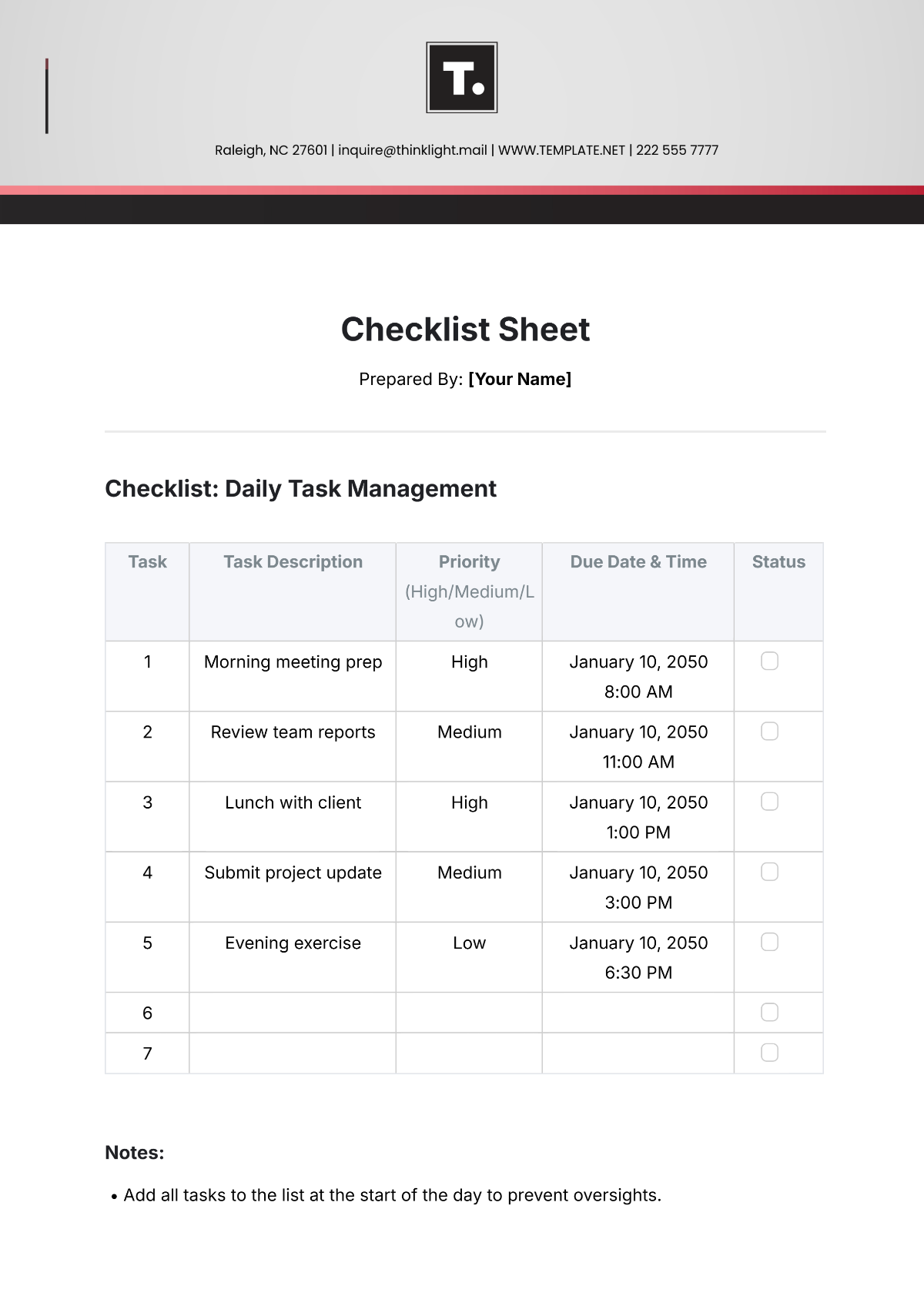

Safety Checklist

[Your Name]

[Your Company Name]

April 18, 2054

[Your Client's Name]

[Your Client's Company Name]

