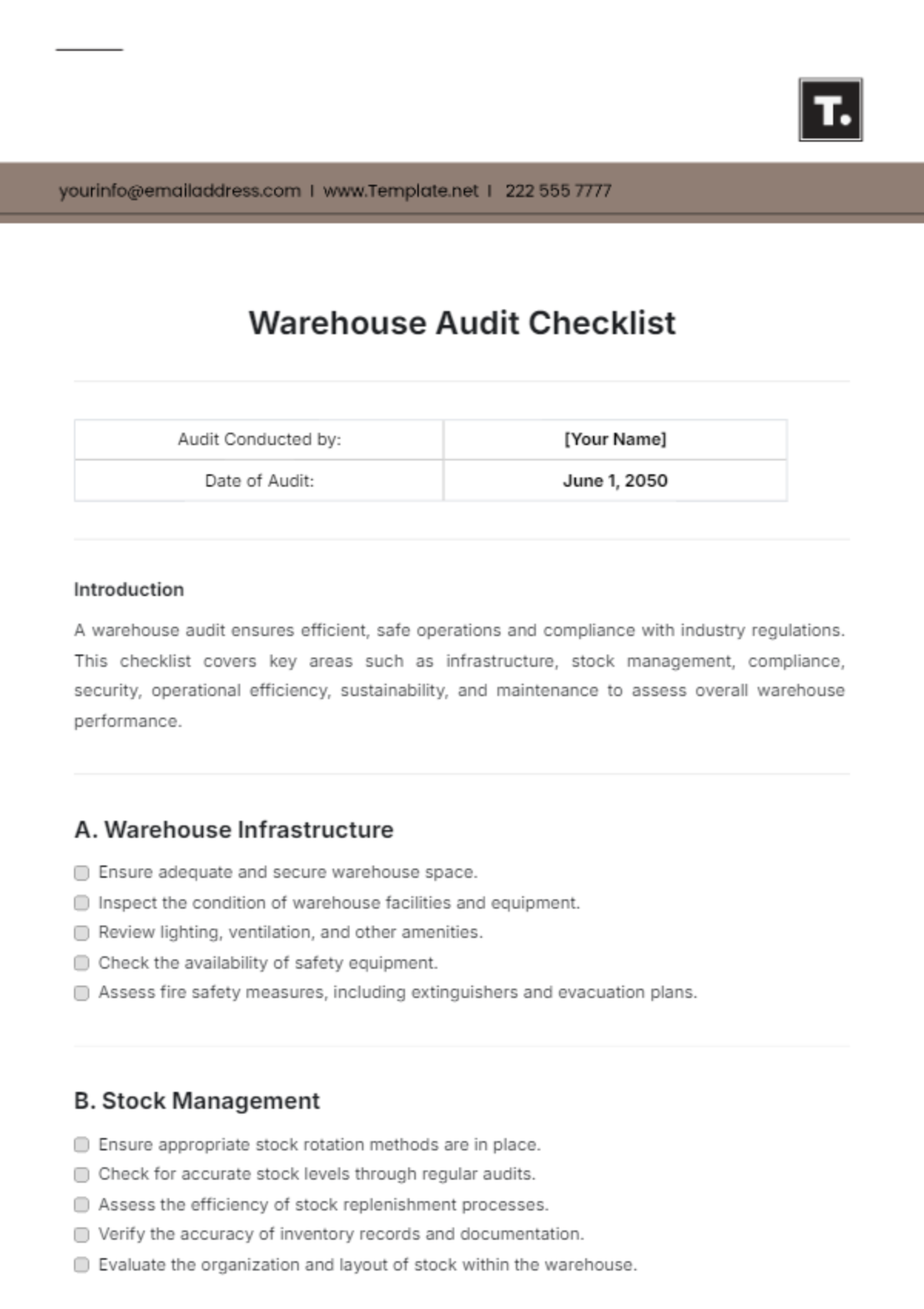

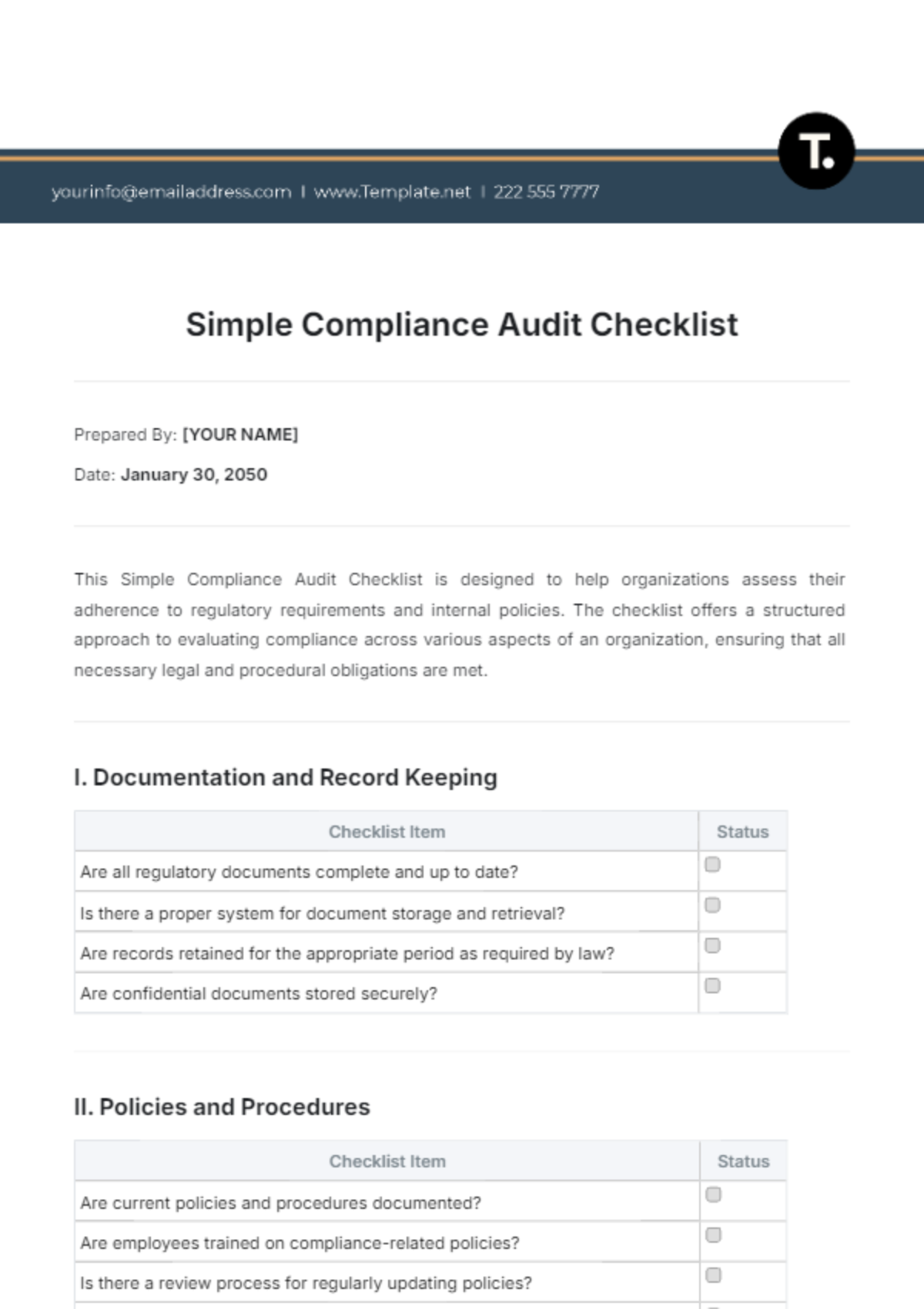

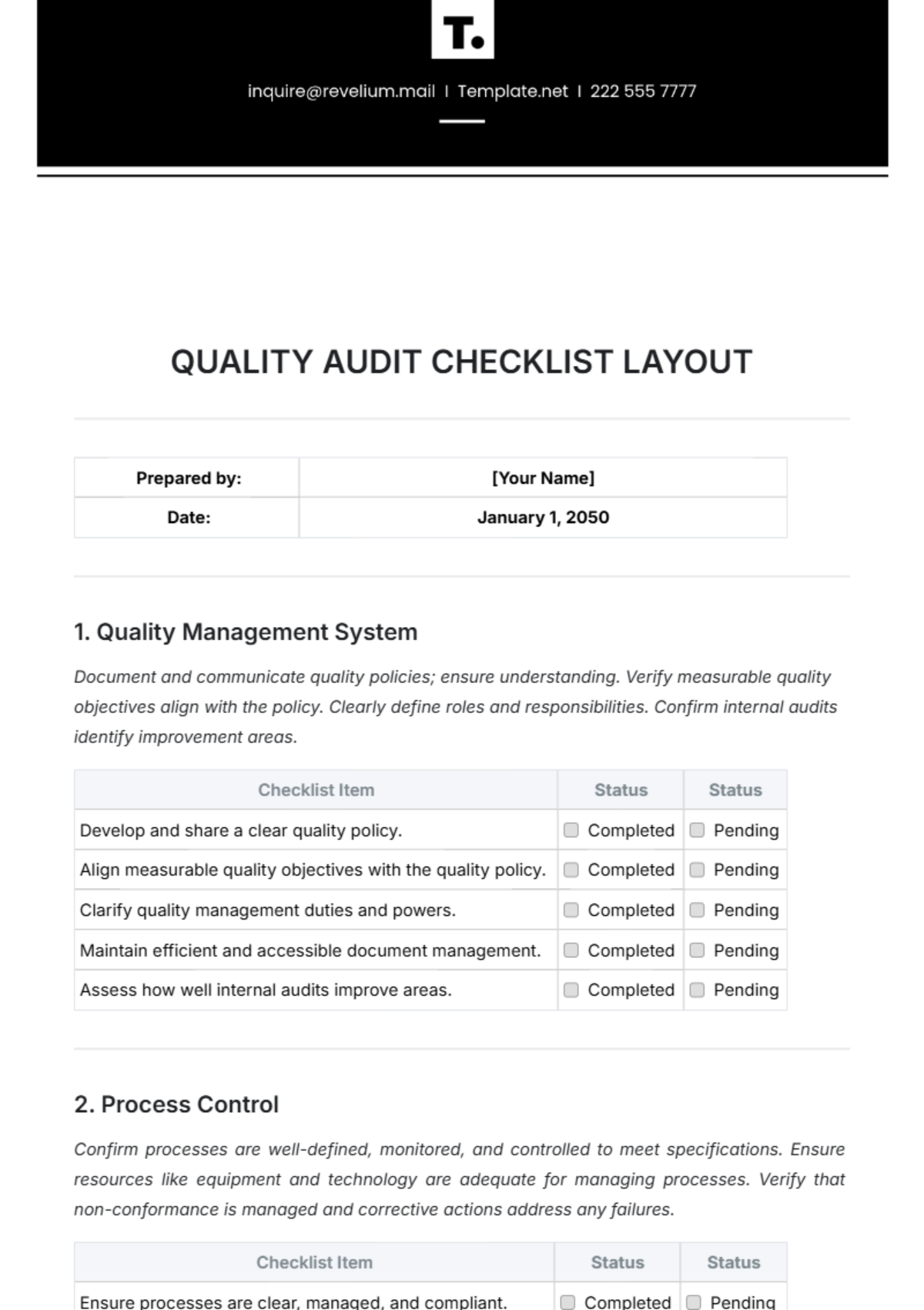

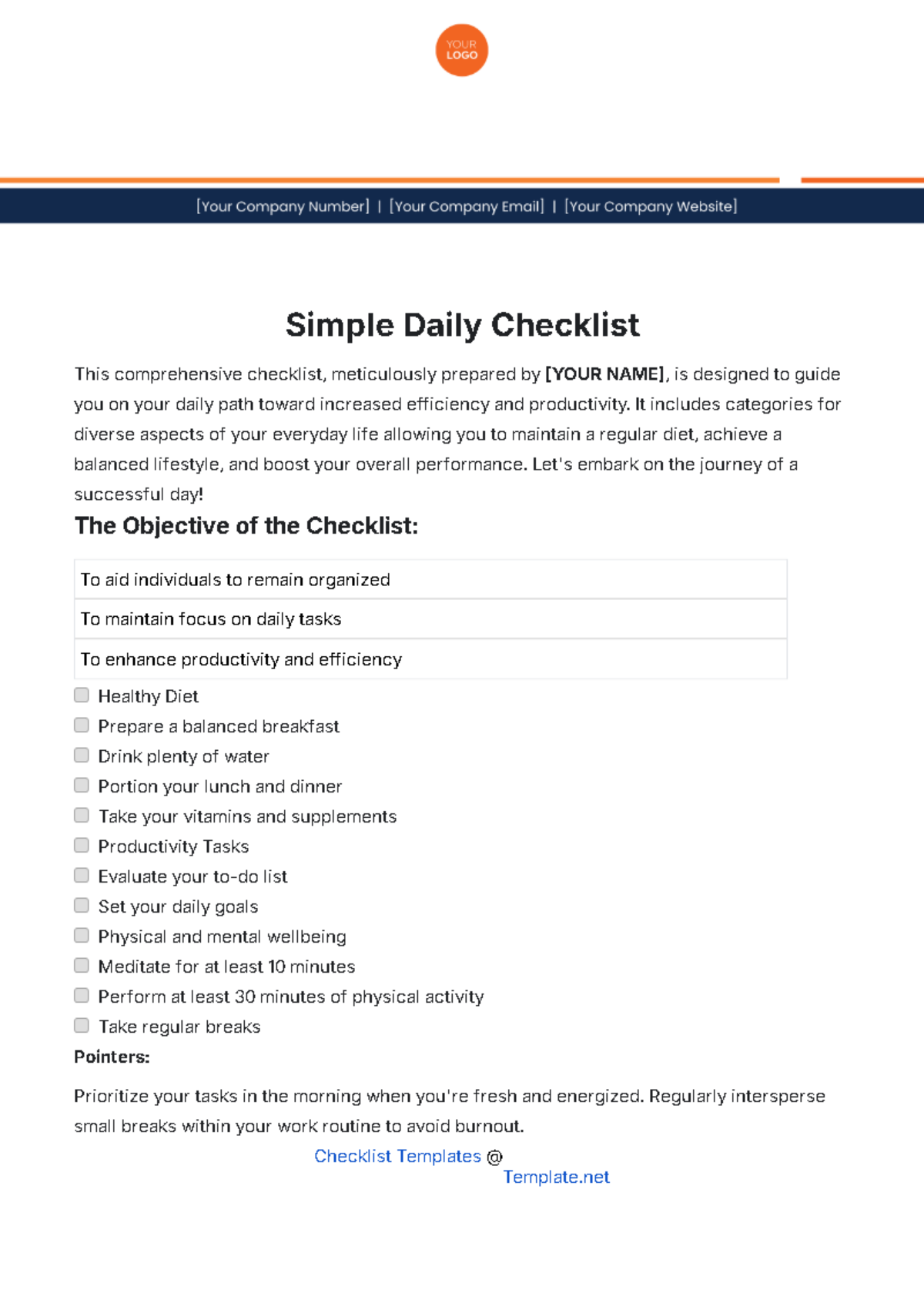

