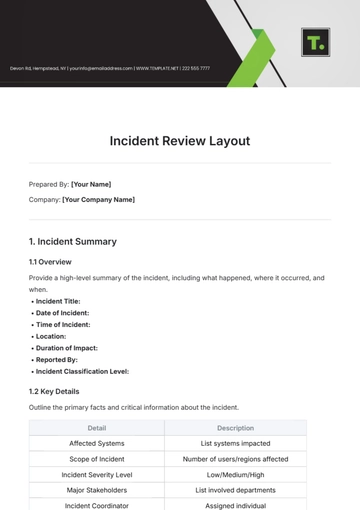

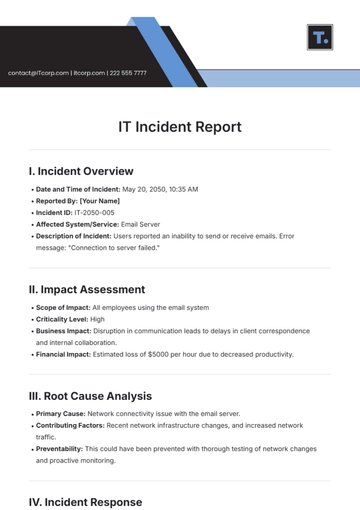

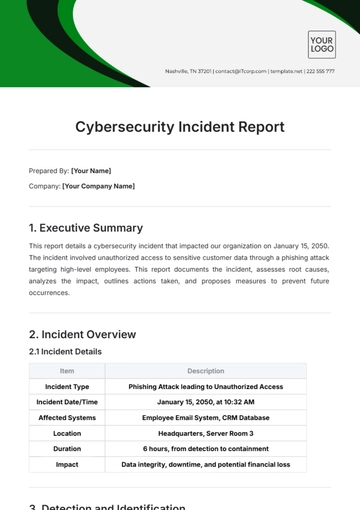

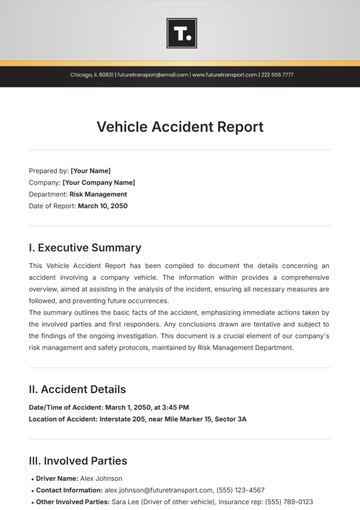

Free Job Incident Report Design

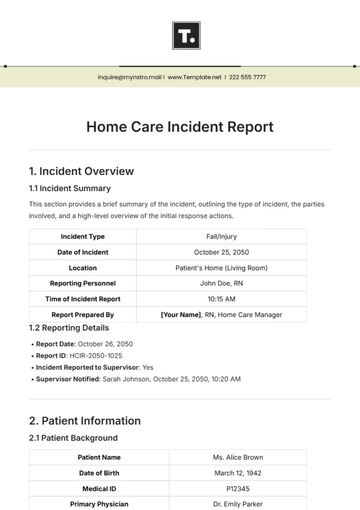

I. Incident Summary

Date of Incident: | October 15, 2050 |

Time of Incident: | 14:30 |

Location: | Factory Floor, Section B |

Report Number: | DIR-2050-10-001 |

Date of Report: | October 16, 2050 |

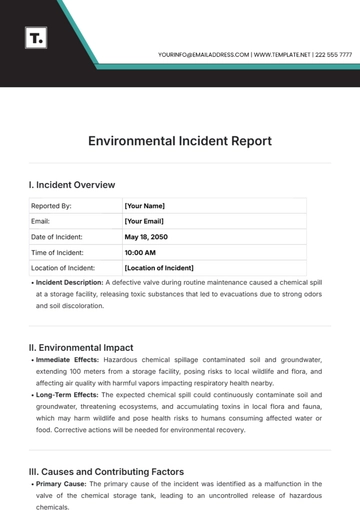

II. Description of Incident

On October 15th, 2050, at approximately 14:30, an incident occurred in Section B of the factory floor. A conveyor belt malfunctioned, causing a temporary production halt and posing potential injury risks to nearby employees. The malfunction was characterized by a sudden stoppage accompanied by a loud noise.

