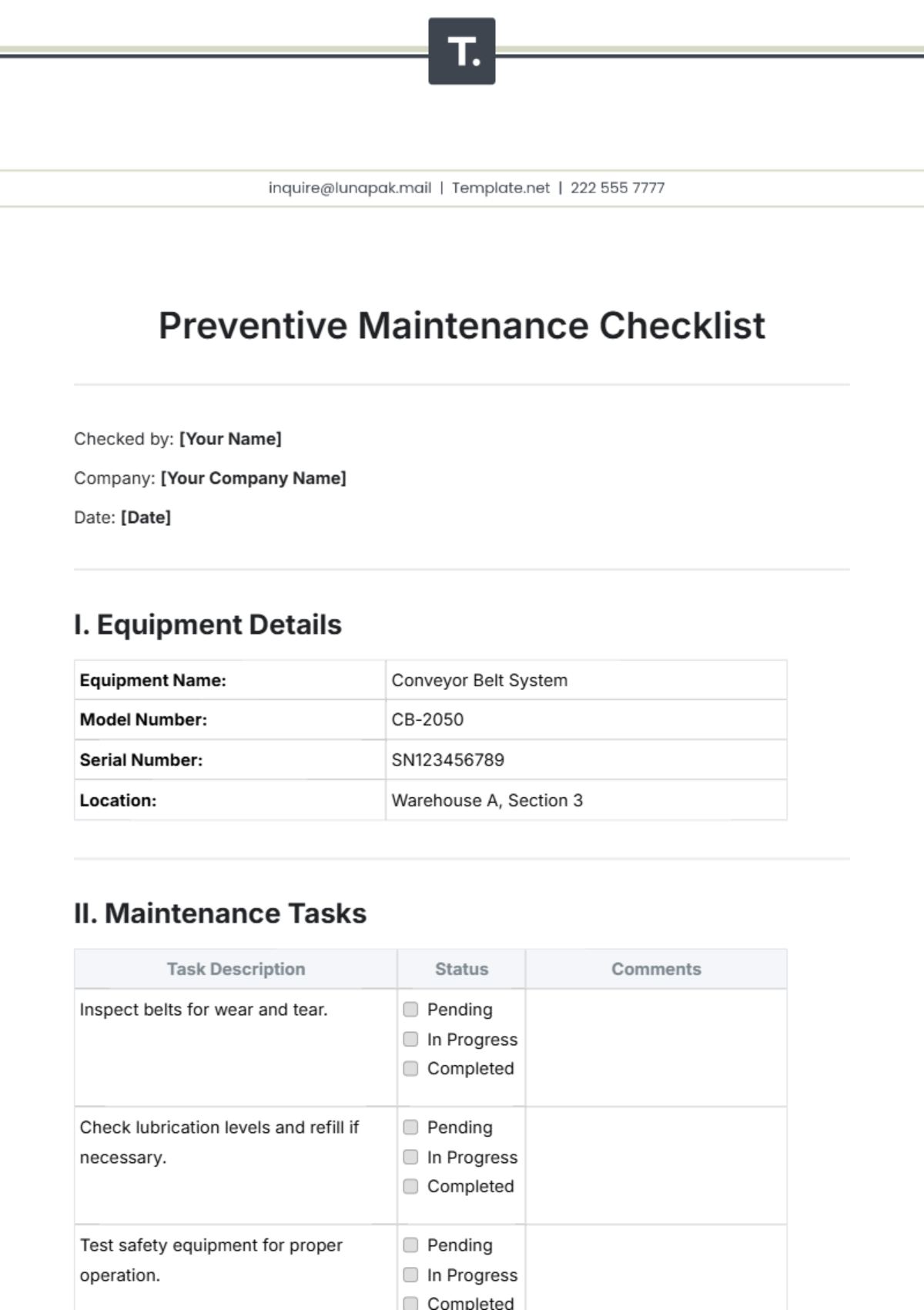

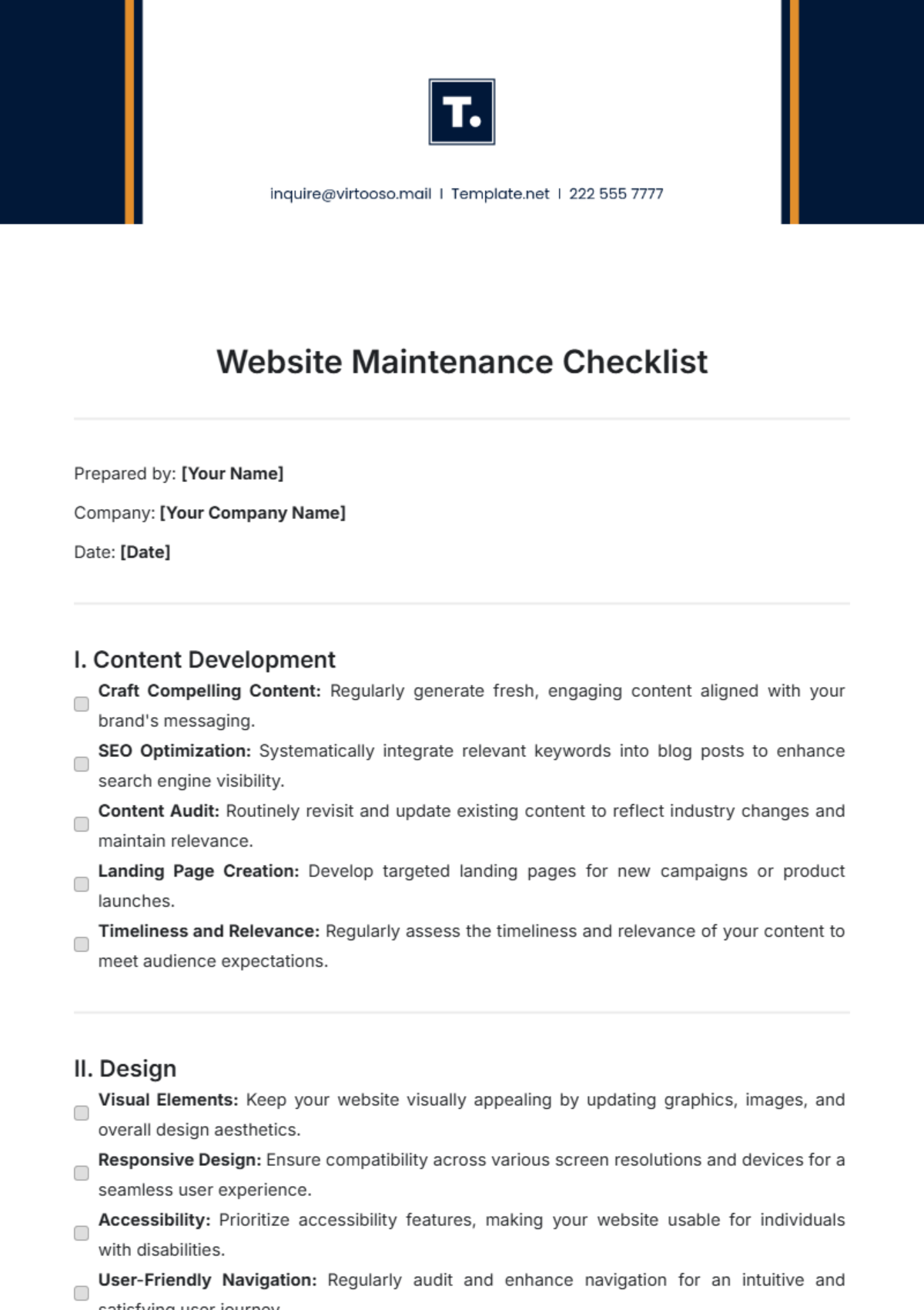

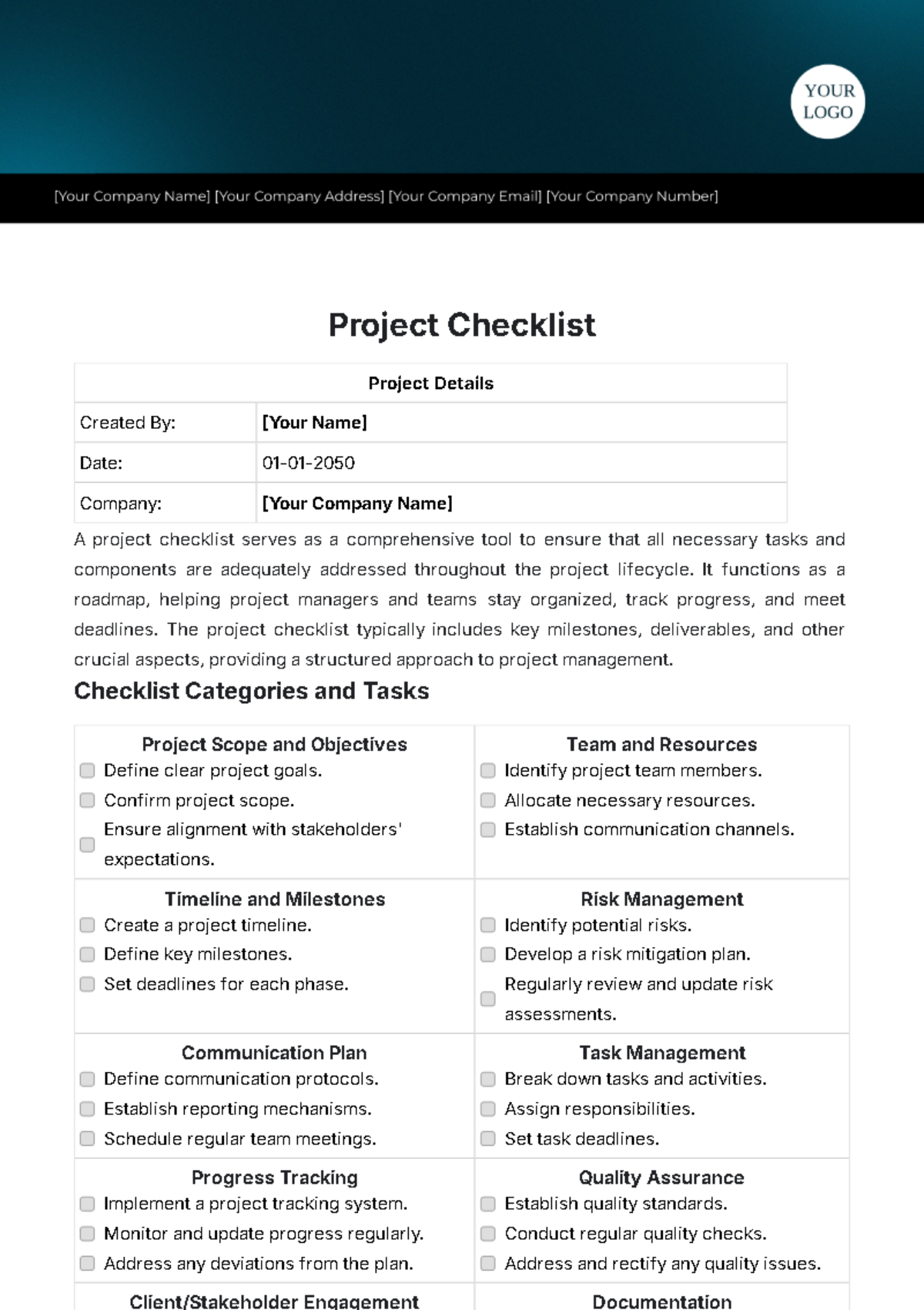

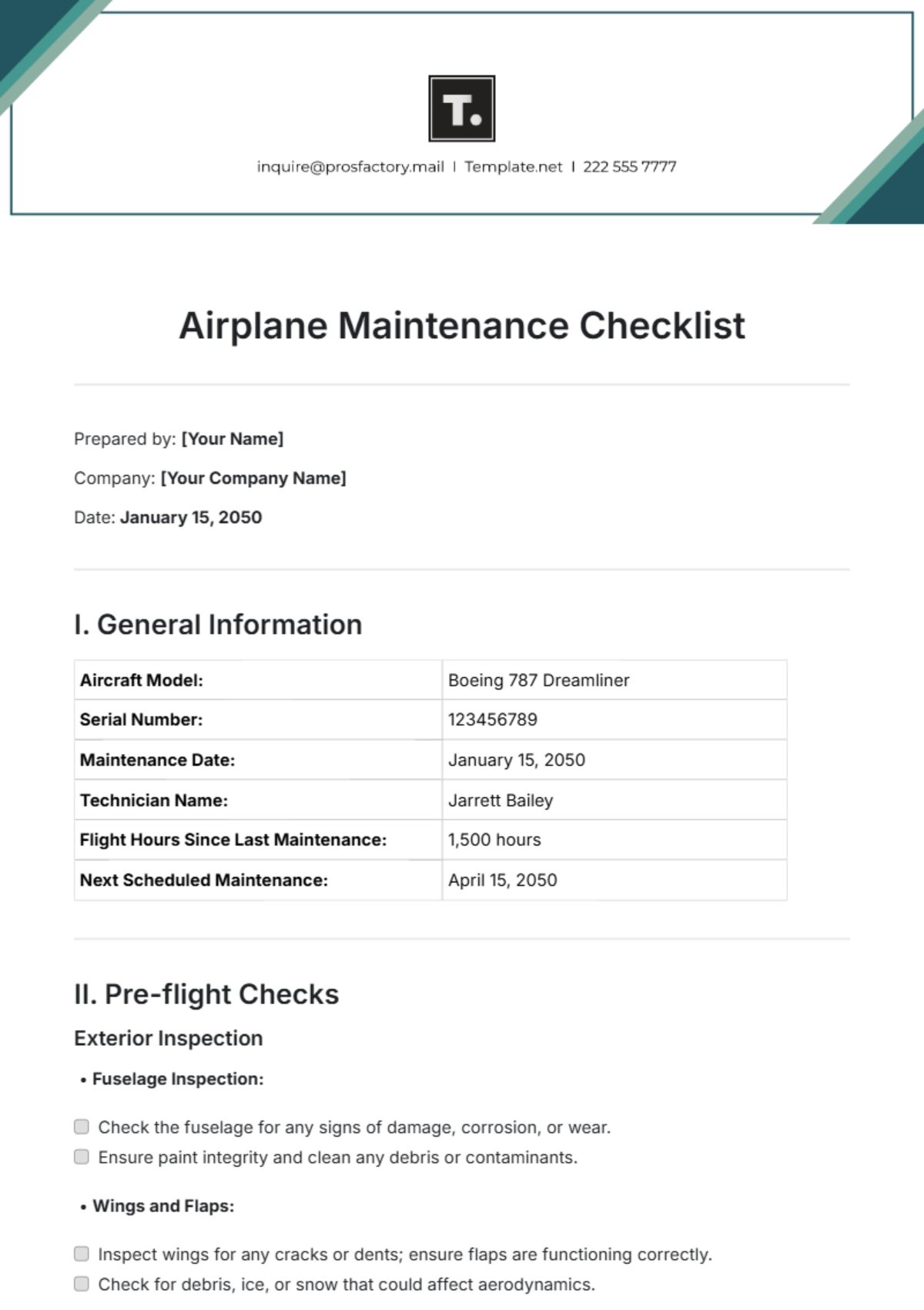

A Comprehensive Checklist for Peak Operational Performance

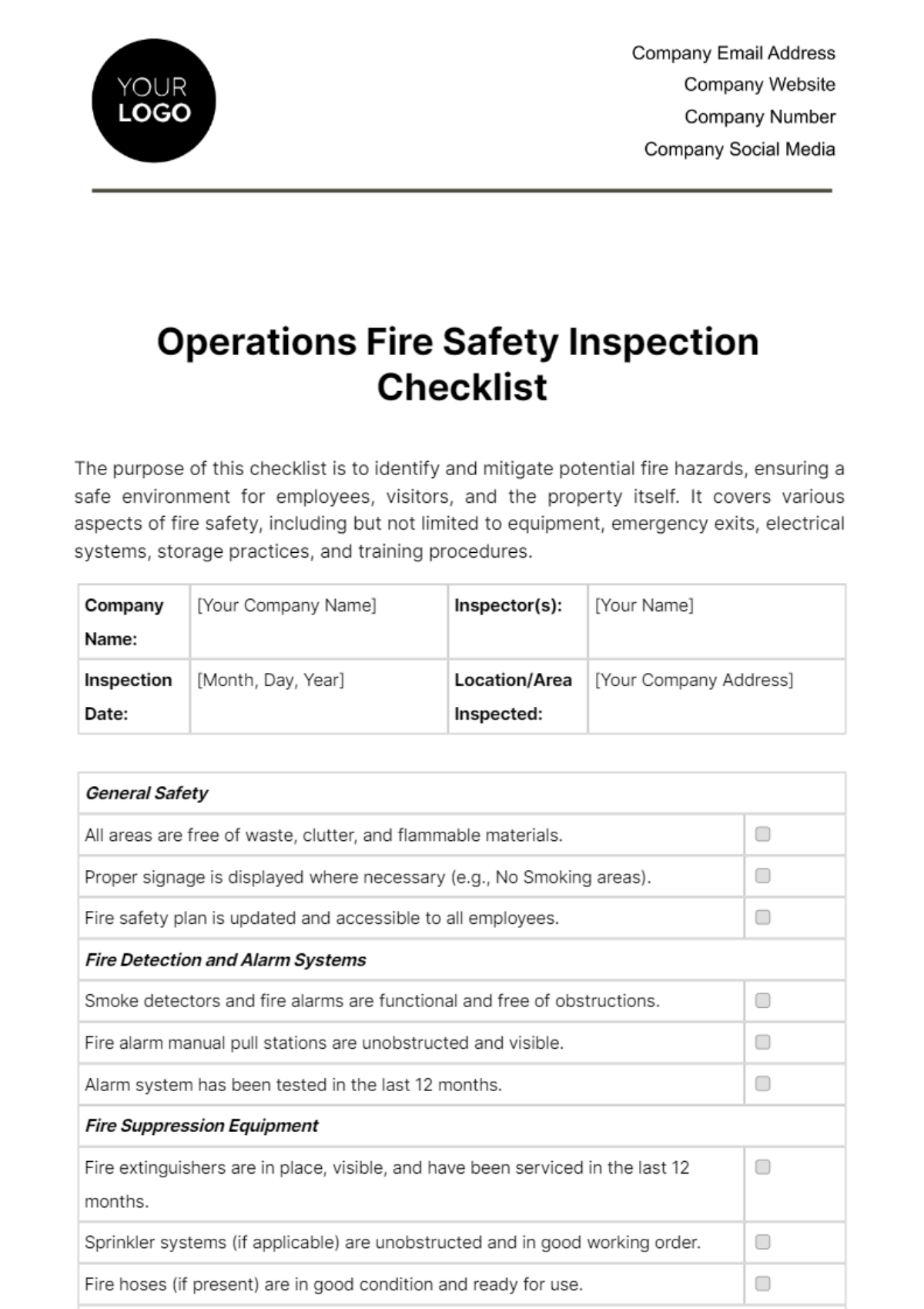

Purpose:

The purpose of this checklist is to establish a daily maintenance routine that aims to:

Identify and address potential issues early.

Promote the longevity and reliability of equipment.

Minimize the risk of downtime and disruptions.

