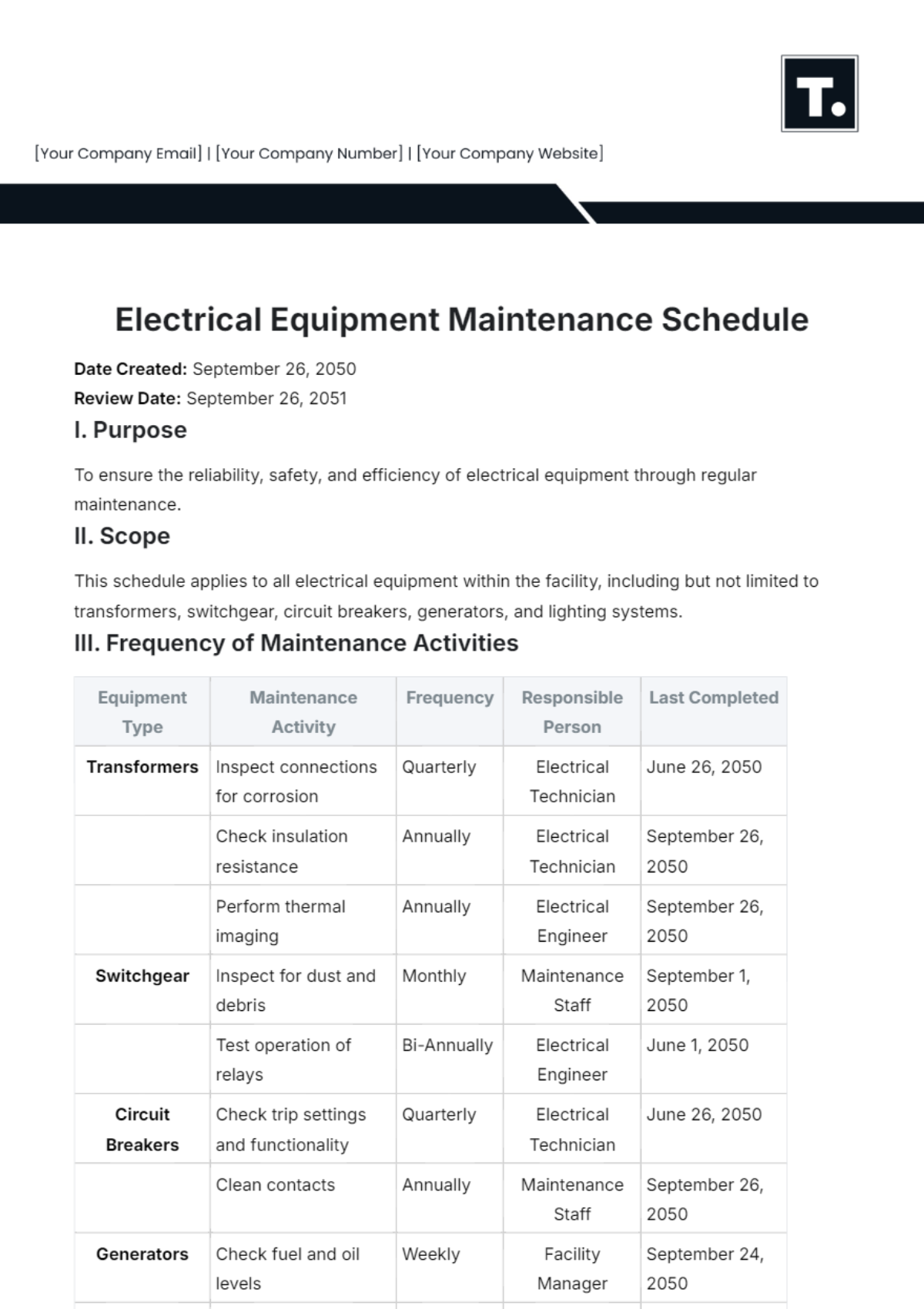

Production Line Maintenance Schedule Format

Company Name: [Your Company Name]

Department: [Department Name]

Schedule Period: [Start Date] to [End Date]

1. Introduction

This document outlines the maintenance schedule for the production line to ensure optimal performance and reduce downtime.

2. Purpose

The purpose of this maintenance schedule is to:

Ensure all equipment is maintained in good working condition.

Minimize unexpected breakdowns.

Extend the lifespan of machinery.