Quality, Safety, and Efficiency in Every Aspect of Manufacturing Operations

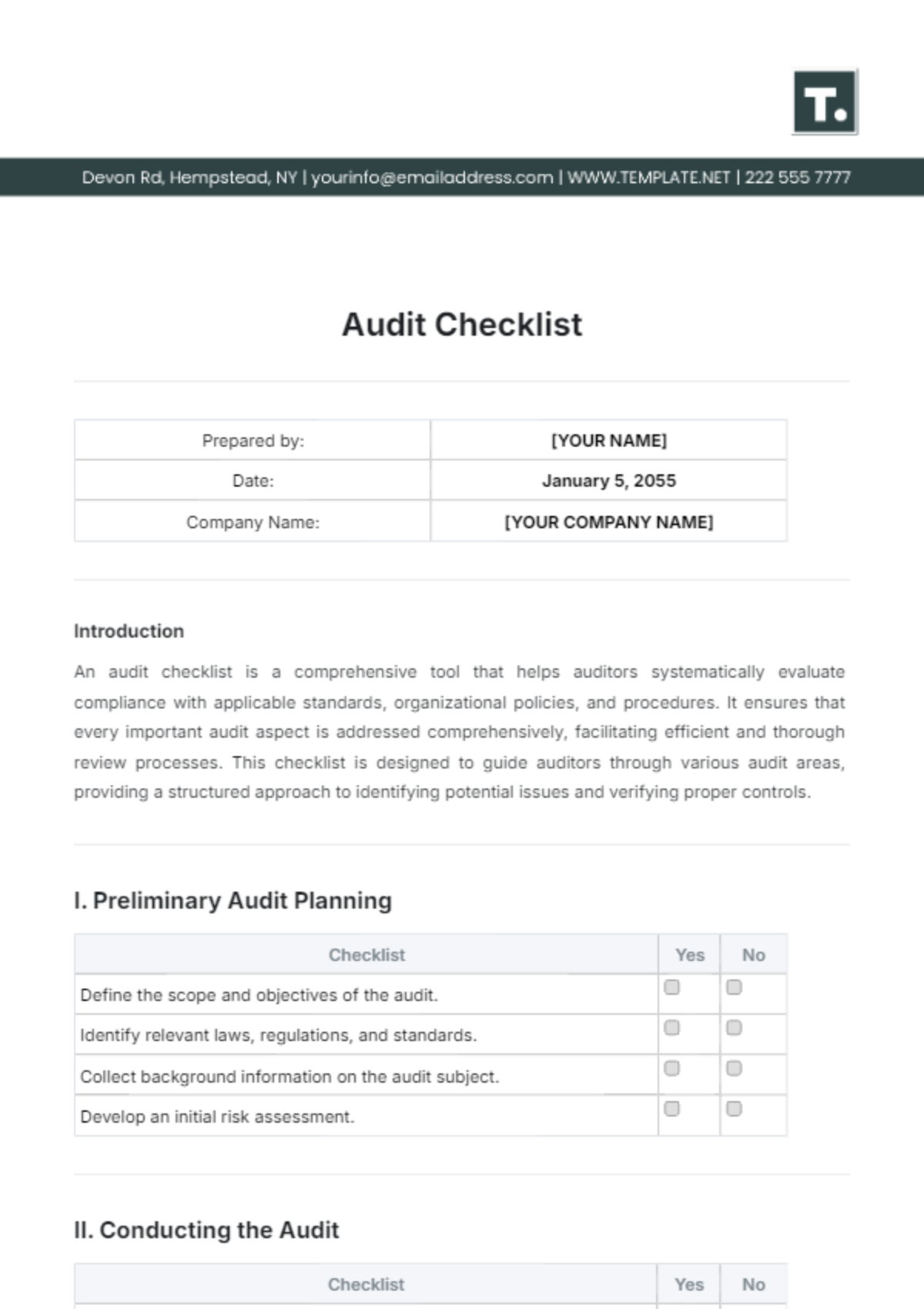

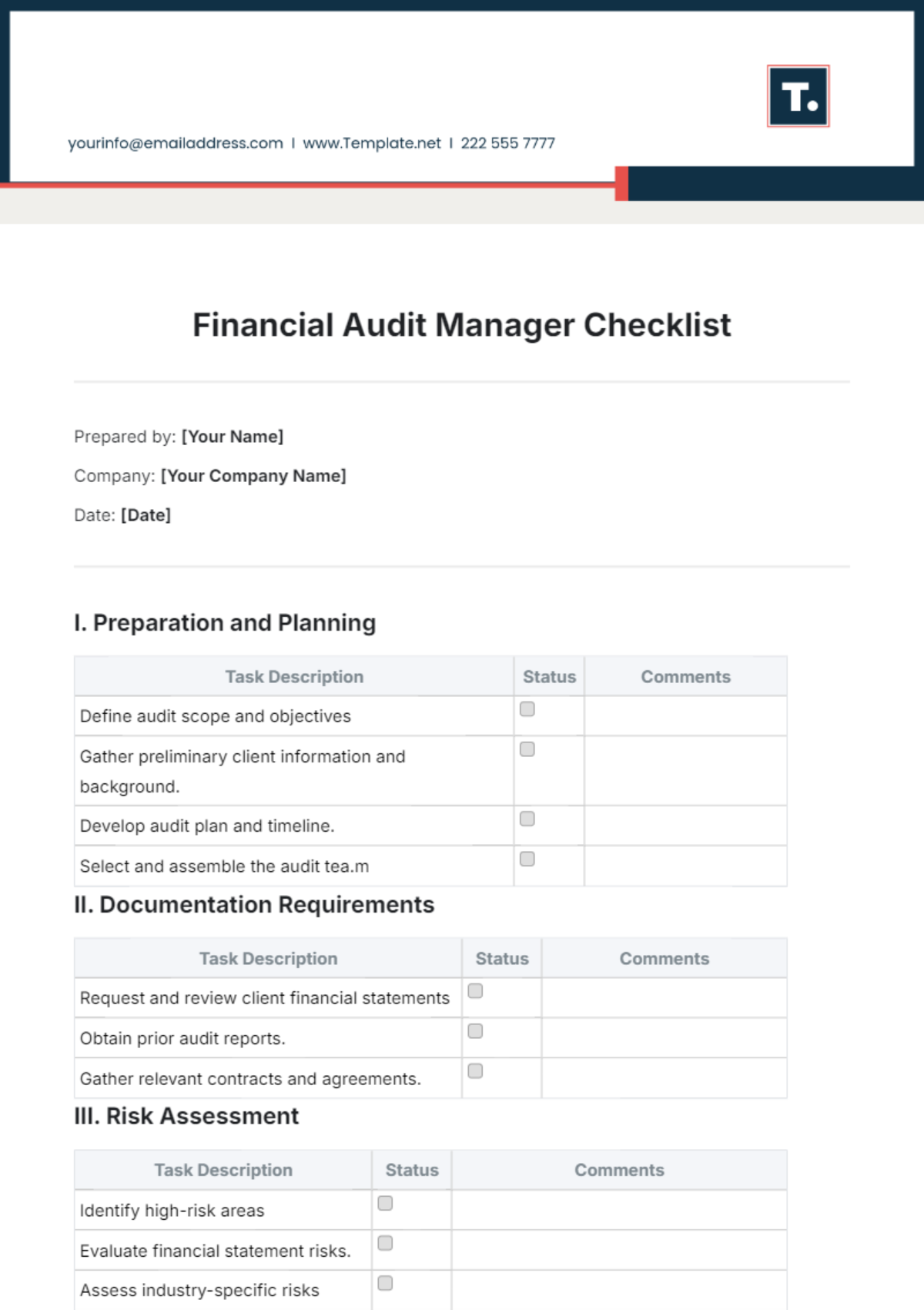

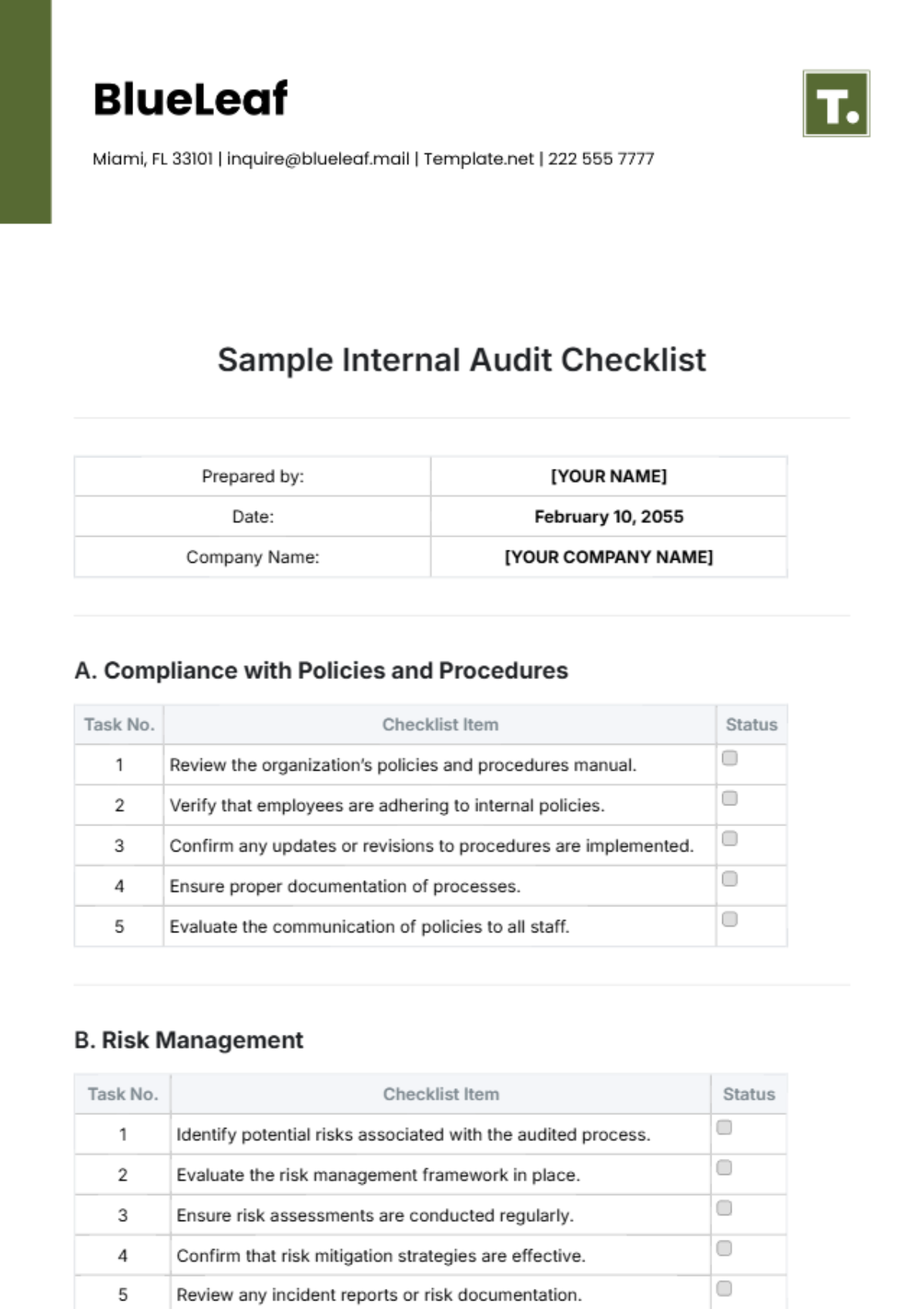

