Free Manufacturing Annual Report

1. Executive Summary

The year 2050 was a transformative and highly successful period for [Your Company Name], marked by innovation, operational efficiency, and environmental stewardship. Despite facing challenges such as global economic uncertainties, supply chain disruptions, and evolving regulatory environments, we successfully navigated these complexities to deliver remarkable results.

Our total revenue reached $[1,500,000,000], a milestone that reflects our commitment to excellence and our ability to adapt to shifting market demands. We experienced significant growth in emerging markets, launched several new products, and expanded our portfolio with sustainable solutions that align with customer priorities and global standards.

Furthermore, we enhanced operational efficiency across our facilities by implementing state-of-the-art manufacturing technologies. These initiatives reduced production costs by [10]% while improving overall productivity. Sustainability remained a cornerstone of our strategy, as we achieved notable reductions in waste and emissions, demonstrating our dedication to addressing climate change.

This annual report serves to provide stakeholders with a comprehensive overview of our performance, achievements, and strategic priorities as we continue to drive innovation and growth. Our unwavering commitment to excellence ensures that we remain a leader in the global manufacturing industry.

2. Company Overview

[Your Company Name], founded in [2050], has grown into a globally recognized leader in the manufacturing sector. Over the past [60] years, we have built a reputation for delivering innovative and high-quality products that meet the needs of diverse industries, including automotive, electronics, and healthcare.

Operating in over [50] countries and employing [30,000] individuals, we leverage advanced manufacturing techniques and a customer-centric approach to deliver value at scale. Our ability to anticipate industry trends and respond proactively has enabled us to maintain a competitive edge in a rapidly changing global marketplace.

Mission Statement

To revolutionize the manufacturing industry by combining innovation, operational excellence, and sustainability to create value for customers, communities, and the environment.

Vision

To be the global benchmark for innovation and sustainability in manufacturing, setting standards that inspire industries worldwide.

Core Values

Integrity: We believe in transparency, accountability, and ethical business practices.

Innovation: We continuously push boundaries through advanced research and technology integration.

Customer Focus: We prioritize customer satisfaction by delivering tailored, high-quality solutions.

Sustainability: We are committed to reducing our environmental impact and promoting long-term sustainability in every operation.

These values guide our decision-making and ensure that [Your Company Name] continues to thrive as an industry leader.

3. Key Highlights of 2050

The accomplishments of 2050 were diverse, spanning operational, financial, and environmental dimensions:

Record Production Output: Our facilities achieved unprecedented production levels, manufacturing [2,500,000] units across all product lines. This growth was supported by the integration of robotics and automation technologies, which streamlined processes and minimized downtime.

Market Expansion: By successfully entering [3] new international markets, including Asia, South America, and Europe, we expanded our customer base and diversified revenue streams. These new markets are projected to contribute an additional $[200,000,000] annually to our revenue.

Sustainability Milestones: Sustainability remained a key focus area, with significant progress made in reducing energy consumption and waste. These efforts have positioned us as a leader in sustainable manufacturing practices within the industry.

Digital Transformation: Investments in Industry 4.0 technologies, including IoT-enabled systems and AI-driven analytics, resulted in a [20]% boost in operational efficiency. These advancements have provided real-time insights, enabling faster and more informed decision-making.

Customer Satisfaction: We recorded our highest-ever customer satisfaction score of [98]% through enhanced product quality, timely delivery, and proactive customer support initiatives.

These highlights illustrate our ability to excel across multiple dimensions, ensuring long-term value creation for all stakeholders.

4. Financial Performance

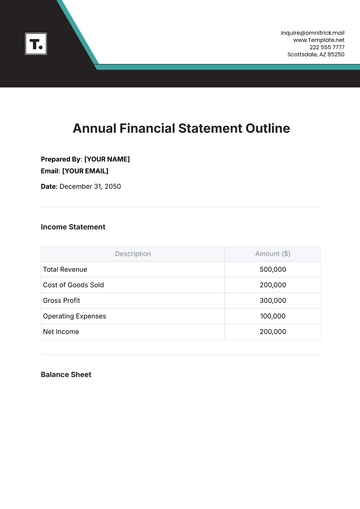

4.1 Revenue and Profit Analysis

The financial results for 2051 underscore the resilience and growth potential of [Your Company Name]. Revenue reached $[1,500,000,000], representing a [12]% increase compared to 2050, while net profit grew by [13]%, reaching $[350,000,000].