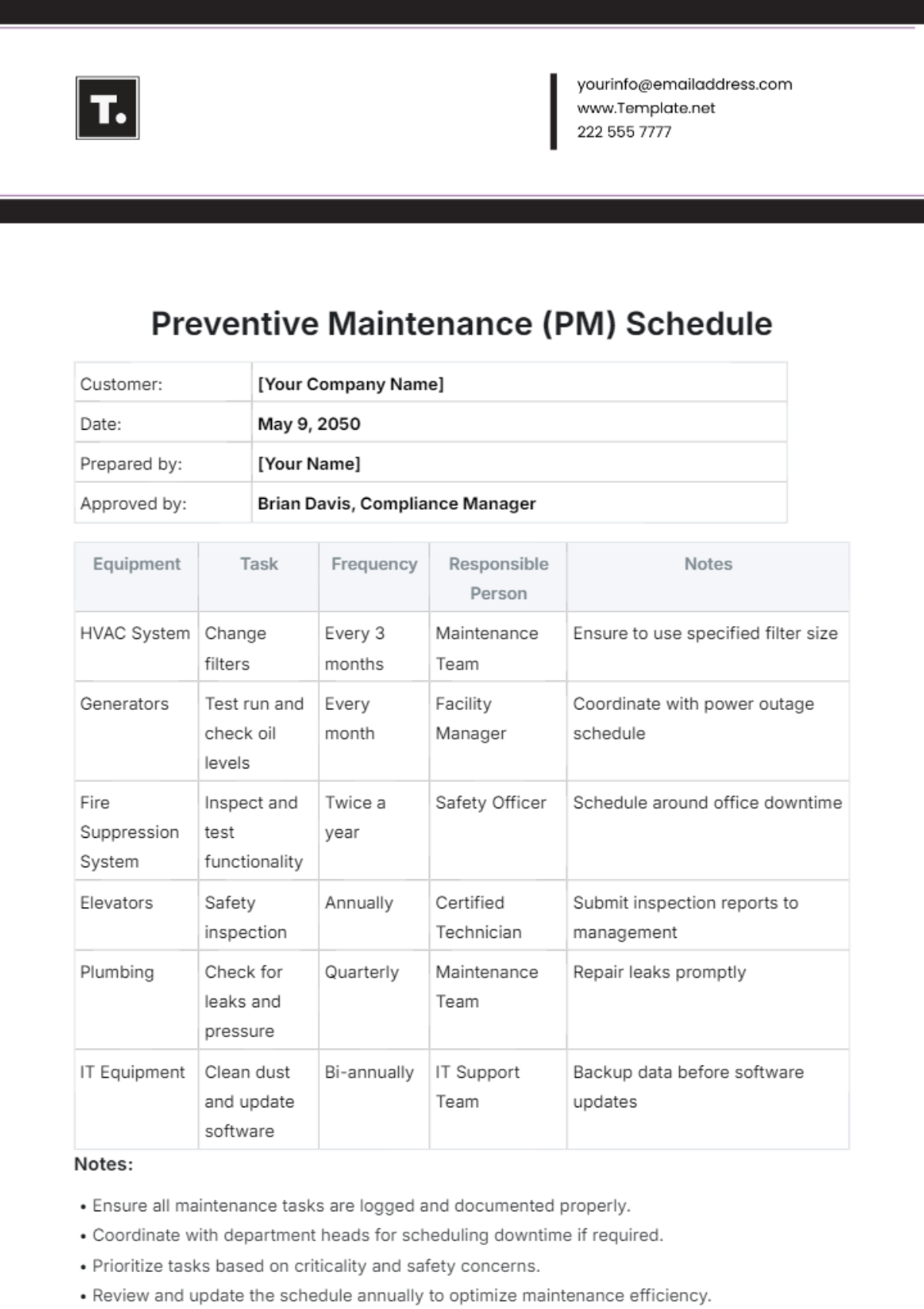

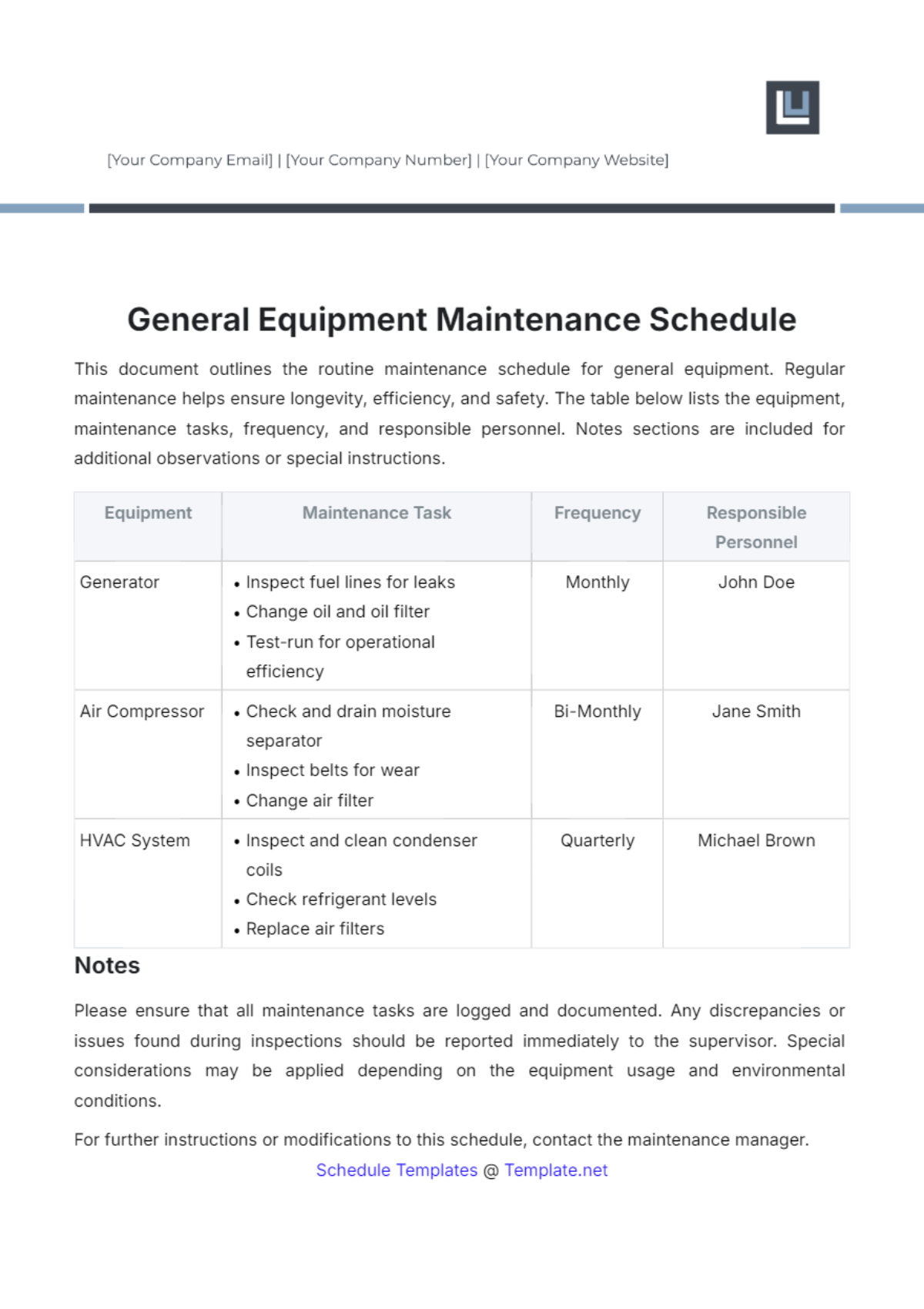

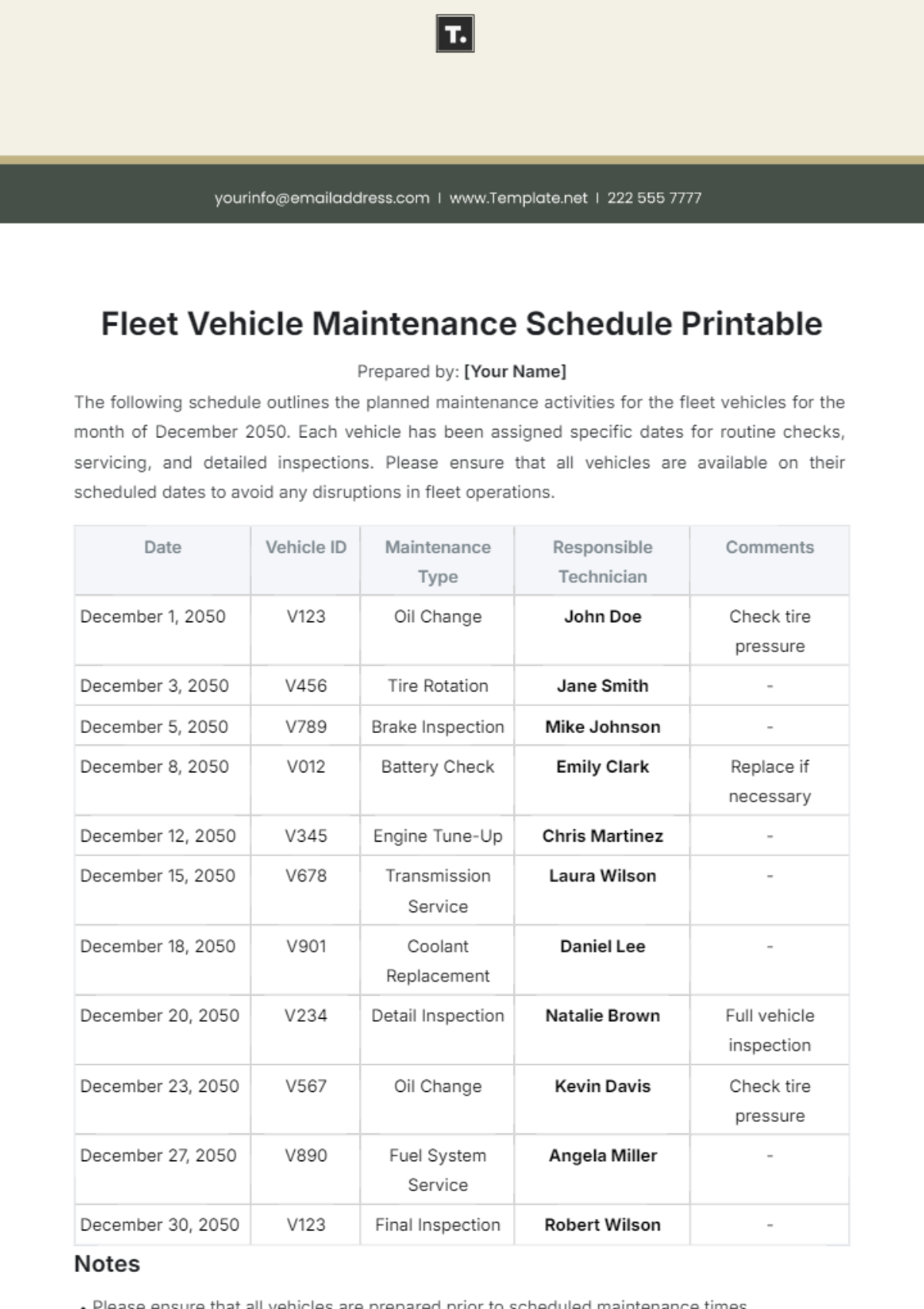

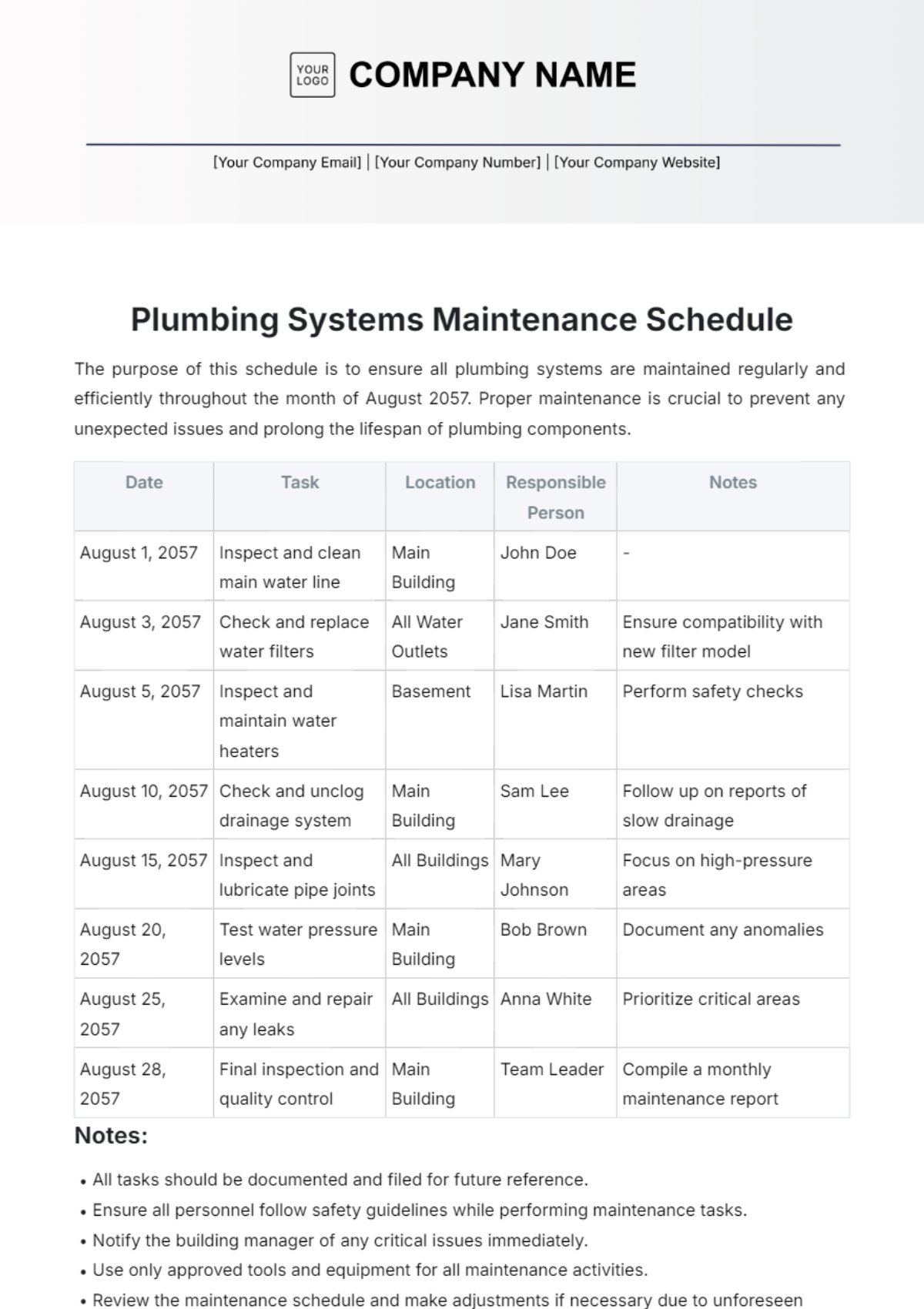

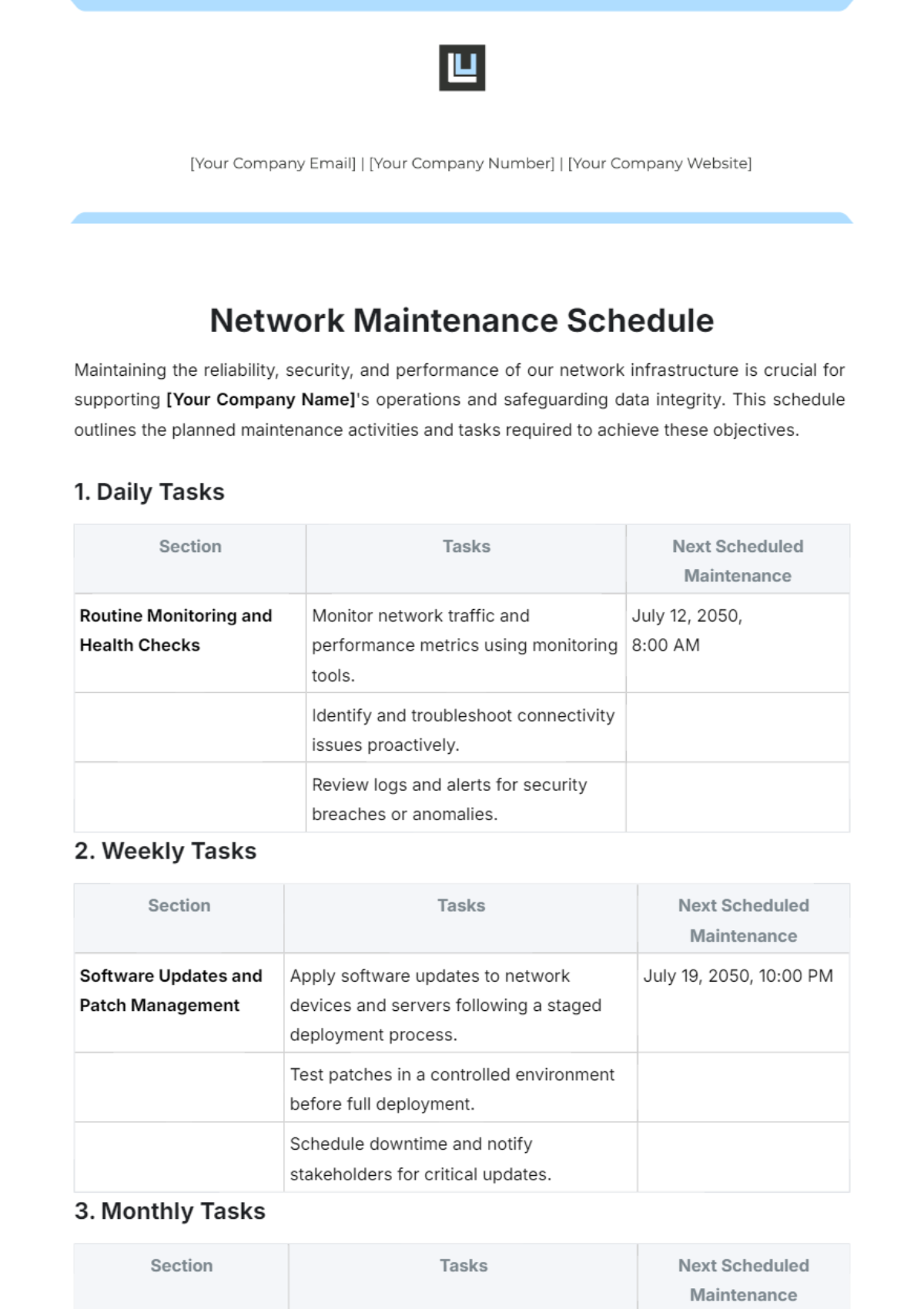

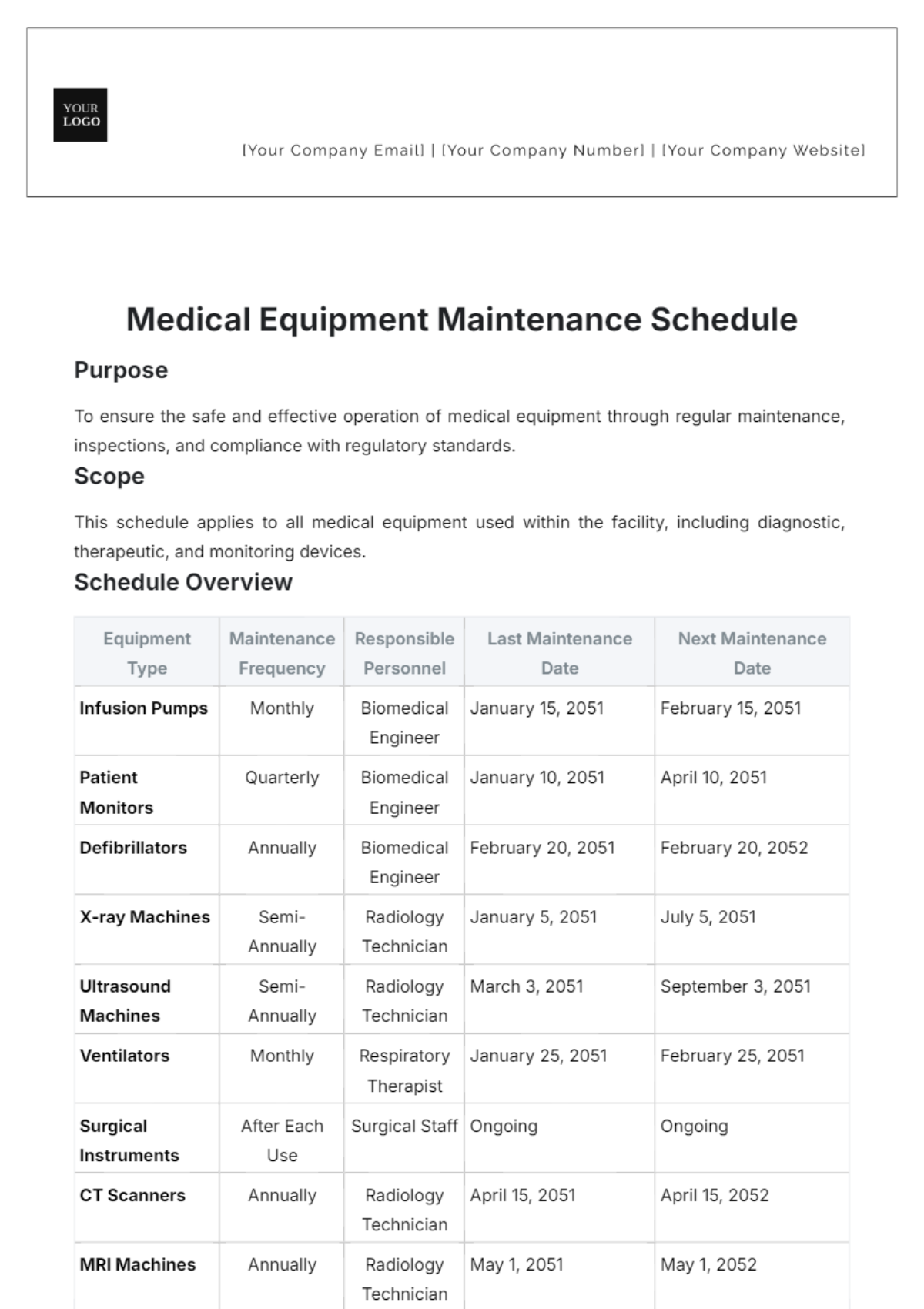

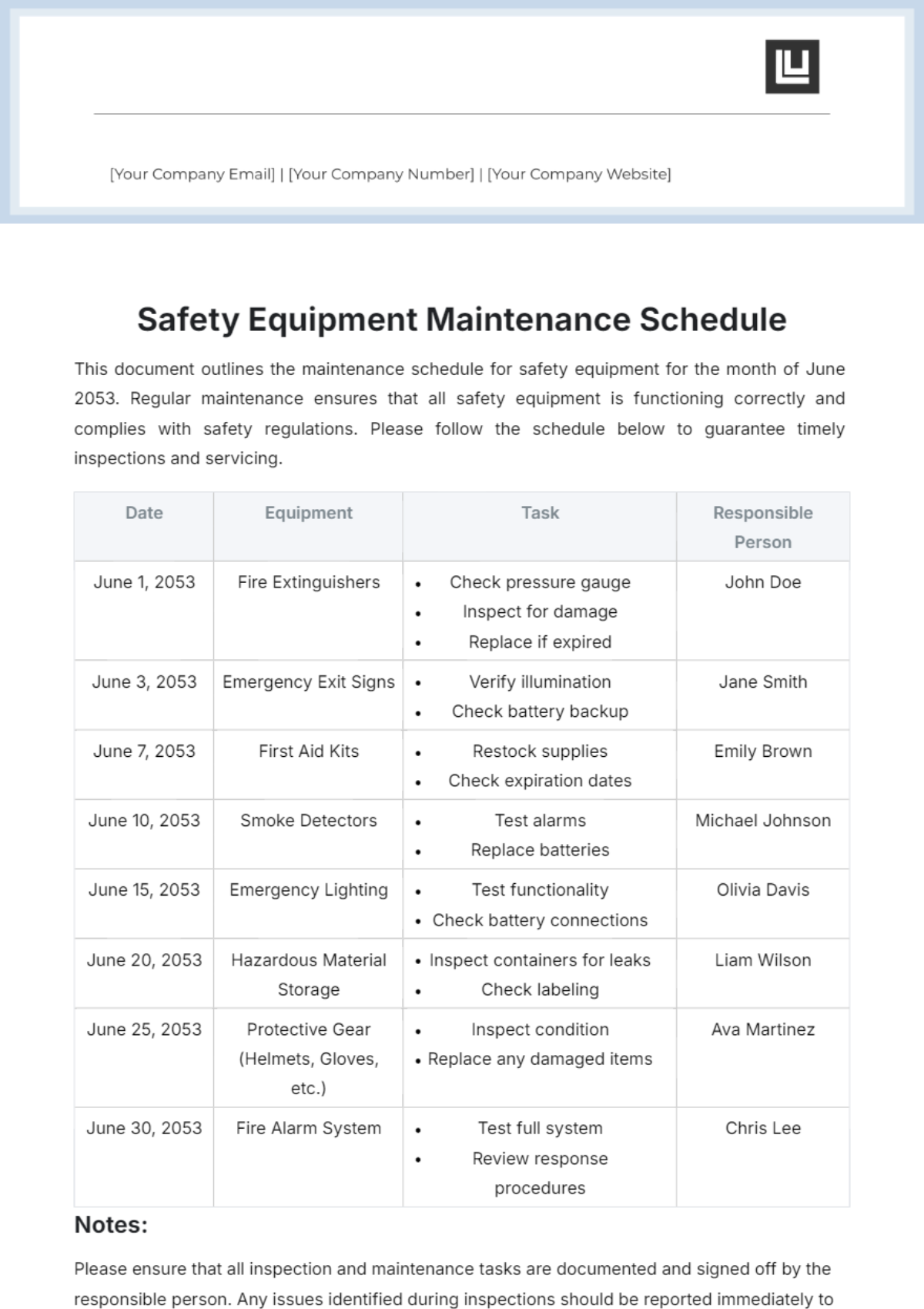

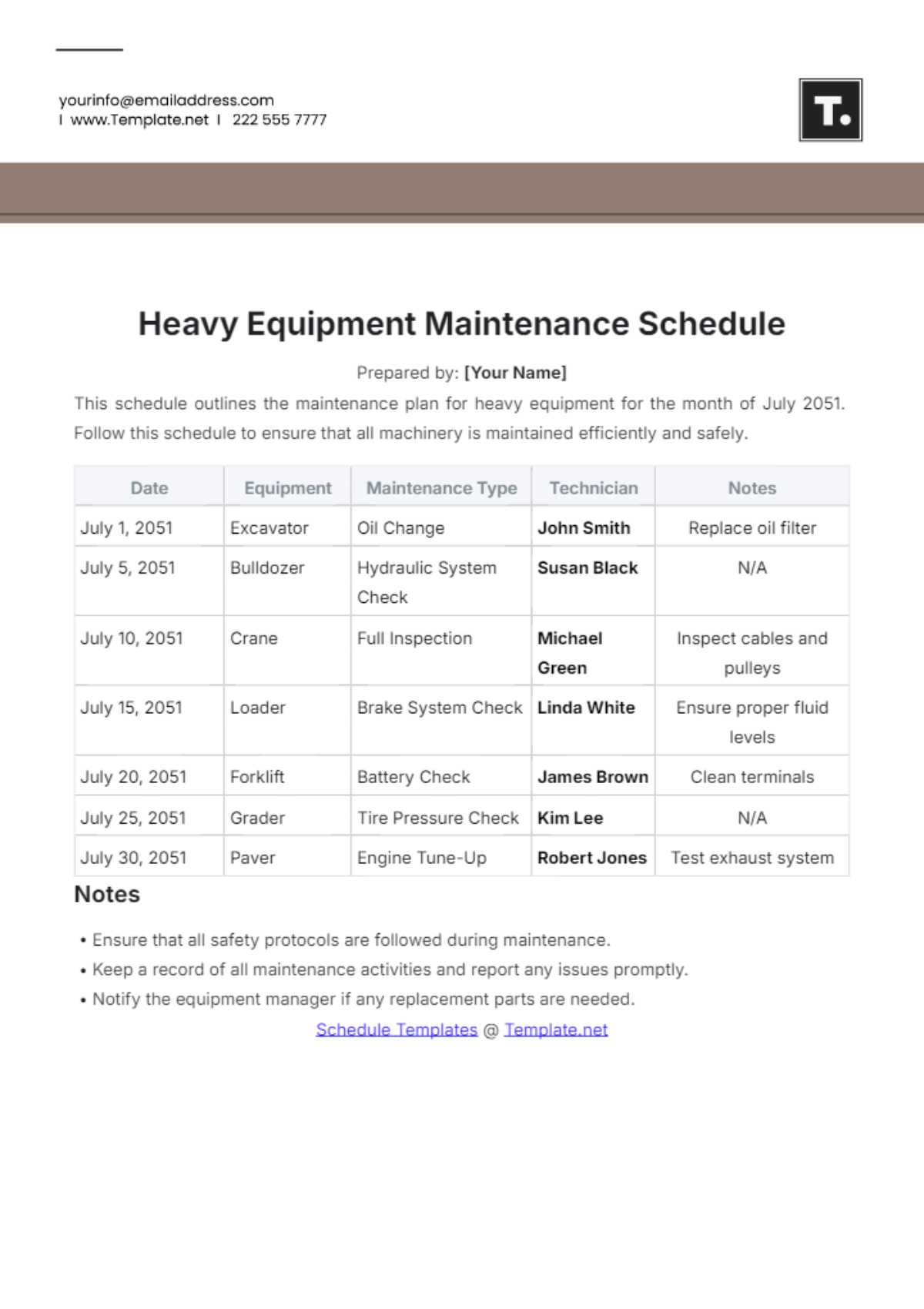

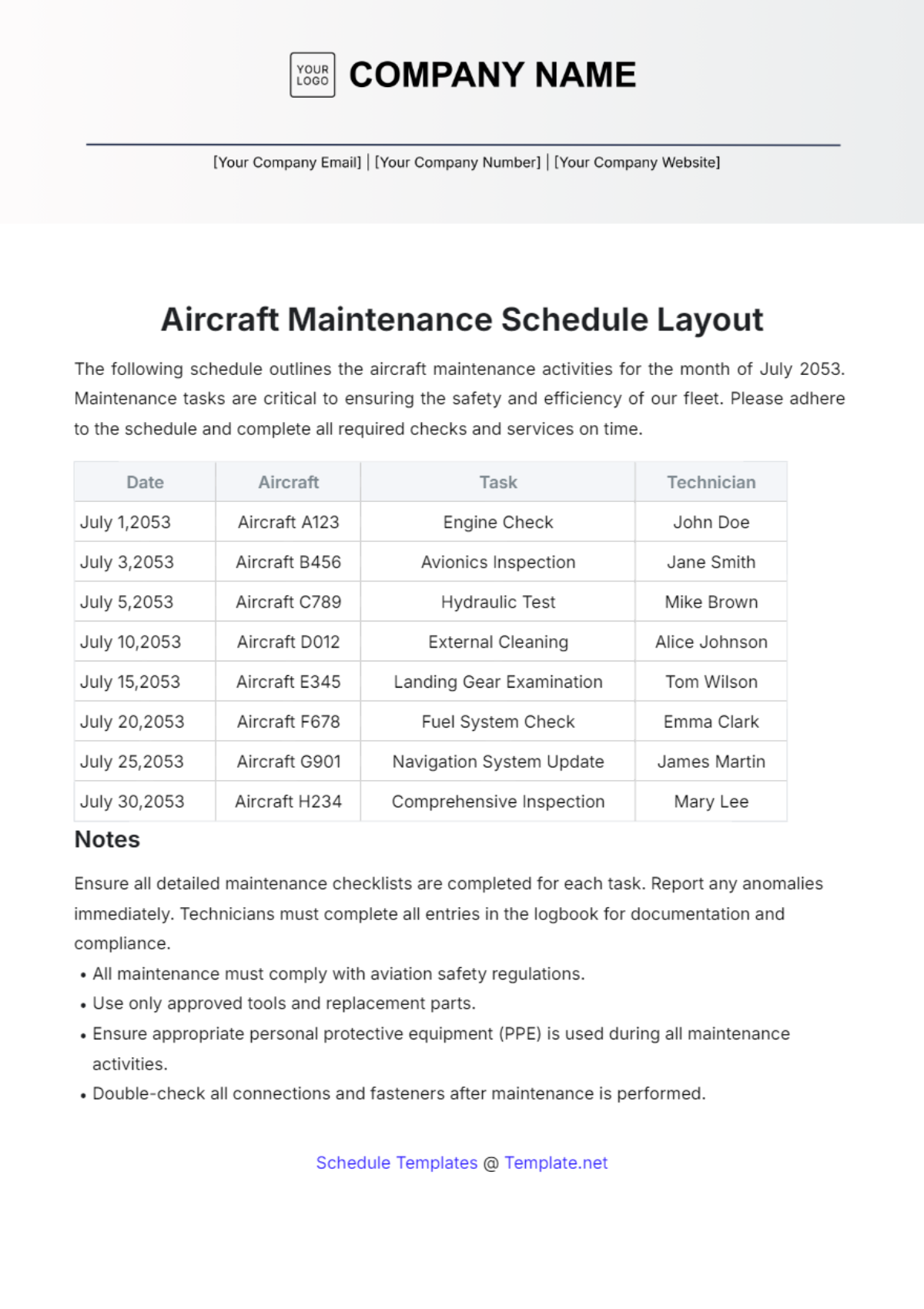