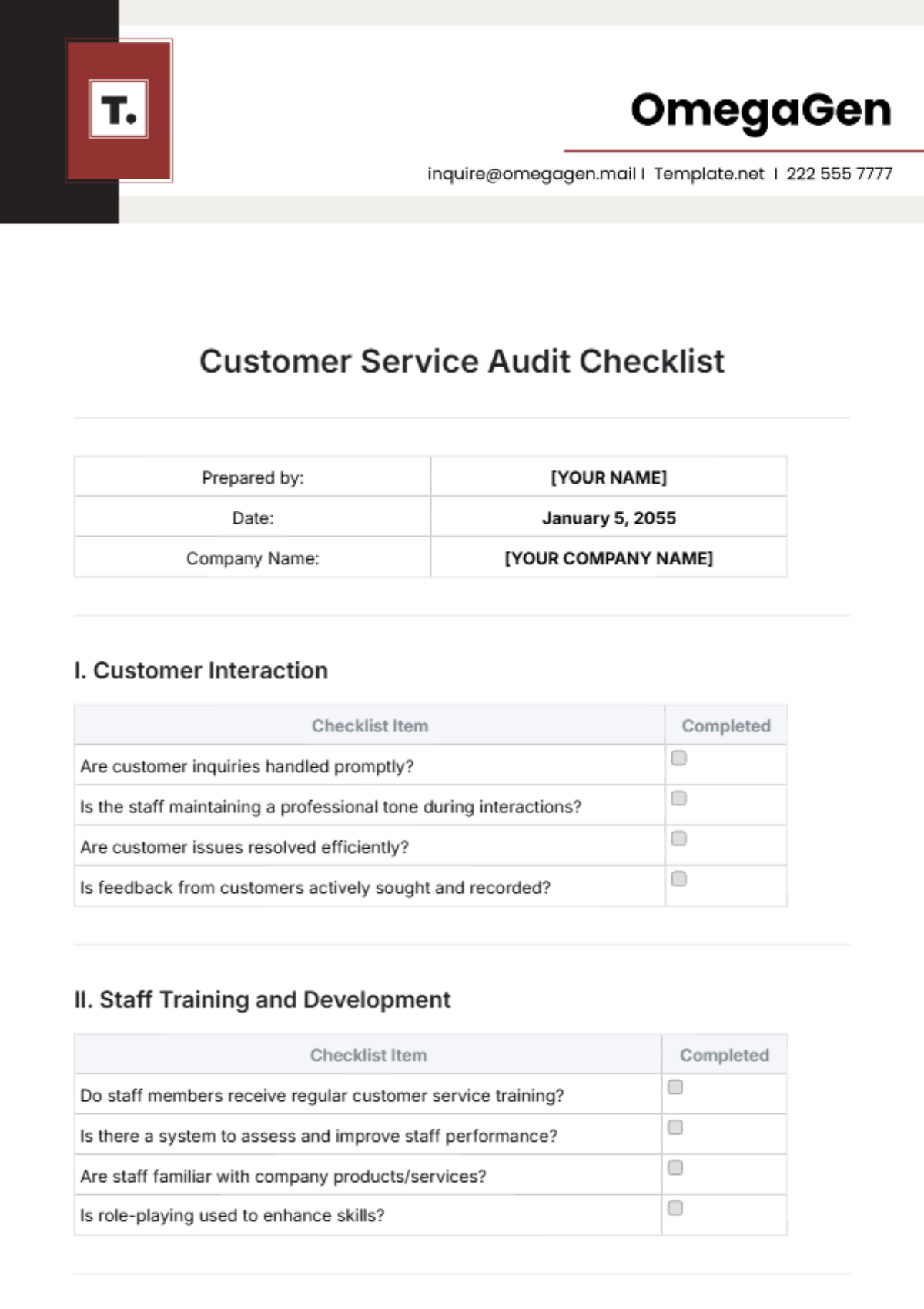

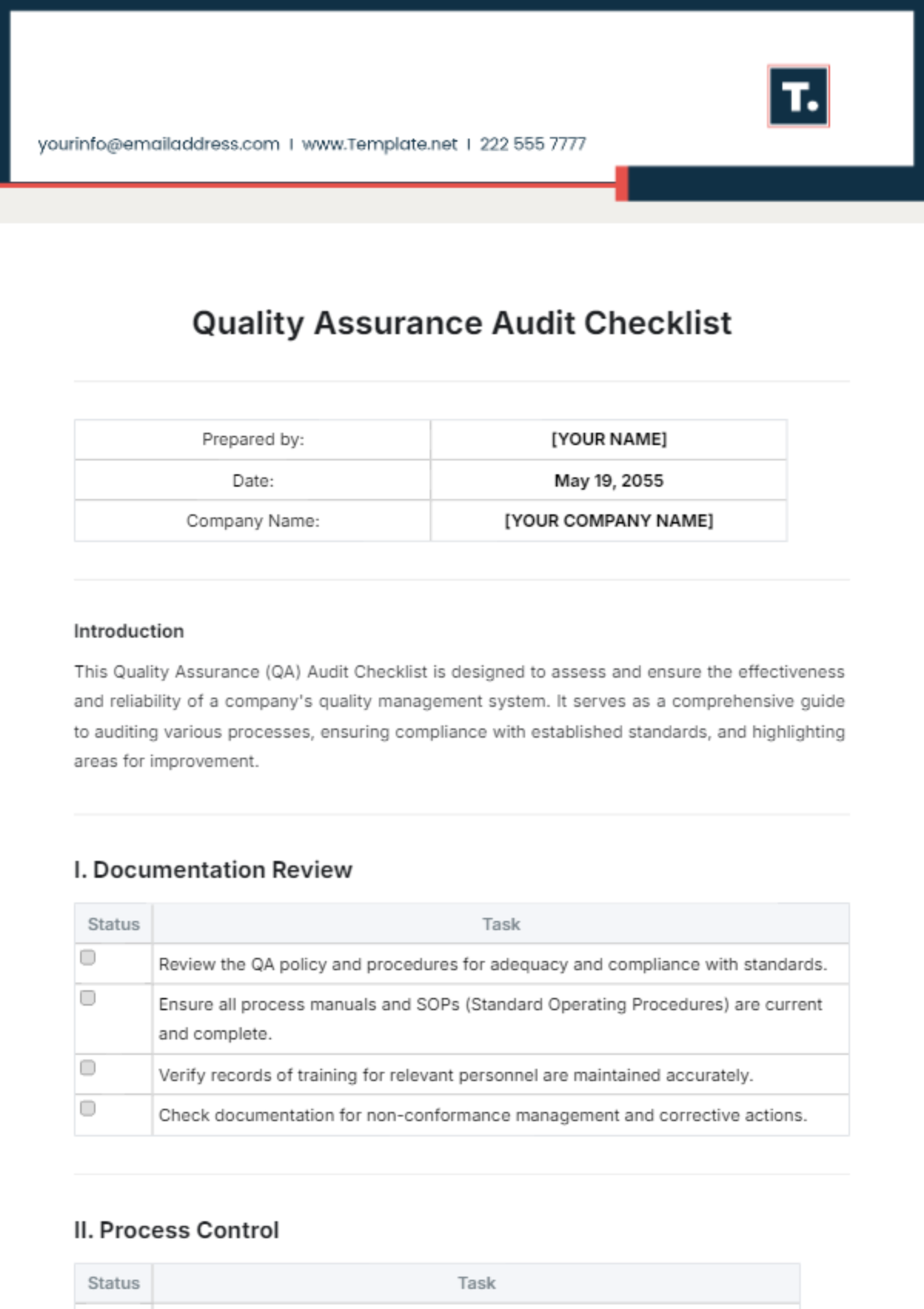

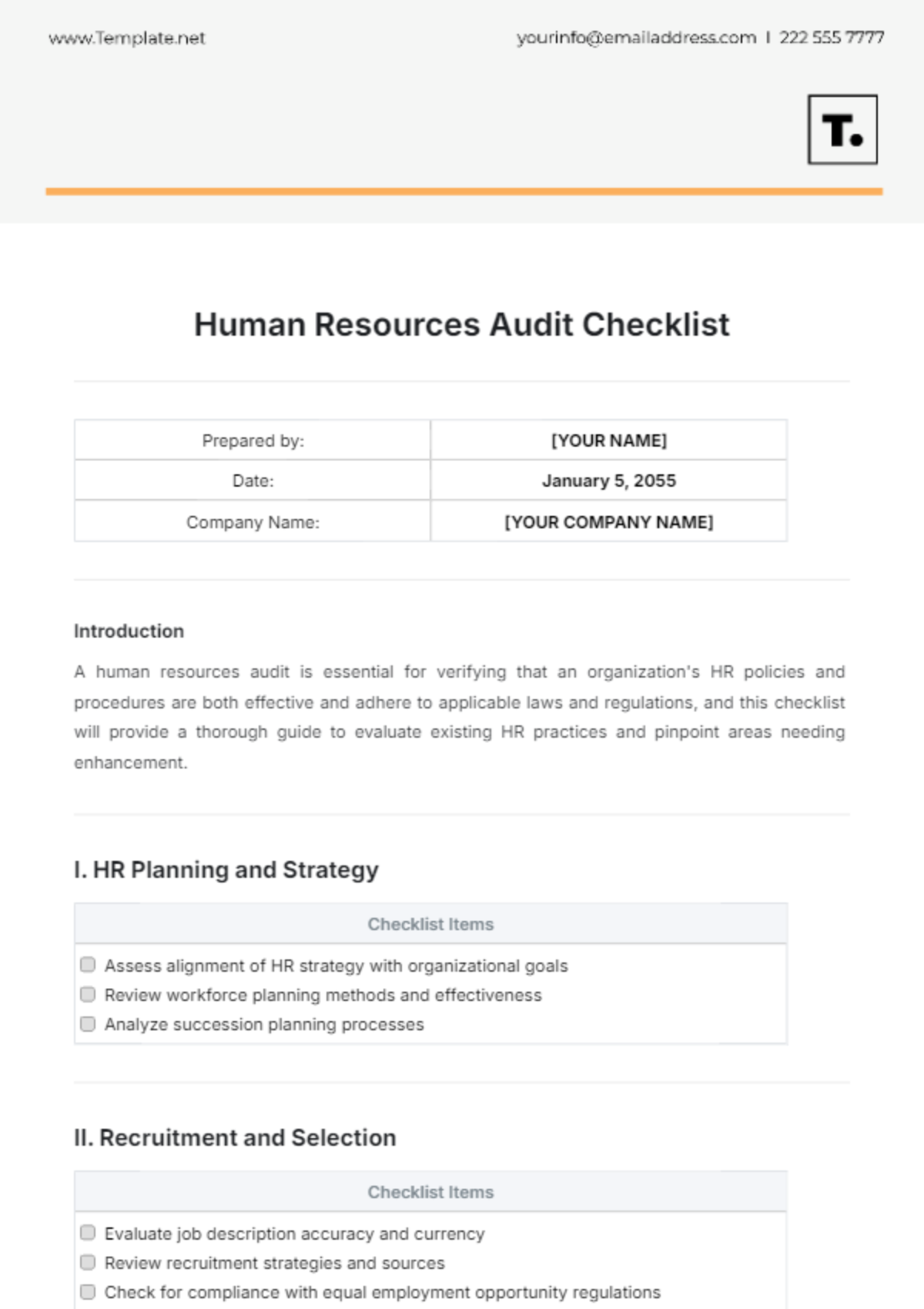

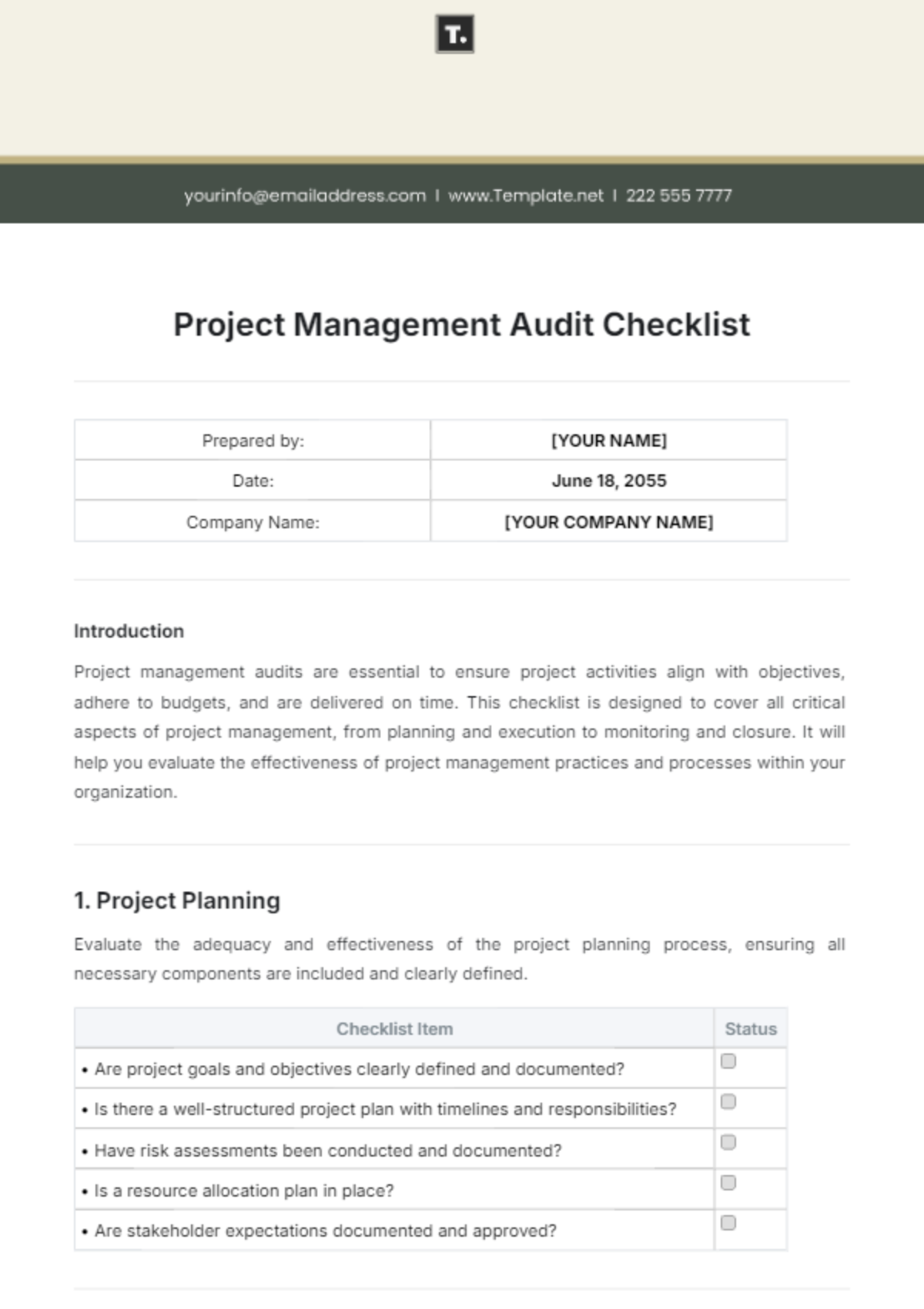