III. Persons Involved

Name | Position | Role in Incident |

|---|---|---|

Caleb Wilson | Machine Operator | Reported the malfunction |

[Your Name] | Supervisor | Contacted maintenance team |

IV. Investigation Findings

4.1 Cause of Incident

Upon investigation, the incident was attributed to a mechanical failure in the conveyor belt system. A worn-out gear resulted in the malfunction, which had not been identified during routine maintenance checks.

4.2 Witness Statements

Caleb Wilson reported hearing a loud noise before the belt stopped moving.

[Your Name] confirmed that the area was immediately secured and maintenance was alerted.

V. Corrective Actions

5.1 Immediate Actions Taken

The following actions were taken promptly after the incident to ensure safety and resume operations:

The affected area was evacuated and cordoned off.

The maintenance team was dispatched to assess and repair the system.

All staff were accounted for, and no injuries were reported.

5.2 Future Preventive Measures

To prevent similar incidents in the future, the following measures have been proposed:

Review and enhance the maintenance schedule to include more frequent inspections.

Implement additional training for employees on reporting irregular equipment noises immediately.

Upgrade the conveyor system with more durable components.

VI. Conclusion

The incident highlighted the need for improved maintenance routines and employee awareness of equipment irregularities. By implementing the corrective actions and preventive measures outlined, similar occurrences can be minimized, ensuring a safer work environment.

VII. Signatures

Prepared By:

Name: [Your Name]

Position: Supervisor

Date: October 16, 2050

Reviewed By:

Name: Daniel Williams

Position: Safety Manager

Date: October 17, 2050

VIII. Additional Documentation

Photographs of the conveyor system and the incident area are attached.

A maintenance log indicating the last inspection date is included.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Document workplace incidents effectively with the Job Incident Report Design Template from Template.net. This fully editable and customizable template provides a structured format for capturing essential details of any incident, ensuring thorough documentation and analysis. Designed for managers and safety officers, it allows you to tailor the content to your organization's specific needs. Streamline your reporting process while promoting accountability and enhancing workplace safety with this user-friendly template.

You may also like

- Sales Report

- Daily Report

- Project Report

- Business Report

- Weekly Report

- Incident Report

- Annual Report

- Report Layout

- Report Design

- Progress Report

- Marketing Report

- Company Report

- Monthly Report

- Audit Report

- Status Report

- School Report

- Reports Hr

- Management Report

- Project Status Report

- Handover Report

- Health And Safety Report

- Restaurant Report

- Construction Report

- Research Report

- Evaluation Report

- Investigation Report

- Employee Report

- Advertising Report

- Weekly Status Report

- Project Management Report

- Finance Report

- Service Report

- Technical Report

- Meeting Report

- Quarterly Report

- Inspection Report

- Medical Report

- Test Report

- Summary Report

- Inventory Report

- Valuation Report

- Operations Report

- Payroll Report

- Training Report

- Job Report

- Case Report

- Performance Report

- Board Report

- Internal Audit Report

- Student Report

- Monthly Management Report

- Small Business Report

- Accident Report

- Call Center Report

- Activity Report

- IT and Software Report

- Internship Report

- Visit Report

- Product Report

- Book Report

- Property Report

- Recruitment Report

- University Report

- Event Report

- SEO Report

- Conference Report

- Narrative Report

- Nursing Home Report

- Preschool Report

- Call Report

- Customer Report

- Employee Incident Report

- Accomplishment Report

- Social Media Report

- Work From Home Report

- Security Report

- Damage Report

- Quality Report

- Internal Report

- Nurse Report

- Real Estate Report

- Hotel Report

- Equipment Report

- Credit Report

- Field Report

- Non Profit Report

- Maintenance Report

- News Report

- Survey Report

- Executive Report

- Law Firm Report

- Advertising Agency Report

- Interior Design Report

- Travel Agency Report

- Stock Report

- Salon Report

- Bug Report

- Workplace Report

- Action Report

- Investor Report

- Cleaning Services Report

- Consulting Report

- Freelancer Report

- Site Visit Report

- Trip Report

- Classroom Observation Report

- Vehicle Report

- Final Report

- Software Report