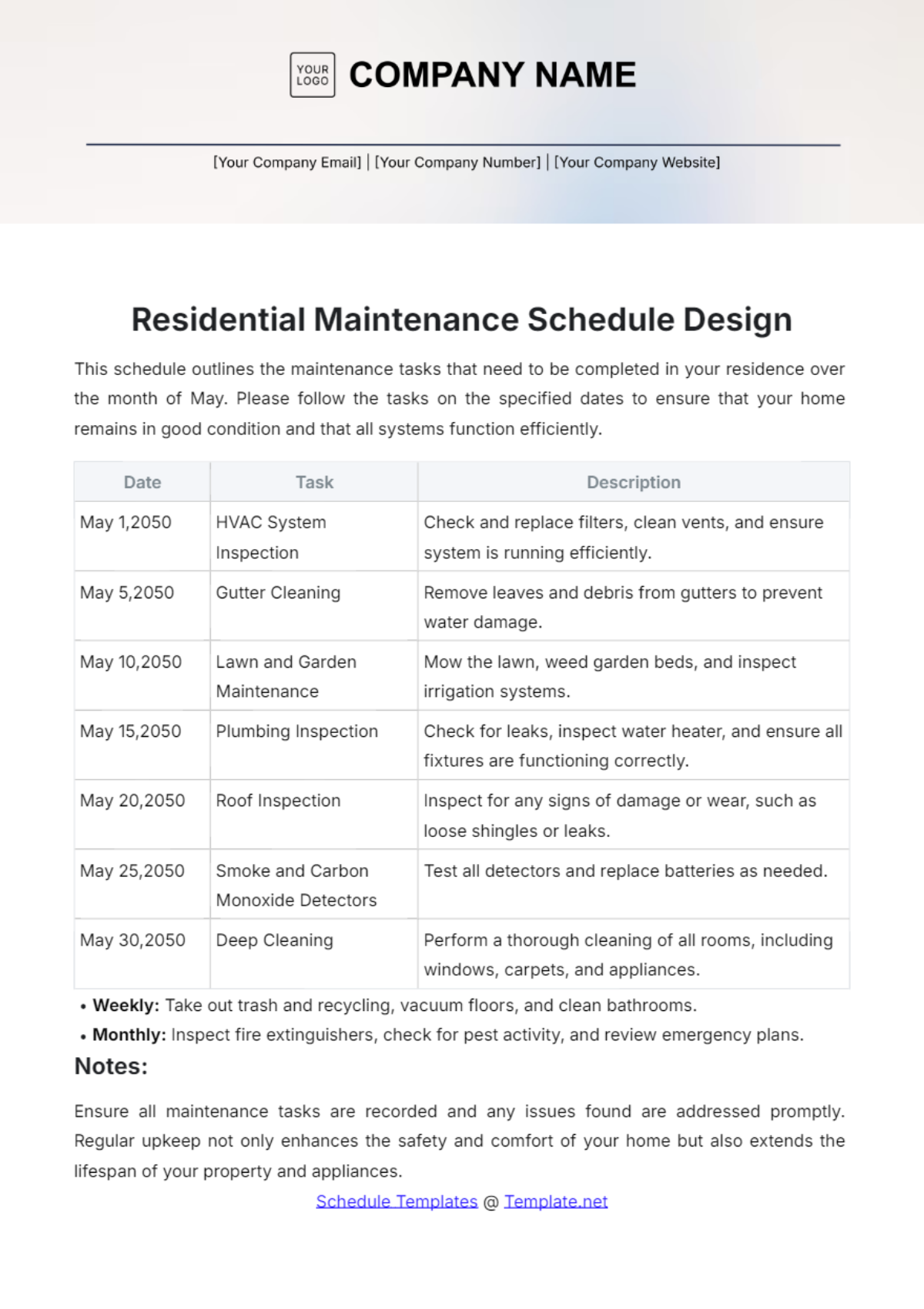

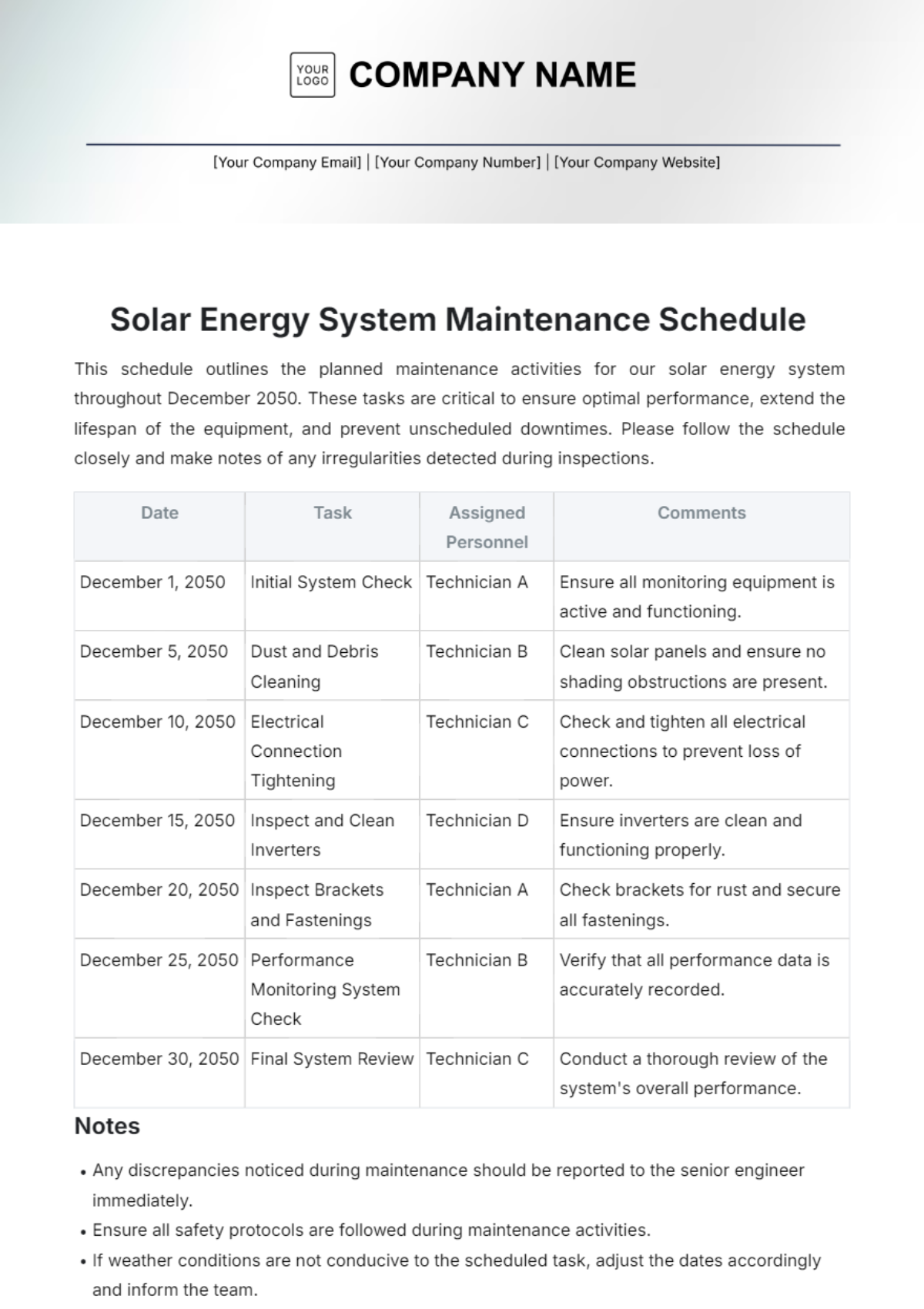

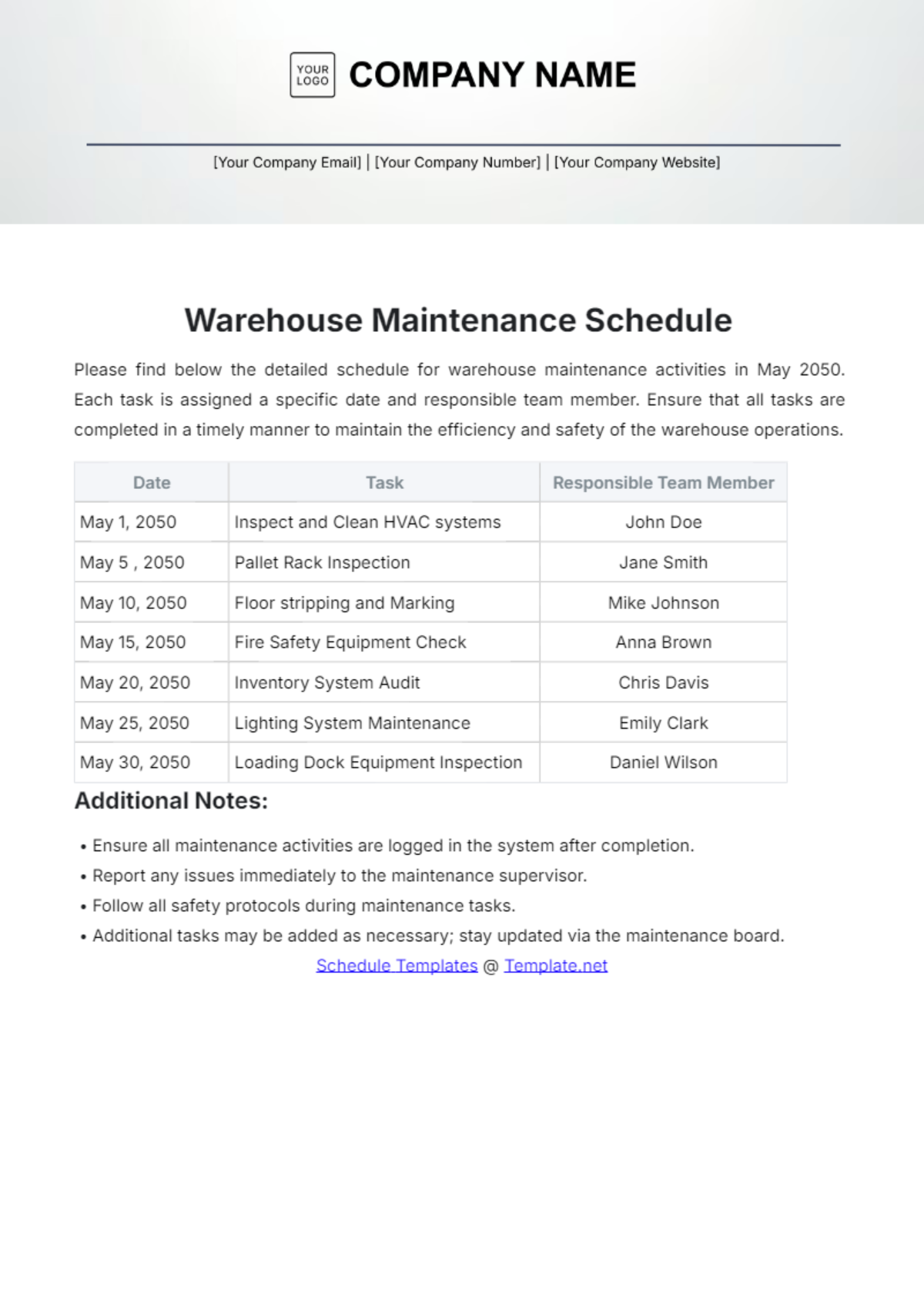

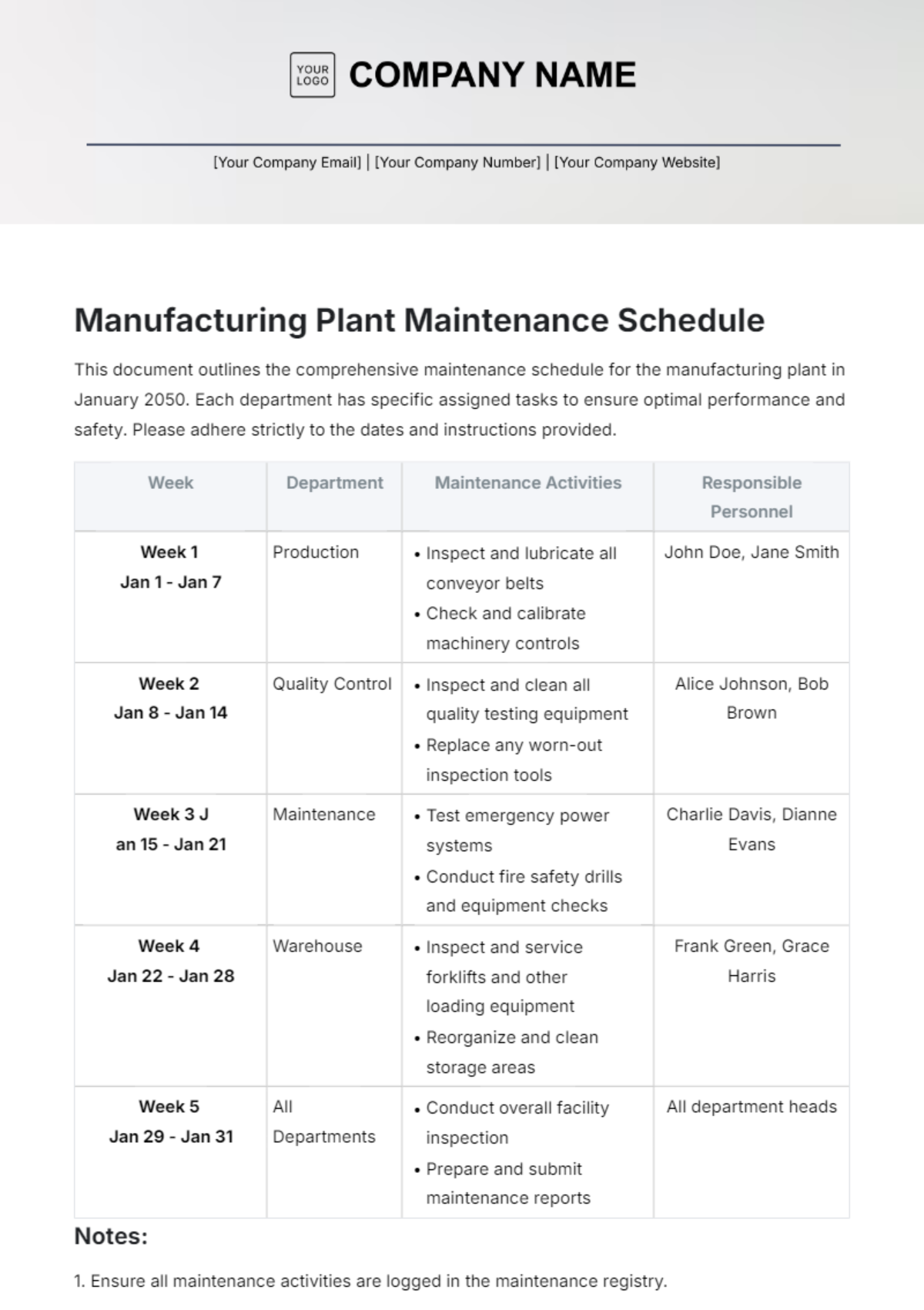

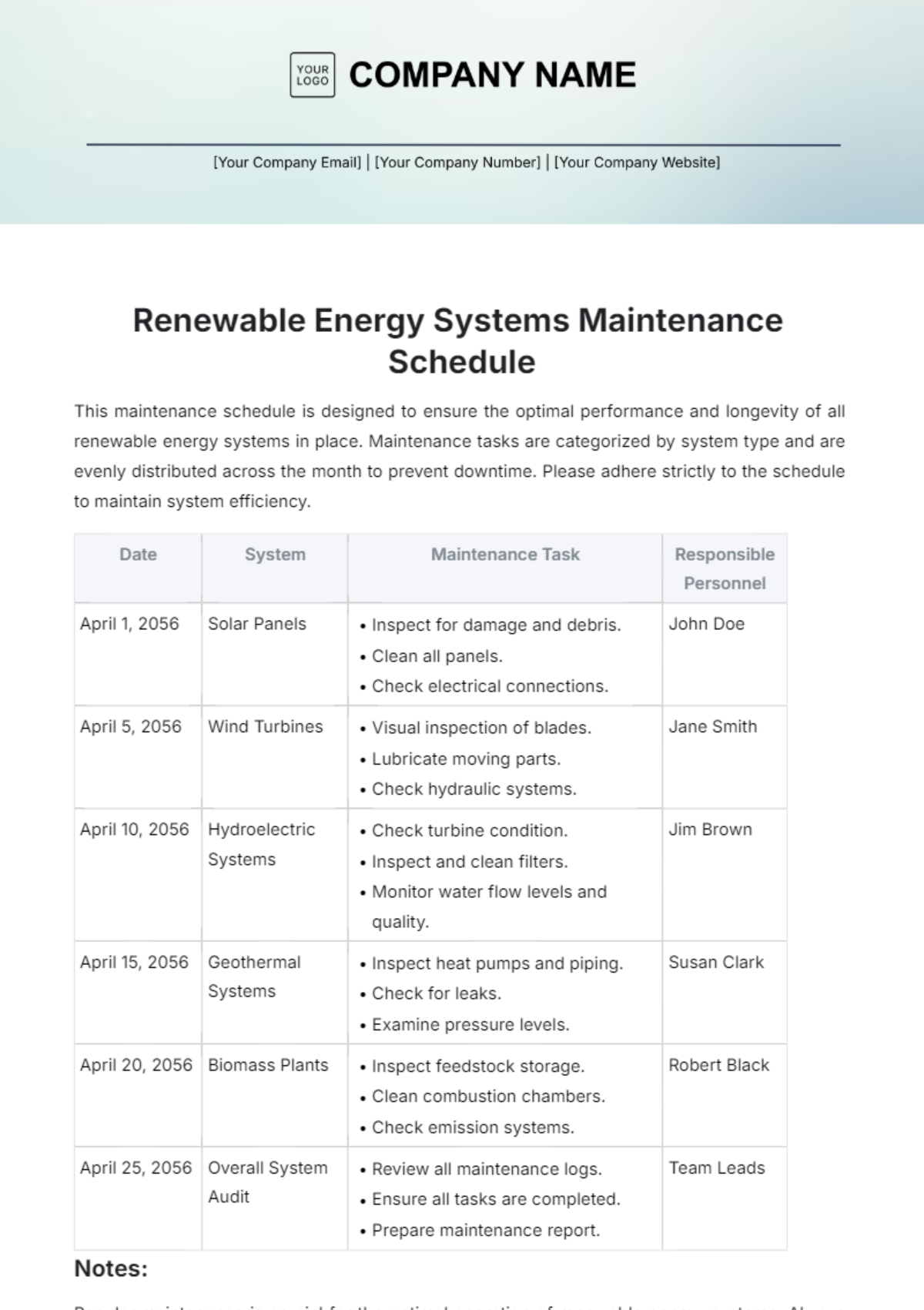

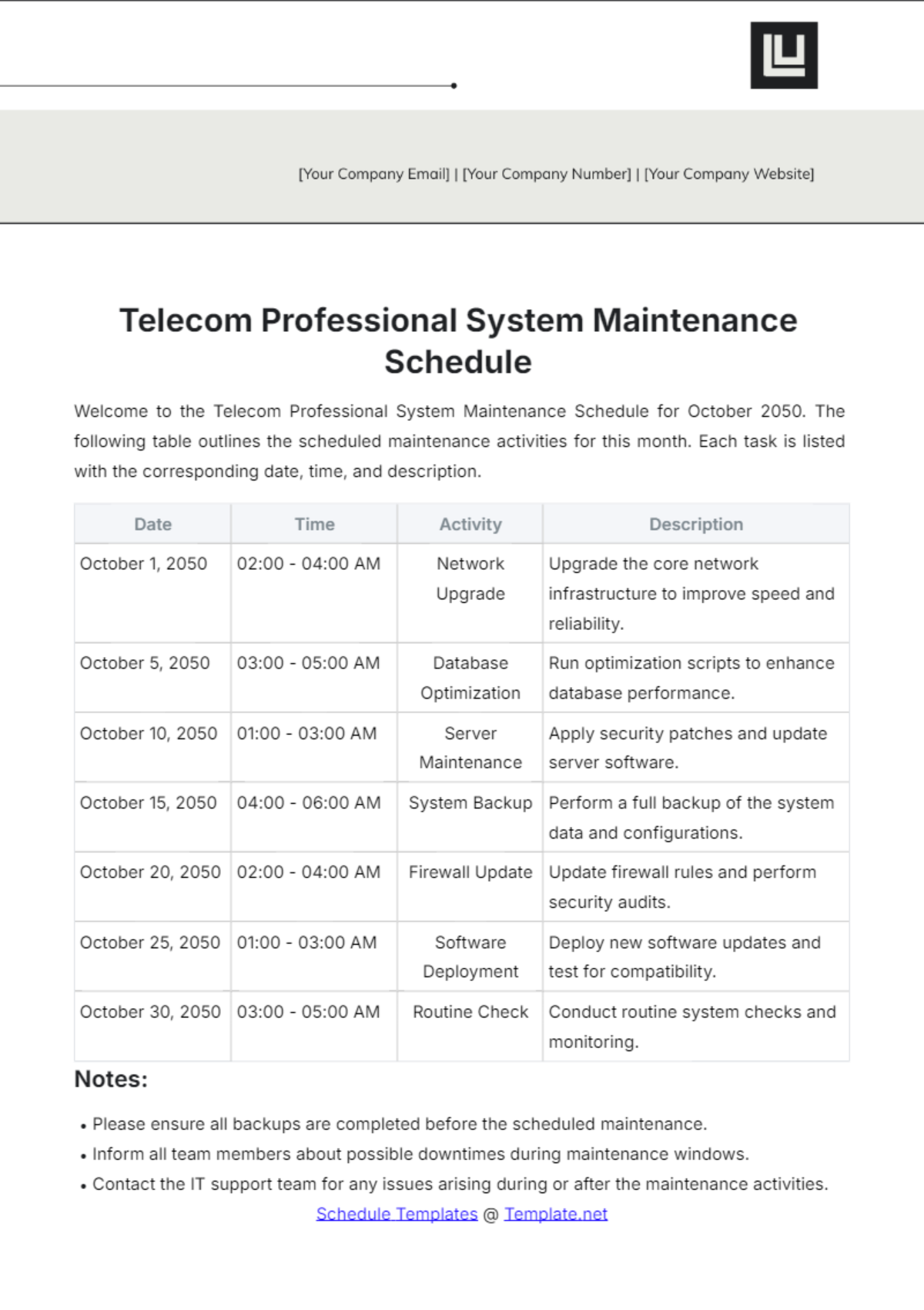

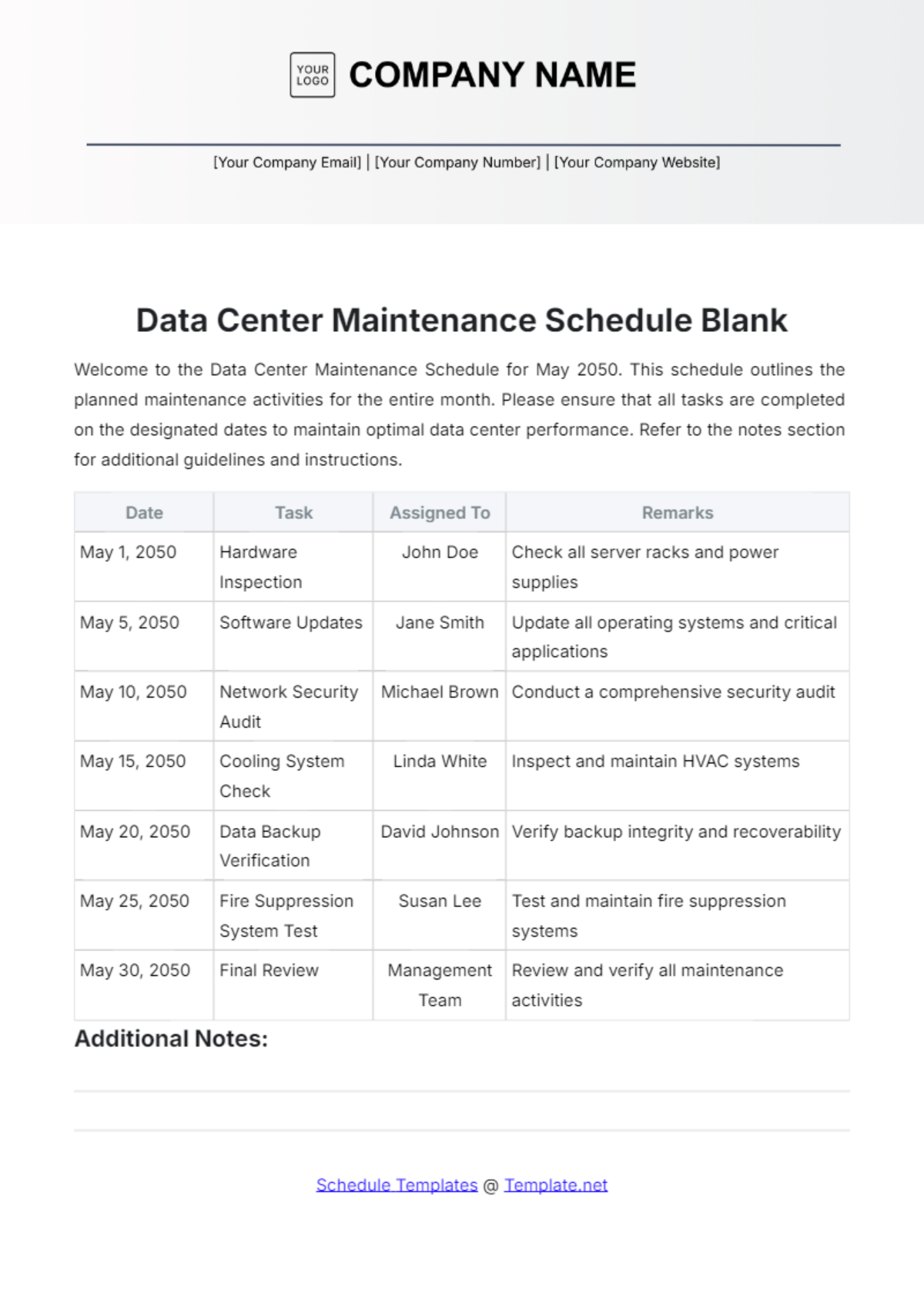

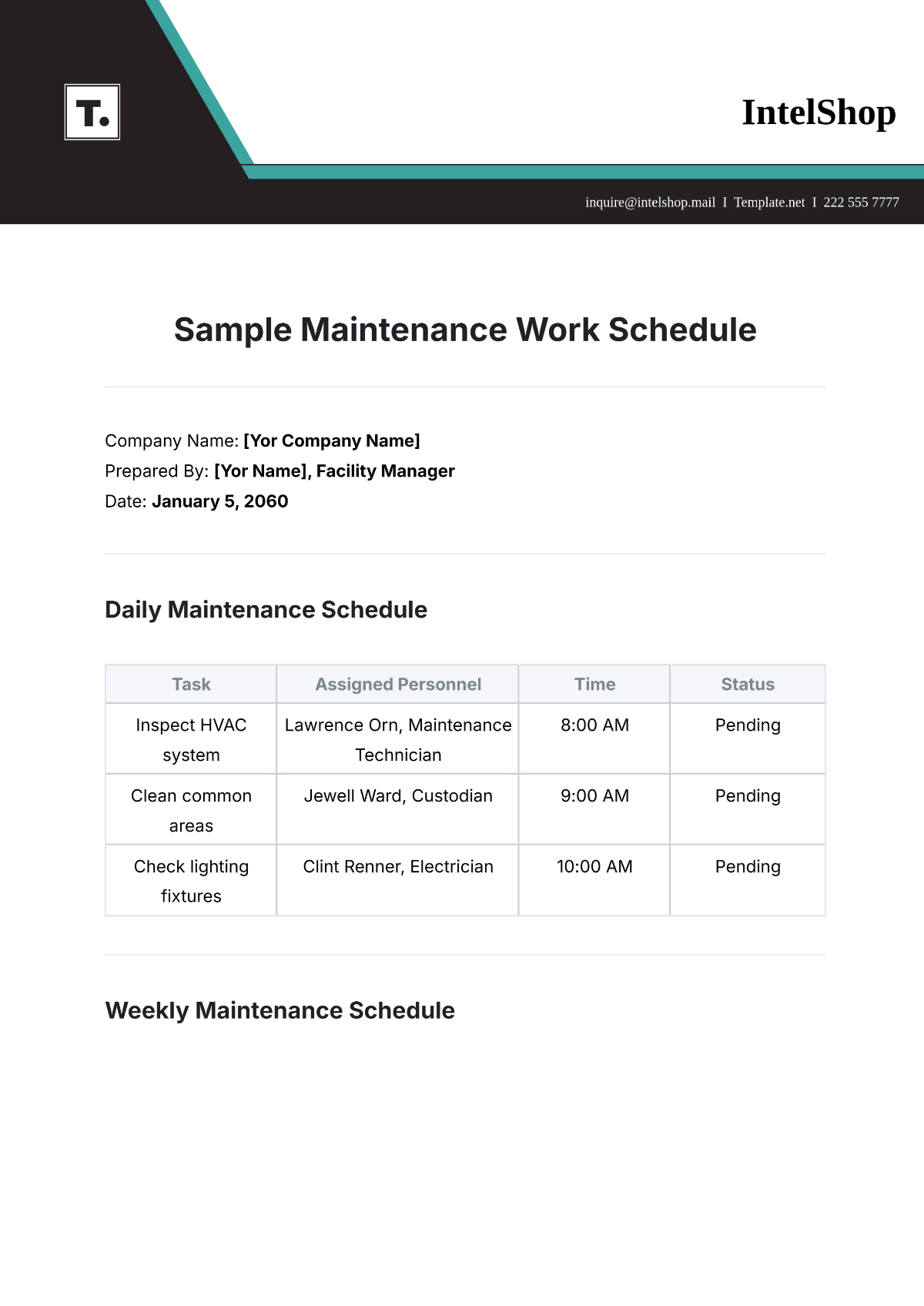

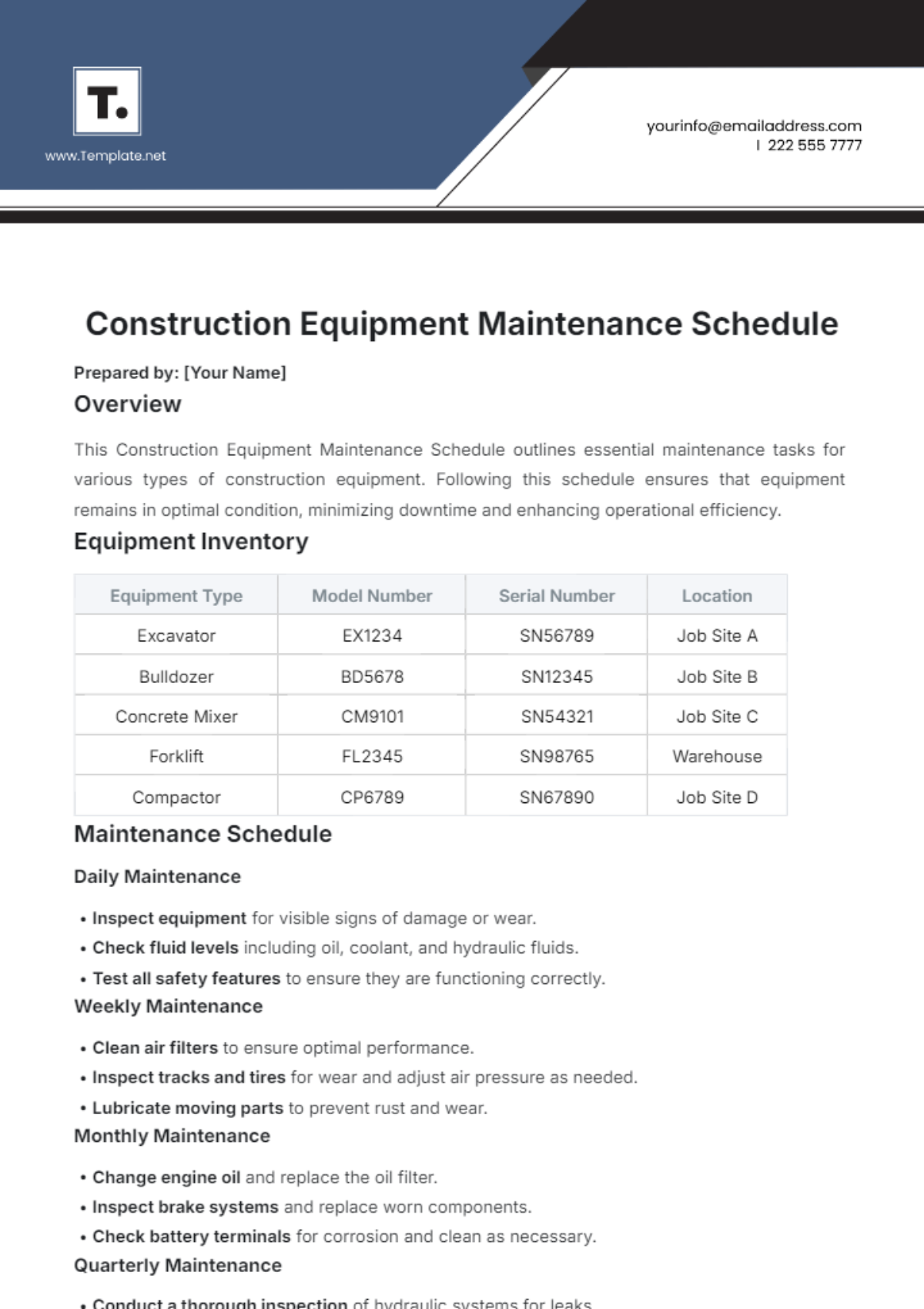

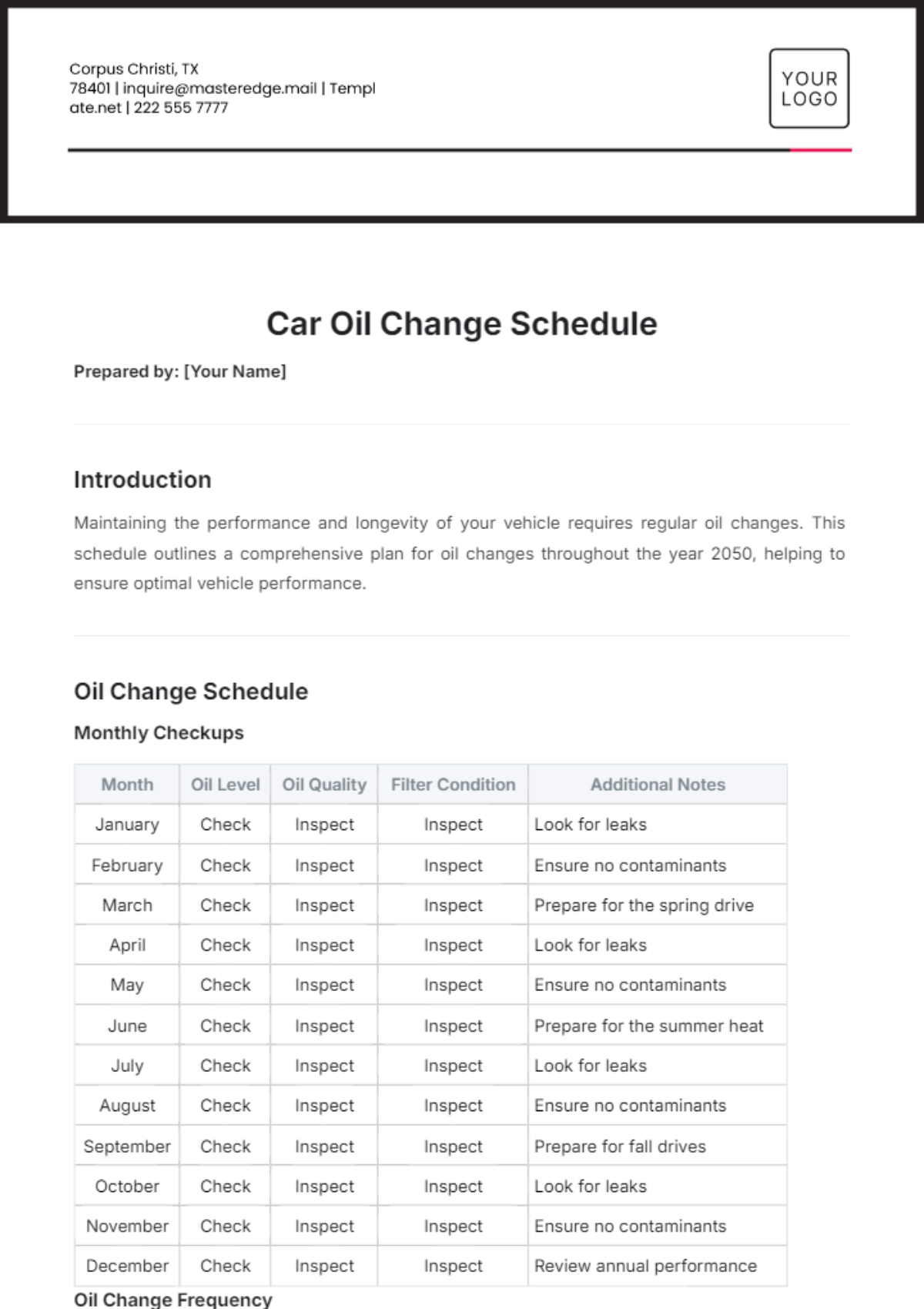

