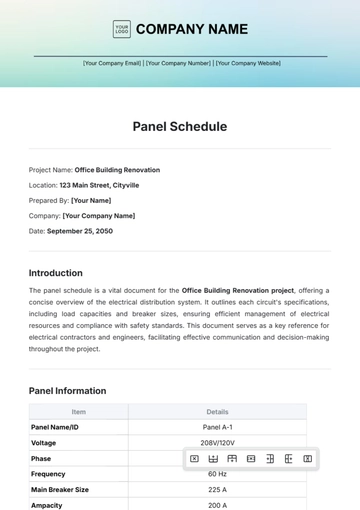

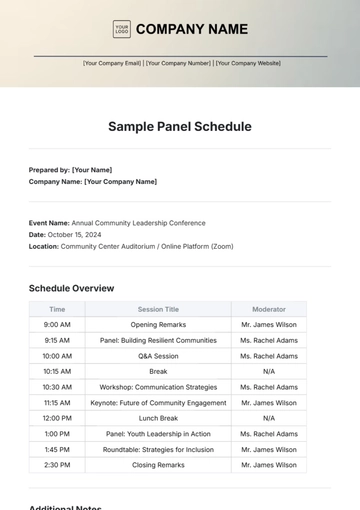

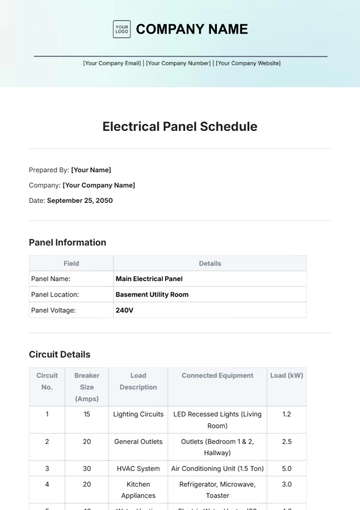

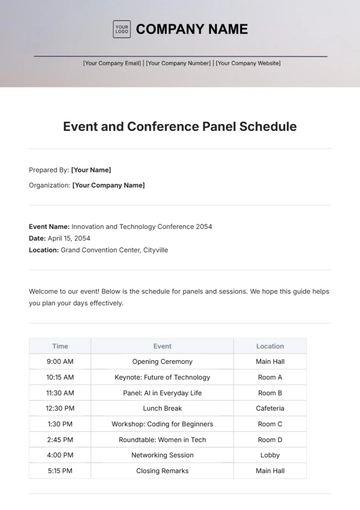

Free Safety Inspection Panel Schedule

Prepared By: [Your Name]

Email: [Your Email]

Company: [Your Company Name]