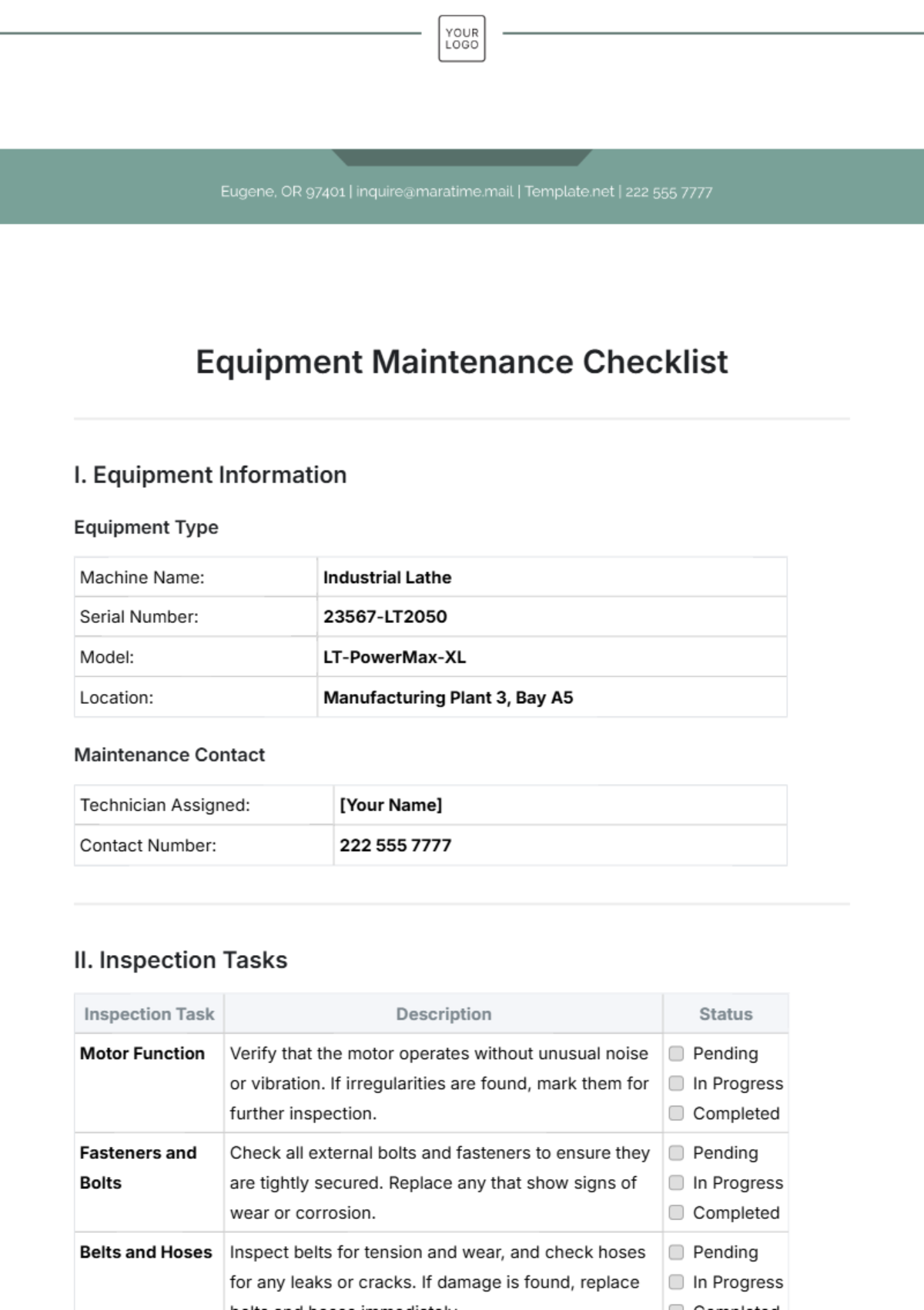

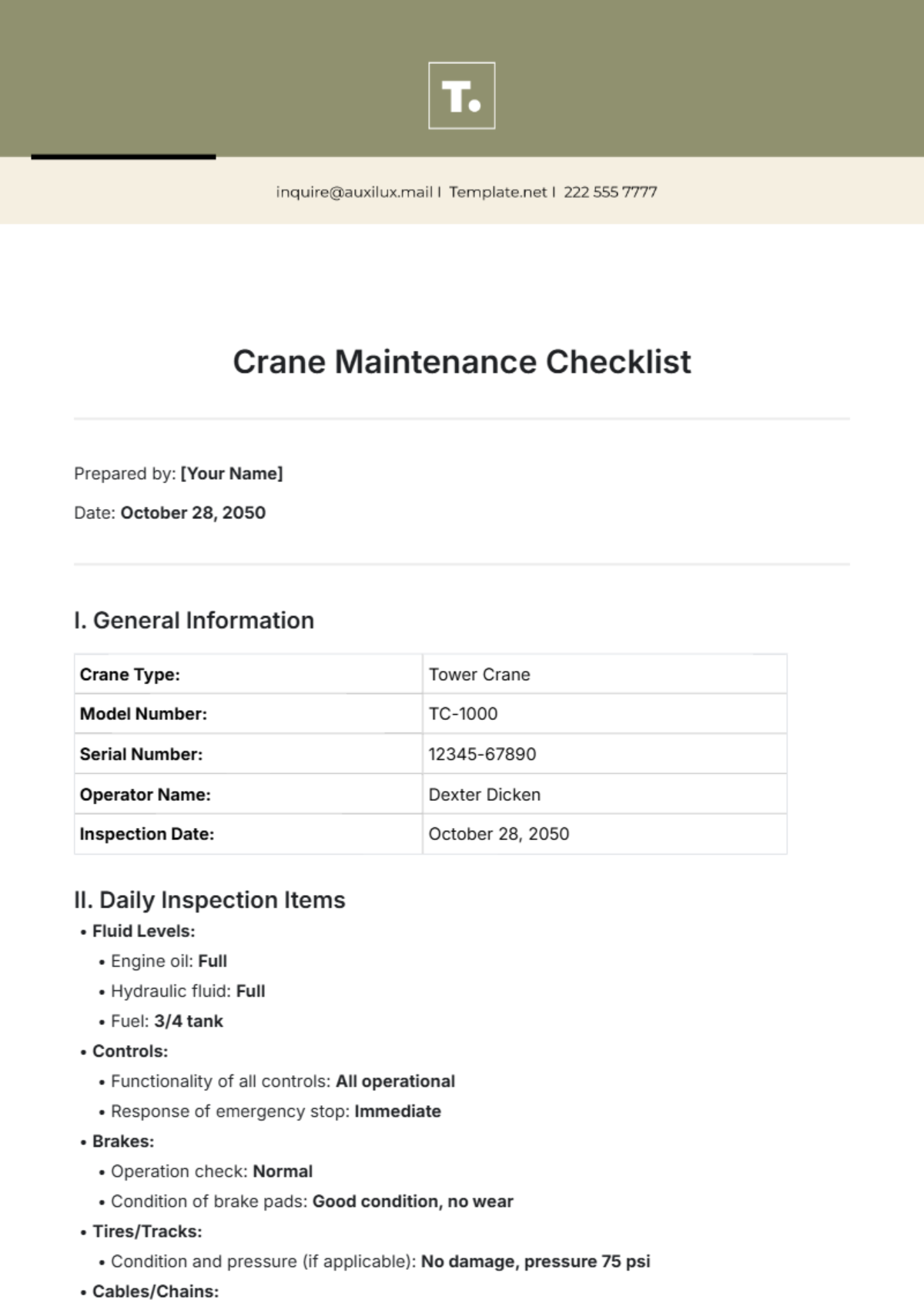

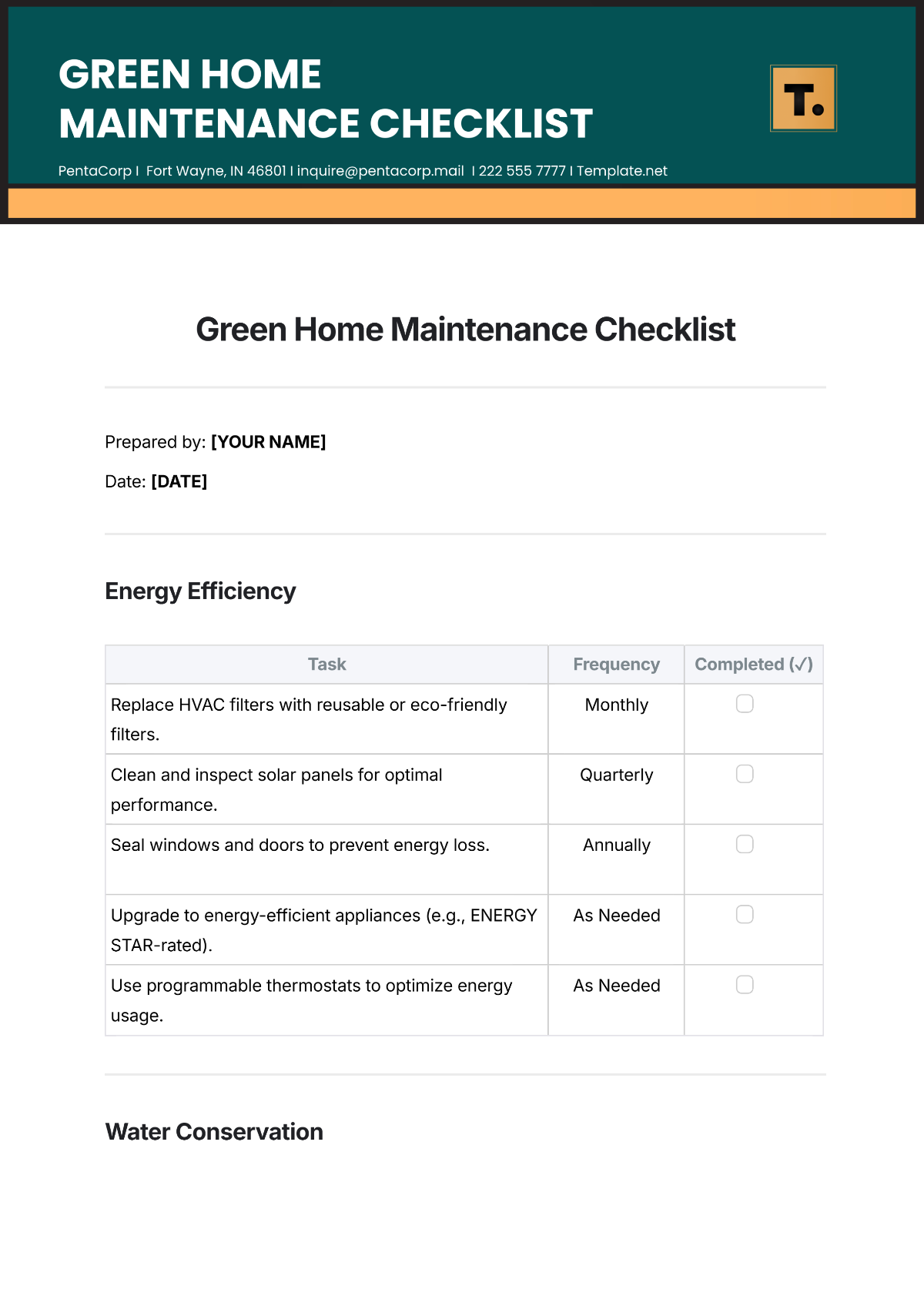

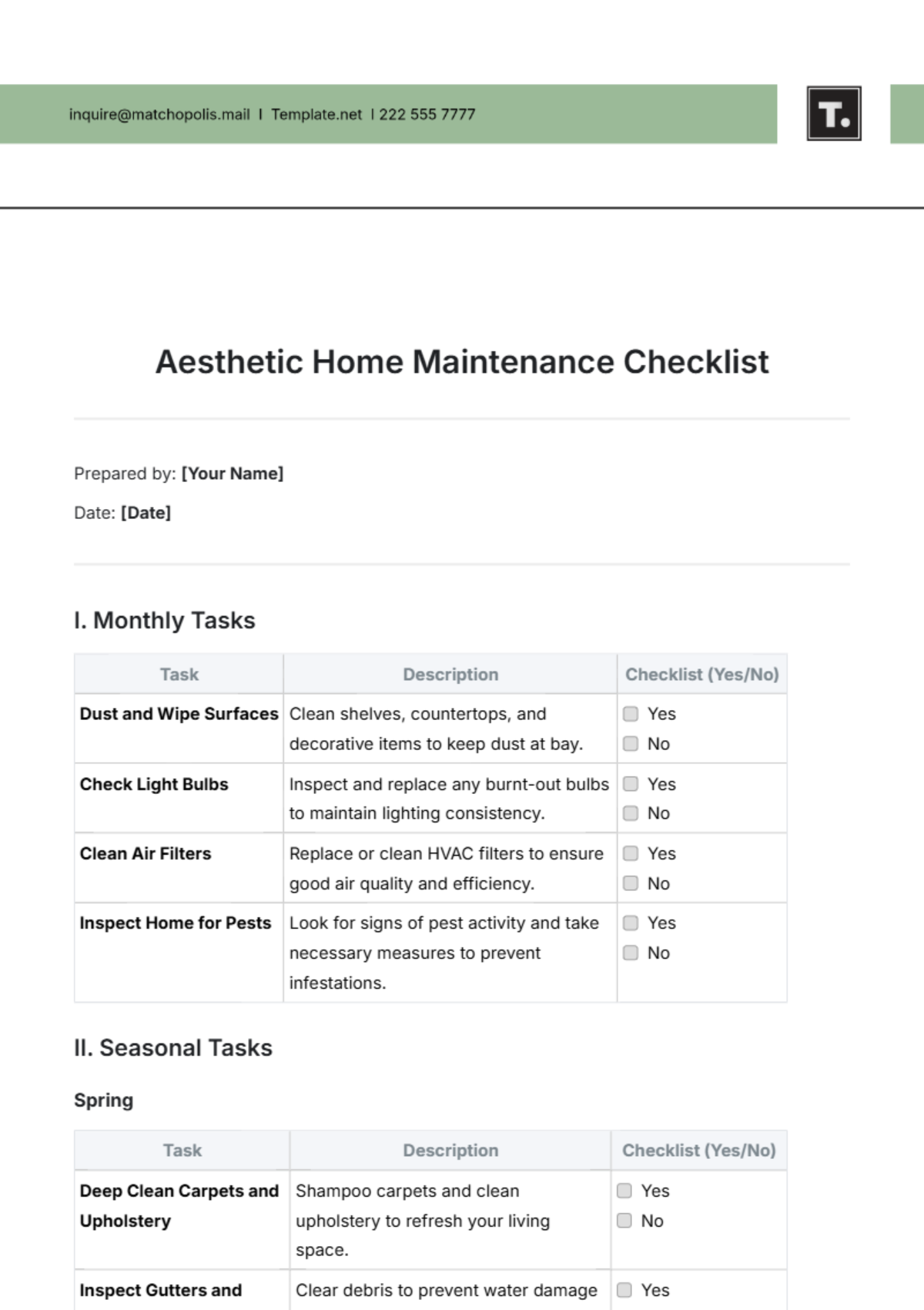

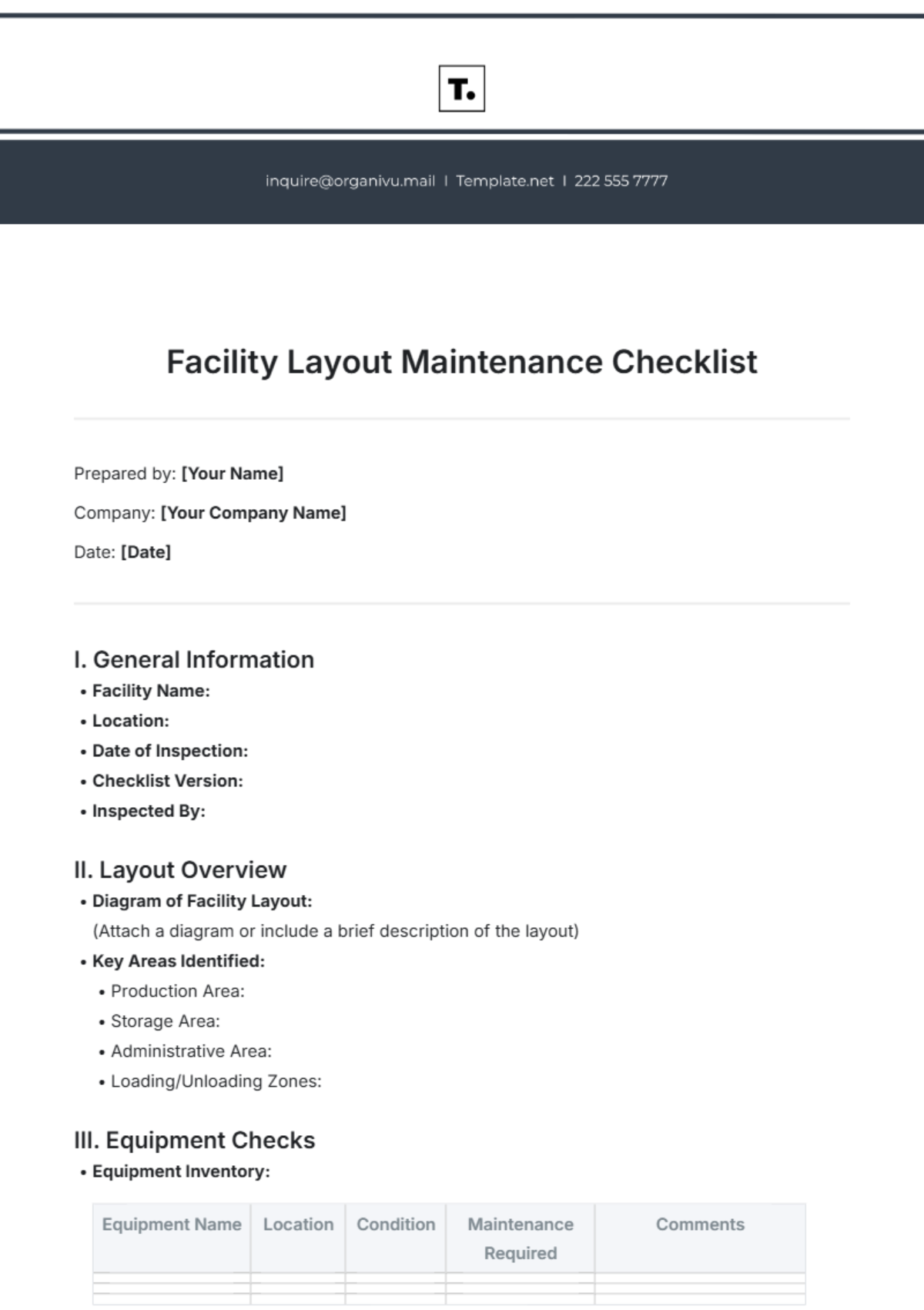

