel Schedule

- Monthly Schedule

- Nursing Home Schedule

- Project Schedule

- Real Estate Schedule

- Freelancer Schedule

- Medication Schedule

- IT and Software Schedule

- Interior Design Schedule

- Travel Schedule

- Travel Agency Schedule

- Hotel Schedule

- Wedding Schedule

- Camp Schedule