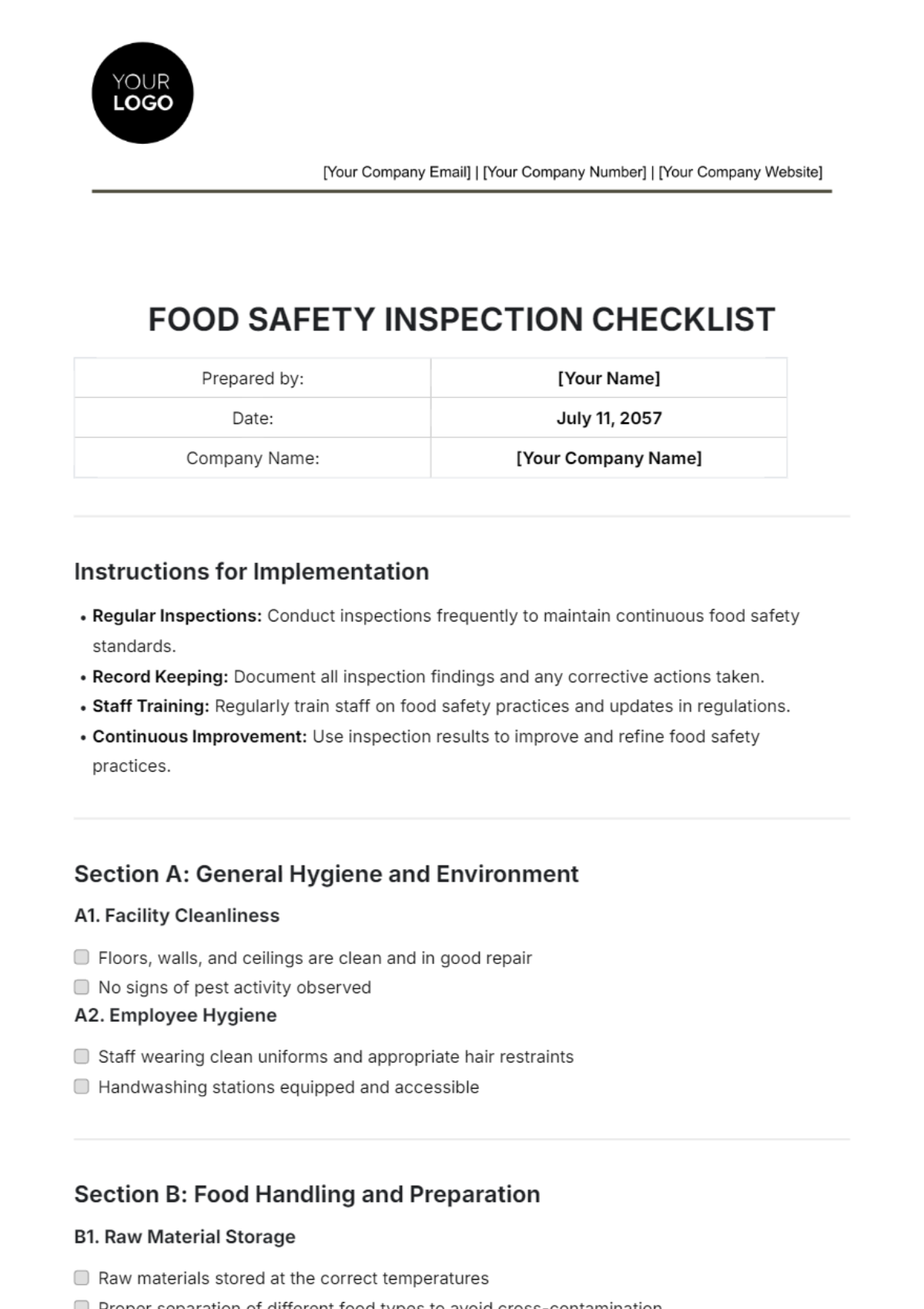

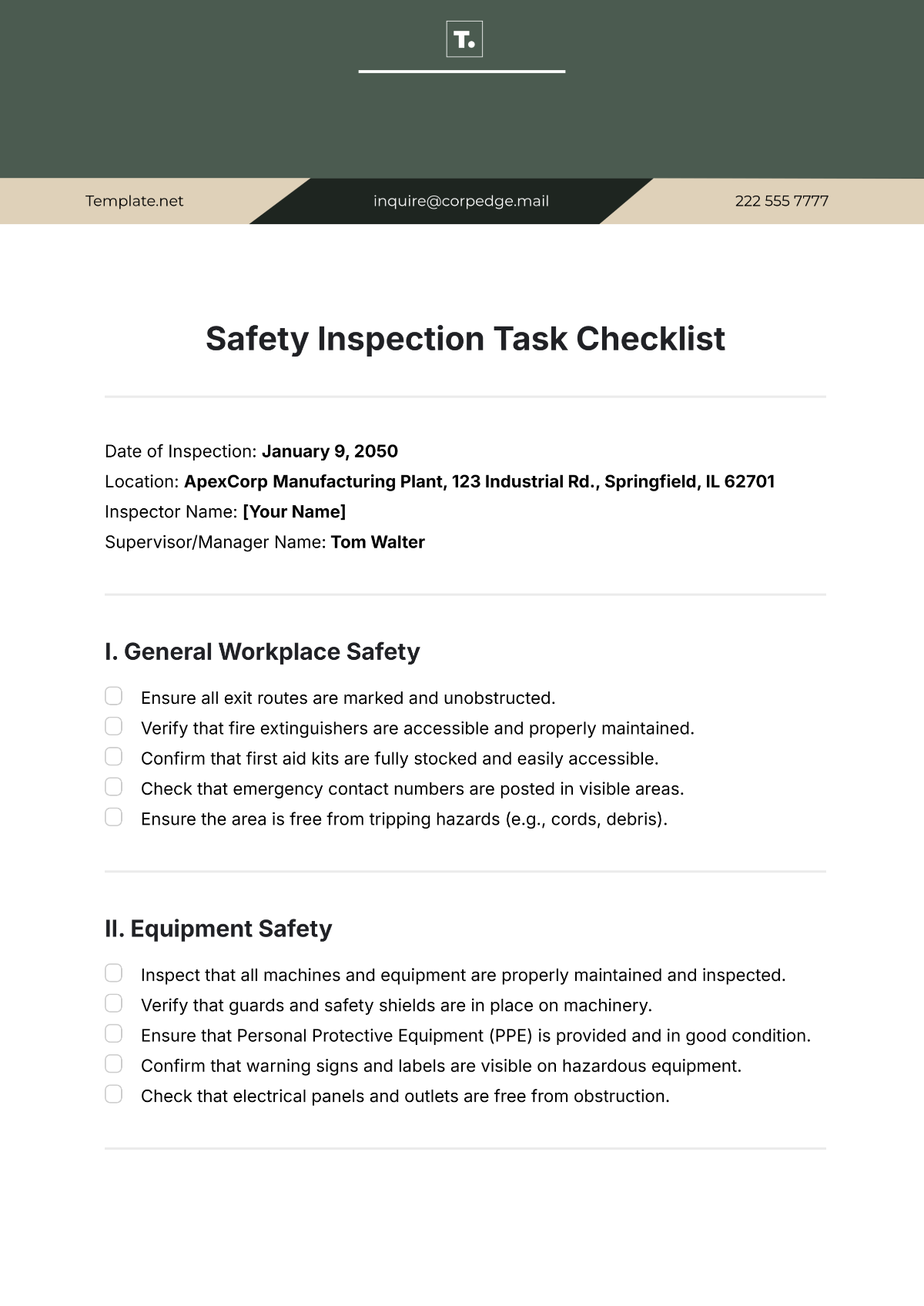

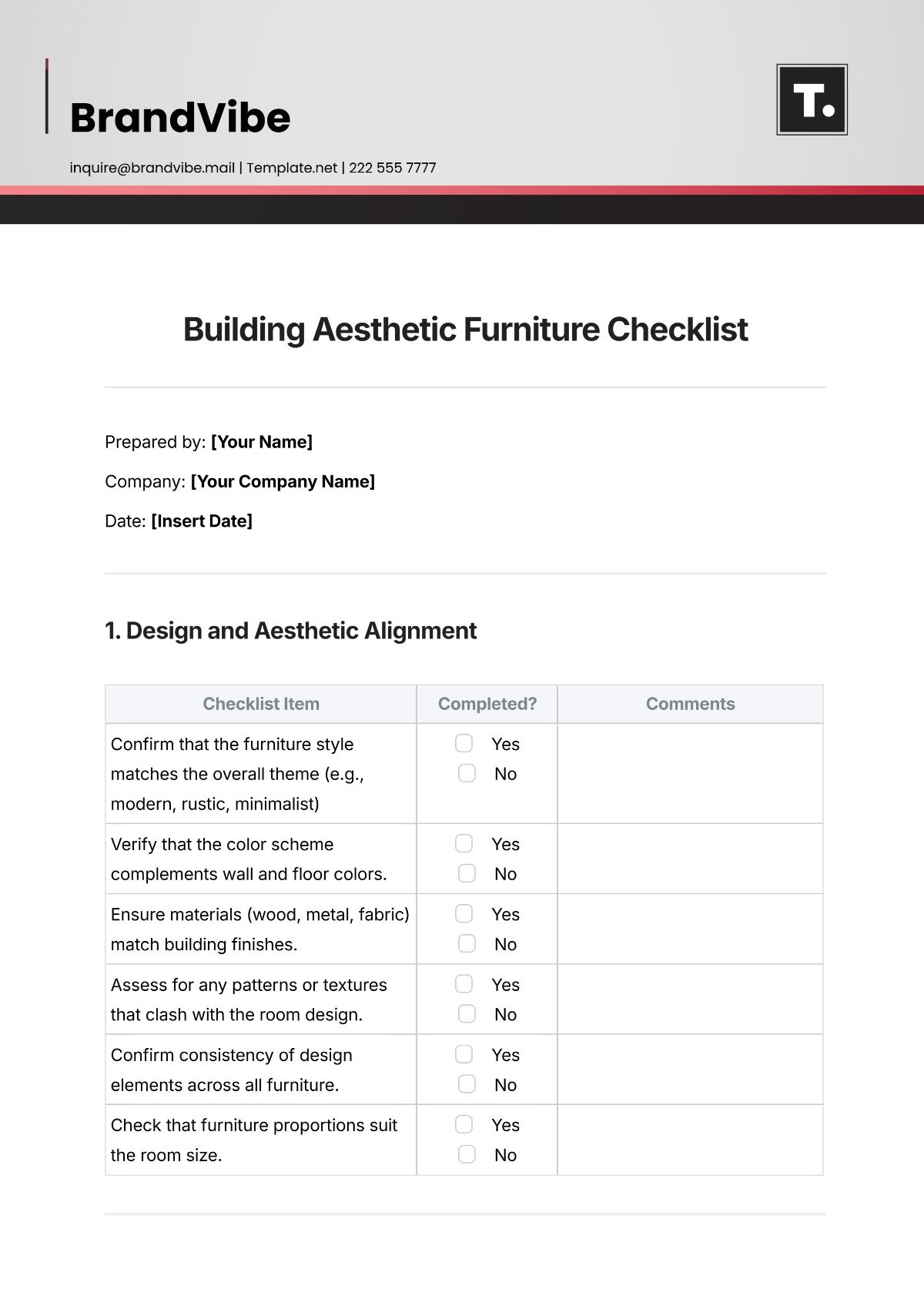