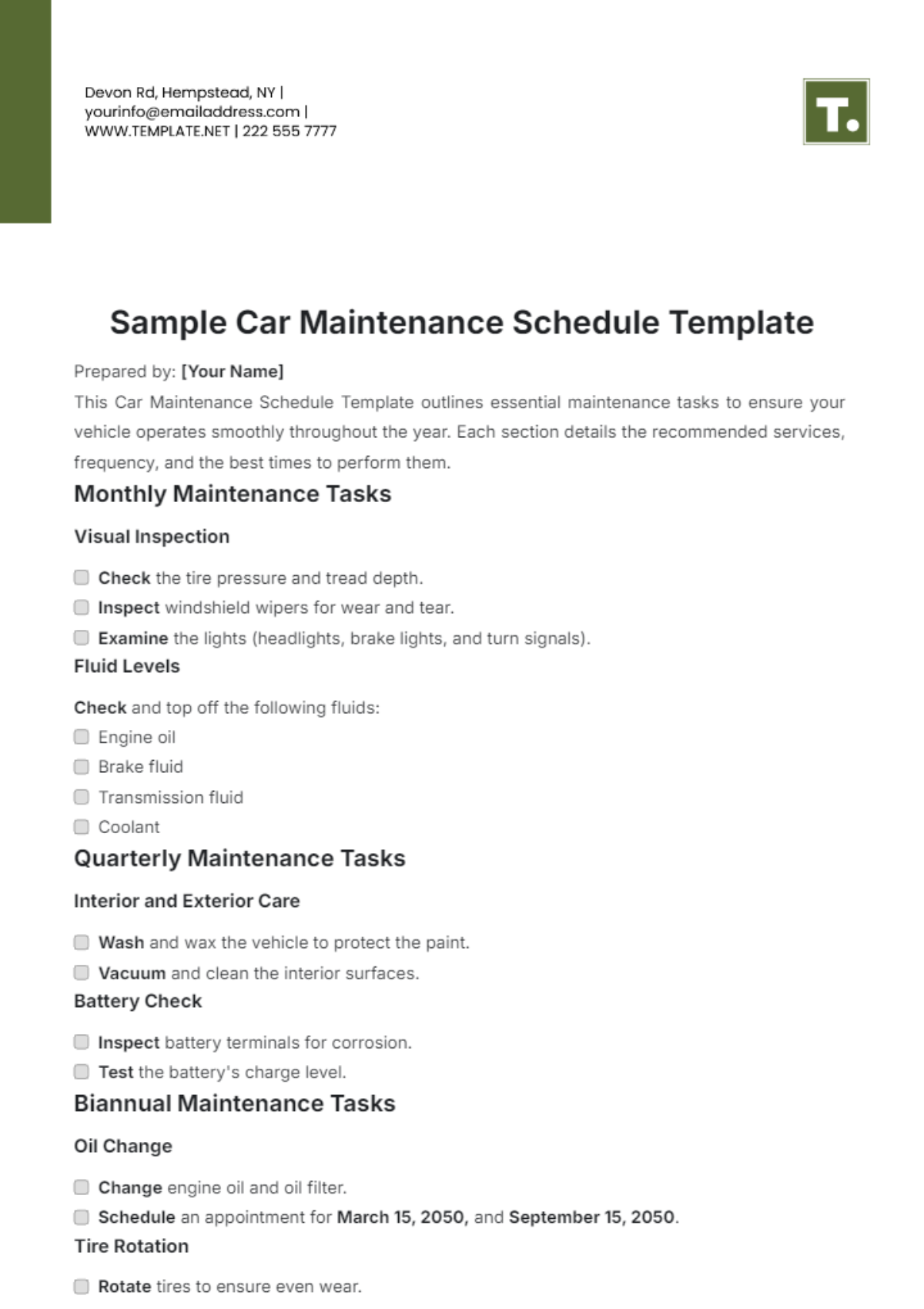

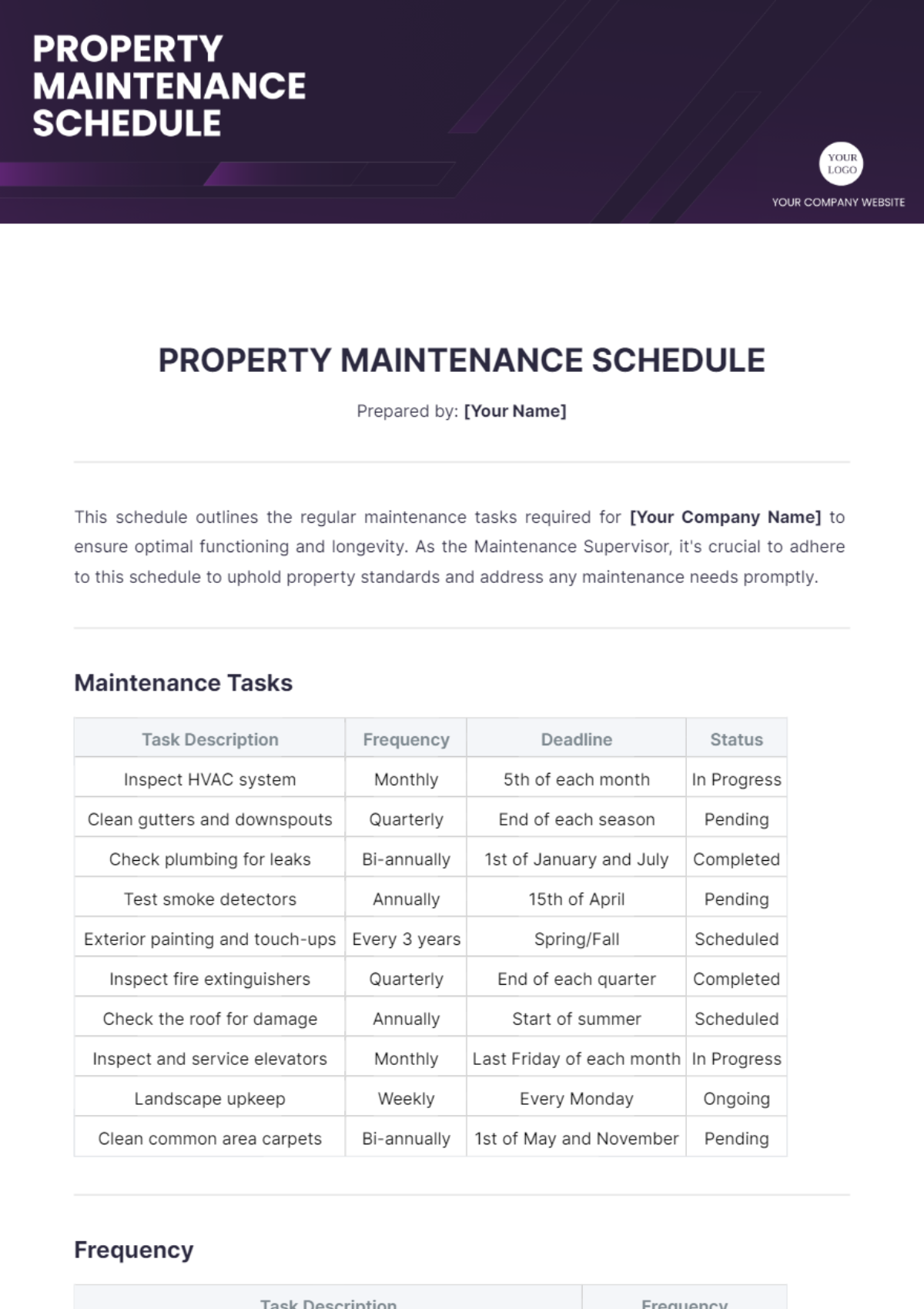

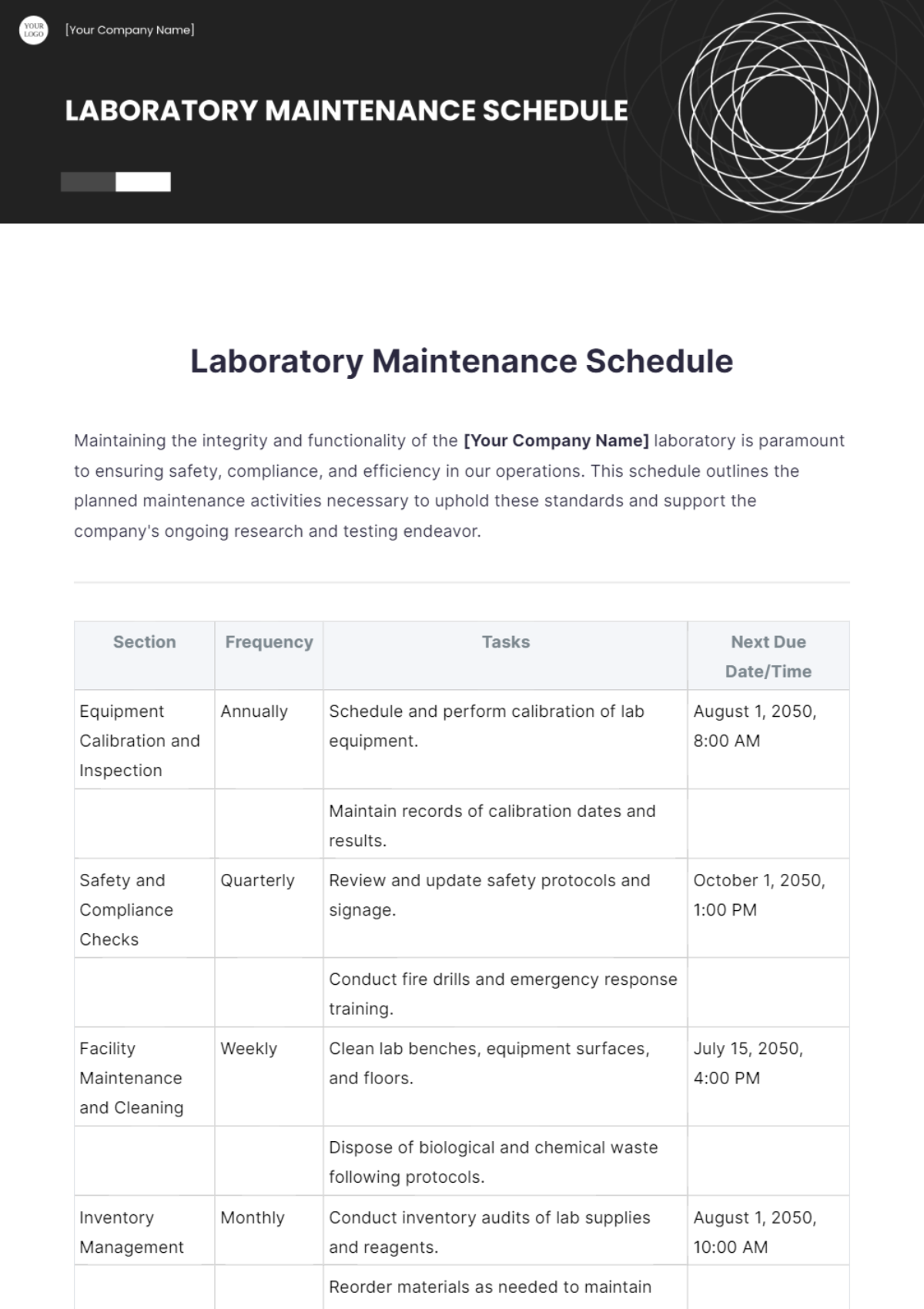

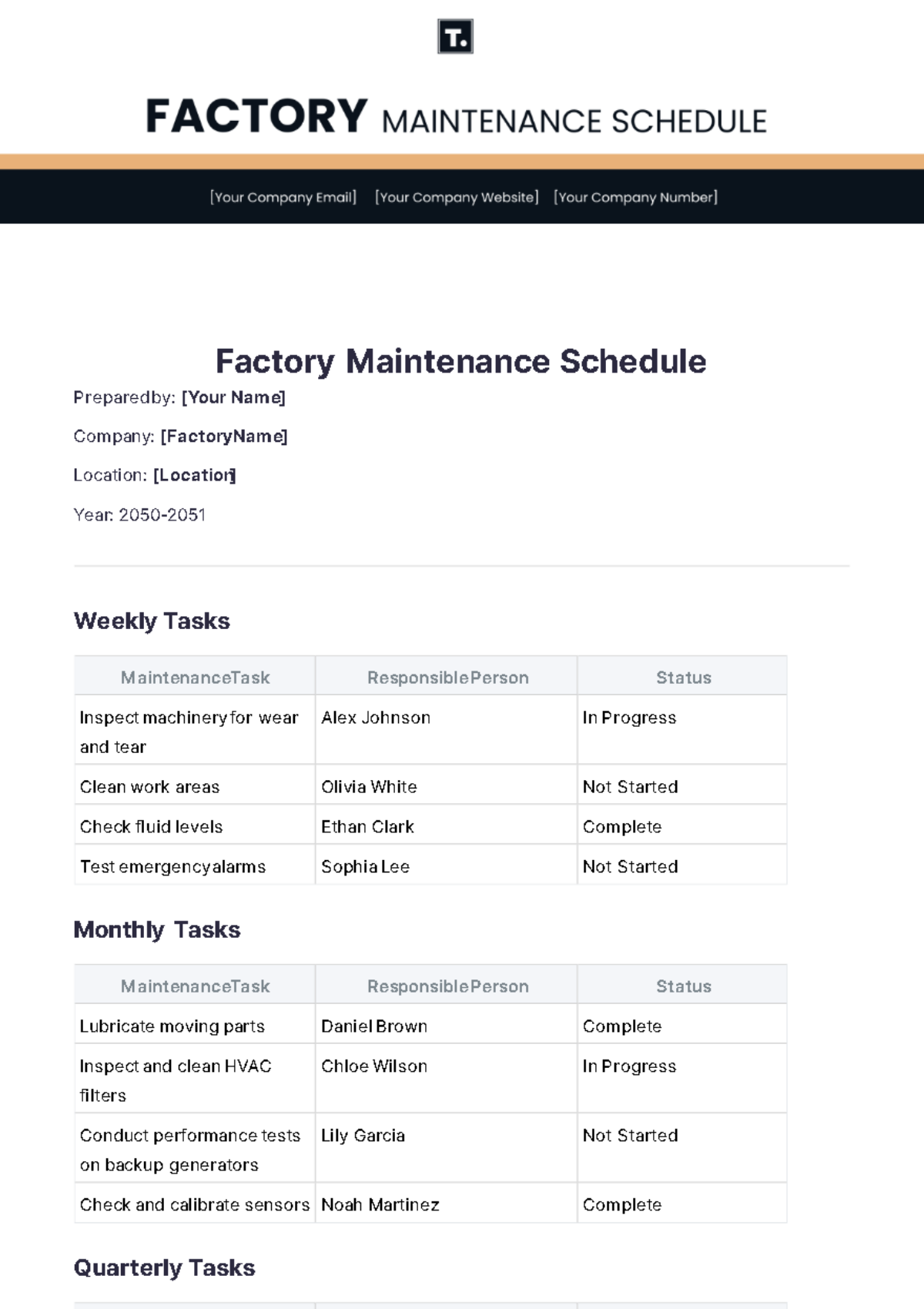

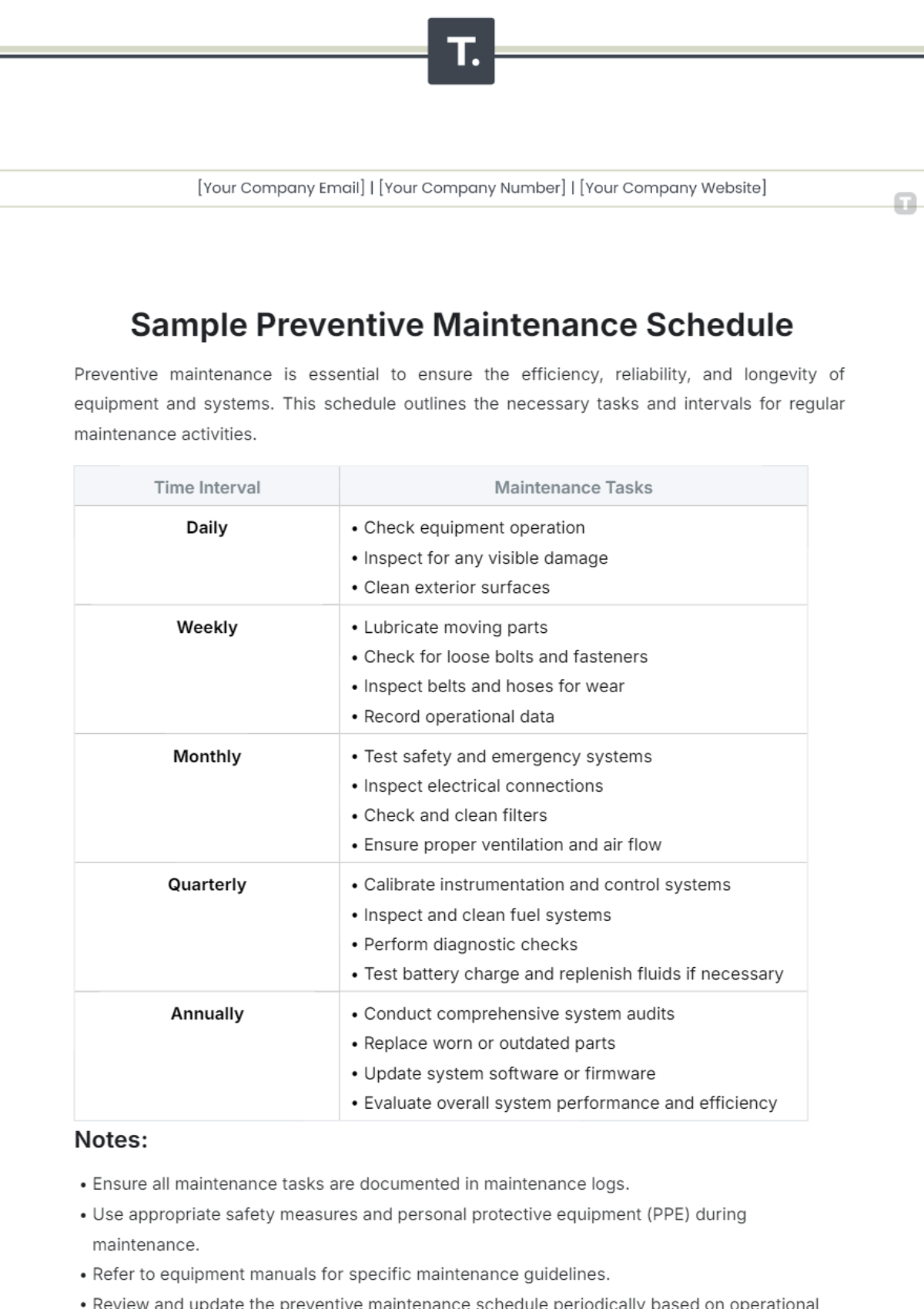

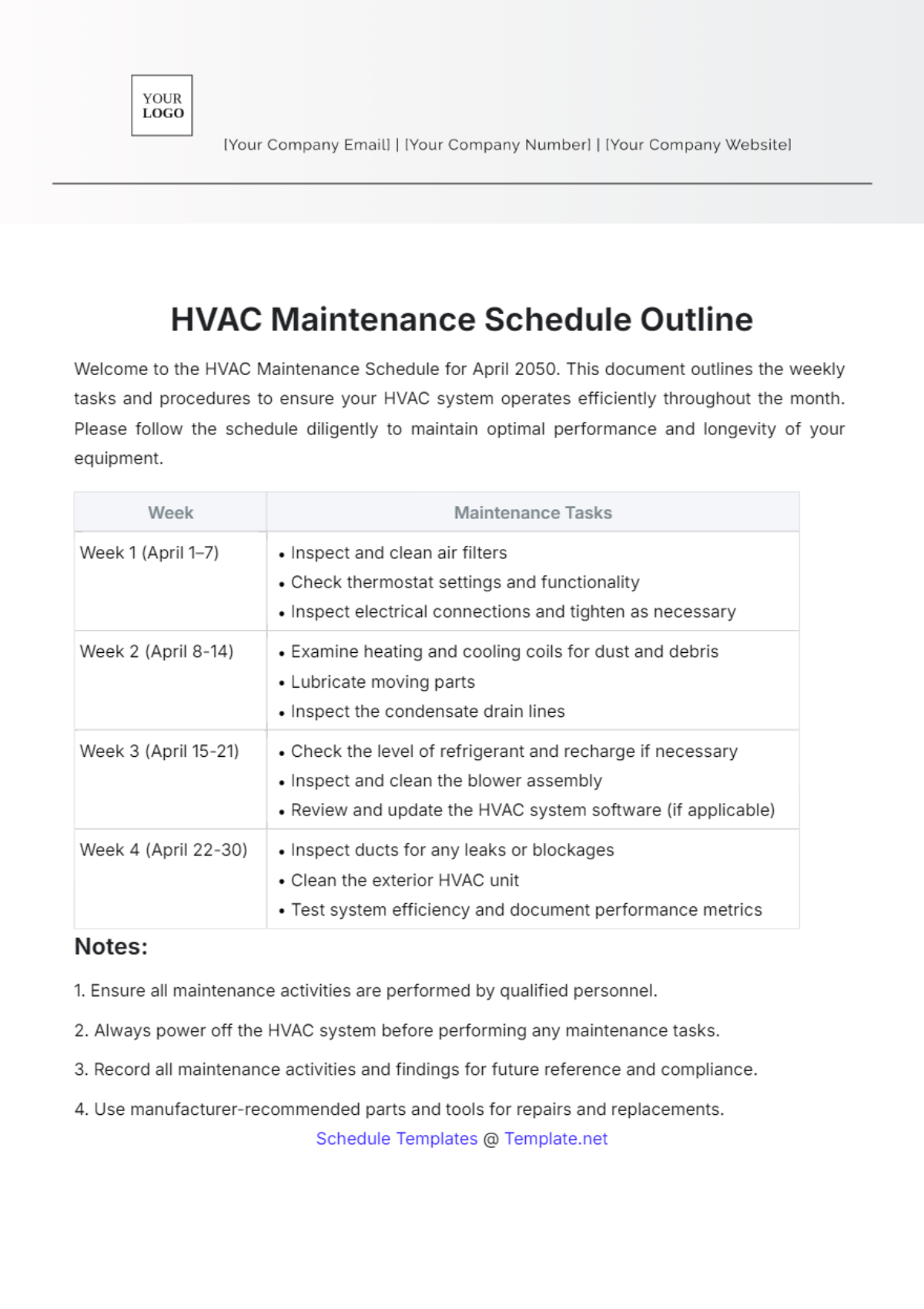

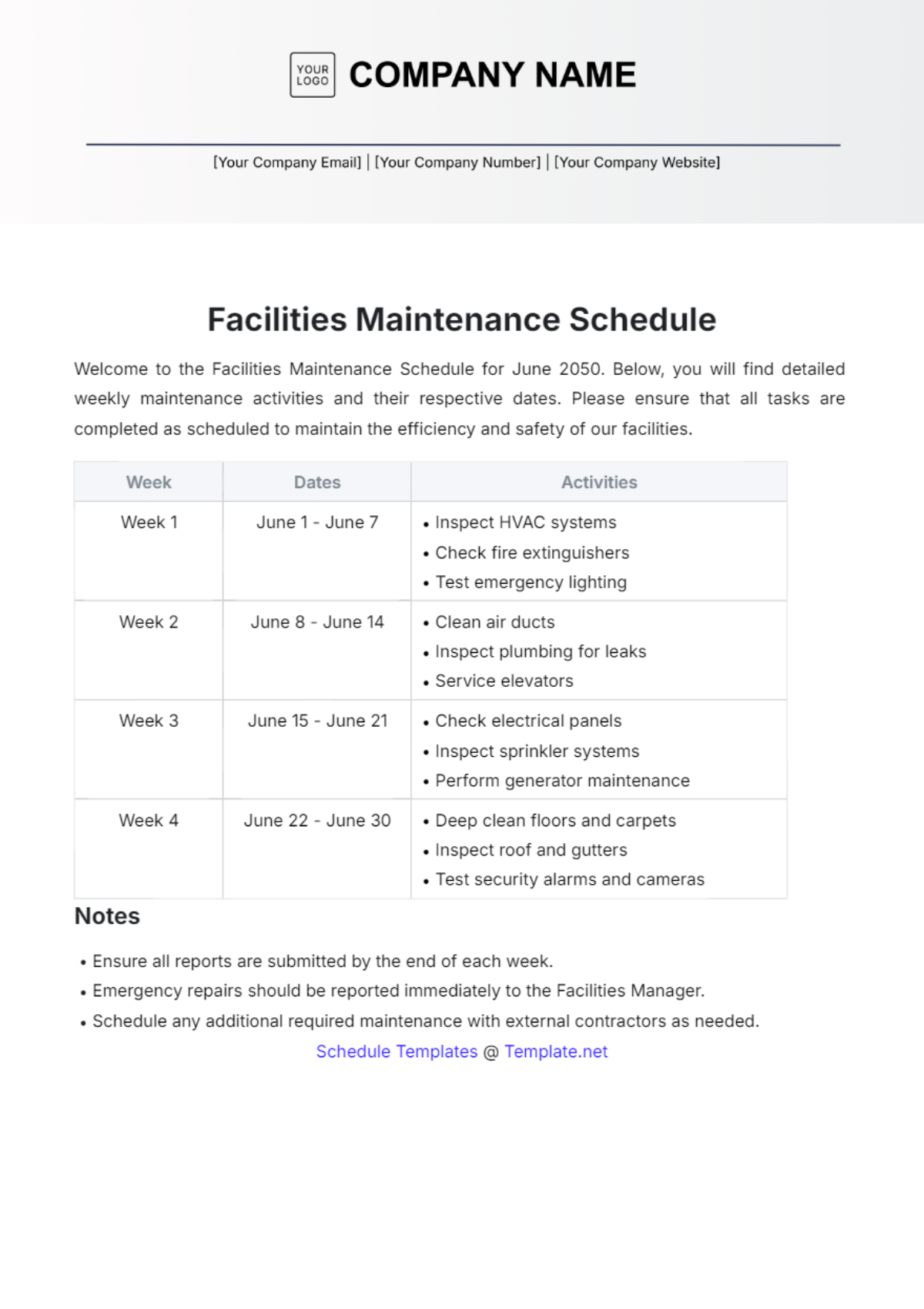

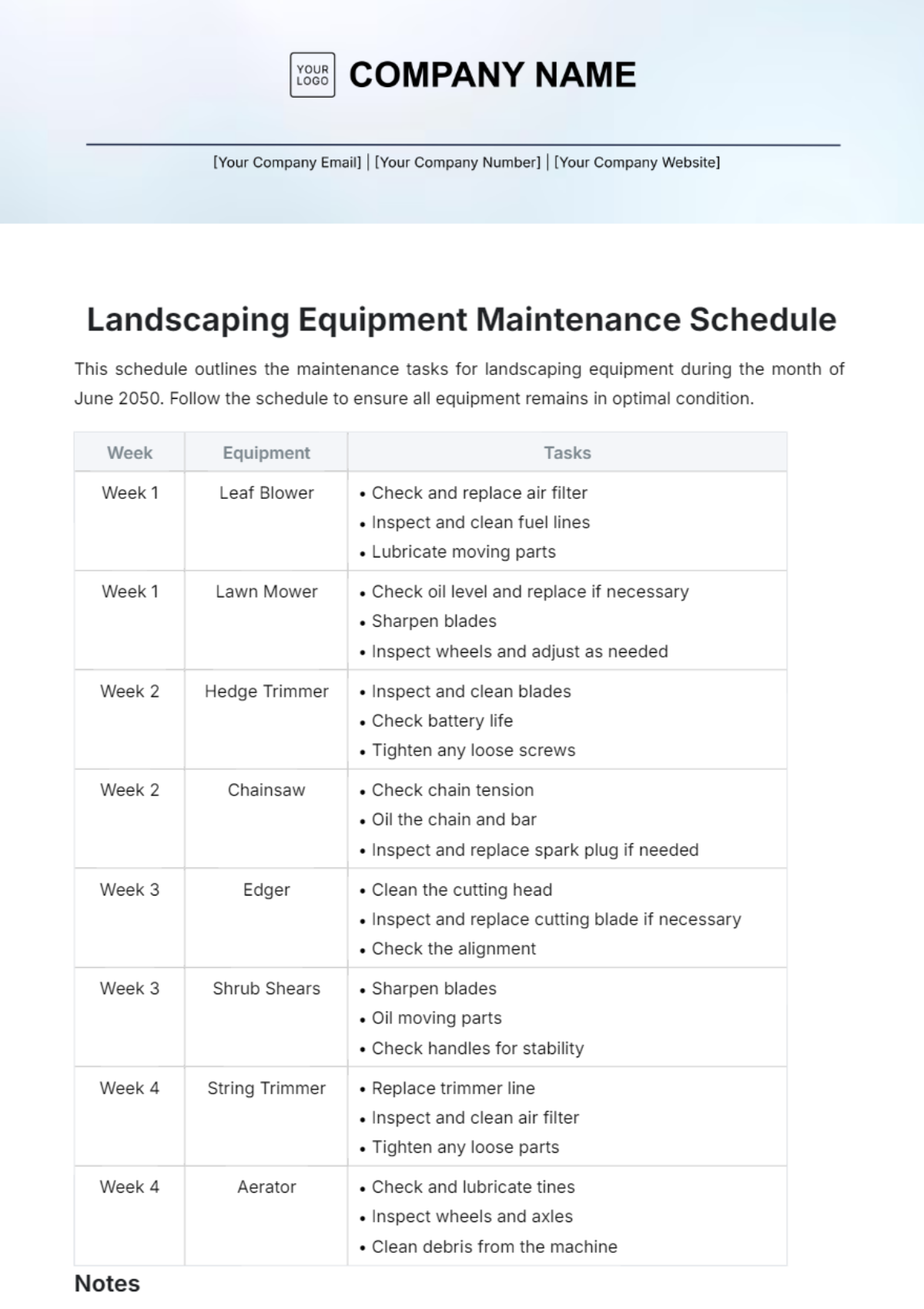

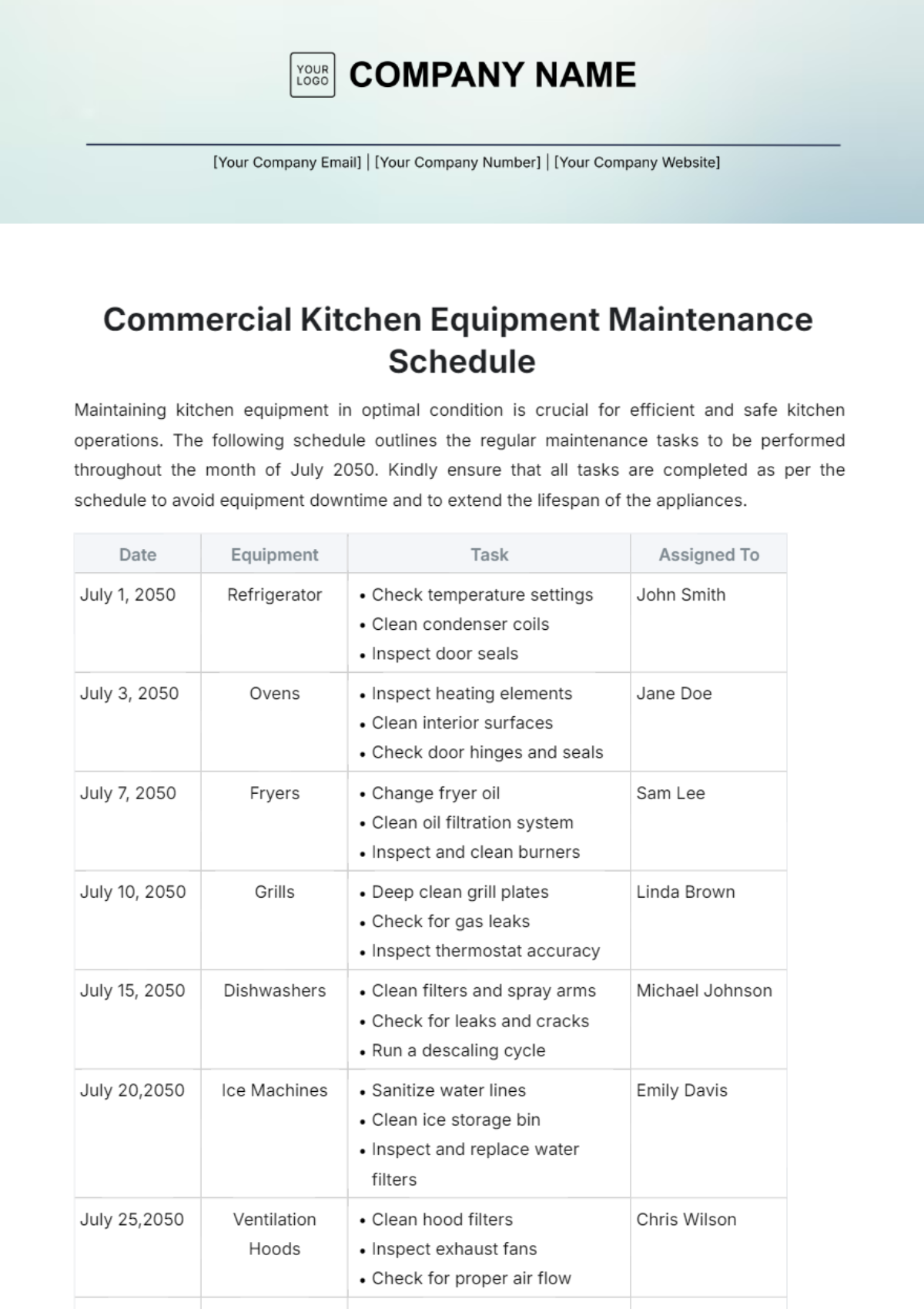