Start-up Procedures

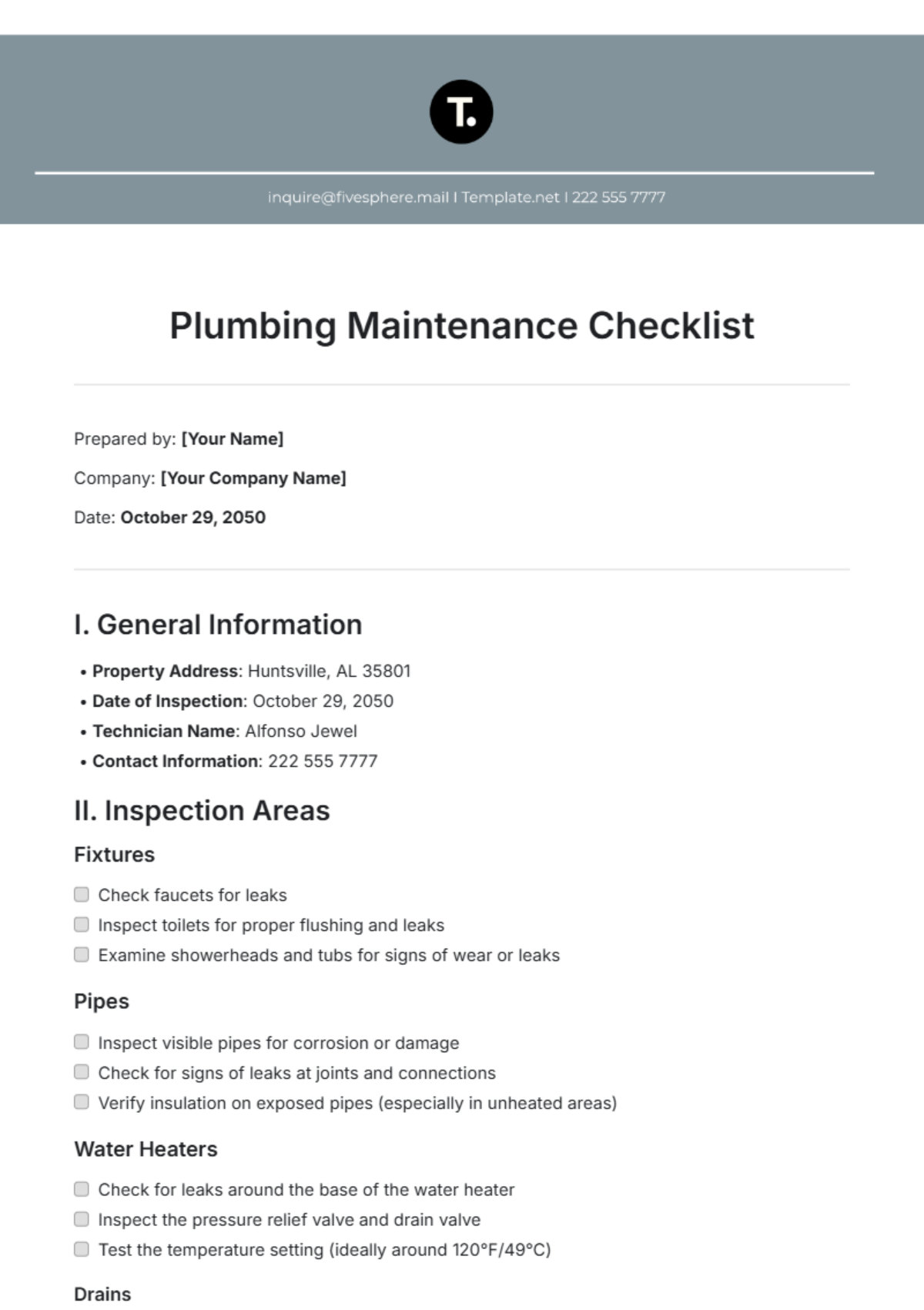

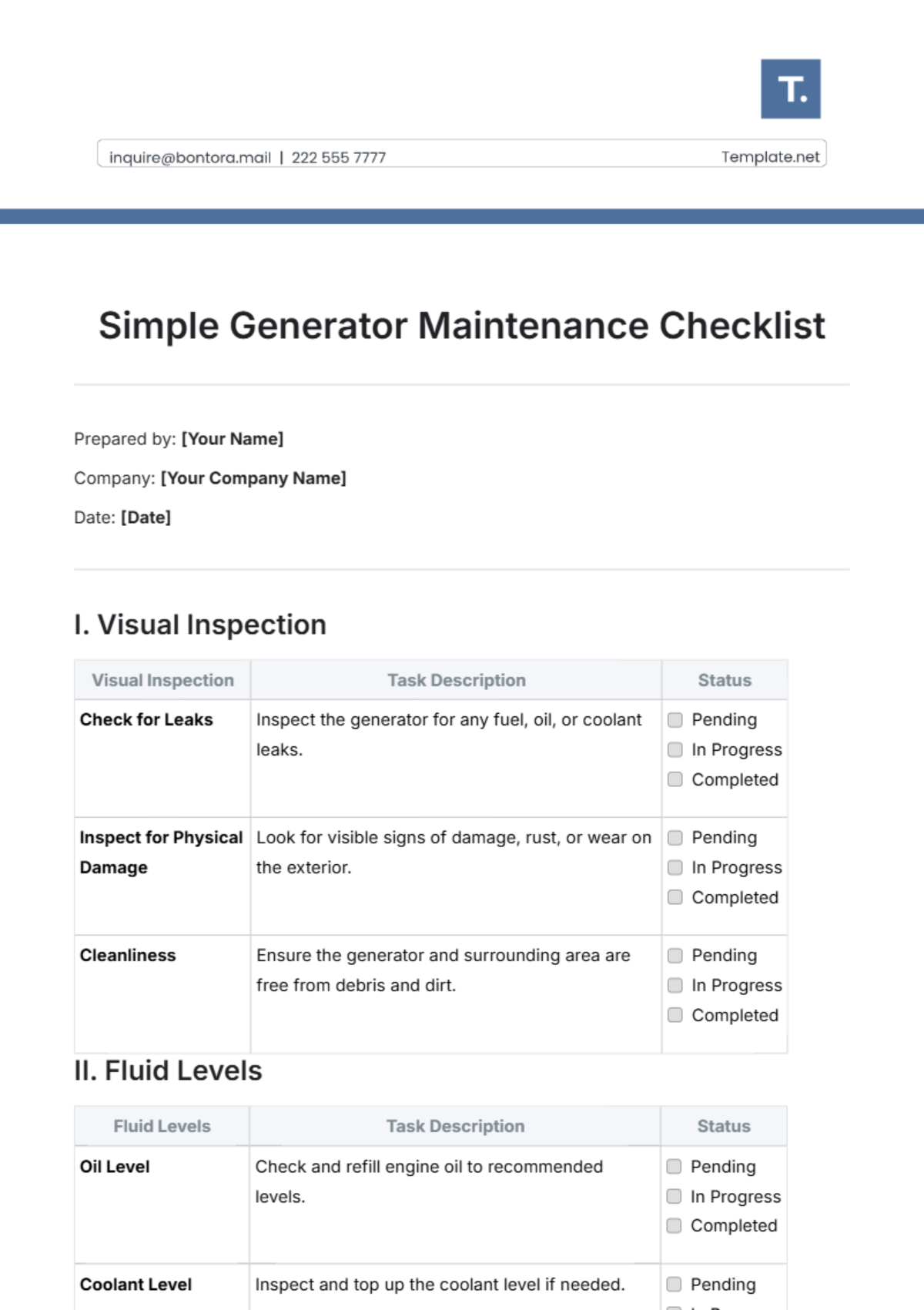

Check fluid levels (oil, coolant, hydraulic fluid).

Inspect for visible leaks and address them as necessary.

Verify proper lubrication of moving parts.

Ensure all safety guards and barriers are in place.

Conduct a brief operational test to detect any unusual sounds or vibrations.