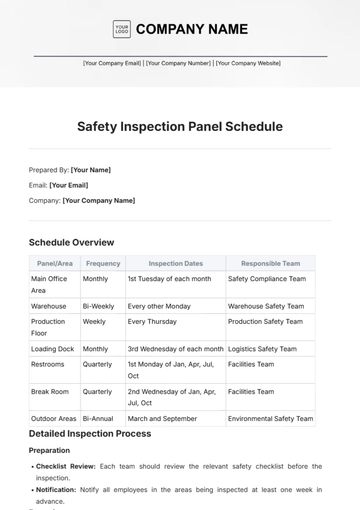

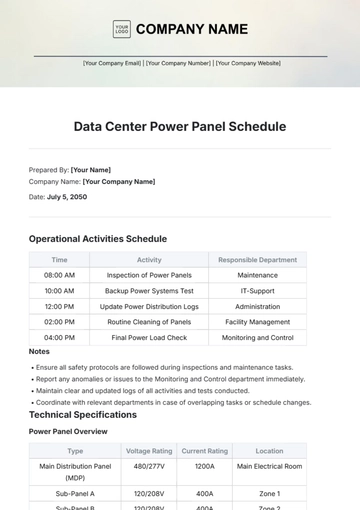

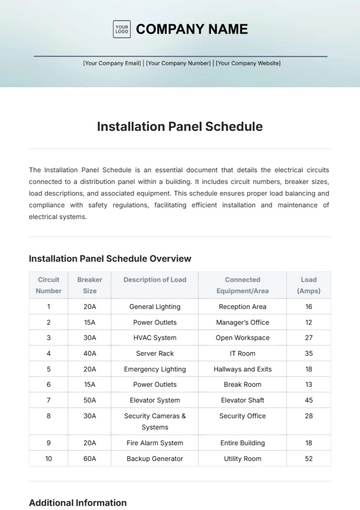

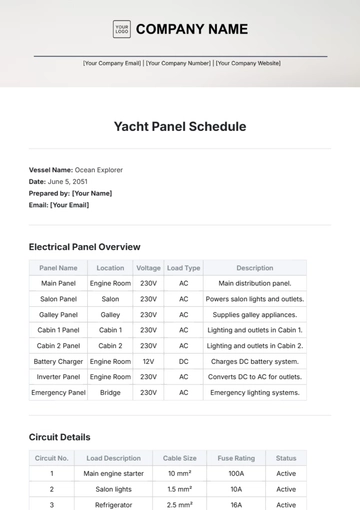

Schedule Overview

Panel/Area | Frequency | Inspection Dates | Responsible Team |

|---|---|---|---|

Main Office Area | Monthly | 1st Tuesday of each month | Safety Compliance Team |

Warehouse | Bi-Weekly | Every other Monday | Warehouse Safety Team |

Production Floor | Weekly | Every Thursday | Production Safety Team |

Loading Dock | Monthly | 3rd Wednesday of each month | Logistics Safety Team |

Restrooms | Quarterly | 1st Monday of Jan, Apr, Jul, Oct | Facilities Team |

Break Room | Quarterly | 2nd Wednesday of Jan, Apr, Jul, Oct | Facilities Team |

Outdoor Areas | Bi-Annual | March and September | Environmental Safety Team |

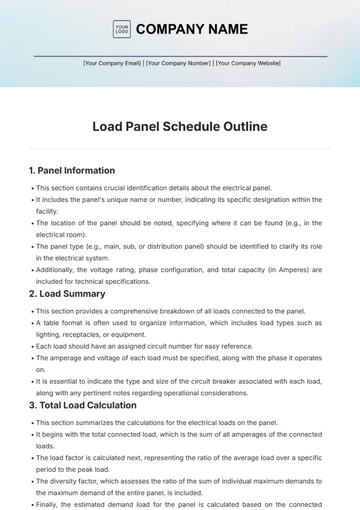

Detailed Inspection Process

Preparation

Checklist Review: Each team should review the relevant safety checklist before the inspection.

Notification: Notify all employees in the areas being inspected at least one week in advance.

Execution

Walkthroughs led by the responsible team, utilizing detailed checklists for consistency.

Engage employees in discussions about their safety concerns during the inspection.

Reporting

Document Findings: Inspection findings should be documented within 48 hours of each inspection.

Action Items: Identify and prioritize action items based on severity and potential impact on safety.

Follow-Up

Action Plan Review: Discuss the action plan in the next team meeting, assigning responsibilities and deadlines.

Employee Training: Organize training sessions for employees on identified safety issues, if necessary.

Continuous Improvement

Feedback Mechanism: Encourage staff to provide ongoing feedback about safety practices.

Annual Schedule Review: At the end of the year, review the inspection schedule for effectiveness and make necessary adjustments.

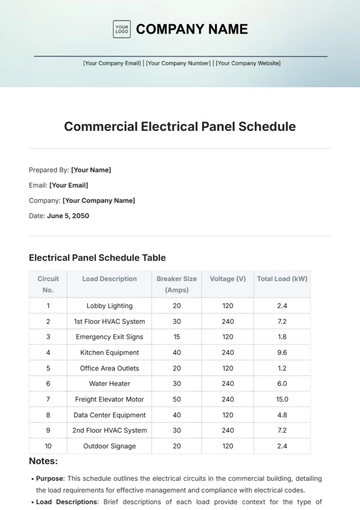

Conclusion

This Safety Inspection Panel Schedule provides a comprehensive framework for regular inspections, fostering a safe working environment through proactive measures and continuous improvement.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