This growth was fueled by strong demand for [specific product categories], strategic pricing adjustments, and cost-saving measures implemented across operations. Moreover, our diversified product portfolio allowed us to mitigate risks associated with regional market fluctuations.

Metric | 2051 | 2050 | % Change |

|---|---|---|---|

Revenue ($) | 1,500,000,000 | 1,340,000,000 | 12% |

Gross Profit ($) | 500,000,000 | 450,000,000 | 11% |

Net Profit ($) | 350,000,000 | 310,000,000 | 13% |

4.2 Operational Costs

Operational costs were effectively managed, contributing to improved profitability. Cost-saving initiatives, such as process optimization and energy efficiency measures, resulted in significant reductions in material and labor expenditures.

Cost Category | Amount ($) | % of Revenue |

|---|---|---|

Materials | 650,000,000 | 43% |

Labor | 400,000,000 | 27% |

Technology Investments | 200,000,000 | 13% |

Others | 250,000,000 | 17% |

These cost structures reflect our focus on sustainable and efficient resource utilization.

4.3 Research and Development Investments

In 2051, we allocated $[100,000,000] to R&D, emphasizing advancements in robotics, AI-driven manufacturing, and renewable energy systems. This investment supports the development of next-generation products and technologies, which are expected to drive future growth and enhance our market position.

5. Manufacturing Operations

5.1 Production Metrics

The year 2050 marked a period of extraordinary achievement for our production output. We not only met but exceeded our annual manufacturing targets, driven by the continued integration of cutting-edge technologies, robust employee training programs, and streamlined operational workflows. The adoption of automated assembly lines, coupled with the implementation of smart sensors and predictive maintenance systems, helped us minimize downtime and optimize production schedules. This allowed us to achieve an increase in overall output by [10]%, resulting in [2,500,000] units produced across our product lines.

We saw substantial growth in the production of [Product A], [Product B], and [Product C]. These categories benefitted from increased market demand, particularly in the texh industry sector, which continues to expand as global trends shift toward more sustainable and efficient products. [Product A] experienced a [15]% increase in units produced, [Product B] rose by [10]%, and [Product C] saw a [5]% rise. This surge in production was accompanied by a proportional increase in market share, further reinforcing our leadership in these segments.

Product Type | Units Produced | % Change from 2050 |

|---|---|---|

[Product A] | 1,200,000 | 15% |

[Product B] | 800,000 | 10% |

[Product C] | 500,000 | 5% |

This strong production performance also reflects our commitment to sustainable practices. We are continuing to invest in production processes that not only meet market demands but also prioritize energy efficiency, waste reduction, and reduced environmental impact.

5.2 Supply Chain Overview

Our supply chain strategy in 2051 focused heavily on increasing resilience and flexibility in the face of global challenges, such as fluctuating material costs, geopolitical tensions, and transportation disruptions. The past year saw us diversify our supplier base across different continents, reducing reliance on any single source. This strategic shift ensured that we could maintain a steady supply of raw materials and components, even in times of uncertainty. We onboarded [5] new suppliers, particularly in Asia and South America, regions that offer competitive pricing and access to high-quality materials.

Moreover, our procurement department established strong, long-term relationships with key suppliers, promoting shared goals around quality, cost-effectiveness, and sustainability. We adopted more advanced technologies, such as blockchain and cloud-based systems, to improve traceability and transparency across the entire supply chain. This enabled us to track raw materials from source to factory floor, ensuring that we adhered to our sustainability commitments and enhanced overall supply chain visibility.

As a result, we improved our on-time delivery rate, achieving a record of [96]% for the year, which is a notable increase from the previous year’s [92]%. This improvement was critical to meeting customer demands in an increasingly competitive market. Additionally, our inventory turnover ratio improved by [5]%, reflecting more efficient inventory management practices and a reduction in excess stock.

5.3 Quality Assurance

At [Your Company Name], quality assurance is a fundamental aspect of our manufacturing process. In 2051, we focused on enhancing the consistency and precision of our products, ensuring that every unit delivered to customers met or exceeded their expectations. Through the use of automated inspection systems and real-time data monitoring, we were able to significantly reduce production defects and streamline quality control processes.

We introduced AI-driven inspection systems that continuously monitor production lines for potential quality issues, immediately flagging any anomalies. These systems were integrated into our existing quality control processes, allowing for immediate corrective actions and reducing human error. In total, we conducted over [50,000] inspections across all production facilities. These inspections resulted in a defect rate of only [0.5]%, which is well below the industry average.