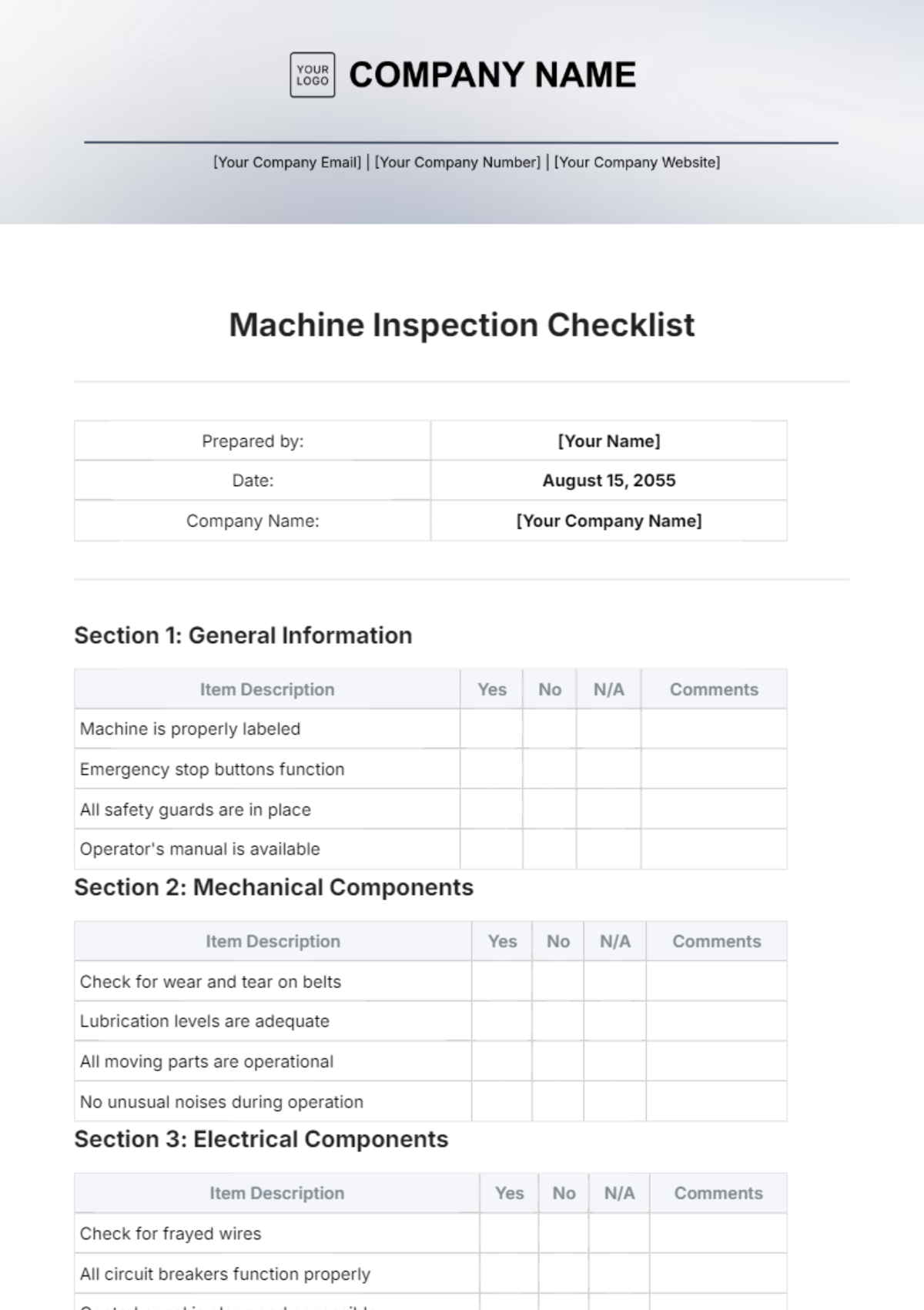

Objective

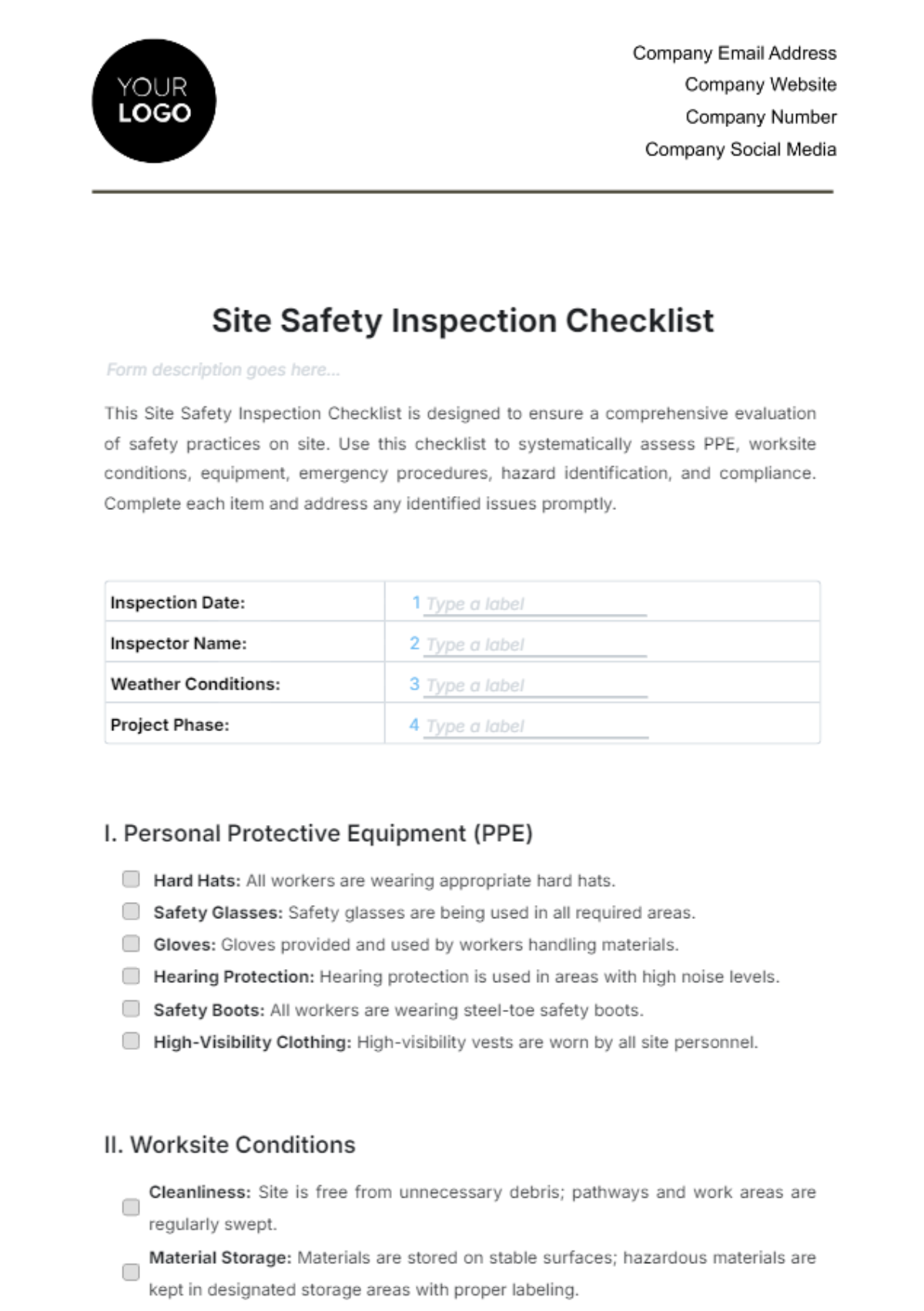

This safety checklist aims to systematically assess welding machines and components, ensuring a secure work environment. By identifying and addressing concerns related to power supply, controls, grounding, and protective equipment, it promotes adherence to safety standards and minimizes the risk of accidents during welding operations.