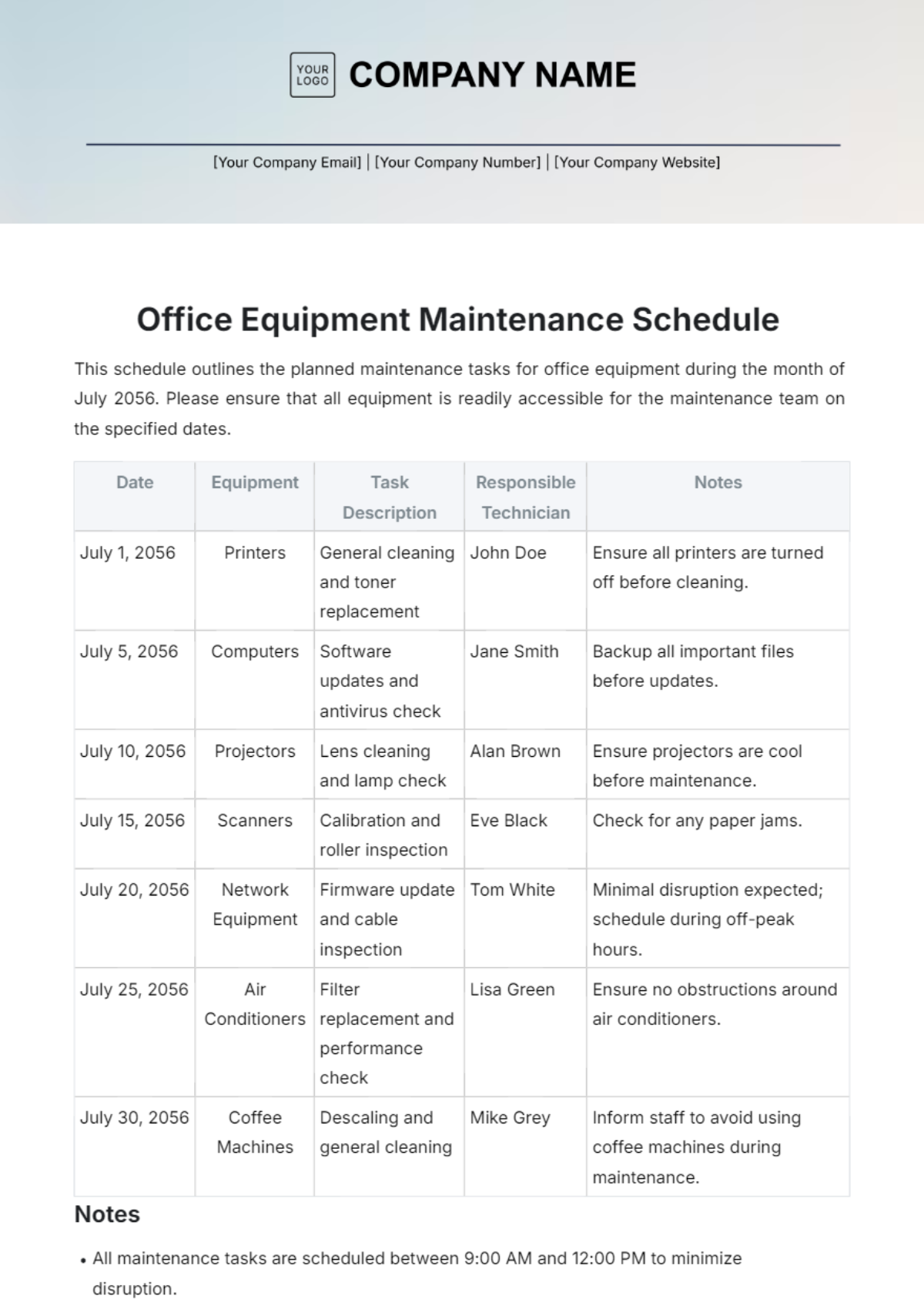

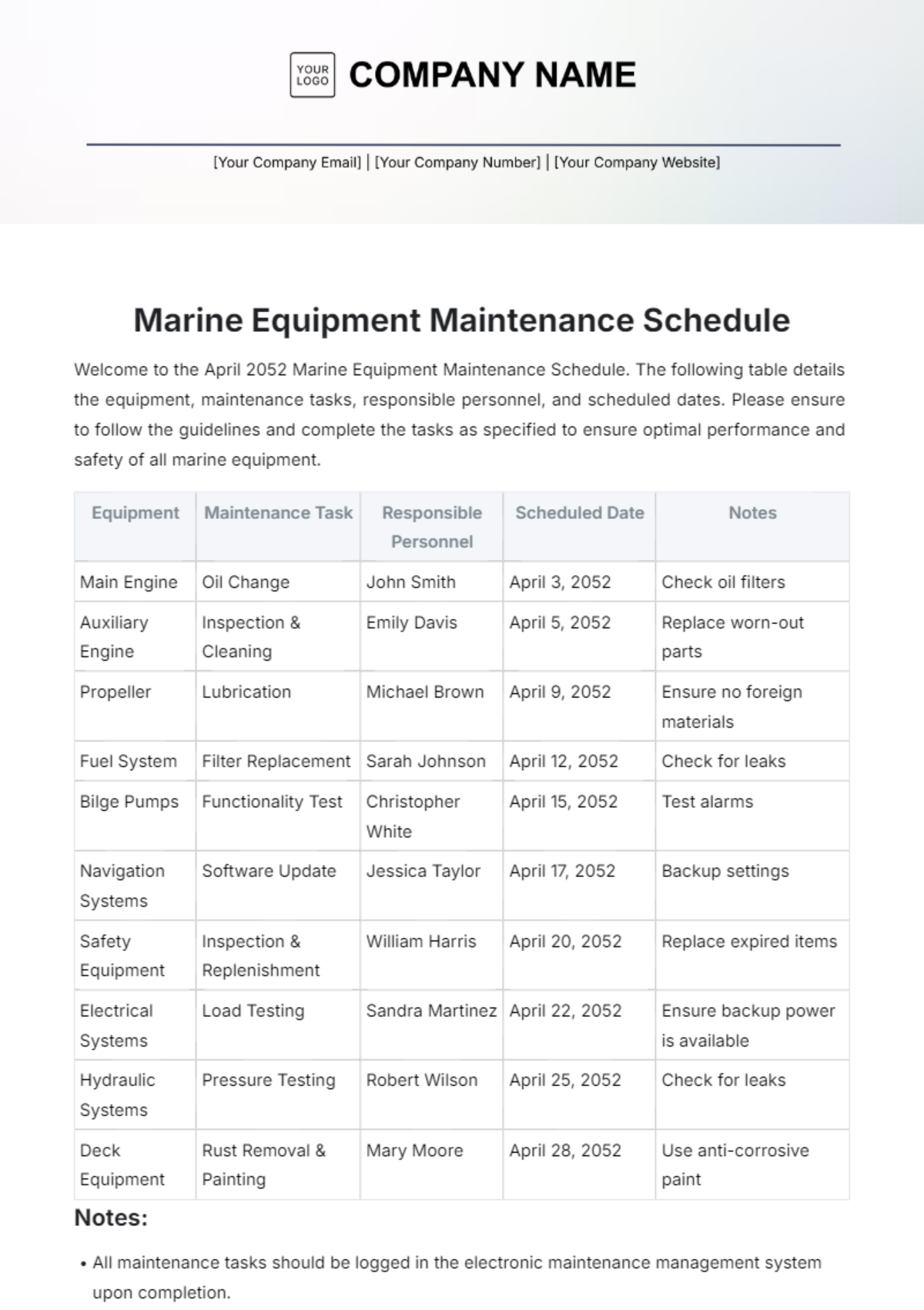

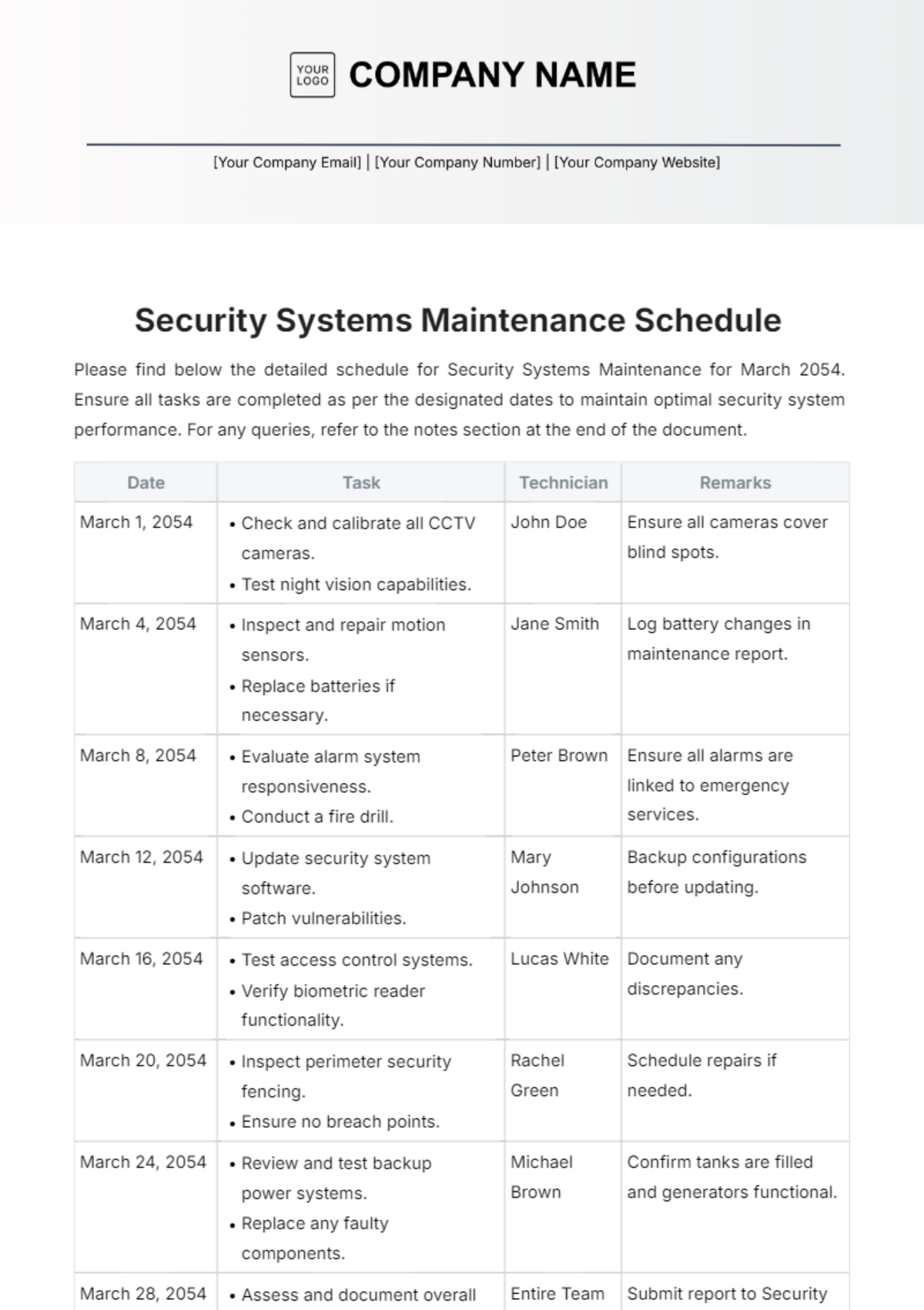

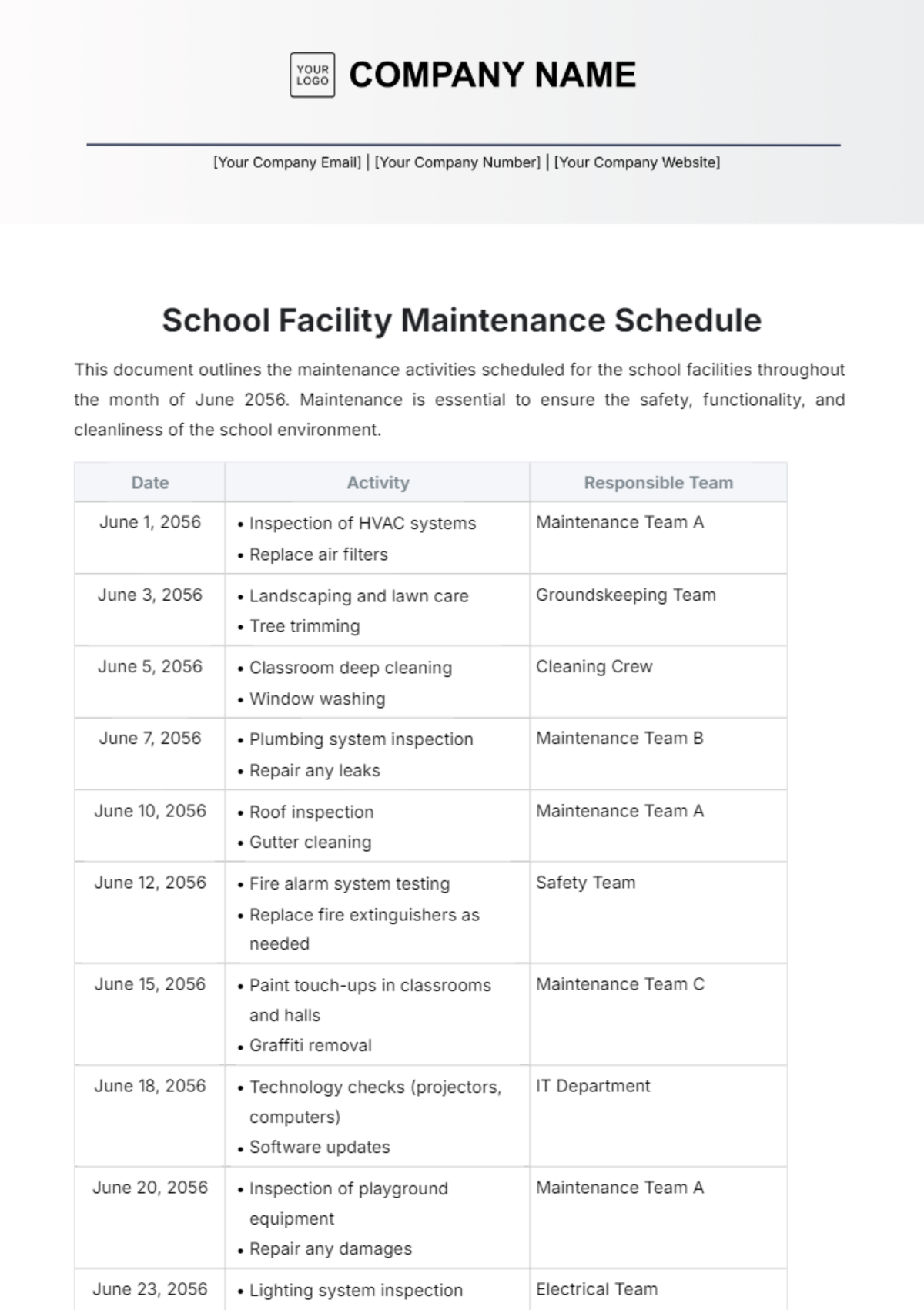

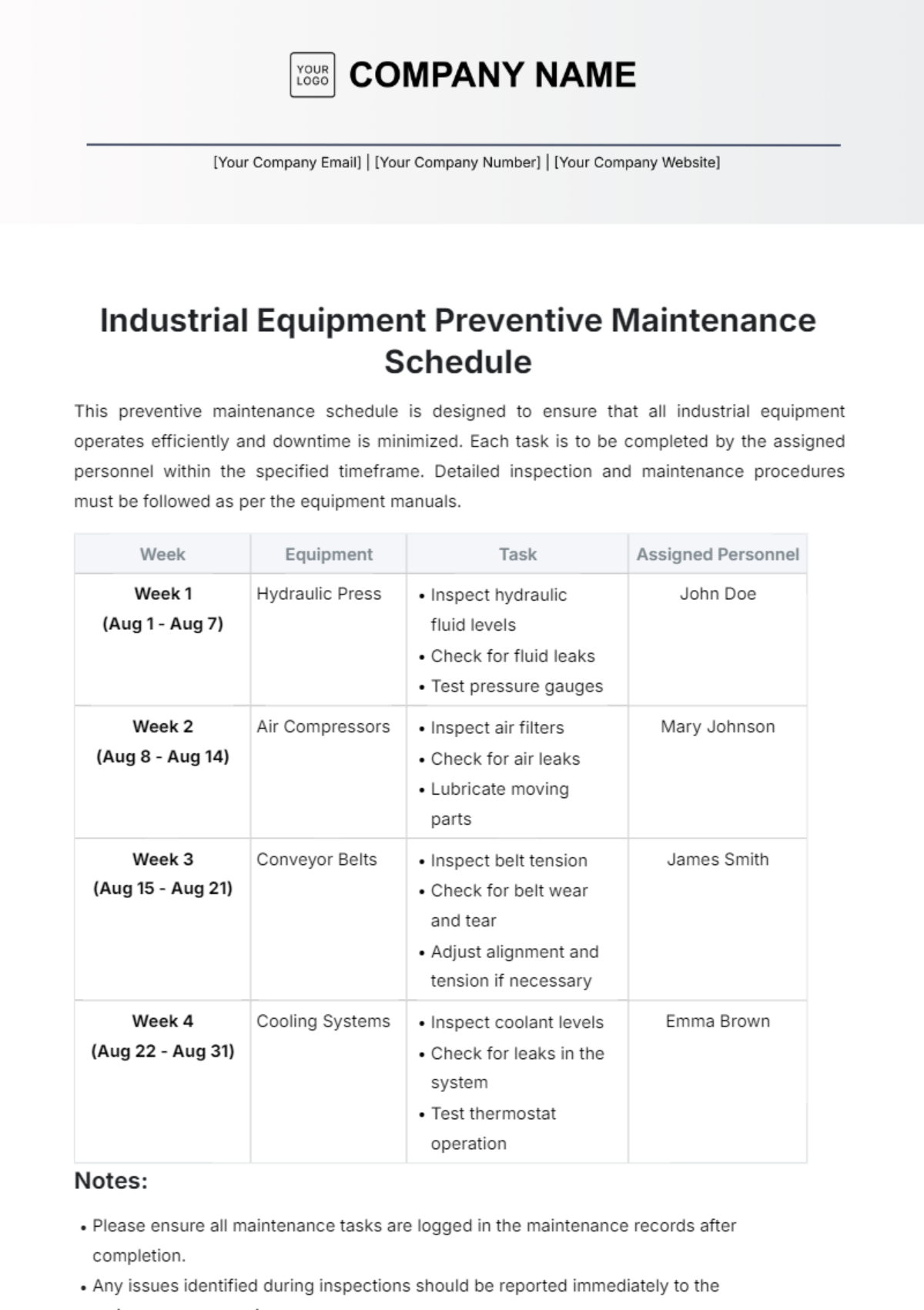

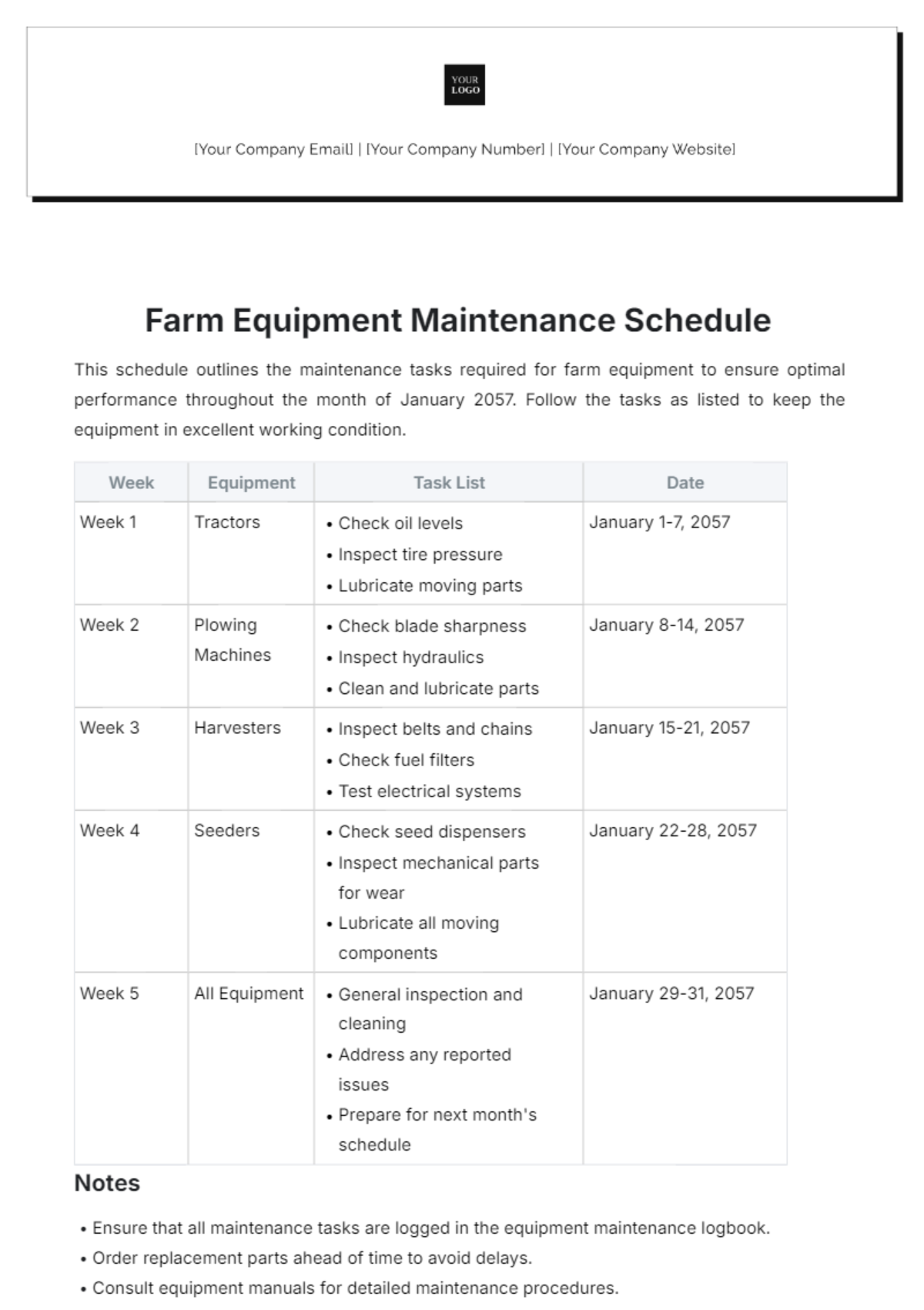

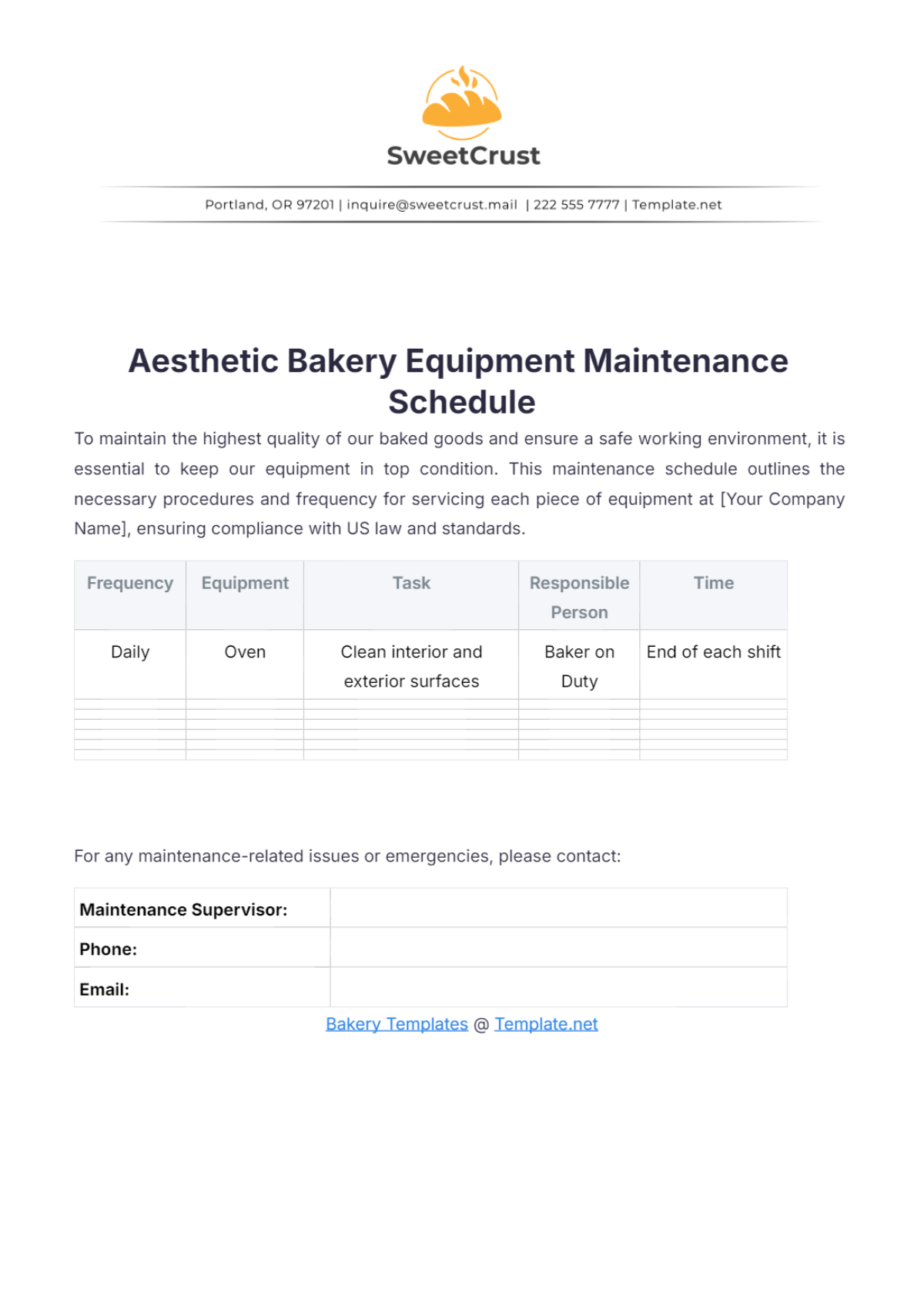

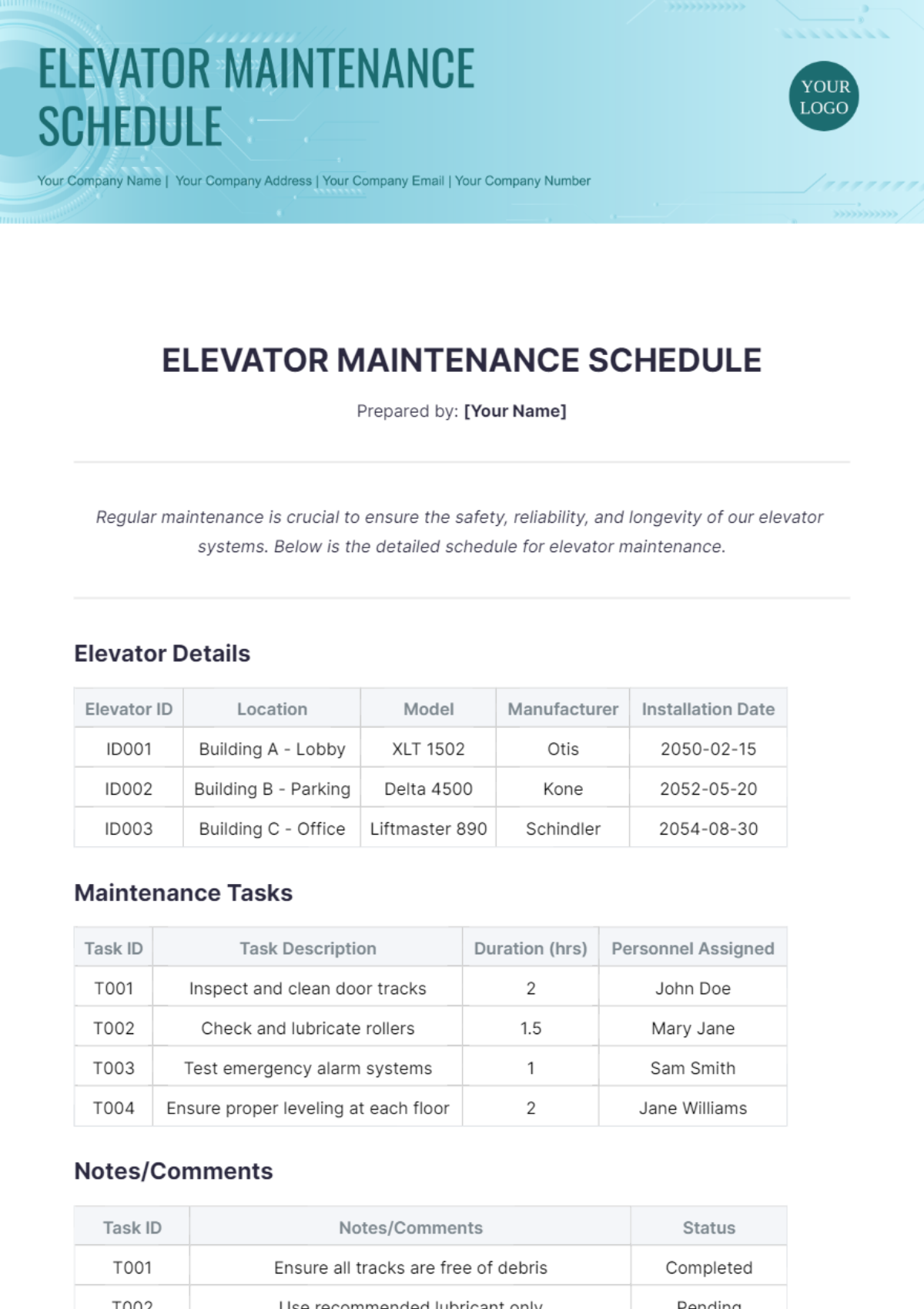

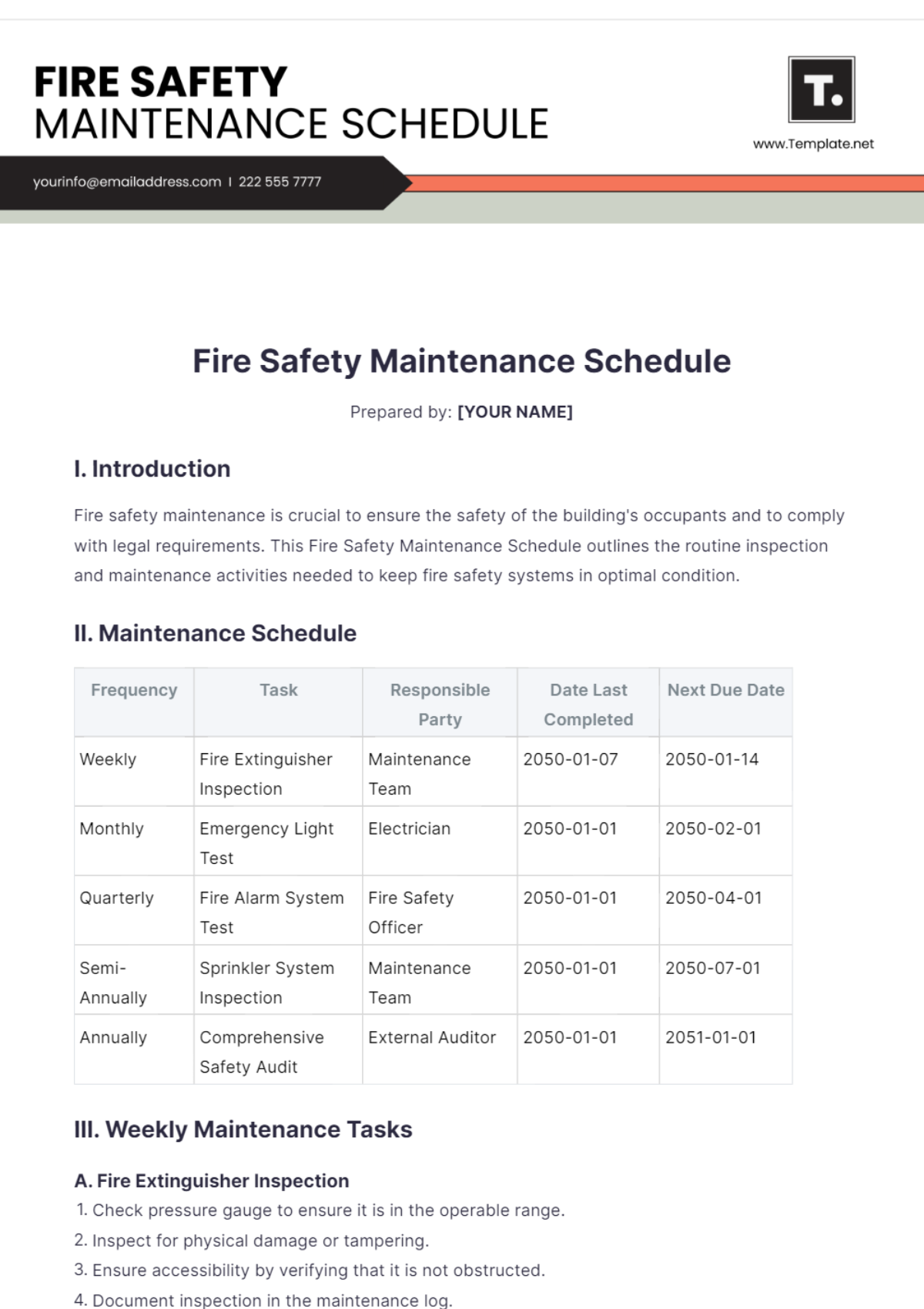

3. Maintenance Schedule