Furthermore, our commitment to quality extends beyond the manufacturing process. We also implemented post-production quality testing, including performance testing, durability testing, and customer feedback analysis. By actively engaging with customers and gathering feedback on product performance in real-world conditions, we were able to continually improve product design and functionality. This proactive approach has significantly strengthened our reputation as a reliable and high-quality manufacturer.

6. Sustainability and Environmental Impact

6.1 Energy Efficiency Measures

In line with our sustainability goals, we continued to prioritize energy efficiency across all of our manufacturing facilities in 2051. Our energy consumption reduction initiatives were robust, resulting in a [30]% reduction in energy usage at our largest production plants. These measures included upgrading to energy-efficient machinery, incorporating smart lighting systems, and optimizing heating and cooling systems. Additionally, several of our factories integrated renewable energy sources, such as solar and wind power, contributing to a [15]% increase in clean energy usage.

The energy efficiency initiatives also delivered significant financial benefits, with savings of approximately $[10,000,000] annually. These savings have been reinvested into further sustainability efforts, including the expansion of our renewable energy infrastructure and the installation of energy-efficient systems in our newer plants.

Looking forward, we are committed to reducing our carbon emissions further by implementing advanced energy management systems. These systems will help monitor and control energy consumption in real-time, identify areas for further savings, and improve overall energy performance across the organization.

6.2 Waste Management

Our waste management efforts have yielded significant improvements in 2051, with the company reducing overall manufacturing waste by [15]%. This was achieved through the adoption of lean manufacturing principles and the transition to more sustainable materials. For example, we successfully switched to biodegradable packaging for [Product B], resulting in a [20]% reduction in packaging waste alone.

Additionally, we expanded our recycling programs, ensuring that materials such as metals, plastics, and cardboard were consistently recycled, reducing our reliance on landfills. We also began using a closed-loop system for several of our key products, where components that are no longer in use are recycled into new products. This circular approach aligns with our goal of minimizing the environmental impact of our operations.

Our waste reduction efforts also resulted in a significant cost savings, estimated at $[5,000,000], which helped offset some of the rising material costs in the global market.

6.3 Emissions Reduction Initiatives

[Your Company Name] remains steadfast in its commitment to reducing its carbon footprint. In 2051, we achieved a reduction of [50,000] metric tons of CO2 emissions through a combination of energy efficiency measures, waste management initiatives, and increased use of renewable energy sources. This progress is a direct result of our strategic shift toward greener manufacturing practices, including the installation of carbon capture technologies in key facilities.

Additionally, we invested in electric vehicles for our internal transportation needs, further reducing our dependence on fossil fuels and lowering our emissions. These vehicles have contributed to a [5]% decrease in transportation-related CO2 emissions within our operations.

In line with our goal of achieving net-zero emissions by [2060], we are continually exploring new technologies and partnerships to reduce our environmental impact. Our next major step will be the expansion of our renewable energy infrastructure, which will significantly reduce our reliance on non-renewable energy sources and decrease emissions further.

7. Workforce Development

7.1 Employee Training and Growth

At [Your Company Name], we recognize that our employees are key to our ongoing success. In 2050, we invested $[20,000,000] in employee development programs aimed at enhancing skills, increasing job satisfaction, and fostering career advancement. These initiatives included advanced training on emerging technologies, such as artificial intelligence and robotics, as well as leadership development programs for high-potential employees.

In total, over [10,000] employees across multiple regions participated in these programs, equipping them with the knowledge and expertise required to thrive in the ever-evolving manufacturing landscape. In addition to technical training, we also prioritized soft skills development, including communication, problem-solving, and teamwork.

Our employee training initiatives have had a direct impact on productivity, with trained workers achieving a [10]% higher output compared to previous years. Furthermore, employee engagement surveys indicated an increase in job satisfaction by [15]%, reflecting the positive effects of our investment in workforce development.

7.2 Diversity and Inclusion

[Your Company Name] continues to make significant strides in fostering a diverse and inclusive workplace. In 2051, we focused on increasing representation across all levels of the organization, with a particular emphasis on gender diversity. Women now represent [45]% of our workforce, up from [40]% in 2050, and [35]% of leadership positions are held by women, a [5]% increase from last year.

We also launched [3] new initiatives aimed at supporting underrepresented groups, including mentorship programs, diversity recruitment efforts, and employee resource groups. These initiatives have helped create a more inclusive work environment, where all employees feel valued and empowered to contribute their best work.