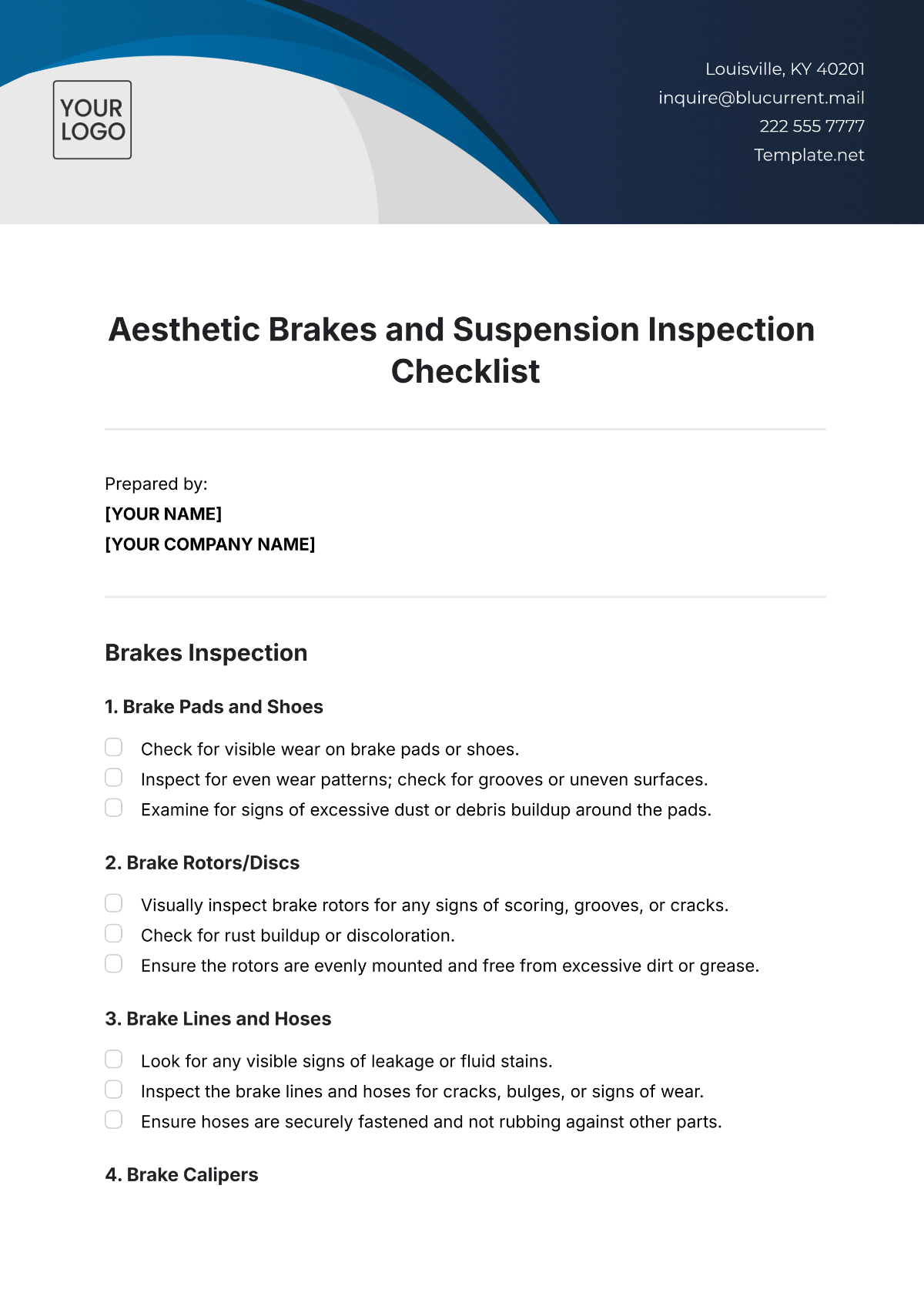

Power Supply:

Verify that the welding machine is connected to a stable and appropriately rated power source.

Inspect power cables for any signs of wear, damage, or exposed wiring.

Check for proper isolation and protection against electrical overloads.

Machine Controls:

Ensure all control buttons and switches are functional and clearly labeled.

Confirm emergency shut-off mechanisms are in place and operational.

Check for proper calibration of controls to avoid operational errors.

Grounding:

Check that the welding machine is properly grounded to prevent electrical hazards.

Inspect grounding cables for integrity and proper connection.

Verify that the grounding system is effective by testing with a multimeter.