Audited by: | Date | Company |

|---|---|---|

[Your Name] | [Date] | [Your Company Name] |

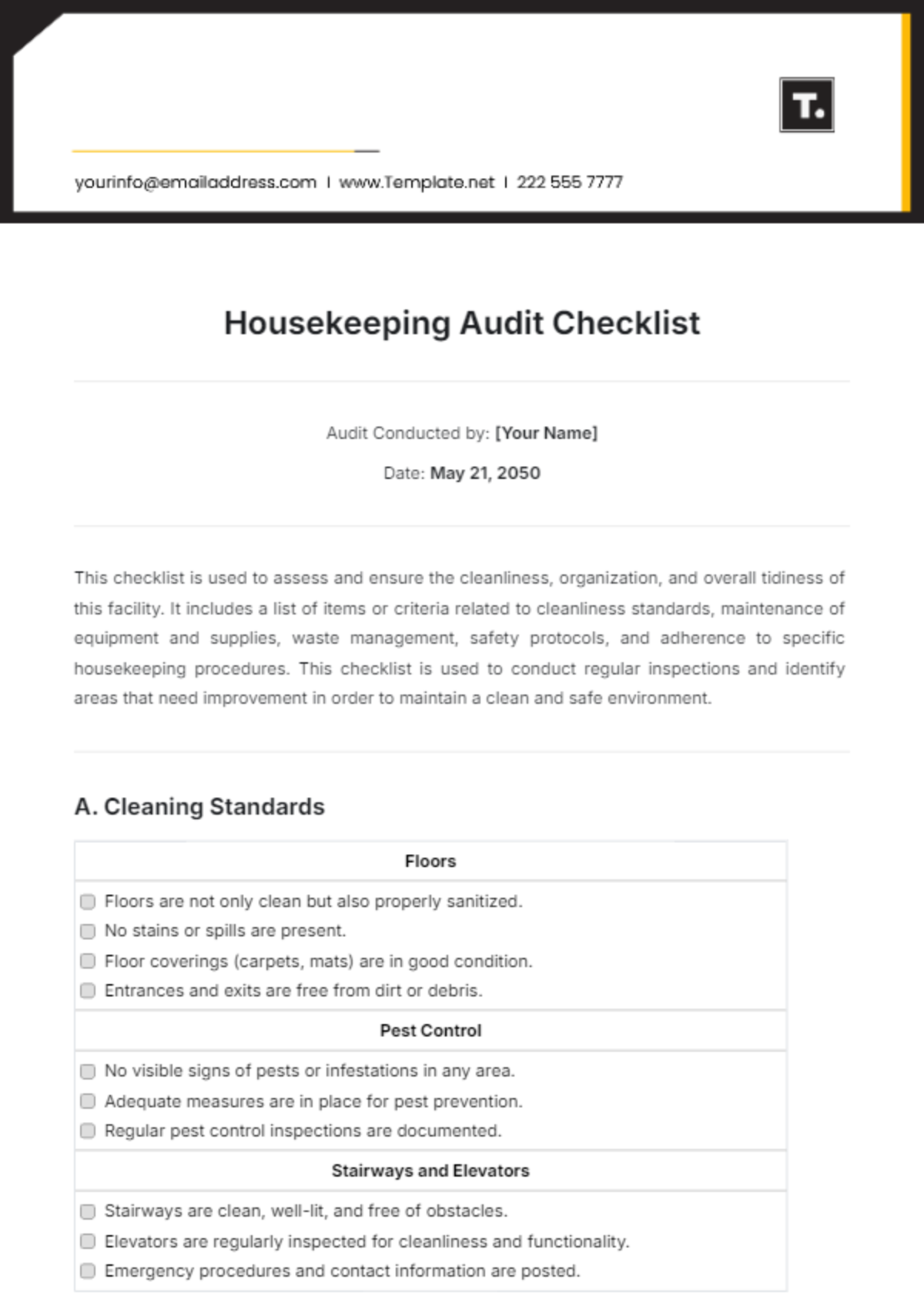

Factory Premises and Documentation

Review of manufacturing facility's cleanliness and organization. | |

Check for necessary certifications and compliance with regulatory documents. | |

Examination of safety and sanitary procedures in practice. | |

Assessment of overall facility layout and workflow efficiency. | |

Verification of waste disposal methods and environmental impact considerations. | |