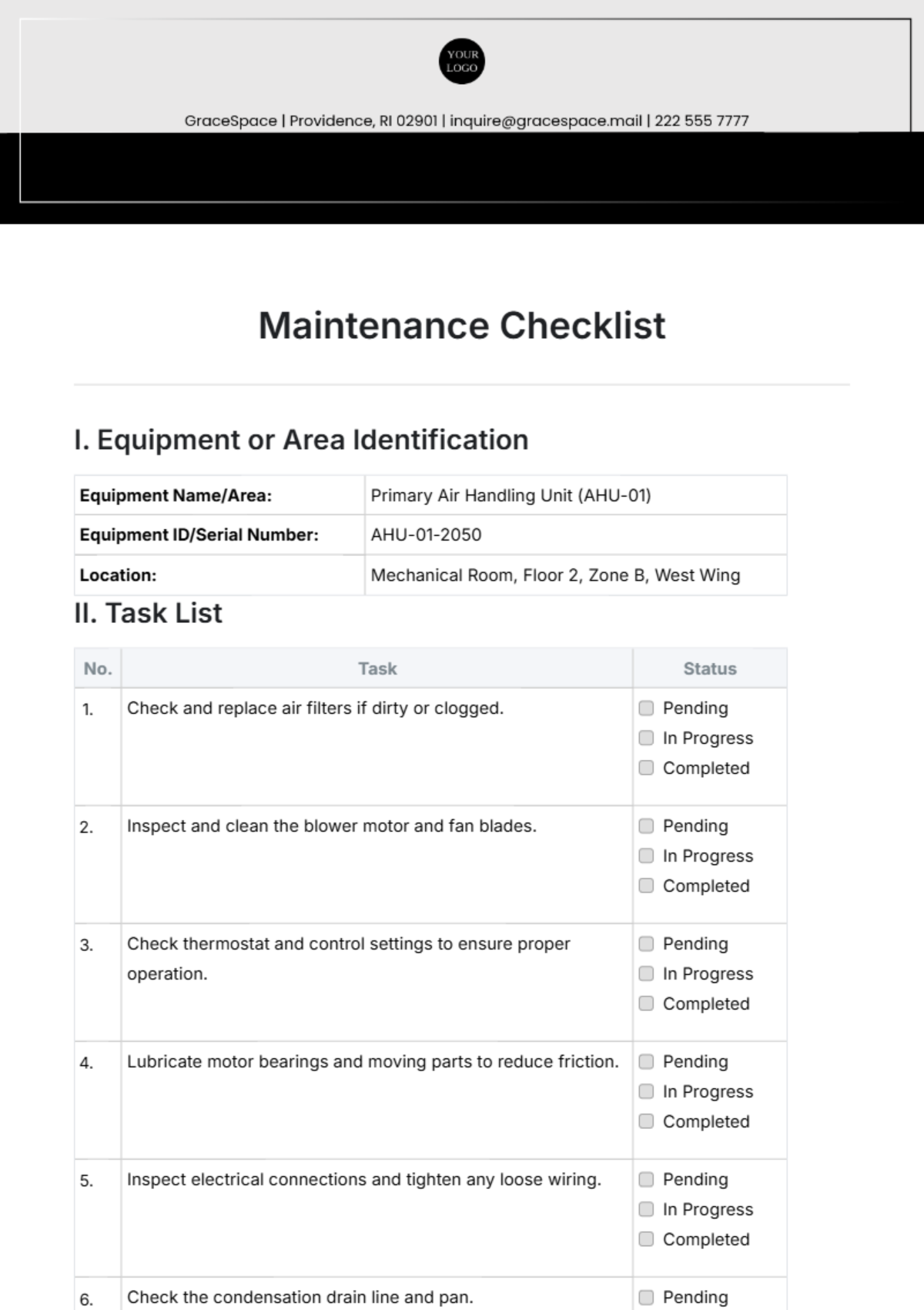

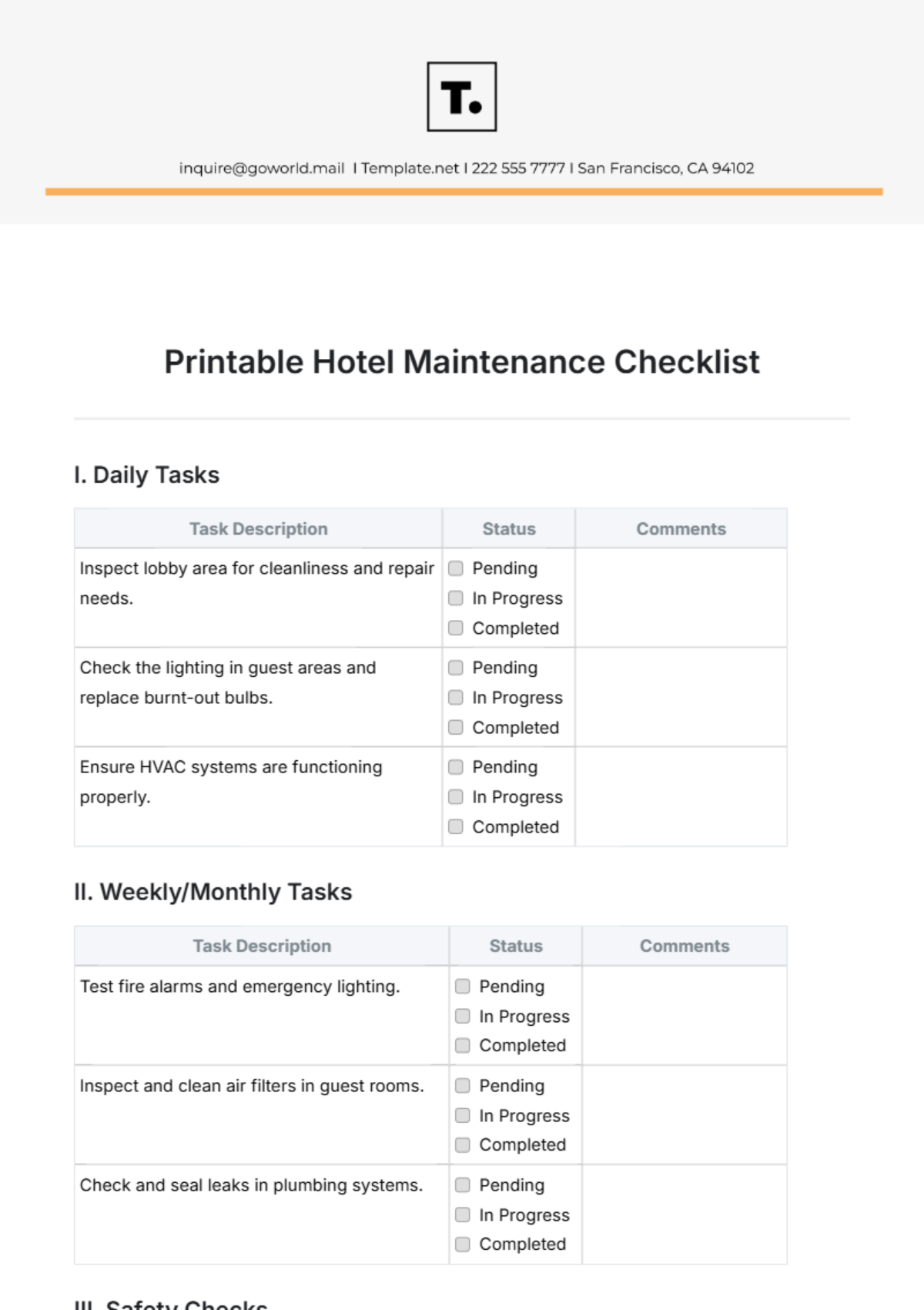

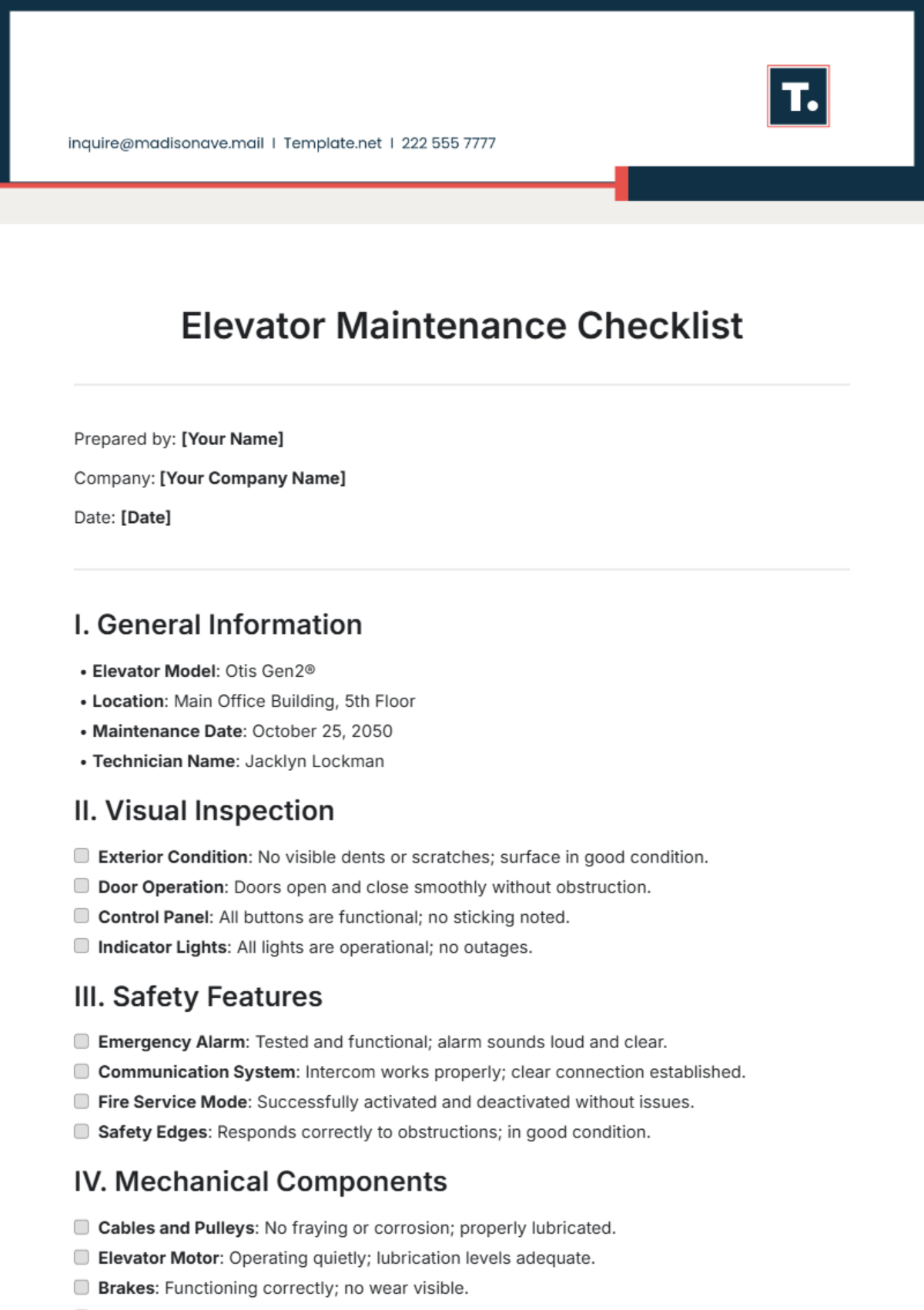

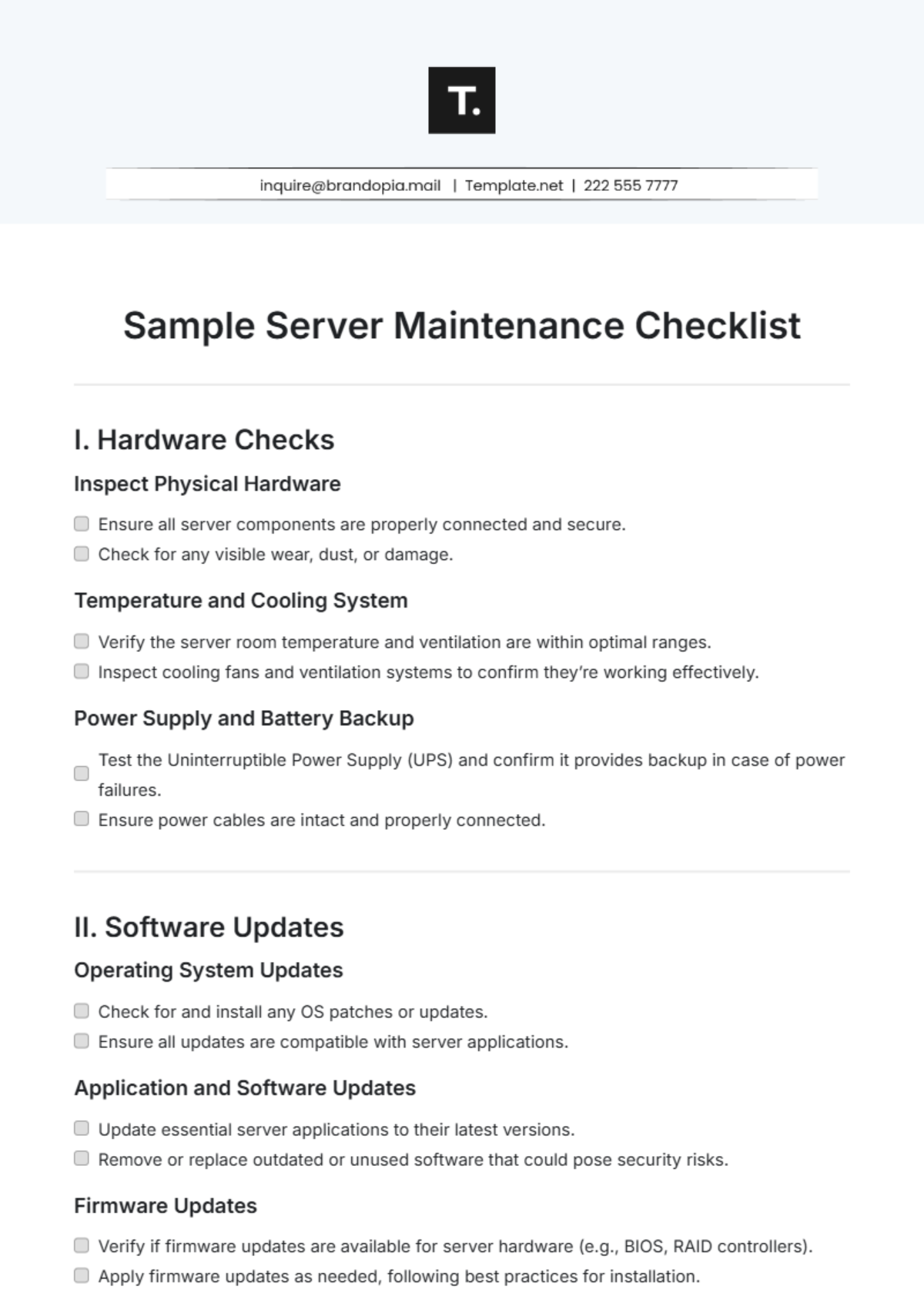

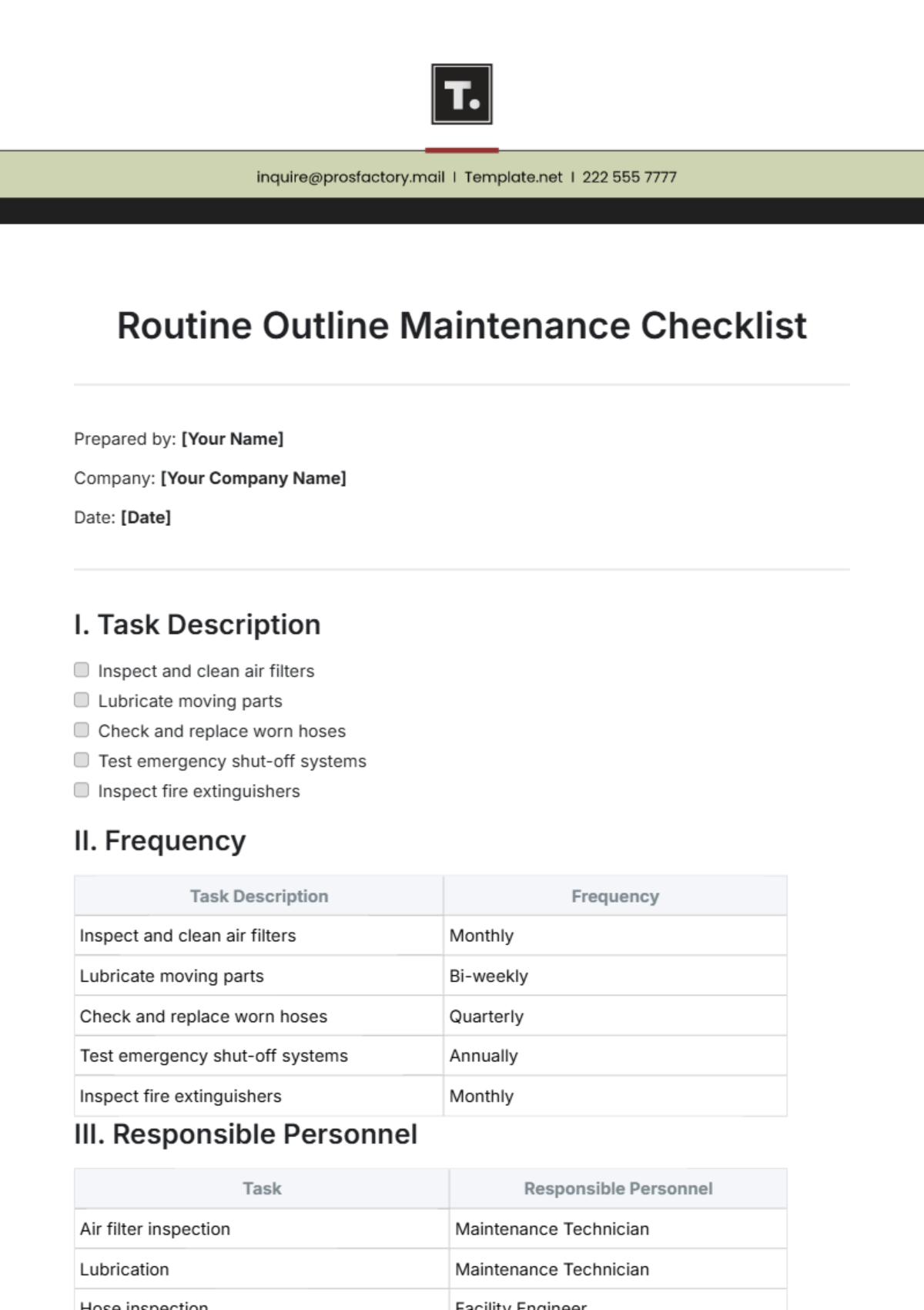

Equipment maintenance

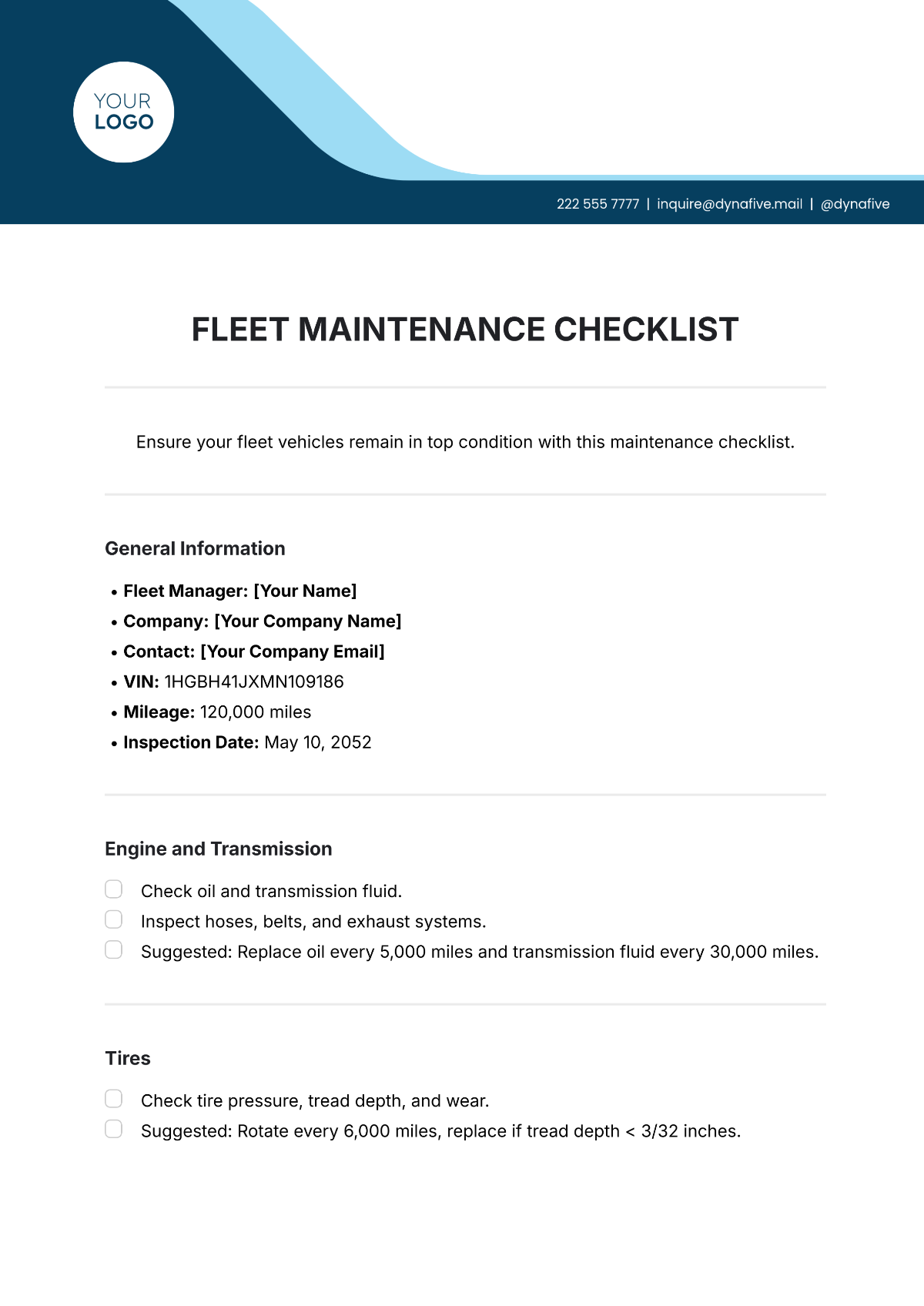

Regular engine checks for vehicles and machinery