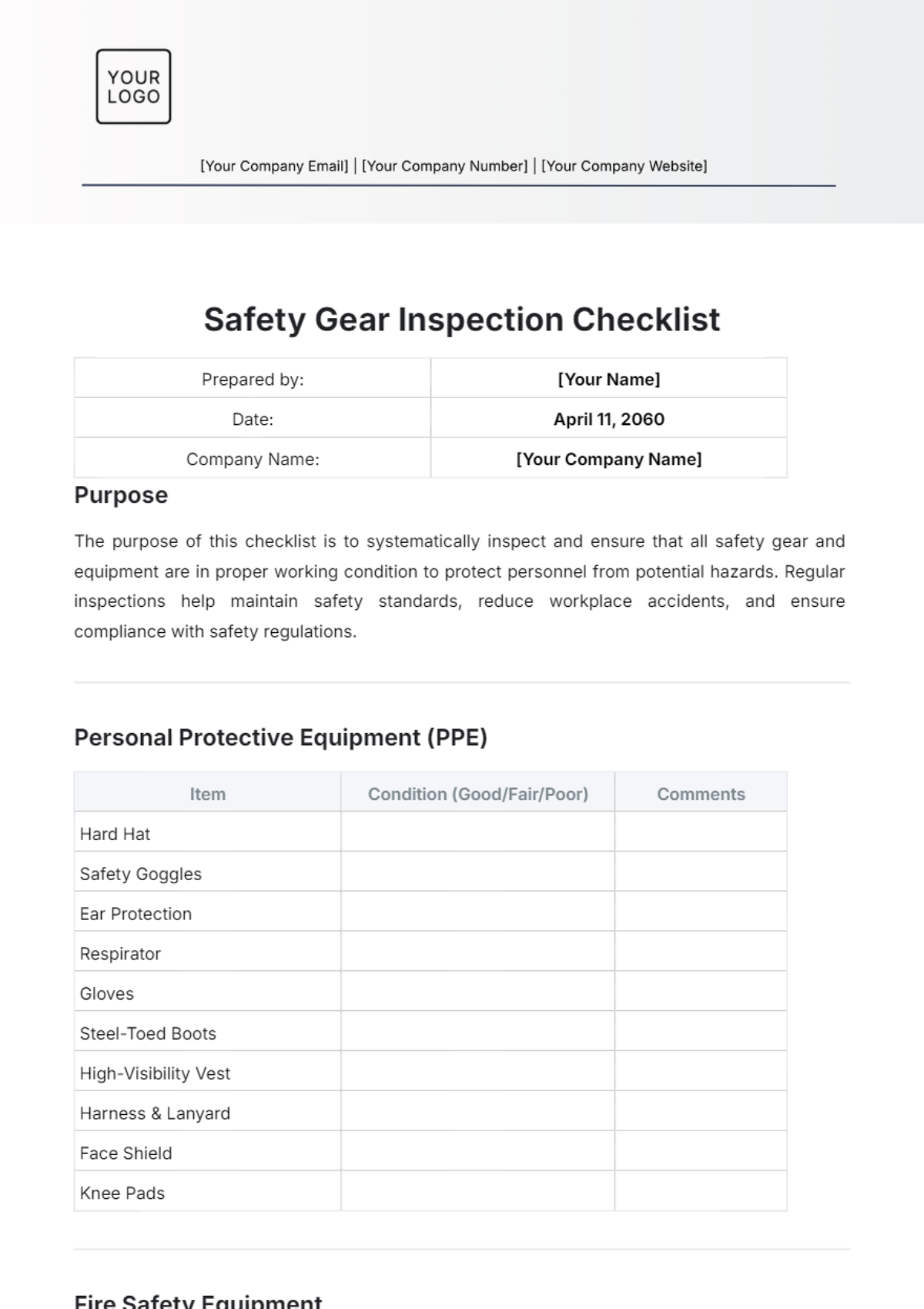

Protective Equipment:

Confirm the availability and condition of personal protective equipment (PPE) such as welding helmets, gloves, and safety glasses.

Ensure proper storage and accessibility of PPE near the welding station.

Check that all operators are trained in the correct usage of PPE.

Ventilation:

Verify the adequacy of ventilation systems to control fumes and gases.

Ensure ventilation hoods and exhaust systems are in good working condition.

Confirm that the welding area is well-ventilated to minimize exposure to airborne contaminants.

Regular adherence to this checklist will contribute to a safer working environment, reducing the risk of accidents and ensuring compliance with industry safety standards.