Tool Inspection for Construction

Prepared by: [Your Name]

I. Introduction

The purpose of a Tool Inspection for Construction is to ensure that the tools and equipment used during construction projects are safe and effective for operation. This process helps in identifying potential hazards associated with faulty equipment and prevents operational mishaps. This report outlines the comprehensive inspection process, methodology, findings, and recommendations for maintaining tool integrity and safety compliance.

II. Inspection Objectives

The primary objectives of the tool inspection are:

To verify that all tools and equipment are in good working condition.

To identify any wear and tear or damage that may affect tool performance.

To ensure compliance with relevant safety standards and regulations.

To provide recommendations for repairs, maintenance, or replacements.

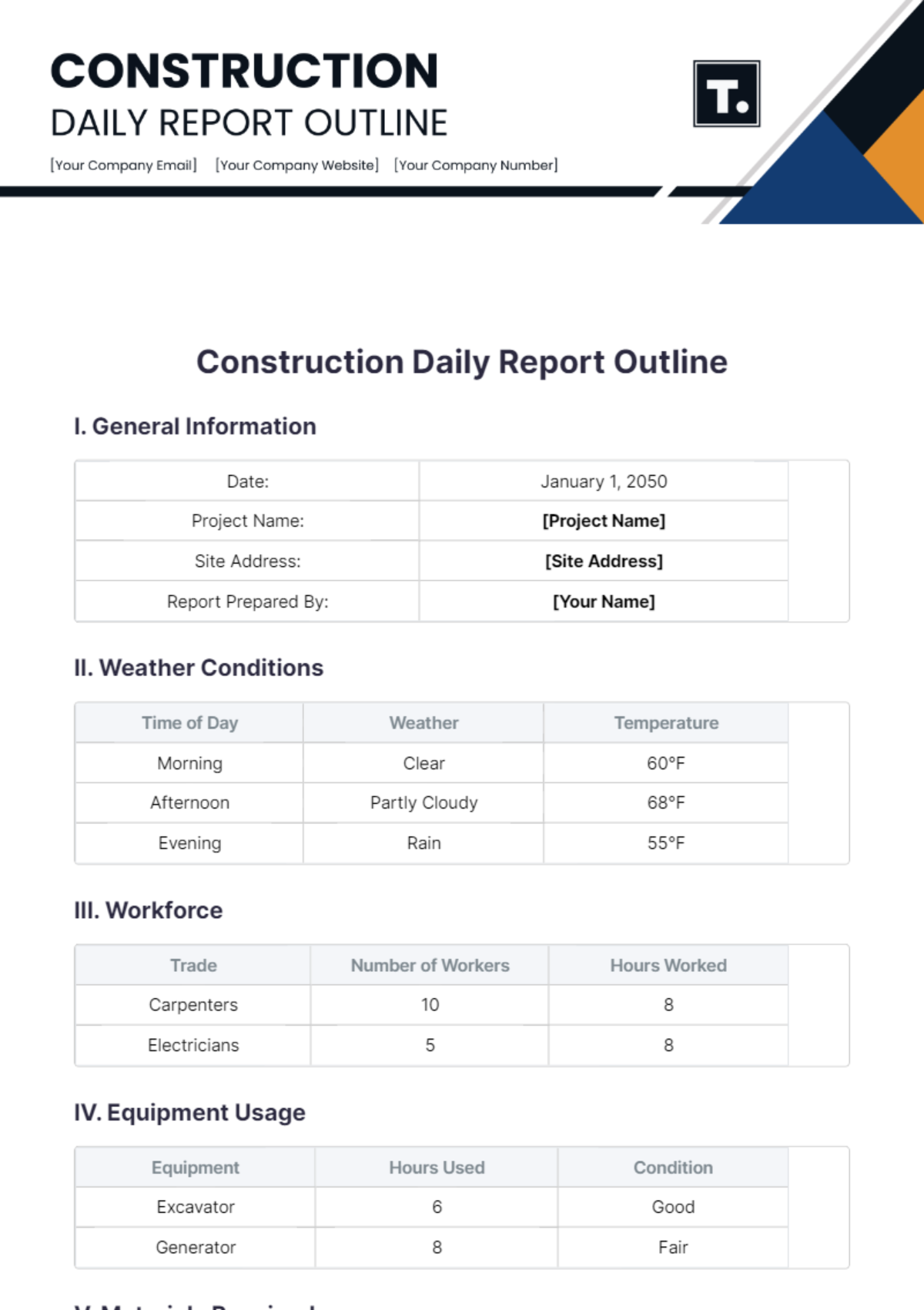

III. Inspection Methodology

A. Tool Categories

Tools and equipment are categorized for inspection under the following groups:

Hand Tools

Power Tools

Heavy Machinery

Personal Protective Equipment

Ladders and Scaffolding

B. Inspection Checklist

The following checklist is used during the inspection process:

Item | Inspection Criteria |

|---|---|

Hand Tools | Check for rust, cracks, and proper insulation on handles. |

Power Tools | Inspect for functional switches, frayed cords, and tight seals. |

Heavy Machinery | Ensure proper fluid levels, check brakes, and operational gauges. |

Personal Protective Equipment | Verify expiration dates, integrity of materials, and cleanliness. |

Ladders and Scaffolding | Check for stability, missing parts, and non-slip surfaces. |

IV. Inspection Findings

A. Hand Tools

Upon inspection, most hand tools were found to be in acceptable condition. However, a few items showed signs of rust and required immediate cleaning and oiling. No cracks were found, but some insulation on handles needs repair.

B. Power Tools

Power tools generally passed the inspection, but several were noted to have slightly frayed cords, requiring attention. All switches were operational, although one tool had a defect in its sealing gasket, necessitating replacement.

C. Heavy Machinery

All heavy machinery inspected had adequate fluid levels. A few machines had minor brake adjustments needed, and one piece of equipment had a malfunctioning gauge which requires servicing.

D. Personal Protective Equipment

While most personal protective equipment was in good condition, some items were past their expiration dates and should be replaced. A couple of helmets showed minor scratches, indicating the need for further monitoring.

E. Ladders and Scaffolding

Ladders and scaffolding were in excellent condition with no missing parts. However, one ladder showed signs of surface wear and would benefit from the application of anti-slip material.

V. Recommendations

Based on the findings, the following actions are recommended:

Immediate cleaning and oiling of hand tools showing rust.

Repair of insulation on tool handles where necessary.

Replacement of frayed cords for power tools and faulty sealing gaskets.

Adjustment of machinery brakes and repair of malfunctioning gauges.

Replacement of expired personal protective equipment items.

Application of anti-slip material to worn ladder surfaces.

VI. Conclusion

Regular tool inspections are vital to ensure the safety and efficiency of construction operations. By addressing wear, damage, and non-compliance issues promptly, the risk of accidents can be significantly reduced and productivity maintained. This report serves as a guidance document to implement necessary measures for ongoing tool maintenance and safety standard adherence.