Review of emergency response plans and evacuation procedures. |

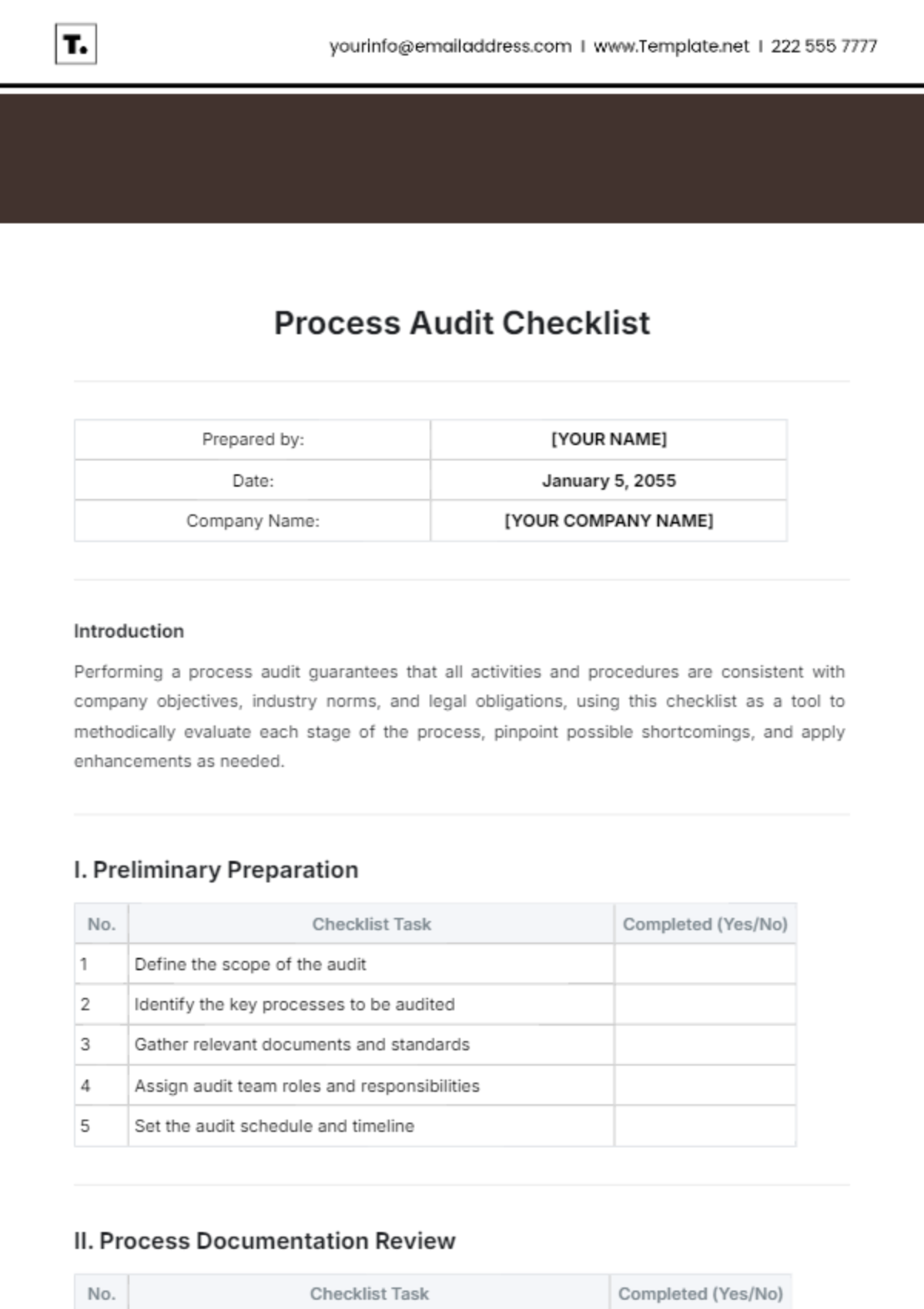

Process Control and Quality Assurance

Evaluate process and product control systems. | |

Verify the effectiveness of error detection and defect prevention methods. | |

Check consistency and reliability of product quality tests. | |

Assessment of process variability and its impact on product quality. | |

Validation of process change control procedures. | |

Review of statistical process control (SPC) implementation and analysis. |

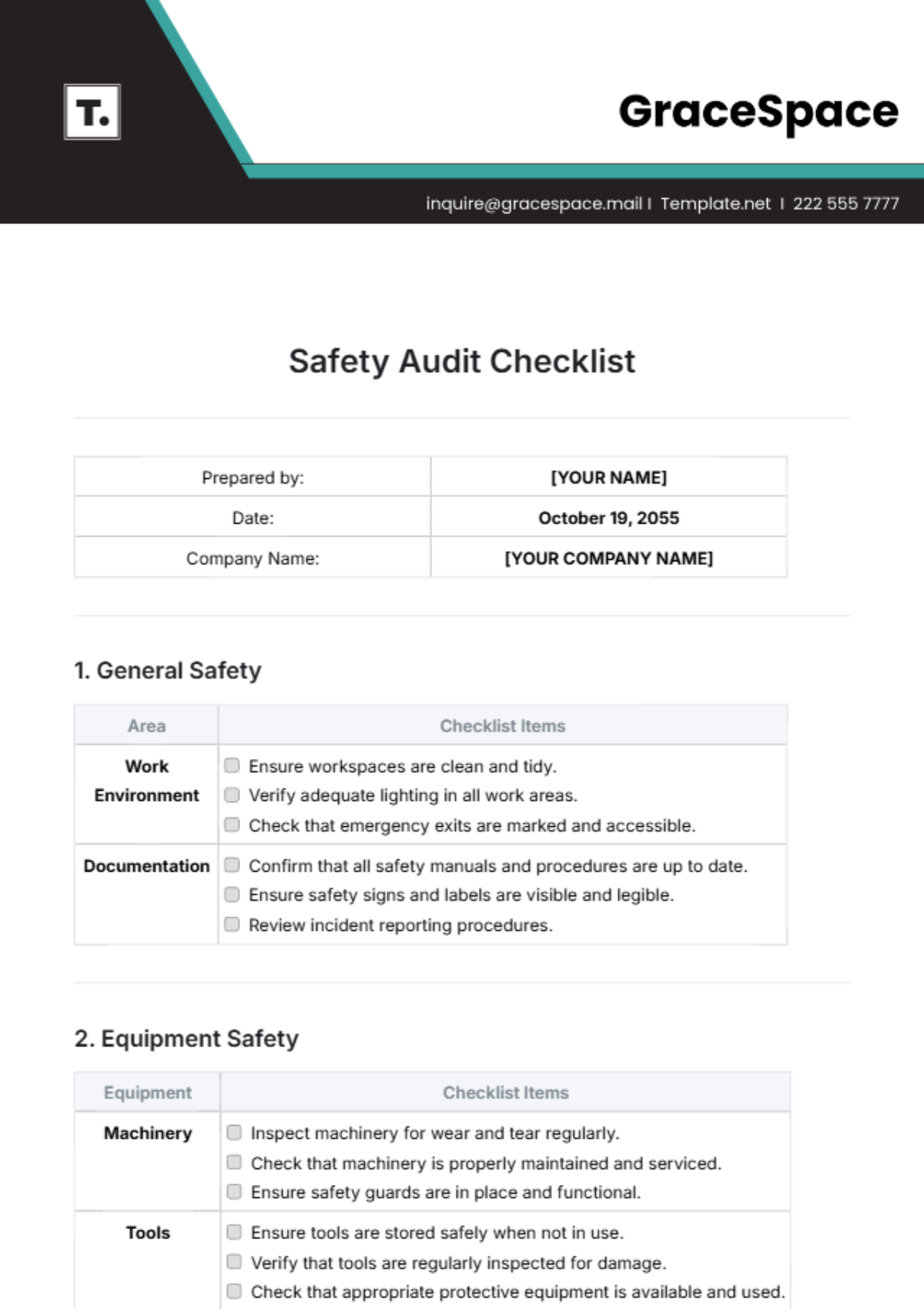

Personnel and Training

Ensure competency of staff based on roles and responsibilities. | |

Review staff training programs and their effectiveness. | |

Assessment of cross-functional training opportunities. | |

Validation of training records and documentation. | |

Review of employee performance appraisal systems. | |

Analysis of employee engagement and satisfaction surveys. |

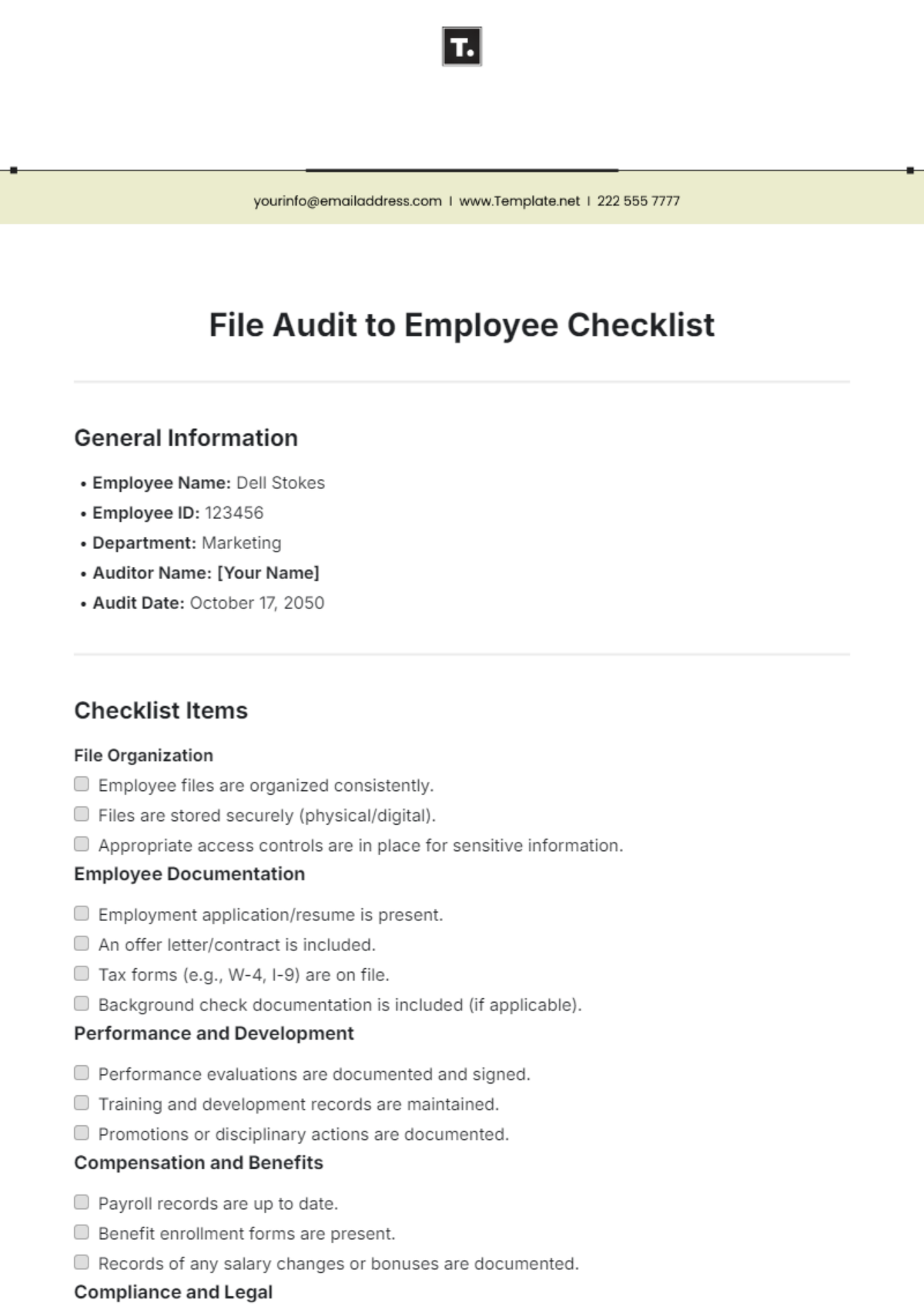

Supplier Quality Management

Evaluate supplier qualification procedures. | |

Analyze the quality of raw materials supplied. | |

Check supplier performance assessment procedures. | |

Validation of supplier communication channels. | |

Assessment of supplier risk management strategies. | |

Review of contingency plans for potential supply chain disruptions. |

Product Handling and Storage Conditions

Verify proper product package conditions for transportation and delivery. | |

Check control mechanisms for storage temperature, humidity, and other necessary parameters. | |

Inspection of stock rotation and expiration date controls. | |

Assessment of product handling procedures during loading and unloading. | |

Validation of inventory management systems. | |

Review of transportation security measures. |

Machine Equipment Maintenance and Calibration

Assessment of preventive maintenance activities. | |

Review of equipment calibration records. | |

Verification of machine functionality and safety features. | |

Evaluation of spare parts availability and inventory management for critical equipment. | |

Validation of equipment change control procedures. | |

Inspection of maintenance logs and documentation of equipment history. |