Maintenance Task | Frequency | Assigned To | Start Date | End Date |

|---|---|---|---|---|

Check and lubricate bearings | Weekly | [Name/Position] | [Date] | [Date] |

Inspect conveyor belts | Weekly | [Name/Position] | [Date] | [Date] |

Clean machinery | Monthly | [Name/Position] | [Date] | [Date] |

Replace worn parts | Quarterly | [Name/Position] | [Date] | [Date] |

Test safety devices | Biannually | [Name/Position] | [Date] | [Date] |

Conduct a full system audit | Annually | [Name/Position] | [Date] | [Date] |

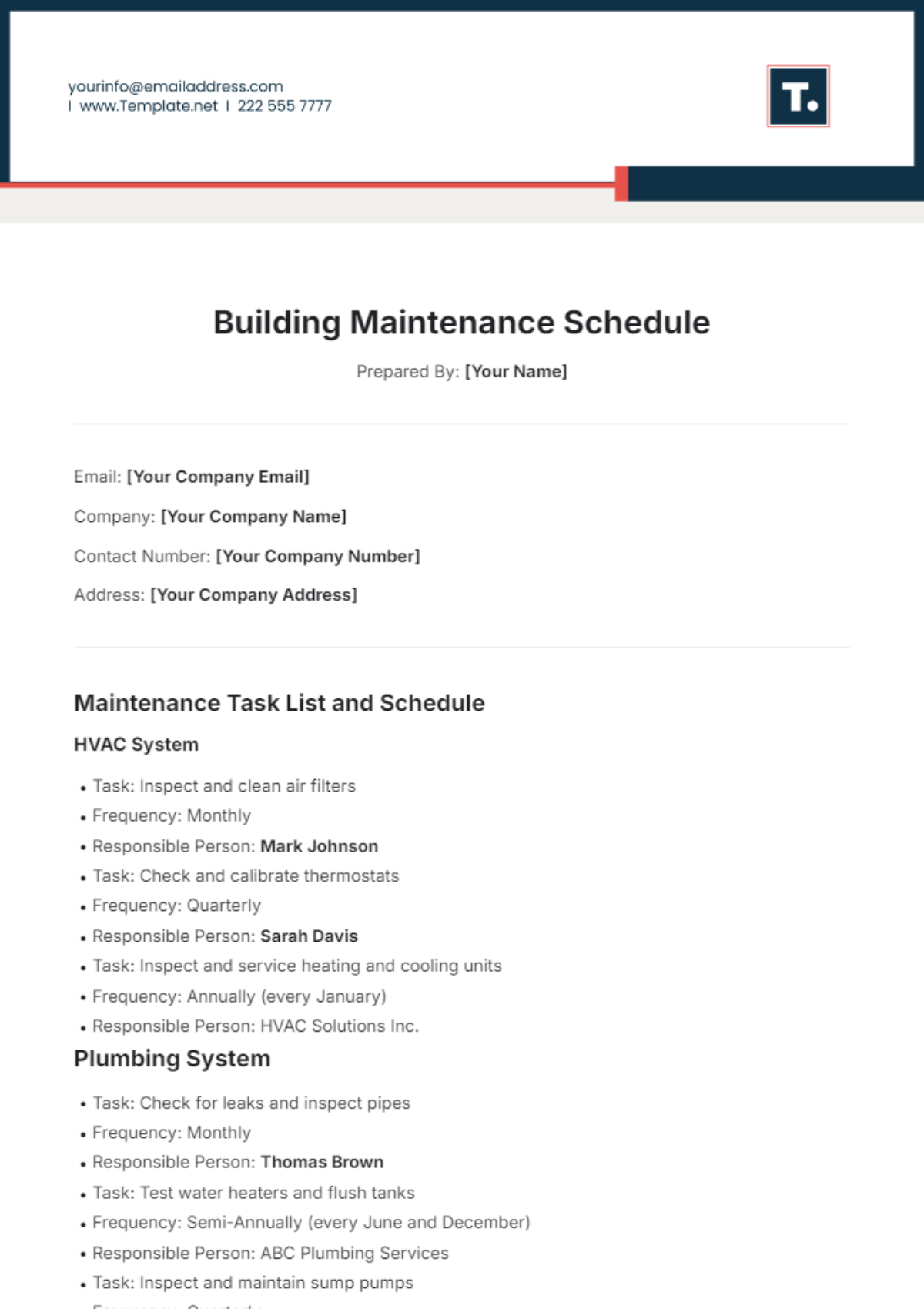

4. Responsibilities

Maintenance Supervisor: Oversee maintenance activities and ensure tasks are completed on time.

Technicians: Perform maintenance tasks as assigned.

Operators: Report any issues with equipment to the maintenance supervisor.

5. Evaluation Process

Monthly Review: Assess the completion of maintenance tasks and adjust schedules as needed.

Feedback Mechanism: Operators to provide feedback on equipment performance and any recurring issues.

Notes:

This schedule should be updated regularly based on operational needs.

Ensure all personnel involved in maintenance are trained and aware of their responsibilities.