Diversity and inclusion have been proven to enhance innovation and creativity, and we are seeing the benefits of these efforts. Our product development teams, which are more diverse than ever, have brought fresh ideas and perspectives that have driven innovation and improved our competitive positioning.

7.3 Safety Performance

Safety remains a top priority at [Your Company Name]. In 2051, we implemented several new safety protocols and enhanced training programs to ensure a safe working environment for all employees. As a result, our incident rate decreased by [33]%, a significant improvement from the previous year.

We introduced new safety technologies, such as wearable devices that monitor employees' physical conditions and alert supervisors to potential hazards. Additionally, regular safety drills and hazard identification workshops were conducted across all facilities to ensure that employees remain aware of potential risks and know how to respond effectively.

Our commitment to safety extends to all parts of the organization, and we have made significant investments in maintaining a safety-conscious culture. The improvements in safety have not only protected our employees but have also helped to reduce operational disruptions and costs related to workplace incidents.

8. Strategic Goals for 2051 and Beyond

As we look ahead, [Your Company Name] is committed to maintaining its leadership position within the manufacturing industry. We have set the following ambitious strategic goals for 2051 and beyond:

Revenue Growth: Our goal is to increase annual revenue to $[1,800,000,000] by 2051, driven by market expansion, new product offerings, and deeper penetration into emerging markets. This will be supported by continued investment in research and development.

Technological Advancement: We plan to invest $[250,000,000] in AI-driven manufacturing processes and automation. This investment will streamline production, reduce labor costs, and enhance product quality, ultimately boosting our operational efficiency.

Sustainability Milestones: Achieving [50]% renewable energy usage across all facilities by 2055 remains a core focus. We will also aim to reduce water usage by [25]% and improve waste recycling by [30]%.

These goals will guide our strategic direction in the coming years and ensure that we continue to build on our success.

9. Conclusion

The year 2050 was an extraordinary year for [Your Company Name], marked by innovation, operational excellence, and a commitment to sustainability. As we look toward 2051 and beyond, we are confident that our strategic priorities will enable us to continue leading the manufacturing industry and creating long-term value for our stakeholders.

We thank our employees, customers, partners, and investors for their ongoing support and look forward to achieving even greater success in the years to come. Together, we will shape the future of manufacturing.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Provide stakeholders with clear insights into your manufacturing performance with the Manufacturing Annual Report Template from Template.net. Editable and customizable, this template lets you present data on production, quality, and financial performance. The AI Editor Tool enables you to personalize the report for a professional, branded presentation.

You may also like

- Sales Report

- Daily Report

- Project Report

- Business Report

- Weekly Report

- Incident Report

- Annual Report

- Report Layout

- Report Design

- Progress Report

- Marketing Report

- Company Report

- Monthly Report

- Audit Report

- Status Report

- School Report

- Reports Hr

- Management Report

- Project Status Report

- Handover Report

- Health And Safety Report

- Restaurant Report

- Construction Report

- Research Report

- Evaluation Report

- Investigation Report

- Employee Report

- Advertising Report

- Weekly Status Report

- Project Management Report

- Finance Report

- Service Report

- Technical Report

- Meeting Report

- Quarterly Report

- Inspection Report

- Medical Report

- Test Report

- Summary Report

- Inventory Report

- Valuation Report

- Operations Report

- Payroll Report

- Training Report

- Job Report

- Case Report

- Performance Report

- Board Report

- Internal Audit Report

- Student Report

- Monthly Management Report

- Small Business Report

- Accident Report

- Call Center Report

- Activity Report

- IT and Software Report

- Internship Report

- Visit Report

- Product Report

- Book Report

- Property Report

- Recruitment Report

- University Report

- Event Report

- SEO Report

- Conference Report

- Narrative Report

- Nursing Home Report

- Preschool Report

- Call Report

- Customer Report

- Employee Incident Report

- Accomplishment Report

- Social Media Report

- Work From Home Report

- Security Report

- Damage Report

- Quality Report

- Internal Report

- Nurse Report

- Real Estate Report

- Hotel Report

- Equipment Report

- Credit Report

- Field Report

- Non Profit Report

- Maintenance Report

- News Report

- Survey Report

- Executive Report

- Law Firm Report

- Advertising Agency Report

- Interior Design Report

- Travel Agency Report

- Stock Report

- Salon Report

- Bug Report

- Workplace Report

- Action Report

- Investor Report

- Cleaning Services Report

- Consulting Report

- Freelancer Report

- Site Visit Report

- Trip Report

- Classroom Observation Report

- Vehicle Report

- Final Report

- Software Report