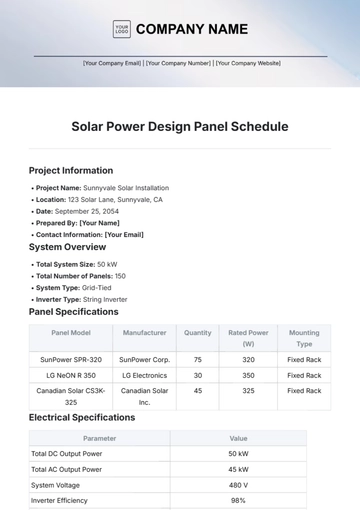

Ensure compliance and enhance safety with the Safety Inspection Panel Schedule Template from Template.net. This editable and customizable template allows you to efficiently organize and track safety inspections, ensuring all necessary details are easily accessible. With its clear layout, you can tailor the content to meet specific requirements and streamline your inspection processes. Simplify your safety management today by downloading this essential template for effective oversight!

You may also like

- Schedule Appointment

- Work Schedule

- Weekly Schedule

- Cleaning Schedule

- Payment Schedule

- School Schedule

- Maintenance Schedule

- Daily Schedule

- Class Schedule

- Workout Schedule

- Event Schedule

- Marketing Schedule

- Weekly Cleaning Schedule

- Work From Home Schedule

- Payroll Schedule

- Restaurant Schedule

- Kitchen Cleaning Schedule

- Schedule of Values

- Hourly Schedule

- Study Schedule

- University Schedule

- Construction Schedule

- Preventive Maintenance Schedule

- Fitness Schedule

- Education Schedule

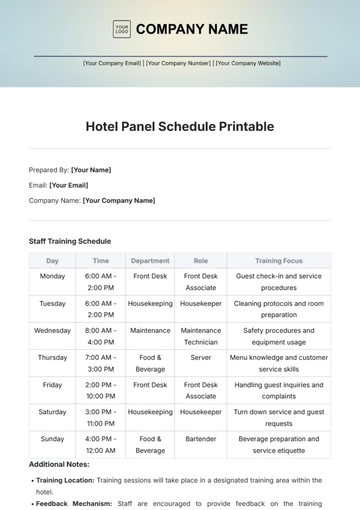

- Training Schedule

- Agency Schedule

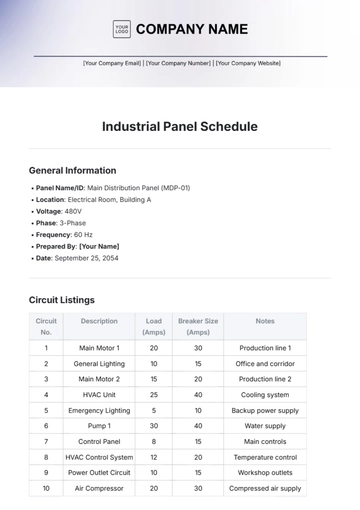

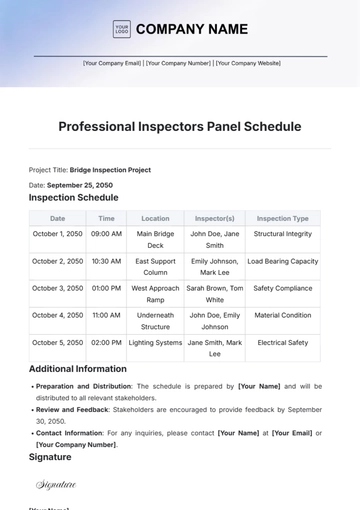

- Panel Schedule

- Monthly Schedule

- Nursing Home Schedule

- Project Schedule

- Real Estate Schedule

- Freelancer Schedule

- Medication Schedule

- IT and Software Schedule

- Interior Design Schedule

- Travel Schedule

- Travel Agency Schedule

- Hotel Schedule

- Wedding Schedule

- Camp Schedule