Regular oil changes for vehicles and machinery

Check lights and electronic equipment

Examine safety features and emergency equipment

Inspect for physical wear and tear on equipment

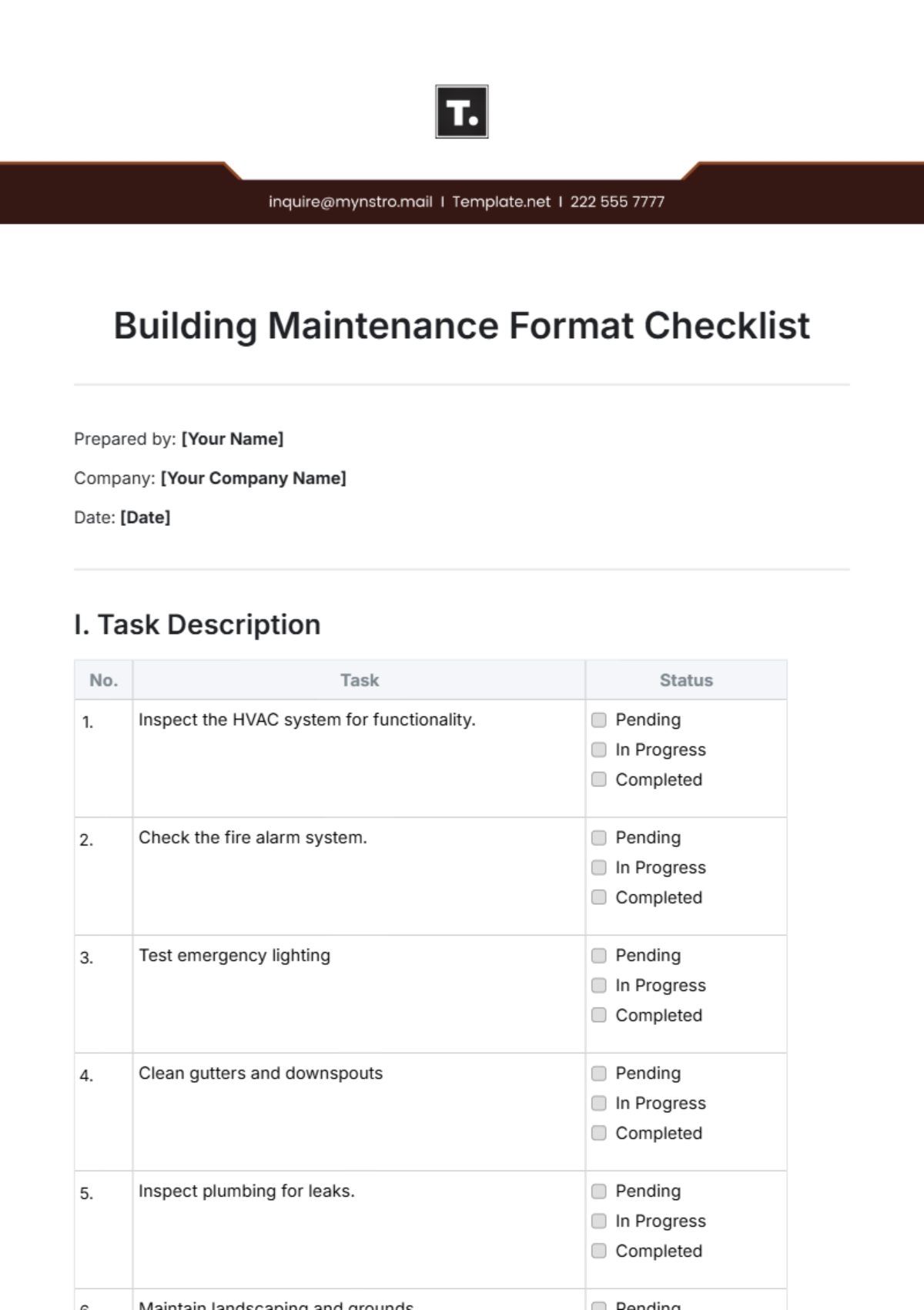

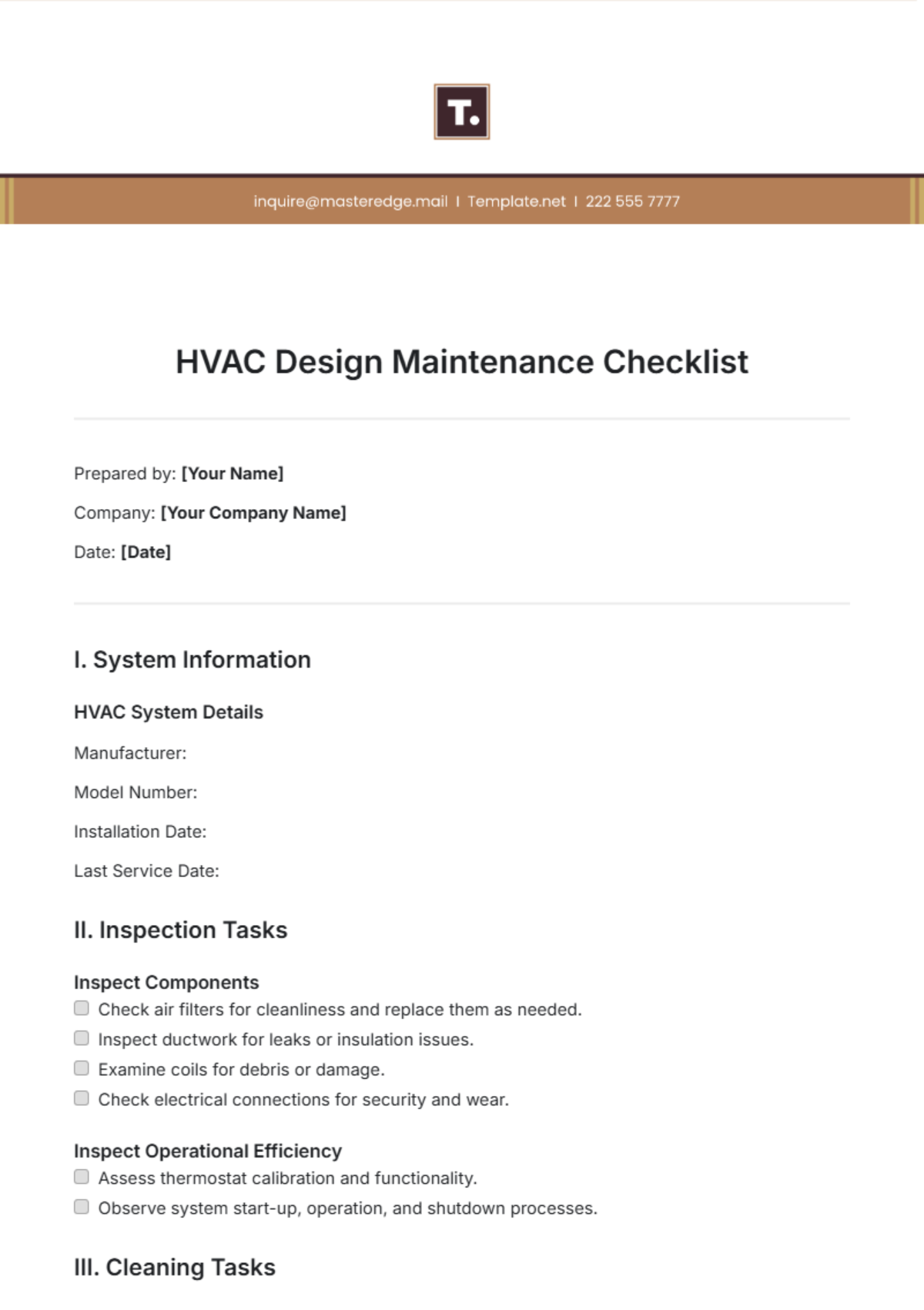

Safety and Controls

Test emergency stop features and ensure their proper functionality.

Inspect and clean switches, buttons, and control panels.

Check the functionality of safety interlocks.

Verify the condition of electrical cables and connections.

Confirm the availability and condition of personal protective equipment (PPE).

Inspection Date: 01 January 2050